Ultra-low temperature resistant environment-friendly flexible cable and preparation method thereof

A low-temperature-resistant, flexible cable technology, applied in cable/conductor manufacturing, insulated cables, flexible cables, etc., can solve problems such as halogen pollution, human body and environmental hazards, and achieve good mechanical properties, strong cold resistance, brittle The effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: An ultra-low temperature resistant environment-friendly soft cable, including an ultra-fine copper wire, an insulating layer and a protective layer. One cable core, the insulating layer and the protective layer have the same composition, the cross-sectional diameter of the ultra-fine copper wire is 0.04mm, and the bundle pitch of the ultra-fine copper wire is 8 times;

[0039] Both the insulating layer and the protective layer include the following components by weight: 30 parts of polyvinyl chloride resin, 20 parts of EPDM rubber, 15 parts of cold-resistant plasticizer, 20 parts of low-temperature resistant modified material, non-halogen flame retardant 10 parts, 20 parts of filler, 2 parts of bisphenol A, 5 parts of stabilizer, 1 part of lubricant, 2 parts of anti-aging agent;

[0040] Among them, the cold-resistant plasticizer includes diisodecyl adipate, hexamethylphosphoric triamide and 2,2,4-trimethyl-1,3-pentanediol with a mass ratio of 1:1.2:2.3 I...

Embodiment 2-6

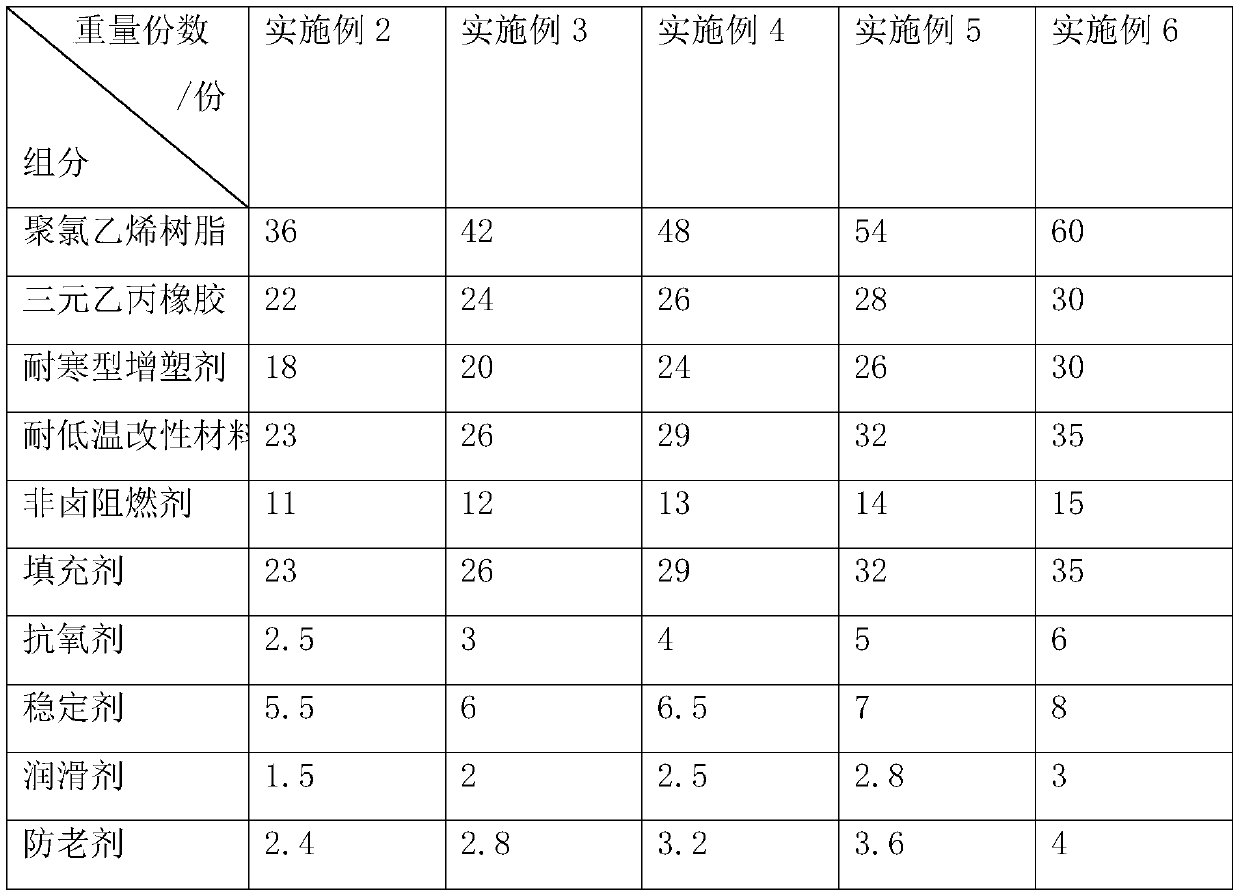

[0050] Embodiment 2-6: An ultra-low temperature resistant environment-friendly flexible cable, the difference from Embodiment 1 is that the components contained in the insulating layer and the protective layer and the corresponding parts by weight of each component are shown in Table 1.

[0051] The components contained in the insulating layer and the protective layer in the embodiment 2-6 of table 1 and the corresponding parts by weight of each component

[0052]

Embodiment 7

[0053] Embodiment 7: An ultra-low temperature resistant environment-friendly flexible cable, the difference from Embodiment 1 is that the non-halogen flame retardant includes 6 parts of antimony trioxide, 15 parts of magnesium hydroxide and 10 parts of aluminum hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com