Superhydrophobic silicon dioxide aerogel micropowder, and preparation method and application thereof

A technology of airgel micropowder and silicon oxide in water, which is applied in the direction of silicon oxide, silicon dioxide, chemical instruments and methods, etc., and can solve the problems of brittle silicon oxide airgel, difficulty in industrial production, and long preparation cycle , to achieve the effects of easy removal, saving resources and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a preparation method of superhydrophobic silica airgel micropowder, comprising:

[0033] Mix the silicon source, low surface tension organic solvent, hydrophobic modifier and alkali catalyst to form a mixed solution, and let it stand to form a silica organogel, and then age;

[0034] The obtained silica organogel is pulverized and then directly dried under normal pressure to obtain superhydrophobic silica airgel micropowder.

[0035] As one of the preferred embodiments, the mixed solution includes: 0.01-20 parts by volume of silicon source, 10-70 parts by volume of low surface tension organic solvent, 0.1-10 parts by volume of hydrophobic modifier and 0.001-0.05 parts by volume of alkali catalyst.

[0036] As one of the preferred solutions, the drying temperature is 25-250° C., and the drying method includes blast drying, spray drying or rotary drying.

[0037] Preferably, the silicon source includes polysiloxane and po...

Embodiment 1

[0062] (1) Synthesis of silica organogel: get 10 parts of polysiloxane, 20 parts of n-hexane, and 2 parts of hexamethyldisilazane and mix them evenly in a stirring tank, drop 10 microliters of ammonia water under stirring, and stir The speed is 50rpm, after stirring for 15 minutes, the mixture is allowed to stand still to form a white opaque organic gel.

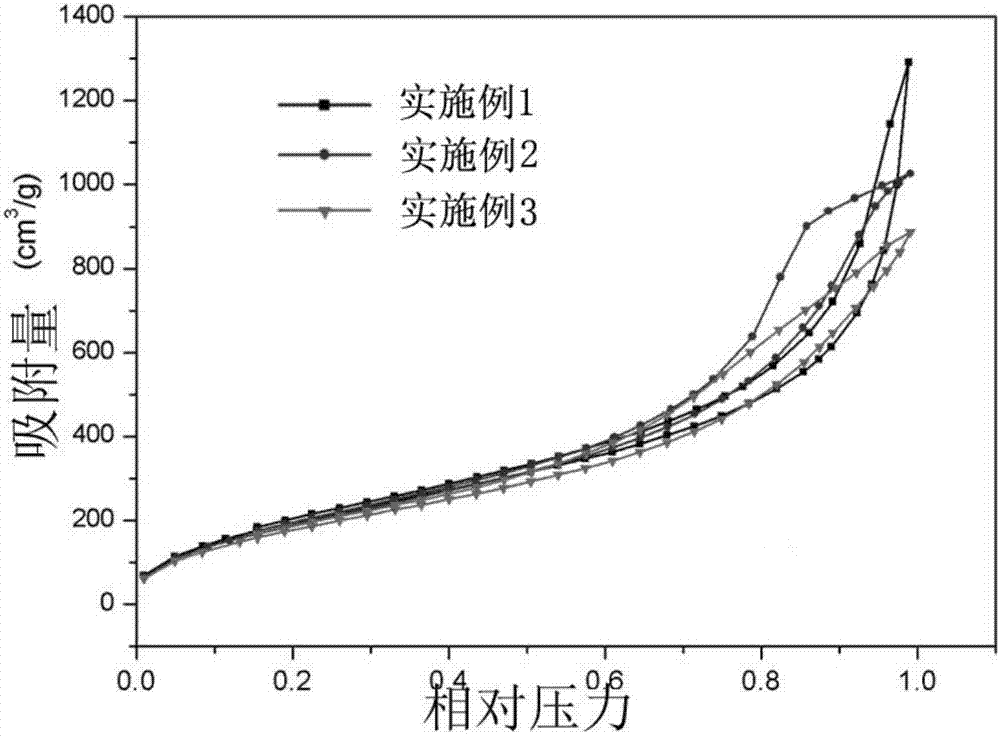

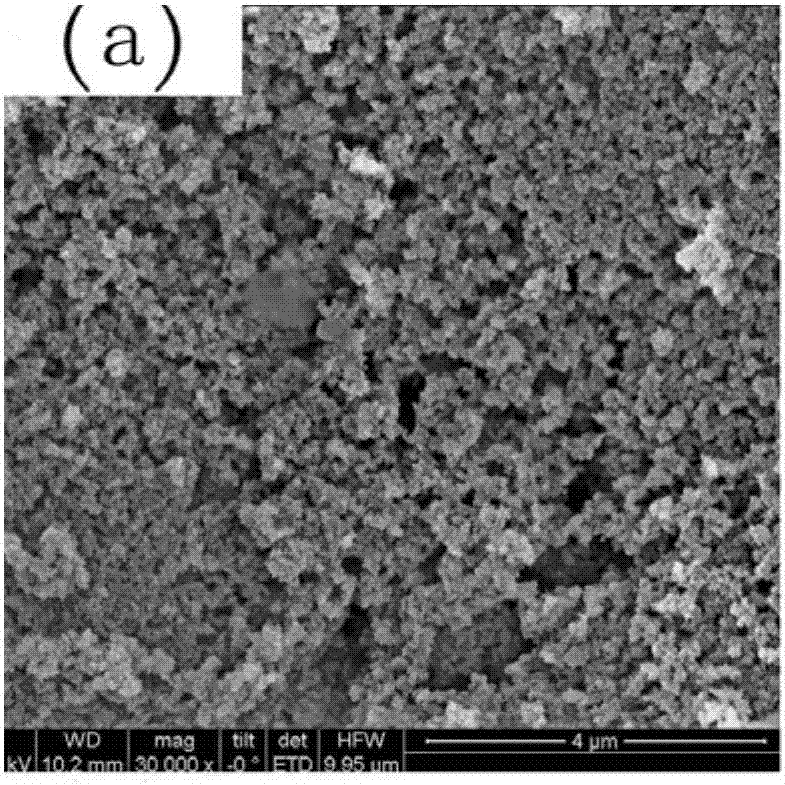

[0063] (2) Drying of wet gel: Dry the silica organogel obtained above at 100°C, and obtain superhydrophobic silica airgel micropowder after 60 minutes. Characterized by BET isothermal adsorption, it can be found that the superhydrophobic oxidation Silica airgel powder has a nanoporous structure. For the isotherm adsorption-desorption curve of this silica airgel powder, please refer to Figure 1a , SEM image see Figure 2a , and other physical parameters such as specific surface area, pore size, density, contact angle, etc. are shown in Table 1.

[0064] (3) Take 100 mg of the obtained airgel micropowder and place it on a pa...

Embodiment 2

[0066] (1) Synthesis of silica organogel: Take 10 parts of polysiloxane, 2 parts of n-hexane, and 1 part of dimethyldimethoxysilane in a stirring tank, mix them evenly, and drop 100 microliters of 0.5M NaOH solution, the stirring speed is 50rpm, after stirring for 1 minute, stand still to form a white opaque organic gel.

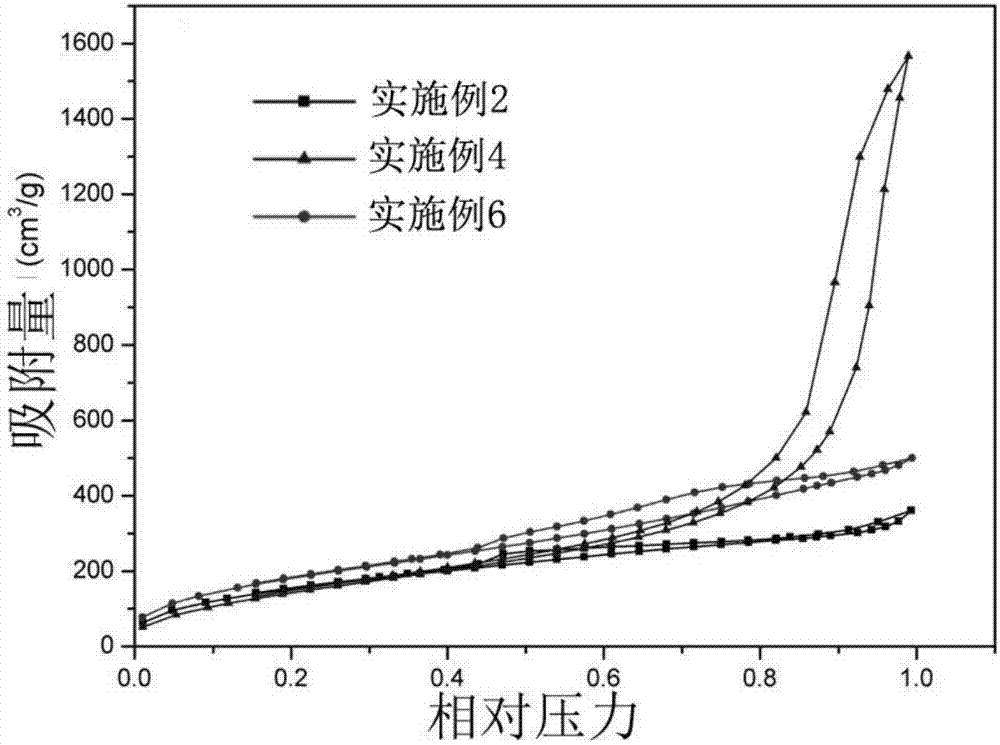

[0067] (2) Drying of the wet gel: dry the silica organogel at 150°C, and obtain superhydrophobic silica airgel micropowder after 60 minutes. Characterized by BET isothermal adsorption, it can be found that the superhydrophobic airgel micropowder With nanoporous structure, please refer to the isothermal adsorption-desorption curve of this silica airgel powder Figure 1b , SEM image see Figure 2b , and other physical parameters such as specific surface area, pore size, density, contact angle, etc. are shown in Table 1.

[0068] (3) Get 50 mg of the gained airgel micropowder, place it on a plastic film (PET), and then use a smooth metal plate to evenly coat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com