Gypsum base hydraulicity building mortar and preparation method thereof

A water-based, hard technology, applied in the field of gypsum-based hydraulic building mortar for construction and its preparation, can solve the problems of pollution, occupation of large land environment, etc., and achieve the effects of reducing cost, normal setting time and high water retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the percentage by weight of each raw material of the mixed material: quartz sand (medium sand, passing through a 5mm sieve) 79.99%, phosphogypsum powder (specific surface area 532m 2 / kg) 9.00%, slag powder (specific surface area 424m 2 / kg) 7.20%, limestone powder (specific surface area 884m 2 / kg) 3.00%, Portland cement clinker (specific surface area 379m 2 / kg) 0.80%, methyl cellulose ether 0.01%; mix quartz sand, phosphogypsum powder, slag powder, limestone powder, Portland cement clinker powder and methyl cellulose ether to make a mixture; then press The weight ratio of the mixed material to water is 1:0.50, add water and stir evenly to obtain gypsum-based hydraulic construction mortar.

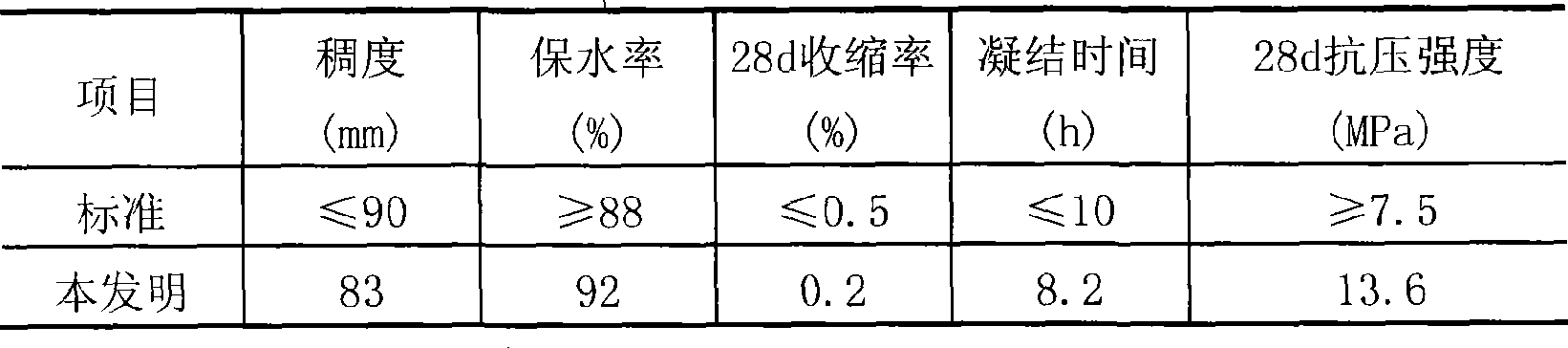

[0033] Then test according to JGJ70-1990 "Basic Performance Test Method of Building Mortar", the results are shown in Table 1, it can be seen that all technical indicators are in line with DMM7.5 dry-mixed masonry mortar in DGJ32 / J13-2005 Ready-mixed Mortar Technica...

Embodiment 2

[0037] According to the percentage by weight of each raw material of the mixed material: quartz sand (medium sand, through 2.5mm sieve) 76.68%, phosphogypsum powder (specific surface area 532m 2 / kg) 10.47%, slag powder (specific surface area 424m 2 / kg) 8.37%, limestone powder (specific surface area 884m 2 / kg) 3.49%, Portland cement clinker (specific surface area 379m 2 / kg) 0.93%, calcium lignoxanthate 0.05%, methyl cellulose ether 0.01%; quartz sand, phosphogypsum powder, slag powder, limestone powder, Portland cement clinker, calcium lignoxanthate and formazan The base cellulose ether is stirred evenly to make a mixed material; then the weight ratio of the mixed material to water is 1:0.50, the mixed material and water are selected, and the mixed material is added with water and stirred evenly to obtain a gypsum-based hydraulic construction mortar.

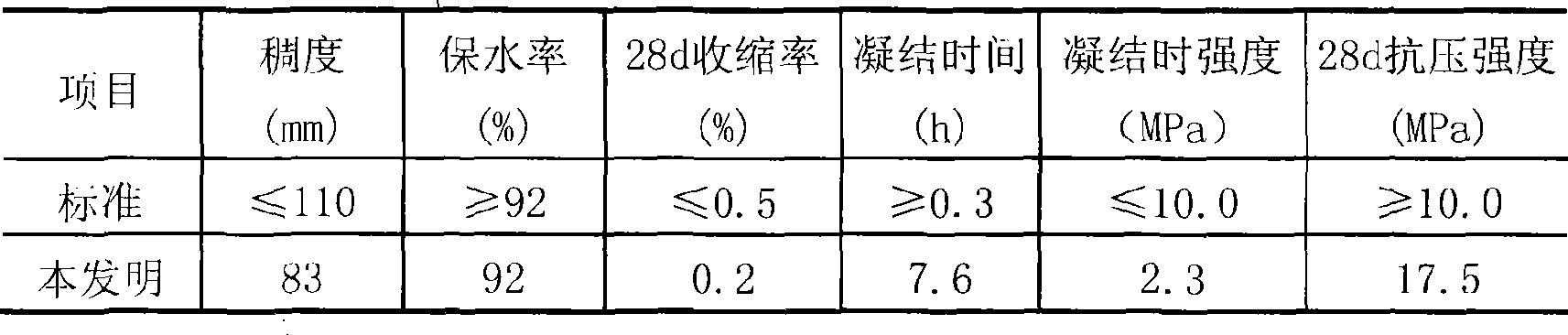

[0038] Then according to JGJ70-1990 "Basic Performance Test Method of Building Mortar" and JGJ / T136-2001 "Technical Regula...

Embodiment 3

[0042] According to the percentage by weight of each raw material of the mixed material: quartz sand (medium sand, passing through a 5mm sieve) 66.60%, phosphogypsum powder (specific surface area 532m 2 / kg) 15.00%, slag powder (specific surface area 424m 2 / kg) 12.00%, limestone powder (specific surface area 884m 2 / kg) 5.00%, Portland cement clinker (specific surface area 379m 2 / kg) 1.33%, calcium lignoxanthate 0.05%, methyl cellulose ether 0.02%; quartz sand, phosphogypsum powder, slag powder, limestone powder, Portland cement clinker, calcium lignoxanthate and formazan The base cellulose ether is stirred evenly to make a mixed material; then the weight ratio of the mixed material to water is 1:0.50, the mixed material and water are selected, and the mixed material is added with water and stirred evenly to obtain a gypsum-based hydraulic construction mortar.

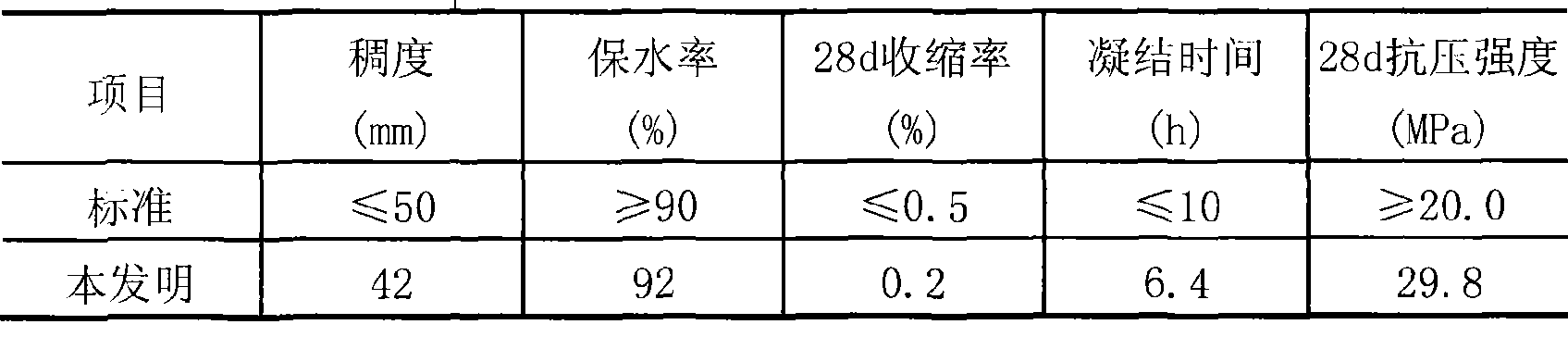

[0043] Then test according to JGJ70-1990 "Basic Performance Test Method of Building Mortar", the results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com