Alkali-activated cement utilizing abandoned clay brick powder and preparation method thereof

A technology for alkali-activated cement and waste clay bricks, applied in the field of cement preparation, can solve the problems of high carbon emission and high energy consumption, and achieve the effects of reducing the burden on the environment, reducing huge pressure, and achieving good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

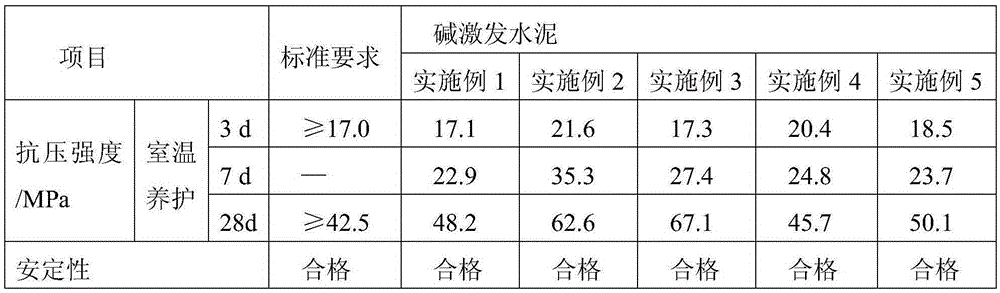

Embodiment 1

[0033] The percentage of used raw material is as follows: waste brick powder: dosage 20%; High-calcium fly ash: dosage 80%; (the sum of waste brick powder and high-calcium fly ash quality is 100%)

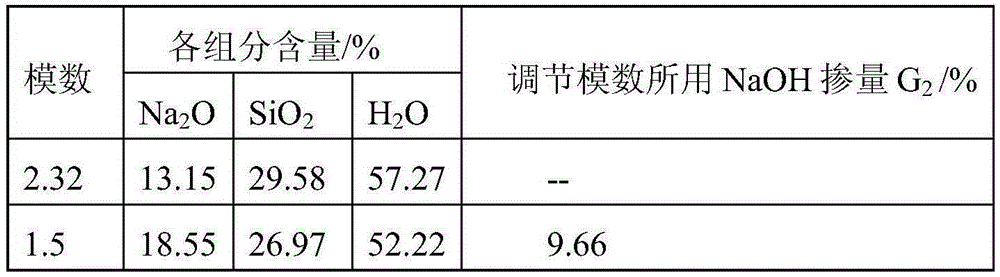

[0034] Compound chemical admixture modulus: 1.5; compound chemical admixture dosage (external mixing): 10%;

[0035] Water-solid ratio: 0.30;

[0036] Mix waste clay brick powder with a mass percentage of 20% and high-calcium fly ash with a mass percentage of 80%, and add a composite chemical admixture accounting for 10% of the mass of waste clay brick powder and high-calcium fly ash; the system water The solid ratio is 0.30, and the water includes two parts: the water contained in the sodium water glass solution and the added water, that is, the water-solid ratio of the control system is 0.30, except for the water contained in the sodium water glass solution. Complementing; mixing, molding, demoulding, wet curing to the age determination, and testing the performance of the alkali...

Embodiment 2

[0039] The percentage of used raw material is as follows: waste brick powder: dosage 30%; High-calcium fly ash: dosage 70%; (the sum of waste brick powder and high-calcium fly ash quality is 100%)

[0040]Compound chemical admixture modulus: 1.5; compound chemical admixture dosage (external mixing): 10%;

[0041] Water-solid ratio: 0.28;

[0042] Mix waste clay brick powder with a mass percentage of 30% and high-calcium fly ash with a mass percentage of 70%, and add a composite chemical admixture accounting for 10% of the mass of waste clay brick powder and high-calcium fly ash; system water The solid ratio is 0.28, and the water in it consists of two parts: the water contained in the sodium water glass solution and the added water. Complementing; mixing, molding, demoulding, wet curing to the age determination, and testing the performance of the alkali-activated cement.

[0043] Wherein: the composite chemical admixture is made by mixing sodium water glass and sodium hydrox...

Embodiment 3

[0045] The percentage of used raw material is as follows: waste brick powder: dosage 30%; High-calcium fly ash: dosage 70%; (the sum of waste brick powder and high-calcium fly ash quality is 100%)

[0046] Compound chemical admixture modulus: 1.5; compound chemical admixture dosage (external mixing): 10%;

[0047] Water-solid ratio: 0.30.

[0048] Mix waste clay brick powder with a mass percentage of 30% and high-calcium fly ash with a mass percentage of 70%, and add a composite chemical admixture accounting for 10% of the mass of waste clay brick powder and high-calcium fly ash; system water The solid ratio is 0.30, and the water includes two parts: the water contained in the sodium water glass solution and the added water, that is, the water-solid ratio of the control system is 0.30, except for the water contained in the sodium water glass solution. Complementing; mixing, molding, demoulding, wet curing to the age determination, and testing the performance of the alkali-act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com