Image forming method and image formed record

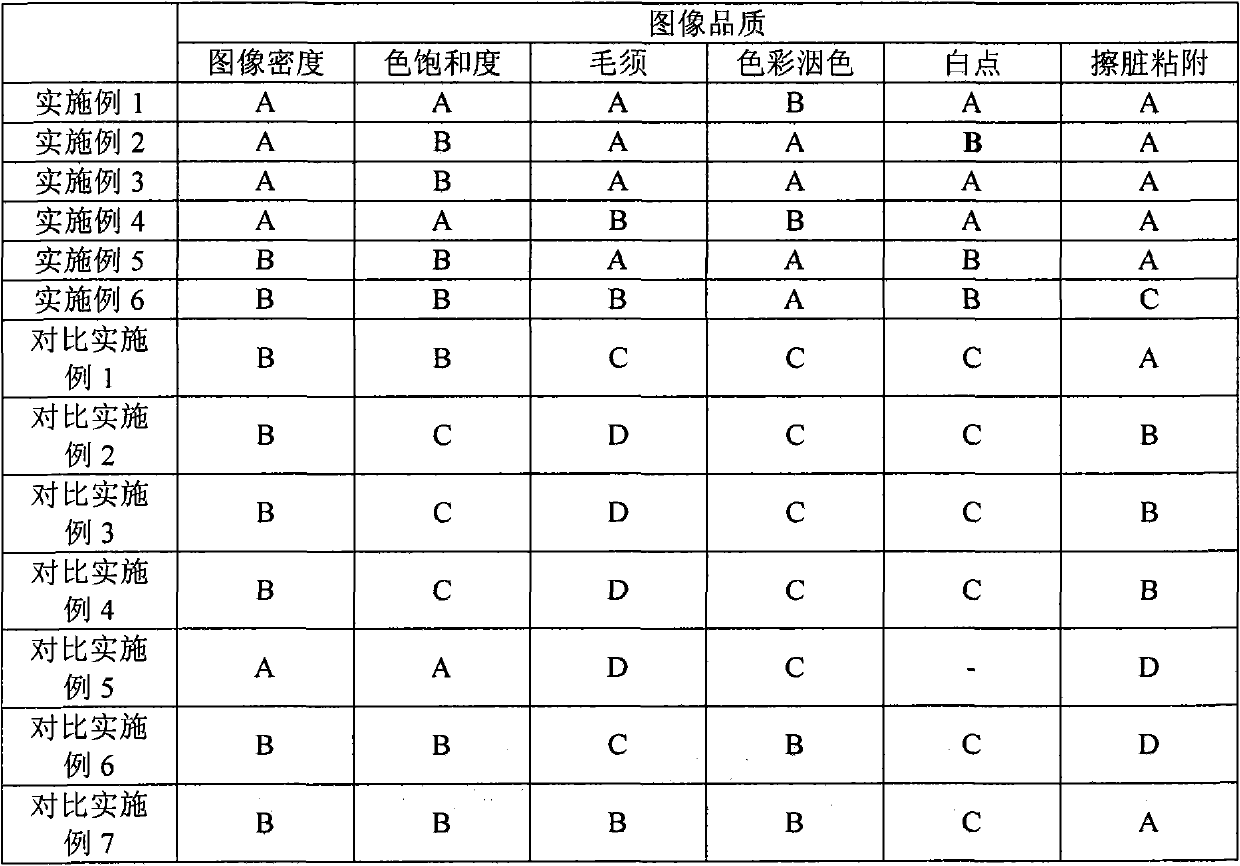

一种图像、记录介质的技术,应用在复制/标记方法、油墨、印刷等方向,能够解决不足以达到形成图像部分耐擦性、减小色彩混合、增强图像密度等问题,达到优异图像牢度、优异图像密度和色饱和度、少色彩洇色的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0272] -Preparation of Polymer Microparticle Dispersion Liquid Containing Magenta Pigment-

[0273]

[0274] Fully replace the interior of a 1L flask equipped with a mechanical stirrer, a thermometer, a nitrogen inlet tube, a return tube and a dropping funnel with nitrogen, and then add 11.2 g of styrene, 2.8 g of acrylic acid, and 12.0 g of dodecyl methacrylate , 4.0 g of polyethylene glycol methacrylate, 4.0 g of styrene macromer and 0.4 g of mercaptoethanol were mixed in a flask, and its temperature was raised to 65° C.

[0275] Subsequently, 100.8g styrene, 25.2g acrylic acid, 108.0g lauryl methacrylate, 36.0g polyethylene glycol methacrylate, 60.0g hydroxyethyl methacrylate, 36.0g styrene A mixed solution of macromonomer, 3.6g mercaptoethanol, 2.4g azodimethylvaleronitrile and 18g methyl ethyl ketone was dropped into the flask. After the dropwise addition, a mixed solution of 0.8 g of azobismethylvaleronitrile and 18 g of methyl ethyl ketone was dropped into the flask ...

preparation Embodiment 2

[0279] -Preparation of Polymer Microparticle Dispersion Liquid Containing Cyan Pigment-

[0280] A polymer microparticle dispersion liquid containing a cyan pigment was prepared in the same manner as in Preparation Example 1, except that the pigment C.I. Pigment Red 122 in Preparation Example 1 was replaced with a phthalocyanine pigment (C.I. Pigment Blue 15:3).

[0281] The average particle diameter (D 50 ). The obtained polymer microparticles in the polymer microparticle dispersion containing the cyan pigment had an average particle diameter (D 50 ).

preparation Embodiment 3

[0283] -Preparation of Polymer Microparticle Dispersion Liquid Containing Yellow Pigment-

[0284] A polymer microparticle dispersion liquid containing a yellow pigment was prepared in the same manner as in Preparation Example 1, except that the pigment C.I. Pigment Red 122 in Preparation Example 1 was replaced with a monoazo yellow pigment (C.I. Pigment Yellow 74).

[0285] The average particle diameter (D 50 ). The polymer microparticles in the obtained polymer microparticle dispersion liquid containing a yellow pigment had an average particle diameter (D 50 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com