Cation-nonionic mixed aqueous polyurethane emulsion and preparation method thereof

A water-based polyurethane, non-ionic hydrophilic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsatisfactory mechanical properties and processing properties of adhesive films, affecting popularization and application, increasing costs, etc., and achieving excellent chemical resistance. The effect of medicinal properties, favorable for promotion and application, and price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

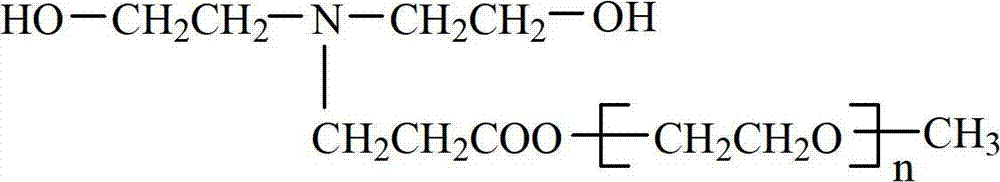

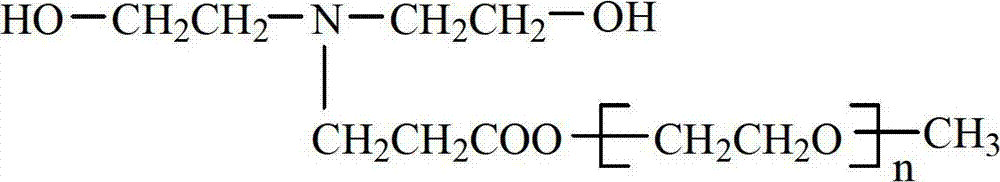

[0031]Example 1 Preparation of nonionic hydrophilic chain extender 3-(N,N-dihydroxyethyl) amino-propionic acid polyethylene glycol monomethyl ether ester

[0032] Add 438 grams (equivalent to 1 mole) of methoxypolyethylene glycol monoacrylate (chemical formula CH 2 =CH-COO(CH 2 CH 2 O) n CH 3 , where n=8, the hydroxyl value is 250~260mgKOH / g, the molecular weight is 438) and 200 grams of solvent acetone, heated to 55~60°C and began to add 105.1 grams (equivalent to 1 mole) of diethanolamine dropwise, and the dropwise was completed within 3 hours , and then heated to 80°C for 8 hours, and after reflux for 8 hours, the solvent acetone was distilled off under reduced pressure to obtain the non-ionic hydrophilic chain extender 3-(N,N-dihydroxyethyl)aminopropionic acid polyethylene glycol monomethyl ether Ester, its hydroxyl value is 200~210mgKOH / g, save it for future use.

Embodiment 2

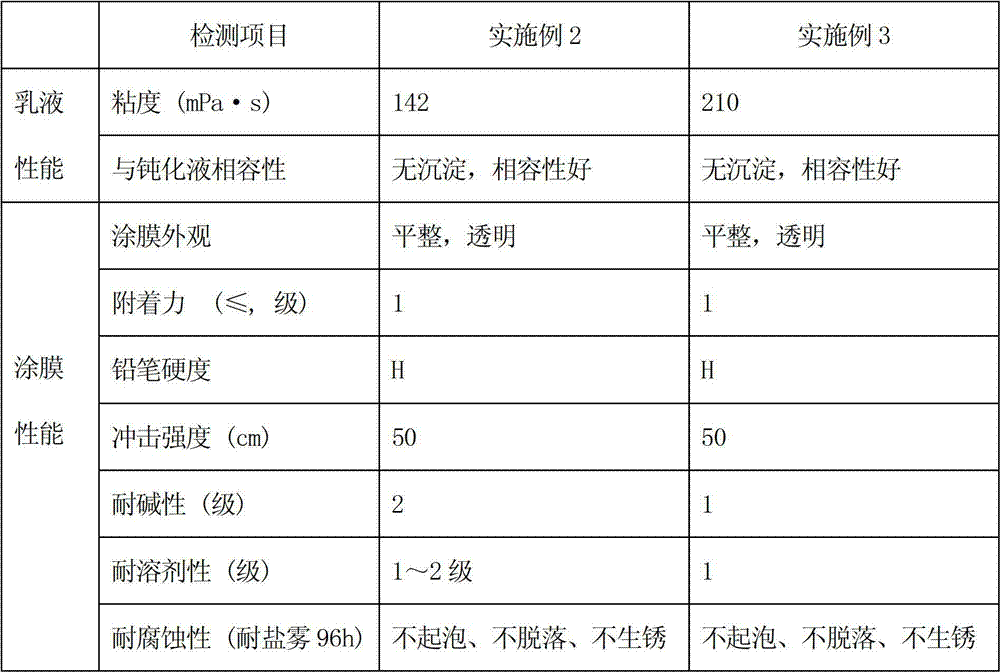

[0033] Embodiment 2 prepares cationic-nonionic mixed type water-based polyurethane emulsion

[0034] The specific operation is as follows:

[0035] ①Preparation of raw materials for the synthesis of cationic-nonionic hybrid water-based polyurethane emulsion

[0036] The amount of each raw material and its percentage in the total weight of raw materials used are as follows:

[0037] The isocyanate is 100 grams of isophorone diisocyanate, accounting for 12.98%,

[0038] Ordinary macromolecular polyols are polyoxypropylene diols, with a number average molecular weight of 2000, a hydroxyl value of 51-61 mgKOH / g, 75 grams, accounting for 9.73%;

[0039] Nonionic hydrophilic chain extender (embodiment 1 system) 25 grams, accounts for 3.24%;

[0040] The ordinary small molecule chain extender is 7.5 grams of ethylene glycol, accounting for 0.97%;

[0041] The crosslinking agent is 5 grams of trimethylolpropane, accounting for 0.65%;

[0042] The cationic hydrophilic chain extend...

Embodiment 3

[0051] The specific operation is as follows:

[0052] ①Preparation of raw materials for the synthesis of cationic-nonionic hybrid water-based polyurethane emulsion

[0053] Basically the same as embodiment 2, the difference is:

[0054] The isocyanate is 78 grams of 2,4-toluene diisocyanate, accounting for 11.04%

[0055] Ordinary macromolecular polyols are polytetrahydrofuran ether polyols, with a number-average molecular weight of 2000, a hydroxyl value of 51-61 mgKOH / g, 75 grams, accounting for 10.61%;

[0056] Nonionic hydrophilic chain extender (embodiment 1 system) 25 grams, accounts for 3.54%;

[0057] Common small molecule chain extender is 6 grams of ethylene glycol, accounting for 0.85%

[0058] The crosslinking agent is 6.8 grams of trimethylolpropane, accounting for 0.96%;

[0059] The cationic hydrophilic chain extender is 15 grams of N-methyldiethanolamine, accounting for 2.12%;

[0060] The catalyst is 0.07 grams of dibutyltin dilaurate, accounting for 0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com