Sludge-high calcium fly ash alkali-excited cement and preparation method thereof

A technology of high-calcium fly ash and alkali excited cement, which is applied in the field of materials to achieve the effects of reducing costs, reducing resource consumption and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

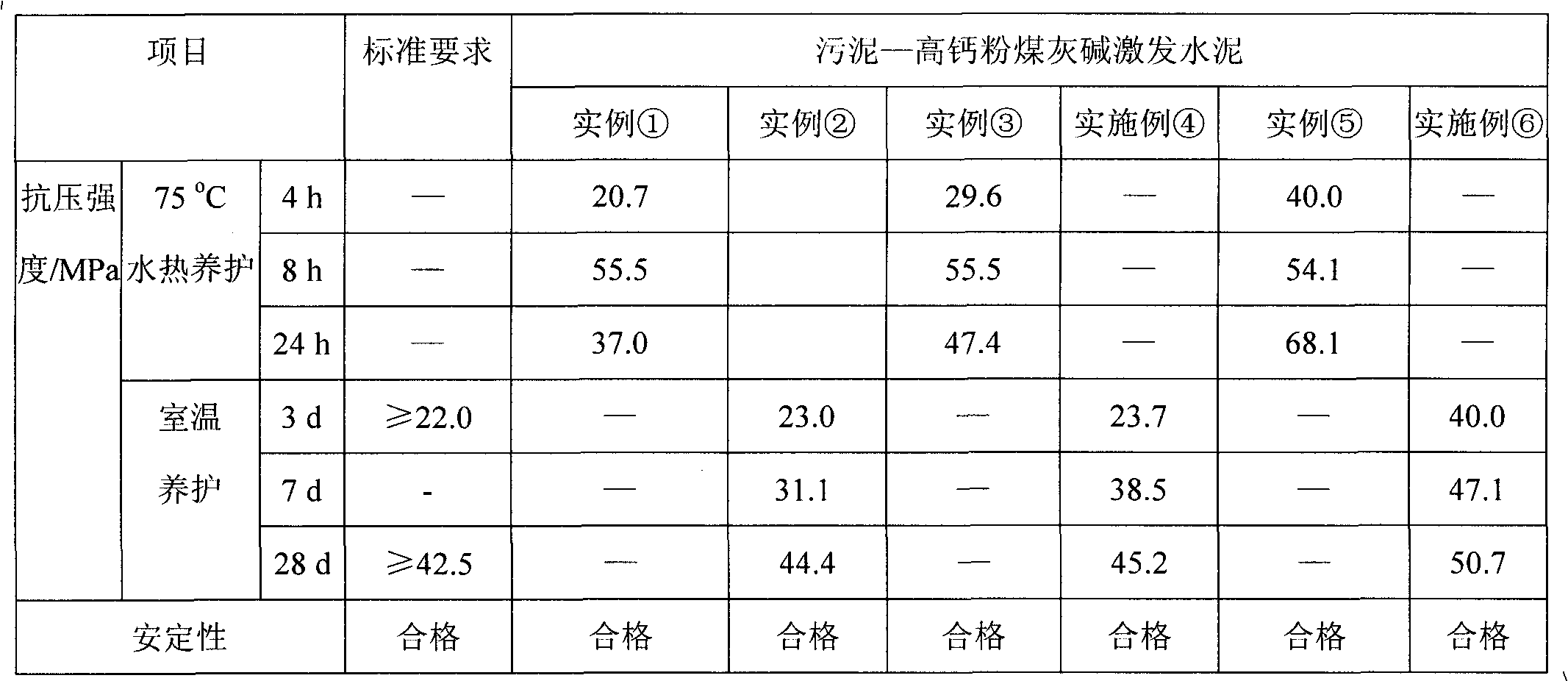

Examples

Embodiment Construction

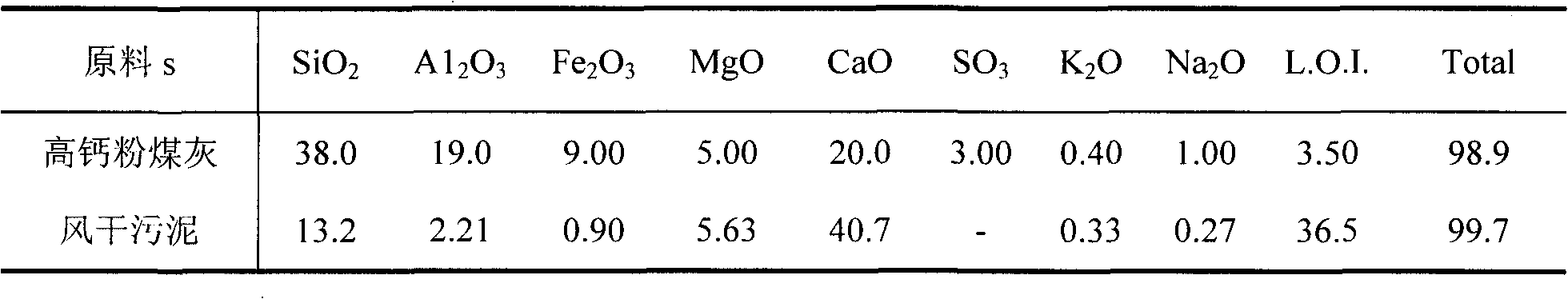

[0021] The main raw material air-dried sludge of the six embodiments of the present invention is the natural air-dried sludge piled up in the field of a water treatment plant, and the high-calcium fly ash is taken from a power plant with a specific surface area of 385m 2 / kg, the main chemical composition and mass percentage (wt.%) of air-dried sludge and high-calcium fly ash are shown in Table 1. Used sodium hydroxide is a chemical reagent containing 99.2% NaOH; commercially available liquid sodium silicate has a solid content of 38.3% and contains 9.1% NaOH 2 O, 29.2% SiO 2 and 61.7% water.

[0022] Table 1 The present invention uses the main chemical composition and content (wt.%) of air-dried sludge and high-calcium fly ash

[0023]

[0024] Example ①

[0025] a. Mix sodium hydroxide with liquid sodium water glass to control its modulus M (SiO 2 ) / n(Na 2 O) is 1.5, made into a compound chemical admixture, aged for 24h, and set aside.

[0026] b. Control the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com