Silicon dioxide anti-reflection film for surface ultrafast hydrophobic treatment and preparation method thereof

A silica and hydrophobic treatment technology, applied in optics, instruments, optical components, etc., to achieve the effects of easy operation, improved abrasion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

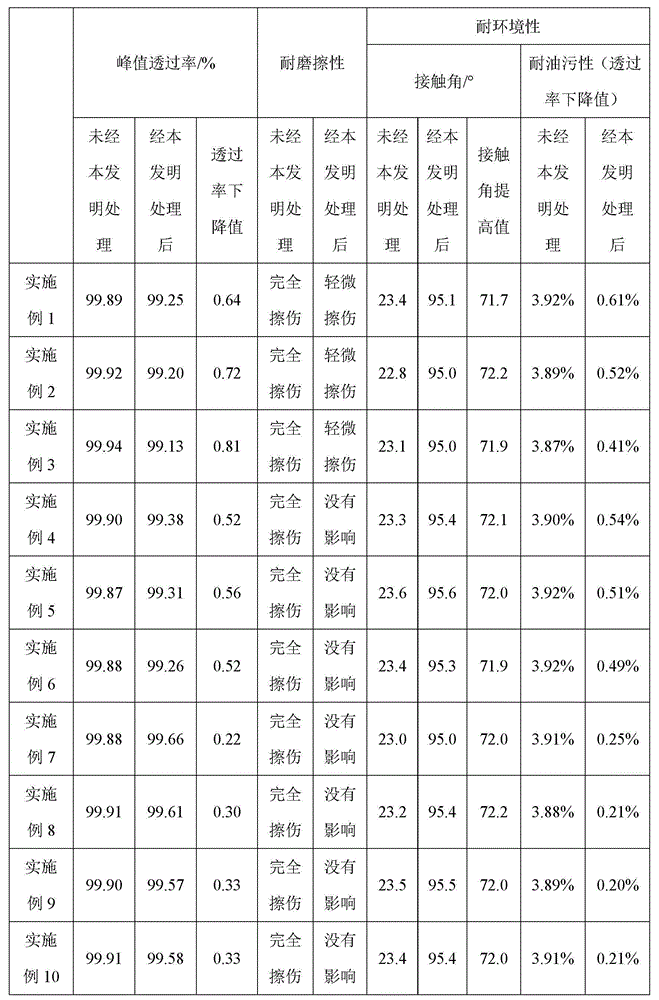

Embodiment 1

[0021] (1) First, add absolute ethanol (analytical grade), deionized water, ammonia water and tetraethyl orthosilicate (analytical grade) into the reaction vessel in sequence at a molar ratio of 1:3.25:37.6:0.17, and react at a constant temperature at 25°C After 2 h, it was taken out, then placed in a closed glass container, and aged in a constant temperature water bath at 30°C for 9 days for later use. The mass concentration of silica in the obtained silica sol was 3%.

[0022] (2) Immerse the washed and dried K9 glass in silica sol, and use the dipping-pulling method to cover the surface of K9 glass with a flat layer of silica sol at a pulling speed of 100 mm / min, and then place it on the Heat treatment at 160 °C for 8 h, and then naturally cool to room temperature to obtain the silica anti-reflection coating.

[0023] (3) Add hydrogen-containing silicone oil with a hydrogen content of 1.5% and Kastredt catalyst to n-hexane at room temperature and mix evenly to obtain a sur...

Embodiment 2

[0026] Since the process conditions for preparing the silicon dioxide anti-reflection coating in steps (1) and (2) of this embodiment are the same as those in Embodiment 1, they are omitted here.

[0027] (3) Add hydrogen-containing silicone oil with a hydrogen content of 1.5% and Kastredt catalyst to n-hexane at room temperature and mix evenly to obtain a surface treatment agent. The mass percentage concentration of hydrogen-containing silicone oil in the surface treatment agent is 0.5%, and Kastredt The concentration of catalyst is 100ppm by the mass of hydrogen-containing silicone oil;

[0028] (4) After immersing the obtained silica AR coating in the surface treatment agent for 2 minutes, pull it away from the surface treatment agent at a speed of 100 mm / min, and then heat and dry it at 120°C for 120 minutes.

Embodiment 3

[0030] Since the process conditions for preparing the silicon dioxide anti-reflection coating in steps (1) and (2) of this embodiment are the same as those in Embodiment 1, they are omitted here.

[0031] (3) Add hydrogen-containing silicone oil with a hydrogen content of 1.5% and Kastredt catalyst to n-hexane at room temperature and mix evenly to obtain a surface treatment agent. The mass percentage concentration of hydrogen-containing silicone oil in the surface treatment agent is 2.5%, and Kastredt The concentration of catalyst is 250ppm by the mass of hydrogen-containing silicone oil;

[0032] (4) After immersing the obtained silica AR coating in the surface treatment agent for 5 minutes, pull it away from the surface treatment agent at a speed of 50 mm / min, and then heat and dry it at 200 °C for 180 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com