Novel composite new material high-strength rubber sound insulation pad and preparation method thereof

A new material and high-strength technology, applied in the field of building materials, can solve the problems of poor noise reduction effect of sound insulation pads, and achieve the effect of good tear strength, high density and good sound insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0069] The embodiment of this application discloses a new composite new material high-strength rubber sound insulation pad, which includes the following components:

[0070] Rubber, foam cotton, adhesives.

[0071] The rubber is a compound of styrene-butadiene rubber and nitrile rubber;

[0072] The foamed cotton is a composite of polyurethane foamed cotton and styrene-butadiene-styrene foamed cotton;

[0073] Adhesives consist of the following components:

[0074] Triphenylmethane triisocyanate, neoprene, polydimethylmethylvinylsiloxane, polyurethane emulsion, methyl vinyl ether-maleic anhydride copolymer, zinc oxide, magnesium oxide, organic solvent.

[0075] The organic solvent is ethyl acetate.

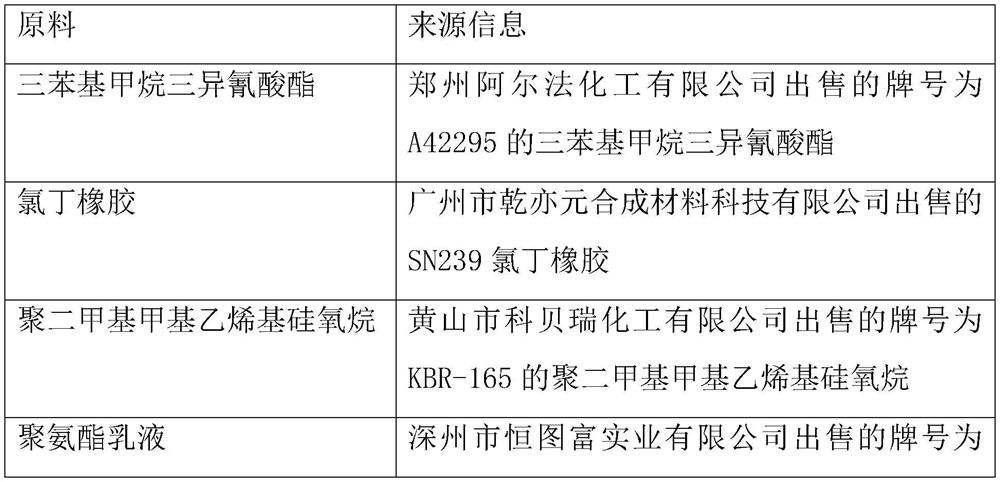

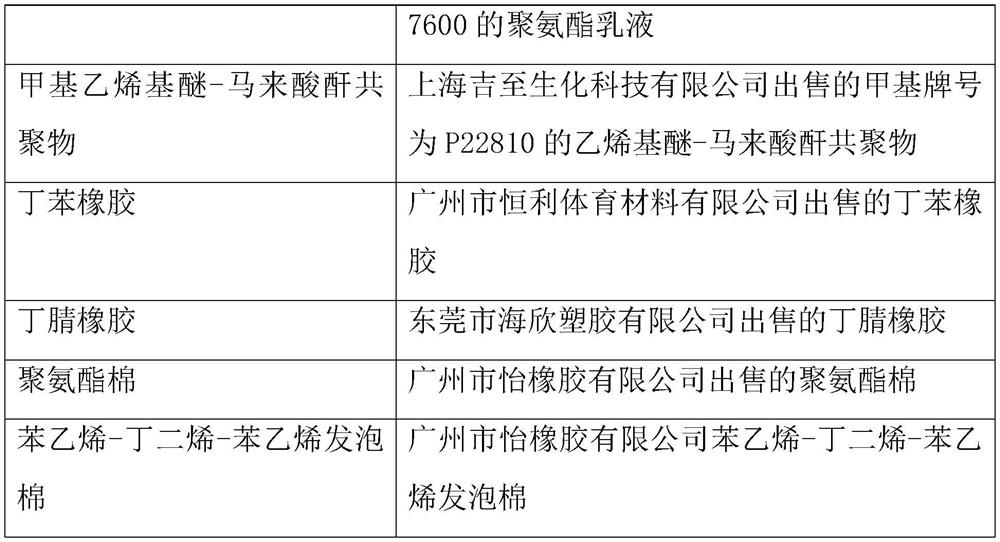

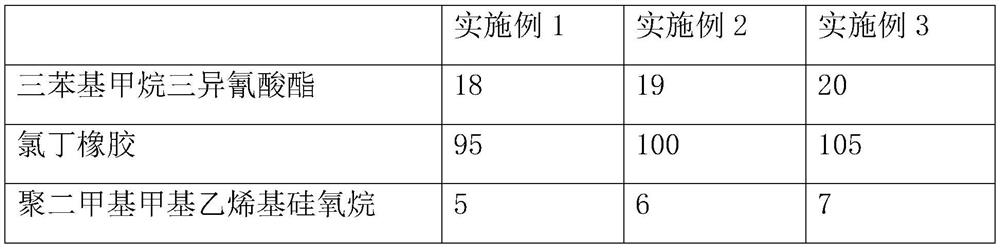

[0076] In embodiment 1-3, the input amount (unit Kg) of each component of adhesive is shown in Table 2 for details

[0077] Table 2

[0078]

[0079]

[0080] In embodiment 1-3, the input amount (unit Kg) of each component of novel composite new material high-strength r...

Embodiment 4

[0090] The embodiment of this application discloses a kind of preparation method of adhesive:

[0091] Compared with embodiment 2, the difference only lies in:

[0092] In the preparation method of adhesive:

[0093] Step 1), adding ethyl acetate, chloroprene rubber, and zinc oxide together into the stirring tank, 60r / min, stirring for 7min, stirring evenly to obtain the first mixture;

[0094] Step 2), add triphenylmethane triisocyanate, polydimethylmethylvinylsiloxane, polyurethane emulsion, methyl vinyl ether-maleic anhydride copolymer to the first mixture, 60r / min, stir for 15min , stir evenly, extract 80% of the volatilized ethyl acetate under the pressure of 0.6Mpa, obtain the second mixture;

[0095] Step 3), adding magnesium oxide to the second mixture, 60r / min, stirring for 8min, stirring evenly to obtain the adhesive;

[0096] Step 4), styrene-butadiene rubber, nitrile rubber, polyurethane foam and styrene-butadiene-styrene foam are added to the crusher and crushe...

Embodiment 5

[0099] The embodiment of this application discloses a kind of preparation method of adhesive:

[0100] Compared with embodiment 2, the difference only lies in:

[0101] In the preparation method of adhesive:

[0102] Step 1), adding ethyl acetate, chloroprene rubber, and zinc oxide together into the stirring tank, 60r / min, stirring for 3min, stirring evenly to obtain the first mixture;

[0103] Step 2), add triphenylmethane triisocyanate, polydimethylmethylvinylsiloxane, polyurethane emulsion, methyl vinyl ether-maleic anhydride copolymer to the first mixture, 60r / min, stir for 7min , stir evenly, extract 90% of the volatilized ethyl acetate under the pressure of 0.2Mpa, obtain the second mixture;

[0104] Step 3), adding magnesium oxide to the second mixture, 60r / min, stirring for 3min, stirring evenly to obtain the adhesive;

[0105] Step 4), styrene-butadiene rubber, nitrile rubber, polyurethane foam and styrene-butadiene-styrene foam are added to the crusher and crushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com