A preparation method of thermally induced flexible phase change energy storage wood

A phase change energy storage and thermal induction technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of poor material flexibility, easy leakage, low thermal conductivity, etc., achieve long service life, low cost, and improve thermal conductivity The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

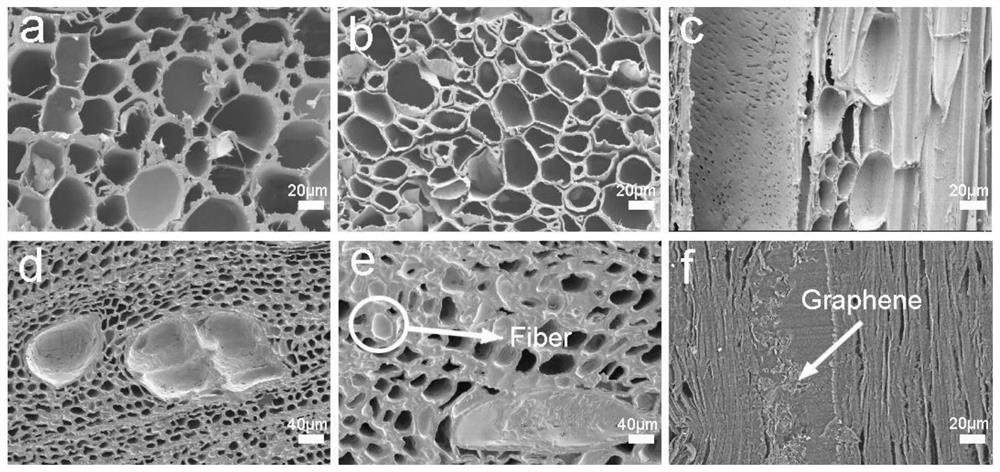

[0023] Embodiment 1: A preparation method of heat-induced flexible phase change energy storage wood, balsa wood with a thickness of 2 mm is processed, and cut into wood chips with a length × width of 40 mm × 20 mm for later use, and the following steps are carried out:

[0024] a. Using N,N dimethylformamide as solvent, configure 53g of 0.08mol / L triethanolamine solution and 45g of 0.3mol / L triphenylmethane triisocyanate solution;

[0025] b. Add the triethanolamine solution in step a into the triphenylmethane triisocyanate solution, and stir at 75° C. for 12 hours to obtain a prepolymer;

[0026] c. Add 13 g of polyethylene glycol-1500 to the prepolymer, and stir at 75° C. for 28 hours to obtain a solid-solid phase change material;

[0027] d. Put the delignified wood into the solid-solid phase change material, vacuum impregnate (0.1 MPa) for 25 minutes, and then dry to obtain the finished product.

Embodiment 2

[0028] Embodiment 2: A preparation method of heat-induced flexible phase-change energy storage wood. The balsa wood with a thickness of 2 mm is processed, and the wood chips with a length × width of 40 mm × 20 mm are cut for use, and the following steps are carried out:

[0029] a. With N,N dimethylformamide as solvent, configure 65g of 0.15mol / L triethanolamine solution and 55g of 0.2mol / L triphenylmethane triisocyanate solution;

[0030] b. Add the triethanolamine solution in step a into the triphenylmethane triisocyanate solution, and stir at 65° C. for 15 hours to obtain a prepolymer;

[0031] c. Add 18 g of polyethylene glycol-1500 to the prepolymer, and stir at 65° C. for 25 hours to obtain a solid-solid phase change material;

[0032] d. Put the delignified wood into the solid-solid phase change material, vacuum impregnate (0.1 MPa) for 35 minutes, and then dry to obtain the finished product.

Embodiment 3

[0033] Embodiment 3: A preparation method of heat-induced flexible phase-change energy storage wood. The balsa wood with a thickness of 2 mm is processed, and the wood chips with a length × width of 40 mm × 20 mm are cut for use, and the following steps are carried out:

[0034] a. With N,N dimethylformamide as solvent, configure 58g of 0.1mol / L triethanolamine solution and 48g of 0.27mol / L triphenylmethane triisocyanate solution;

[0035] b. Add the triethanolamine solution in step a into the triphenylmethane triisocyanate solution, and stir at 70°C for 12 hours to obtain a prepolymer;

[0036] c. Add 15 g of polyethylene glycol-1500 to the prepolymer, and stir at 70° C. for 24 hours to obtain a solid-solid phase change material;

[0037] d. Put the delignified wood into the solid-solid phase change material, vacuum impregnate (0.1 MPa) for 30 minutes, and then dry to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com