Micro/nano size beta-cyclodextrin polymer powder as well as preparation method and application thereof

A cyclodextrin polymer, micro-nano technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of low mechanical strength, limited application efficiency, low adsorption efficiency, etc. To achieve the effect of high adsorption efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

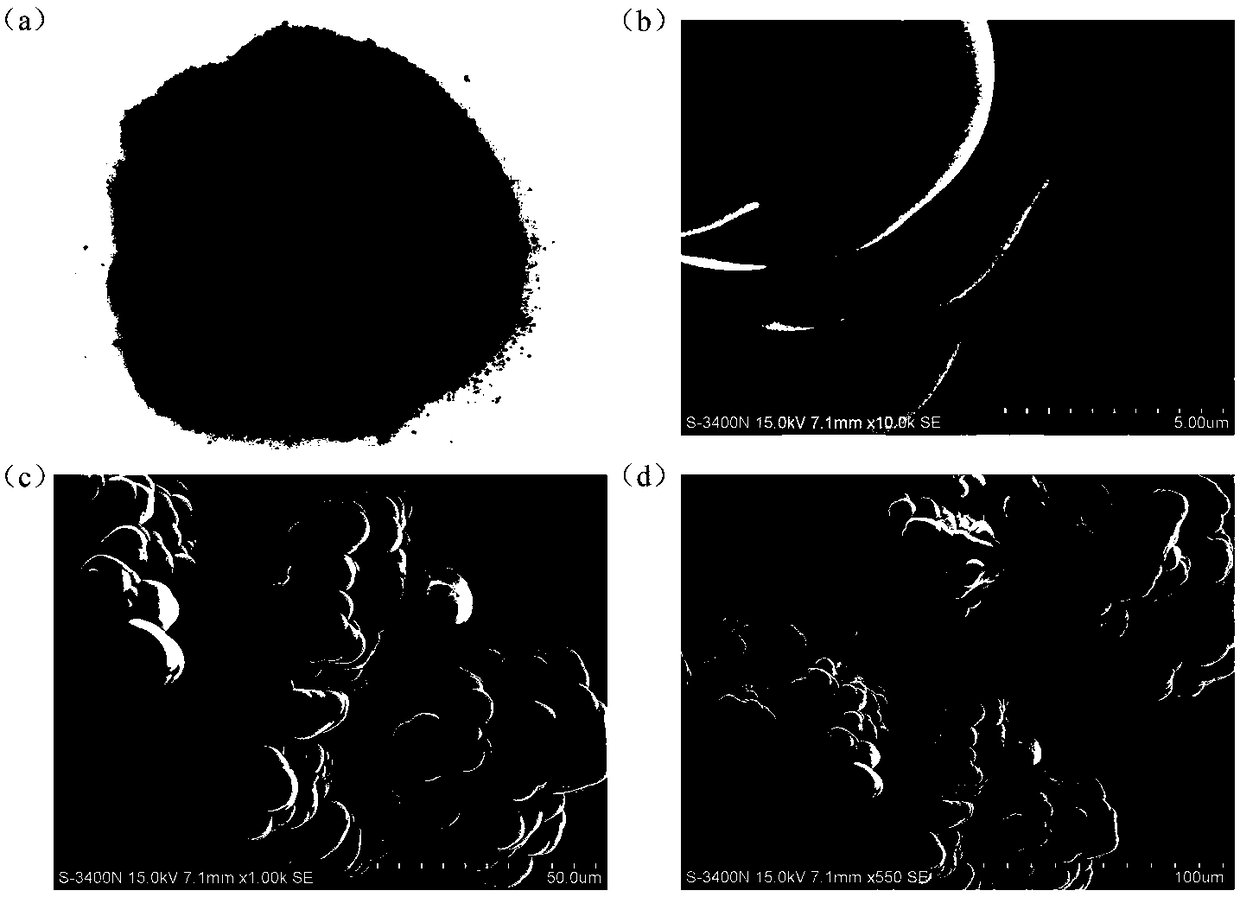

[0030] In this example, no catalyst is added during the preparation process to obtain a micron-sized β-cyclodextrin polymer. The typical sample properties and surface morphology are as follows figure 1 shown.

[0031] The preparation method is as follows:

[0032] Weigh 2.27g of β-cyclodextrin into a 250mL three-neck flask containing 40mL of methyl ethyl ketone, then transfer the three-necked flask to an oil bath equipped with a mechanical stirring device, and stir at room temperature at a speed of 250rpm for 15min. The temperature of the oil bath was gradually increased to 80°C, and 5.44 g of triphenylmethane triisocyanate in ethyl acetate was added dropwise to the reaction solution through a constant-pressure dropping funnel under stirring, and the reaction was continued for 10 h with stirring. After the reaction was completed, the reaction solution was cooled to room temperature and filtered with suction, and then the solid product was washed three times with acetone and h...

Embodiment 2

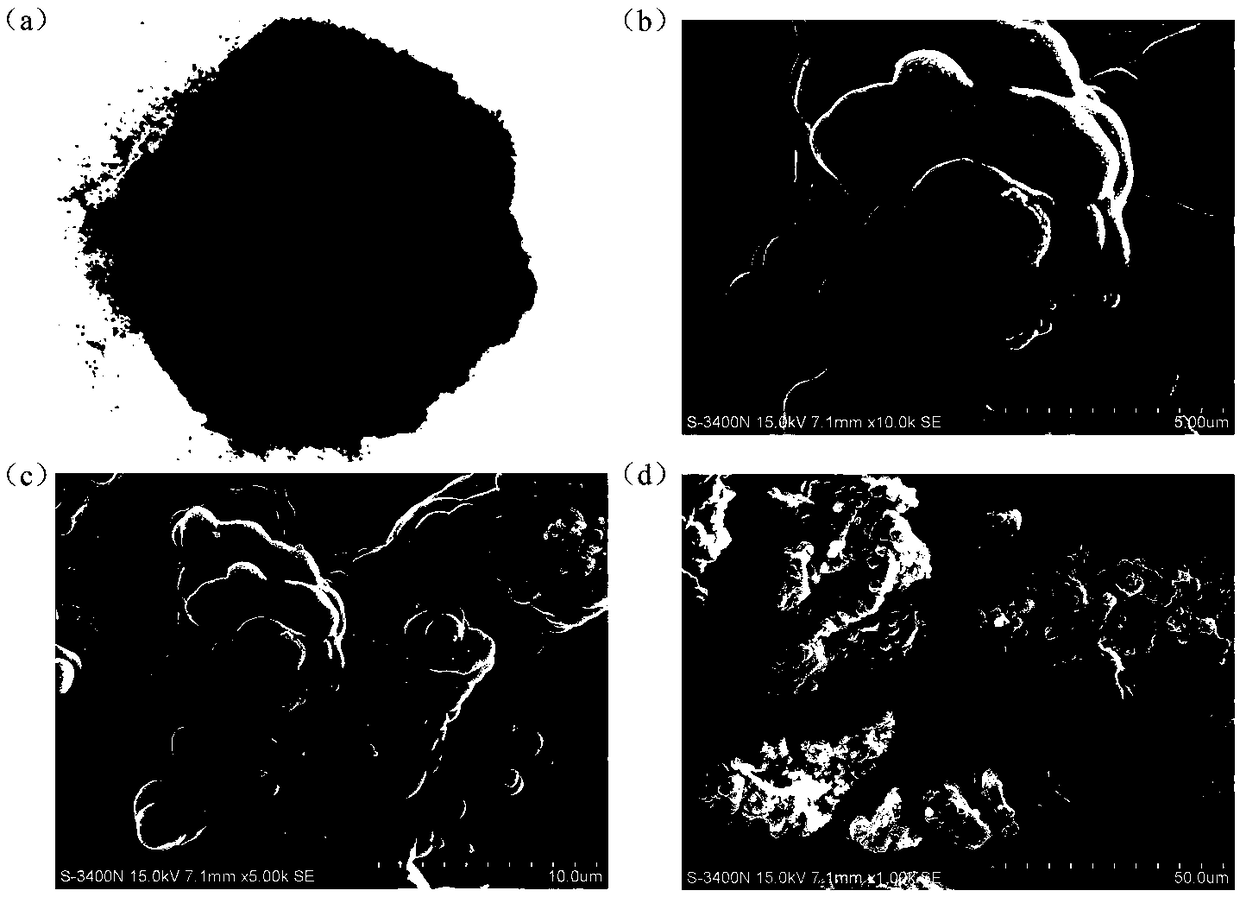

[0034] In this example, tin isooctoate is used as a catalyst to obtain a micron-sized β-cyclodextrin polymer. The typical sample properties and surface morphology are as follows: figure 2 shown.

[0035] The preparation method is as follows:

[0036] Weigh 2.27g of β-cyclodextrin and 0.0486g of tin isooctanoate into a 250mL three-neck flask containing 40mL of butanone, then transfer the three-necked flask to an oil bath with a mechanical stirring device, at room temperature at a speed of 250rpm Stir for 15min. The temperature of the oil bath was gradually increased to 60°C, and 5.44 g of ethyl acetate solution of triphenylmethane triisocyanate was added dropwise to the reaction solution through a constant pressure dropping funnel under stirring, and the stirring reaction was continued for 4 h. After the reaction was finished, the reaction solution was cooled to room temperature and filtered with suction, and then the solid product was washed three times with acetone and 60°...

Embodiment 3

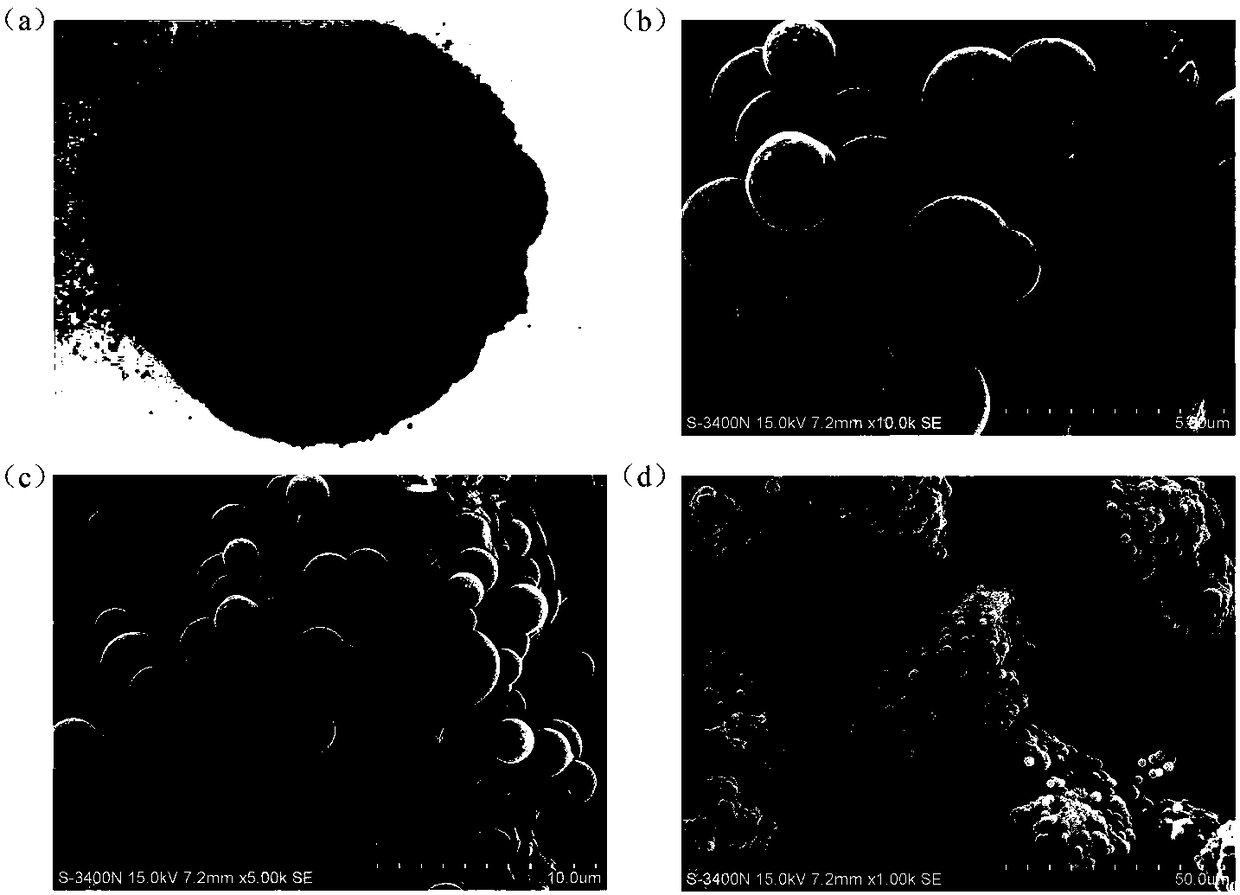

[0038] In this example, N-methylmorpholine is used as a catalyst to obtain a micron-sized β-cyclodextrin polymer. The typical sample properties and surface morphology are as follows image 3 shown.

[0039] The preparation method is as follows:

[0040] Weigh 2.27g β-cyclodextrin and 0.0121g N-methylmorpholine to a 250mL three-necked flask equipped with 40mL butanone, then transfer the three-necked flask to an oil bath with a mechanical stirring device. Stir at 250 rpm for 15 min. The temperature of the oil bath was gradually increased to 60°C, and 10.89 g of ethyl acetate solution of triphenylmethane triisocyanate was added dropwise to the reaction solution through a constant pressure dropping funnel under stirring, and the reaction was continued for 7 hours with stirring. After the reaction, the three-necked flask was taken out, and the reaction liquid was cooled to room temperature, then filtered with suction, and then the solid product was washed three times with acetone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com