Flame-retardant, high-viscosity and environmental-protection sealant

A sealant and environmental protection technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor flame retardancy and applicability, and achieve good temperature resistance and long service life Long, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment relates to a flame-retardant high-viscosity environment-friendly sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0042] 46 parts of vinyl chloride-acrylate copolymers;

[0043] 30 parts of tert-butylphenol-formaldehyde tackifying resin;

[0044] 8 parts of illite powder with a particle size of 20 μm;

[0045] 3 parts of methylisothiazolinone;

[0046] 7 parts of fluff powder with a particle size of 15 μm;

[0047] 5.5 parts of triphenylmethane triisocyanate;

[0048] 3 parts flaxseed gum;

[0049] 4 parts of tris (butoxyethyl) phosphate;

[0050] Dispersant FT-780.8 parts;

[0051] 3 parts of cross-linking agent;

[0052] Accelerator 1 part;

[0053] 1.5 parts of antioxidant;

[0054] 0.4 parts of coupling agent.

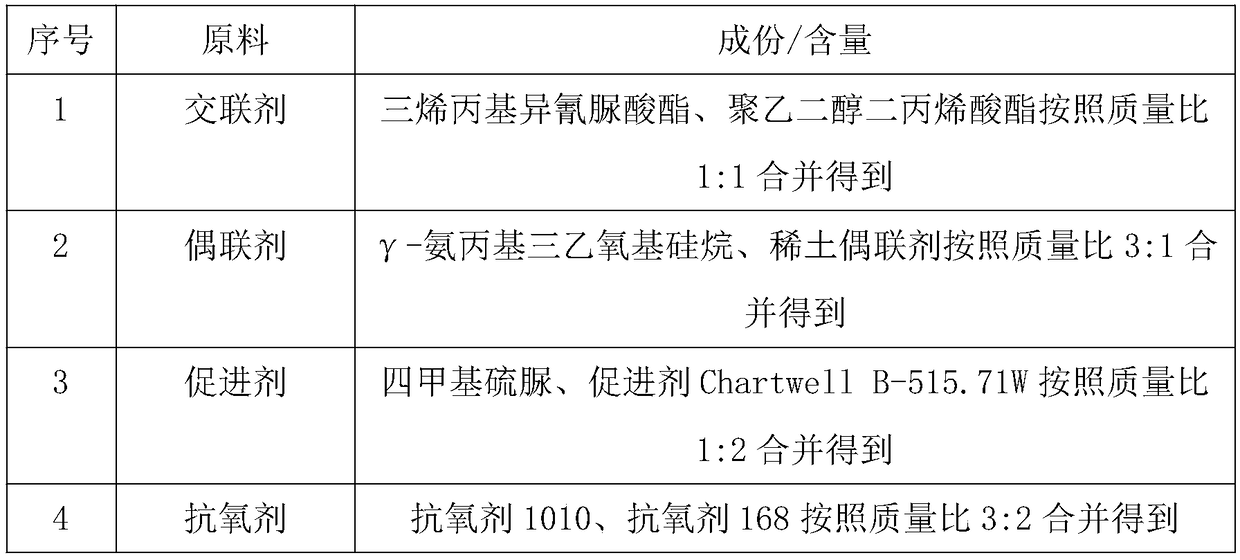

[0055] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 1 below:

[0056] Table 1

...

Embodiment 2

[0063]This embodiment relates to a flame-retardant high-viscosity environment-friendly sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0064] 48 parts of vinyl chloride-acrylate copolymers;

[0065] 34 parts of tert-butylphenolic tackifying resins;

[0066] 10 parts of illite powder with a particle size of 20 μm;

[0067] 3.5 parts of methylisothiazolinone;

[0068] 8 parts of fluff powder with a particle size of 15 μm;

[0069] 6.5 parts of triphenylmethane triisocyanate;

[0070] 3.5 parts of linseed gum;

[0071] 4.5 parts of tris (butoxyethyl) phosphate;

[0072] Dispersant FT-780.9 parts;

[0073] 3.5 parts of crosslinking agent;

[0074] Accelerator 1.2 parts;

[0075] 1.8 parts of antioxidant;

[0076] 0.45 parts of coupling agent.

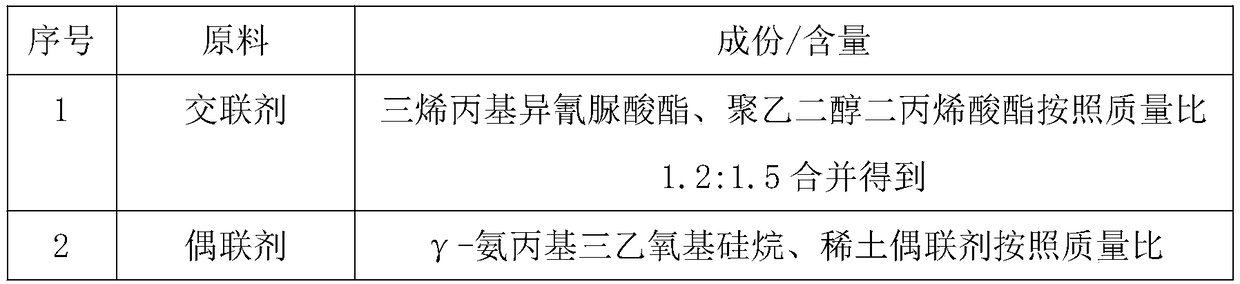

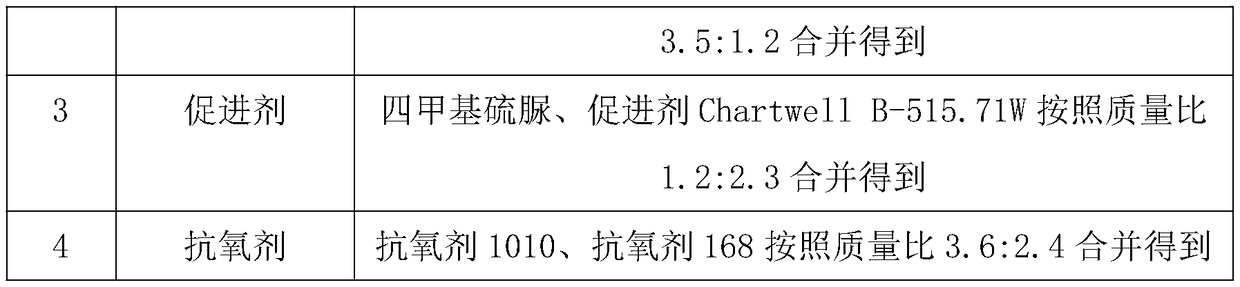

[0077] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 2 below:

[0078] Table 2...

Embodiment 3

[0086] This embodiment relates to a flame-retardant high-viscosity environment-friendly sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0087] 49 parts of vinyl chloride-acrylate copolymers;

[0088] 35 parts of tert-butylphenol-formaldehyde tackifying resins;

[0089] 11 parts of illite powder with a particle size of 25 μm;

[0090] 4 parts of methylisothiazolinone;

[0091] 9 parts of fluff powder with a particle size of 20 μm;

[0092] 7 parts of triphenylmethane triisocyanate;

[0093] 4 parts flaxseed gum;

[0094] 5 parts of tris (butoxyethyl) phosphate;

[0095] Dispersant FT-781 parts;

[0096] 4 parts of crosslinking agent;

[0097] Accelerator 1.3 parts;

[0098] Antioxidant 2 parts;

[0099] 0.5 parts of coupling agent.

[0100] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 3 below:

[0101] table 3

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com