Application of carbide slag solid wastes as raw materials for preparing mineral filling gel material, filling gel material and filling material

A technology of gel material and filling glue, which is applied in the direction of cement production, etc., can solve the problems of insufficient resource utilization of carbide slag and low effective utilization rate, and achieve the effect of dense structure, reduced porosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention has no special limitation on the preparation method of the mine-used filling cementitious material, and it is enough to adopt the technical scheme prepared by the compound well known to those skilled in the art. Specifically, carbide slag solid waste, fly ash, desulfurized gypsum, blast furnace The water slag is mixed with the chemical admixture to obtain the mine filling cementitious material.

[0072] The present invention also provides a mine filling material, comprising the mine filling cementitious material described in the above technical scheme and water and sand, the mass ratio of the mine filling cementitious material, water and sand is 1:[1.5,2.6 ]:[3.5,4.5].

[0073] In the mine filling material provided by the present invention, the mass ratio of the mine filling cementitious material, water and sand is preferably 1:[1.7,2.4]:[3.8,4.2].

[0074] The present invention has no special limitation on the preparation method of the mine filli...

Embodiment 1

[0079] Carbide slag solid waste 10.18% ~ 10.40%, fly ash 60.57%, desulfurization gypsum 5.86% ~ 6.32%, blast furnace slag 16.35%, anhydrous calcium chloride 1.82%, anhydrous sodium sulfate 0.38% ~ 0.51%, silicic acid 0.91% of sodium, 2.13% to 2.65% of sodium hydroxide, and 0.15% to 0.20% of calcium lignosulfonate, a water reducer, are uniformly mixed to obtain a mineral filling cementitious material. Mix the above-mentioned mining filling cementitious material with water and sand in a mass ratio of 1:1.9-2.5:3.8-4 to make a filling material.

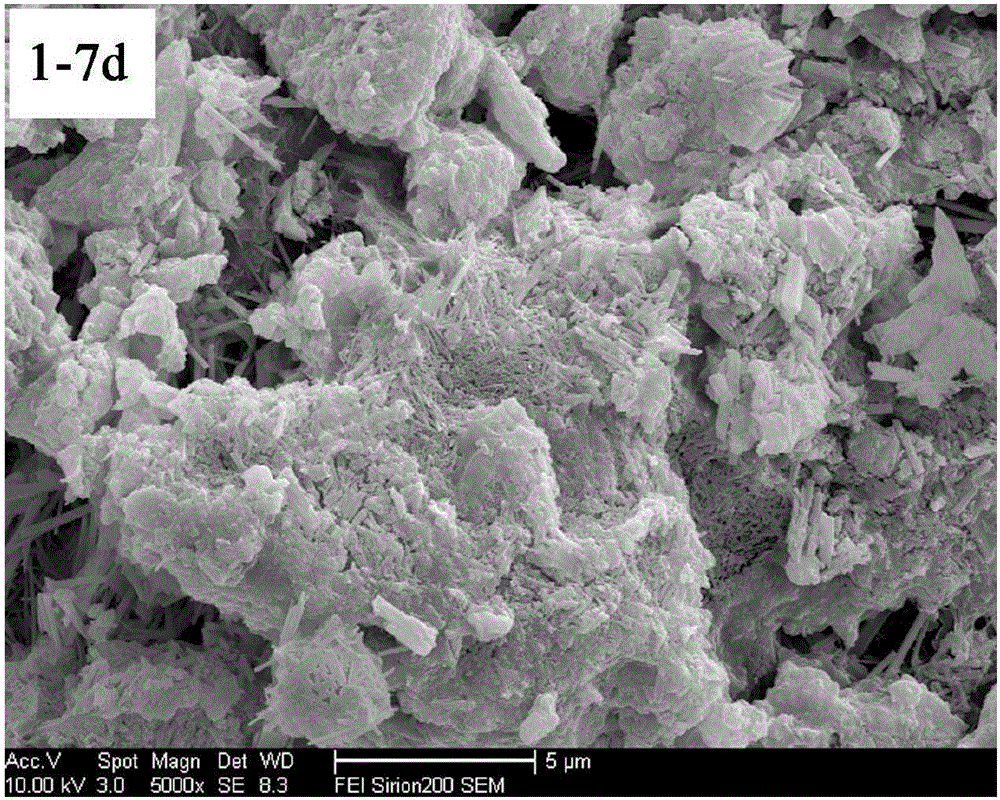

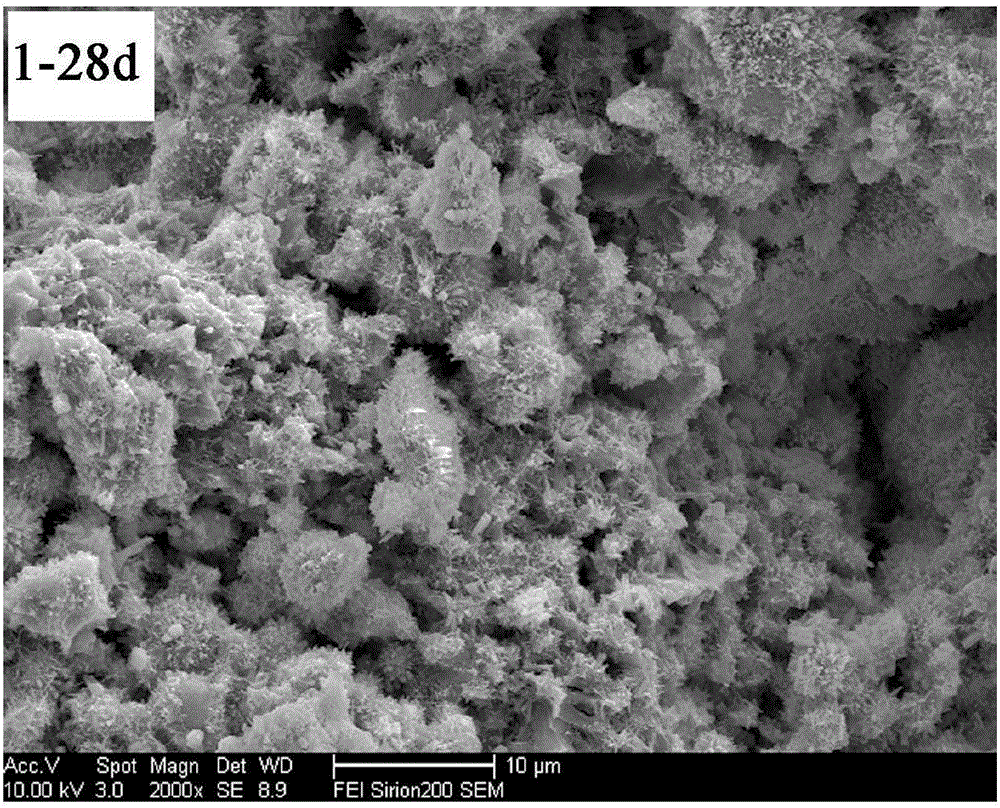

[0080] Inject the prepared fresh filling material into a test mold of 40mm×40mm×160mm for molding, place the formed test block in an environment with a temperature of 20±2°C and a relative humidity of not less than 50%, and demould after 24 hours. Put the demolded test piece in a curing room with a temperature of 20±2°C and a relative humidity of more than 95%. Maintain to the specified age, and test the surface state of 7d and 28d by s...

Embodiment 2

[0083] Carbide slag 10.42%-10.65%, fly ash 62.11%, desulfurization gypsum 6.21%, blast furnace slag 15.96%-16.47%, anhydrous calcium chloride 0.62%-0.75%, anhydrous sodium sulfate 0.56%, sodium silicate 0.37%-0.48%, sodium hydroxide 1.66%-1.95%, water reducer polycyclic aromatic sulfonate formaldehyde condensate or naphthalene series high-efficiency water reducer 0.31%, mix uniformly to obtain mine filling gelling material. Mix the above-mentioned mineral filling cementitious material with water and sand in a mass ratio of 1:2.0-2.4:3.8-4.1 to make a filling material.

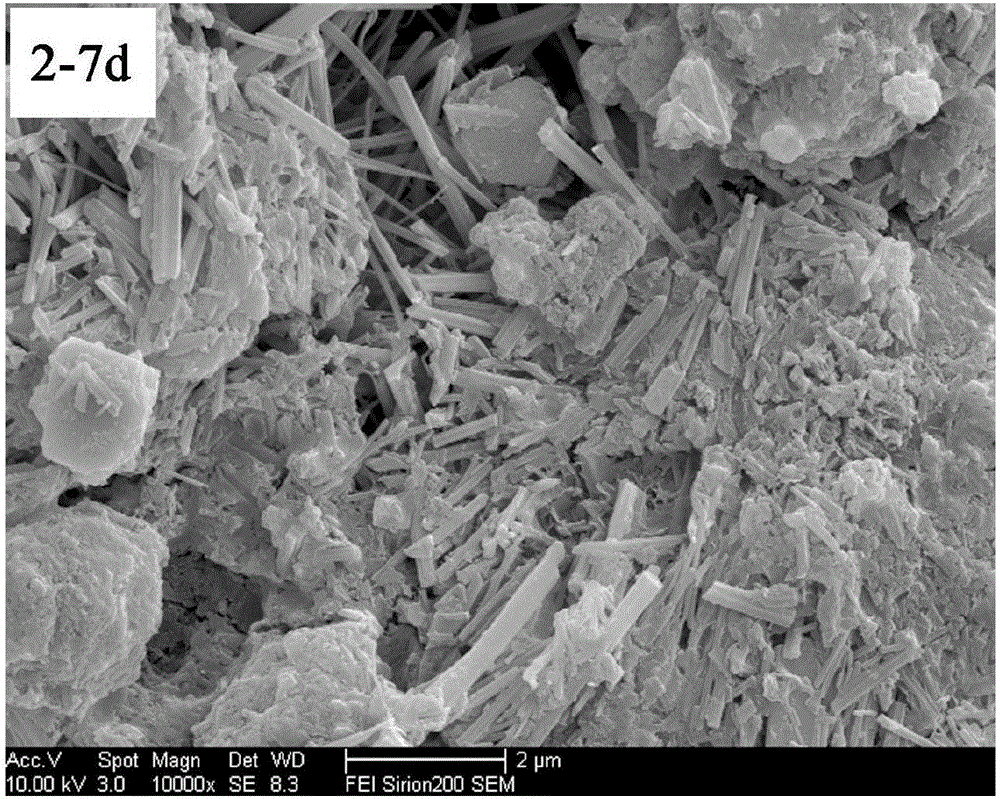

[0084] Inject the prepared fresh filling material into a test mold of 40mm×40mm×160mm for molding, place the formed test block in an environment with a temperature of 20±2°C and a relative humidity of not less than 50%, and demould after 24 hours. Put the demolded test piece in a curing room with a temperature of 20±2°C and a relative humidity of more than 95%. Maintain to the specified age, and test the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com