Water-based urethane resin composition and synthetic leather

A technology of polyurethane resin and resin composition, which is applied in furniture parts, interior decoration, textiles and paper making, etc. It can solve the problems of insufficient wear resistance and hydrolysis resistance, and achieve excellent wear resistance and hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

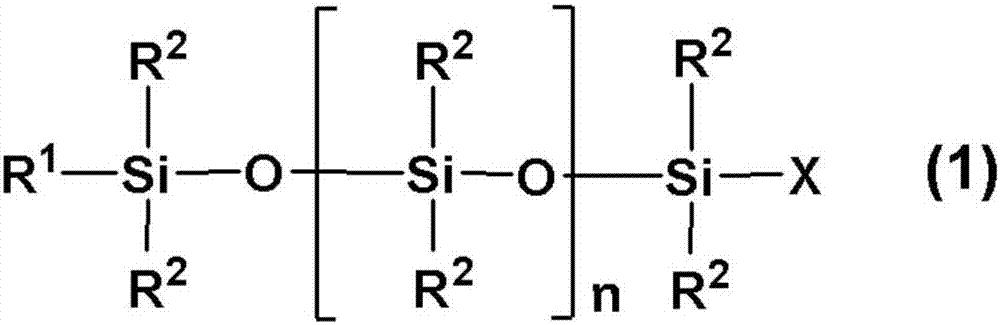

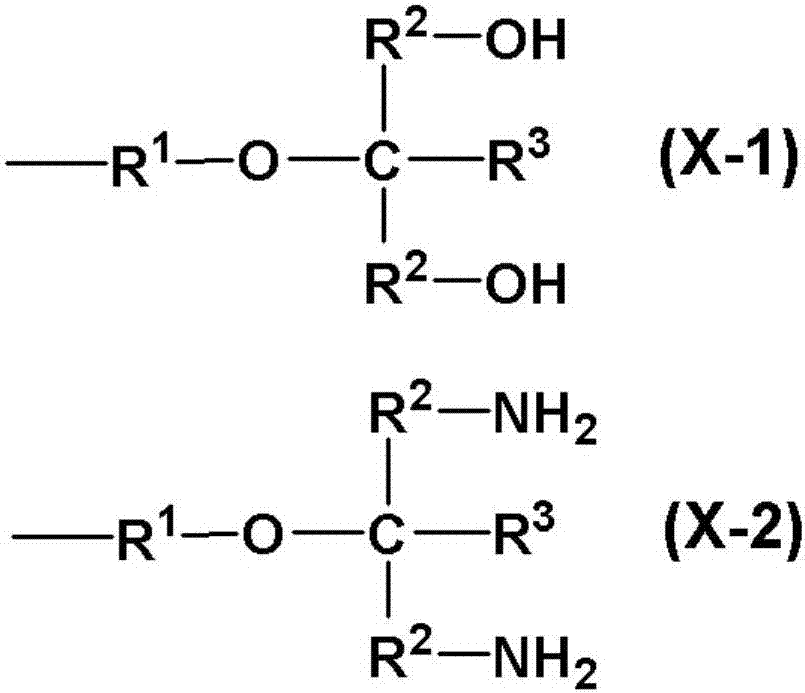

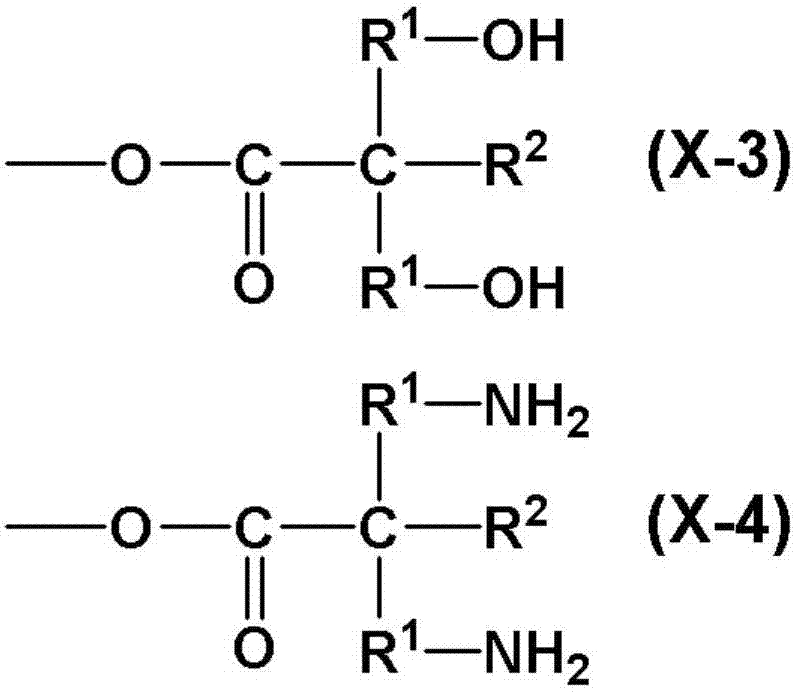

Method used

Image

Examples

Embodiment 1

[0135] [Example 1] Preparation of aqueous polyurethane resin composition (X-1)

[0136] In a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen gas introduction pipe, a polycarbonate diol ("ETERNACOLL UH-200" manufactured by Ube Kosan Co., Ltd., number average molecular weight: 2,000, hereinafter referred to as abbreviation) was added under a nitrogen gas stream. "PC-1".) 500 parts by mass, both-end diol type reactive silicone ("Silaplane FM-4425" manufactured by JNC Co., Ltd. number average molecular weight: 10,000, hereinafter abbreviated as "two-end diol type Si-1" ".) 125 parts by mass, dimethylolpropionic acid (hereinafter abbreviated as "DMPA".) 25 parts by mass, methyl ethyl ketone 360 parts by mass, after uniform mixing, add dicyclohexylmethane diisocyanate (hereinafter abbreviated as "H" 12MDI ".") 177 parts by mass, then, add 0.1 parts by mass of dibutyltin dilaurate, and react at 70°C for about 4 hours, thereby obtaining a...

Embodiment 2

[0137] [embodiment 2] the preparation of aqueous polyurethane resin composition (X-2)

[0138] In a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen reflux tube, under nitrogen flow, polycarbonate diol ("DURANOL T5652" manufactured by Asahi Kasei Chemical Co., Ltd., number average molecular weight: 2,000, hereinafter referred to as "PC-2".) 500 parts by mass, single-ended diol-type reactive silicone ("X-22-176GX-A" manufactured by Shin-Etsu Chemical Co., Ltd., number average molecular weight: 14,000, hereinafter referred to as "single-ended diol Alcohol type Si-1".) 26 parts by mass, 8 parts by mass of DMPA, 269 parts by mass of methyl ethyl ketone, after mixing uniformly, add 86 parts by mass of isophorone diisocyanate (hereinafter referred to as "IPDI") 0.1 parts by mass of dibutyltin laurate was reacted at 70° C. for about 4 hours to obtain a methyl ethyl ketone solution of a urethane prepolymer having an isocyanate group at a mol...

Embodiment 3

[0139] [embodiment 3] the preparation of aqueous polyurethane resin composition (X-3)

[0140] In a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen reflux tube, polycarbonate diol (manufactured by Asahi Kasei Chemical Co., Ltd. "DURANOL T4692, number average molecular weight: 2,000, hereinafter referred to as " PC-3".) 500 parts by mass, single-end diol type reactive silicone ("Silaplane FM-DA21" manufactured by JNC Co., Ltd., number average molecular weight: 5,000, hereinafter referred to as "single-end diol type Si-2" .) 88 mass parts, DMPA26 mass parts, methyl ethyl ketone 332 mass parts, after mixing uniformly, add H 12 145 parts by mass of MDI, and then 0.1 part by mass of dibutyltin dilaurate was added and reacted at 70° C. for about 4 hours to obtain a methyl ethyl ketone solution of a urethane prepolymer having an isocyanate group at a molecular terminal. Next, 20 parts by mass of triethylamine was added to the methyl ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com