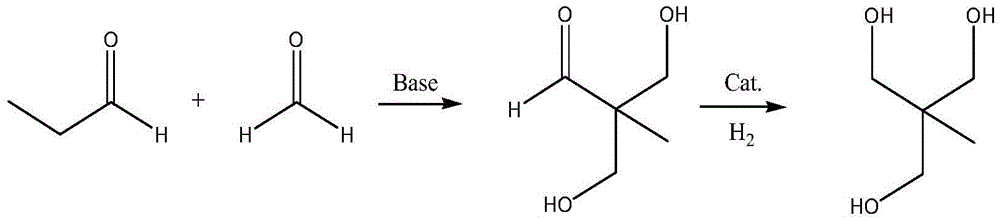

Preparation method of trimethylolethane

A technology of trimethylolethane and methylolpropionaldehyde, which is applied in the field of continuous catalytic hydrogenation of 2,2-dimethylolpropionaldehyde to prepare trimethylolethane, and can solve the effective utilization rate of formaldehyde Low, high formate content, to achieve the effect of reduced formaldehyde consumption, high atomic economy and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) take by weighing 187 grams of copper nitrate, 297g of zinc nitrate hexahydrate, 750g of aluminum nitrate nonahydrate, 64.4g of zirconium oxychloride, 148g of magnesium nitrate and mix and add water to make 5000 milliliters of solutions into the reactor with stirring and heating function, Add 500g of 30% mass fraction of H 2 O 2 Solution, slowly add 25wt% sodium carbonate aqueous solution to the reaction kettle, react at 30 ° C, the pH value is required to be between 9-10 during the reaction, and age at 60-80 ° C for 4-12 hours after the reaction is completed to obtain the corresponding solution. suspensions of mixtures;

[0042] 2) The suspension is centrifuged to obtain solid-liquid two-phase, the solid phase is washed with deionized water, dried at 120 ° C, drying time is 24 hours, calcined at 550-650 ° C for 12 hours, and granulated;

[0043] 3) Using the particles obtained in step 2 as a carrier, vacuum equal volume impregnation of RuCl 3 solution, the loading...

Embodiment 2

[0045] 1) take by weighing 187 grams of copper nitrate, 297g of zinc nitrate hexahydrate, 750g of aluminum nitrate nonahydrate, 64.4g of zirconium oxychloride, 148g of magnesium nitrate and mix and add water to make 5000 milliliters of solutions into the reactor with stirring and heating function, Then add 1000g of 30% mass fraction of H 2 O 2 Solution, slowly add 25wt% sodium carbonate aqueous solution to the reaction kettle, react at 30 ° C, the pH value is required to be between 9-10 during the reaction, and age at 60-80 ° C for 4-12 hours after the reaction is completed to obtain the corresponding solution. suspensions of mixtures;

[0046] 2) The suspension is centrifuged to obtain solid-liquid two-phase, the solid phase is washed with deionized water, dried at 100 ° C, drying time is 36 hours, calcined at 550-650 ° C for 12 hours, and granulated;

[0047] 3) Using the particles obtained in step 2 as a carrier, vacuum equal volume impregnation of RuCl 3 solution, the l...

Embodiment 3

[0049] 1) take by weighing 281 grams of copper nitrate, 297g zinc nitrate hexahydrate, 625g aluminum nitrate nonahydrate, 64.4g zirconium oxychloride, 148g magnesium nitrate and mix and add water to make 5000 milliliters of solutions into the reactor with stirring heating function, Then add 1000g of 30% mass fraction of H 2 O 2 solution, slowly add 25wt% sodium hydroxide aqueous solution to the reaction kettle, react at 30 ° C, the pH value is required to be between 9-10 during the reaction process, and age at 60-80 ° C for 4-12 hours after the reaction, to obtain suspensions of the corresponding mixtures;

[0050] 2) The suspension is centrifuged to obtain solid-liquid two-phase, the solid phase is washed with deionized water, dried at 90°C, the drying time is 48 hours, calcined at 550-650°C for 12 hours, and granulated;

[0051] 3) Using the particles obtained in step 2 as a carrier, vacuum equal volume impregnation of RuCl 3 solution, the loading amount is 1.0%, and calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com