Amine sacrificial agents and methods and products using same

a technology of sacrificial agents and products, applied in the direction of application, solid waste management, sustainable waste treatment, etc., can solve the problems of entrapped air providing no protection, negative influence on bleed characteristics, and other challenges encountered when using certain fly ash, etc., to facilitate air entrainment and facilitate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

PACT Formulation

[0100]A sacrificial agent formulation (PACT) is prepared by mixing polyoxypropylenediamine, dodecyldimethylamine, and optionally sodium diisopropylnapthalenesulfonate. For the following examples, PACT was formulated as follows: 0.05% dodecyldimethylamine and 0.15% polyoxypropylenediamine, by weight of fly ash.

Composition Preparation:

[0101]To prepare the composition, the aggregate is mixed with partial water followed by the portland cement. Fly ash combined with activated carbon is then added followed by the PACT formulation and the air entrainment agent. Alternatively, the PACT formulation can be added directly to the fly ash. Additional water is added to obtain a 4-6 inch slump. The composition is then mixed using a rotary mixer, and tested for volume percentage of air using a pressure meter according to the ASTM C 231 method.

[0102]Activated carbon for the following examples was obtained from three sources:

PAC-A: Norit HgLH (Norit Americas Inc., Marshall, Tex.)

PAC-B...

example 2

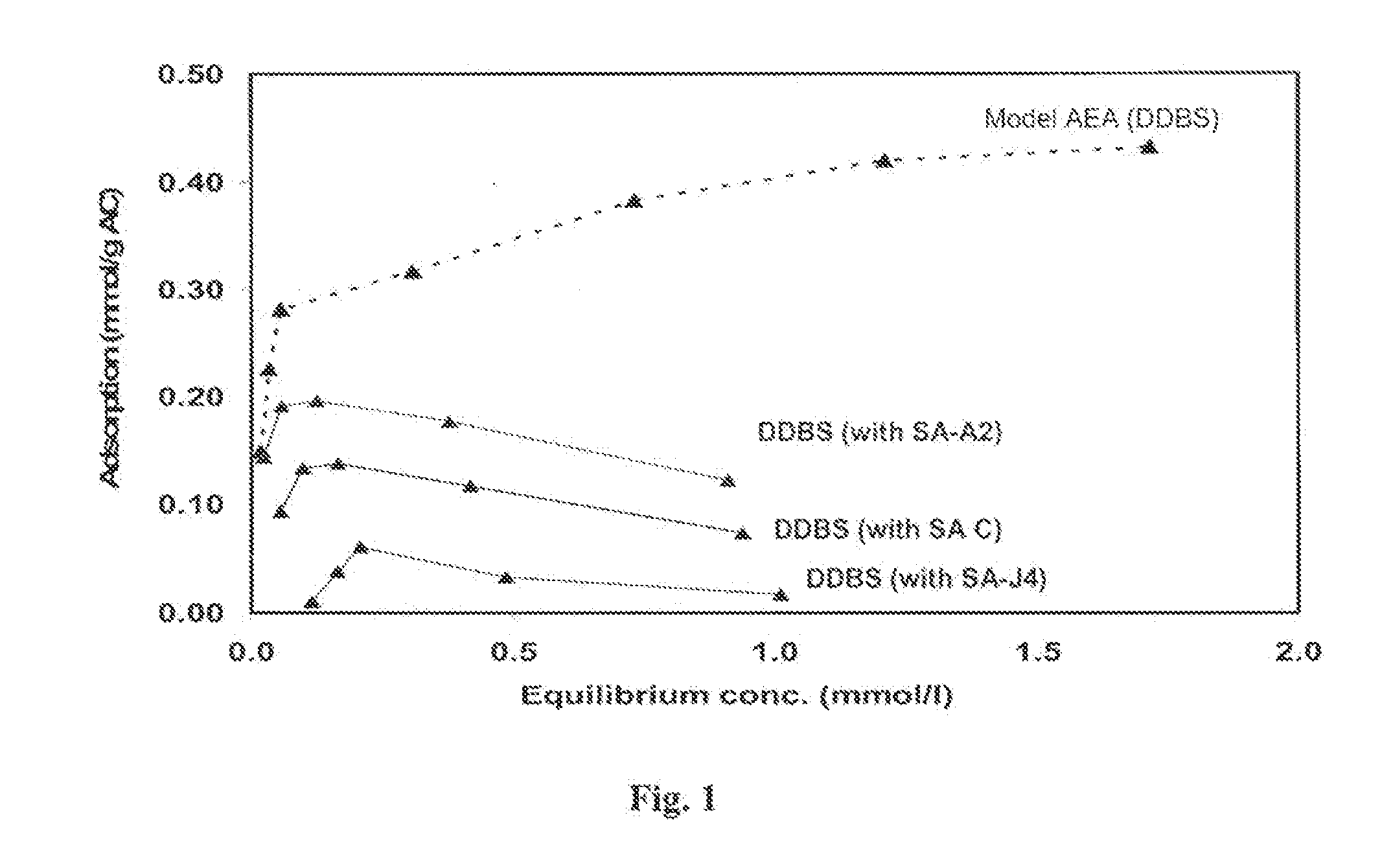

[0104]The competitive absorption by PAC-C with various sacrificial agents at saturated concentrations was determined (FIG. 1). The trace labeled Model AEA (DDBS) displays the absorption of an air entrainment agent (dodecylbenzenesulfonate (DDBS)) by MC activated carbon without the presence of a sacrificial agent. The trace labeled DDBS (with SA-A2) displays the absorption of DDBS by PAC-C and Jeffamine EDR-148. The trace labeled DDBS (with SA-C) displays the absorption of DDBS by MC activated carbon and Jeffamine 230. The trace labeled DDBS (with SA-J4) displays the absorption of DDBS by MC activated carbon and Jeffamine 400.

example 3

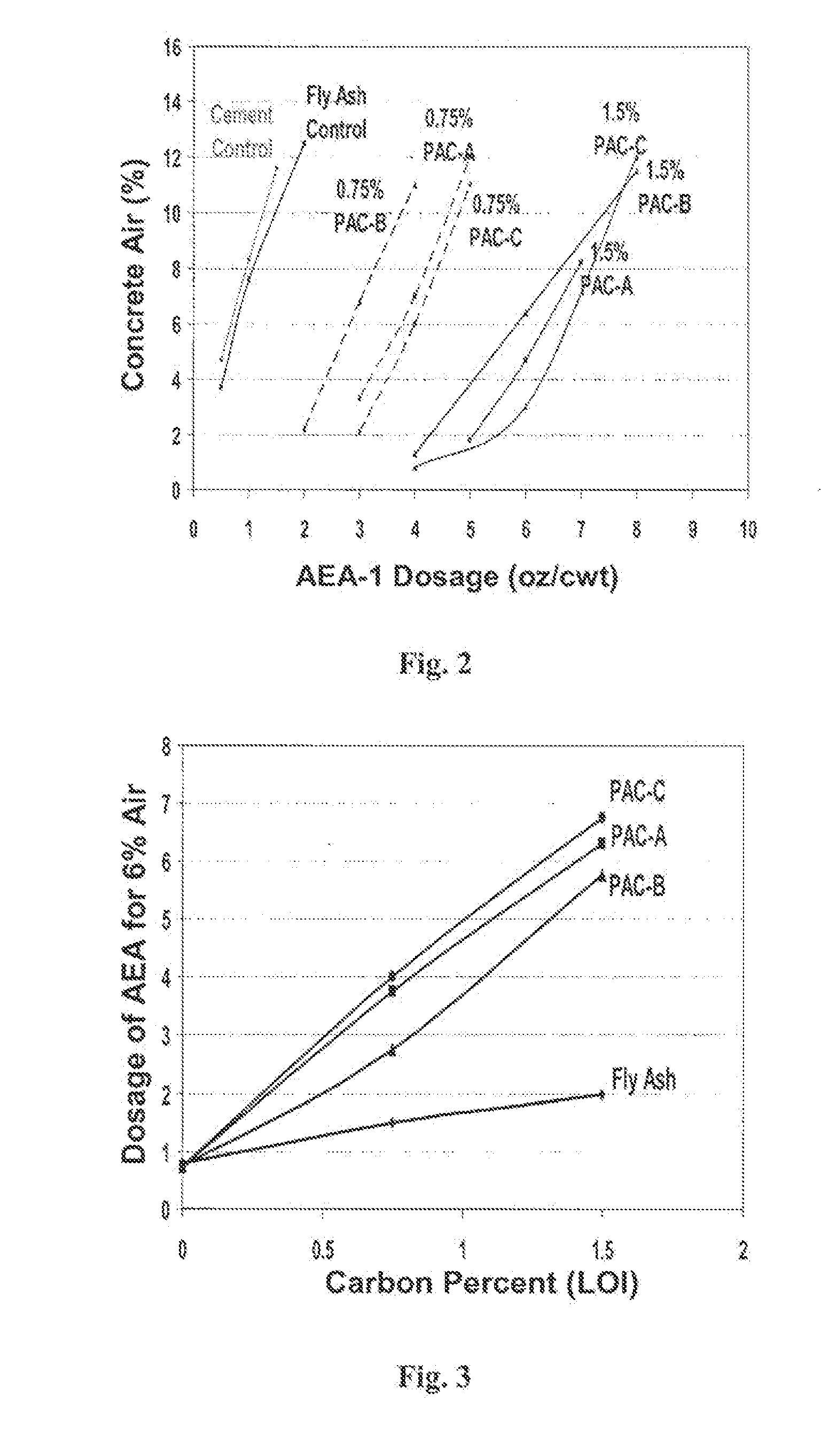

[0105]The percentage of air in concrete with increasing concentrations of air entraining agent AEA-1 with varying amounts of activated carbon samples PAC-A, PAC-B, and PAC-C was determined. The amounts tested for each activated carbon sample include 0.75% and 1.5% (FIG. 2). Cement and fly ash cement independently served as controls. All activated carbon samples increased the air entraining agent demand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| LOI | aaaaa | aaaaa |

| LOI | aaaaa | aaaaa |

| LOI | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com