Novel telescopic pipeline cleaning robot

A technology of telescopic pipes and robots, which is applied in the field of machinery, can solve problems such as high labor intensity, paralyzed traffic, and complicated operations, and achieve the effects of reducing labor intensity, improving the working environment, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

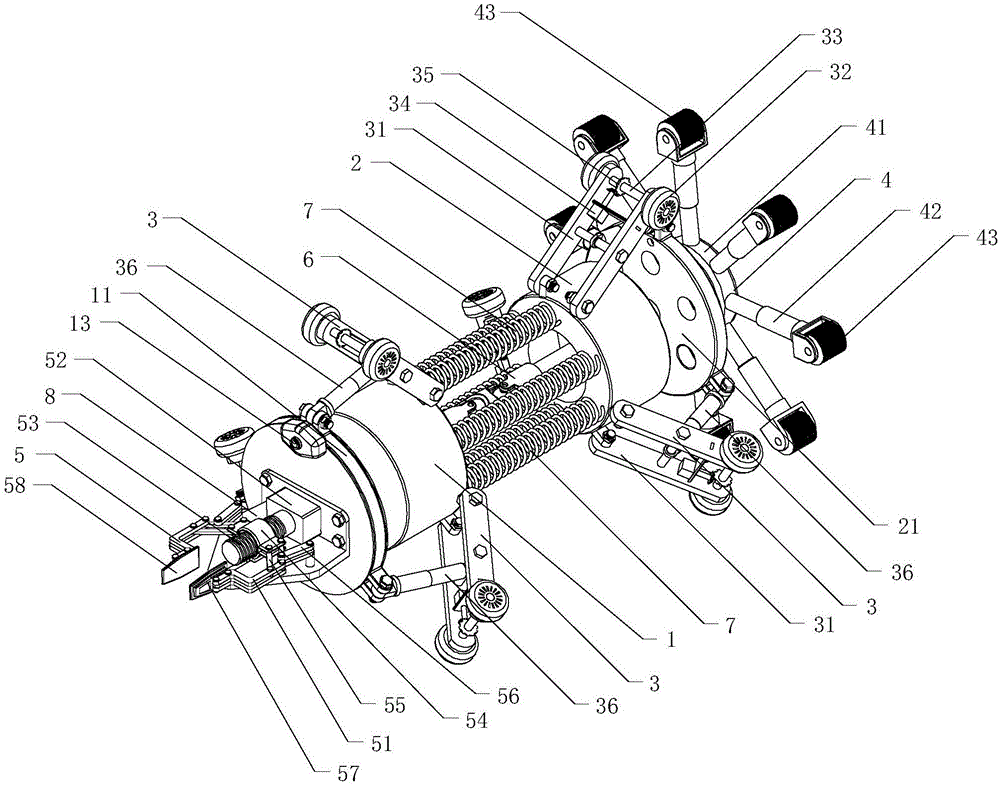

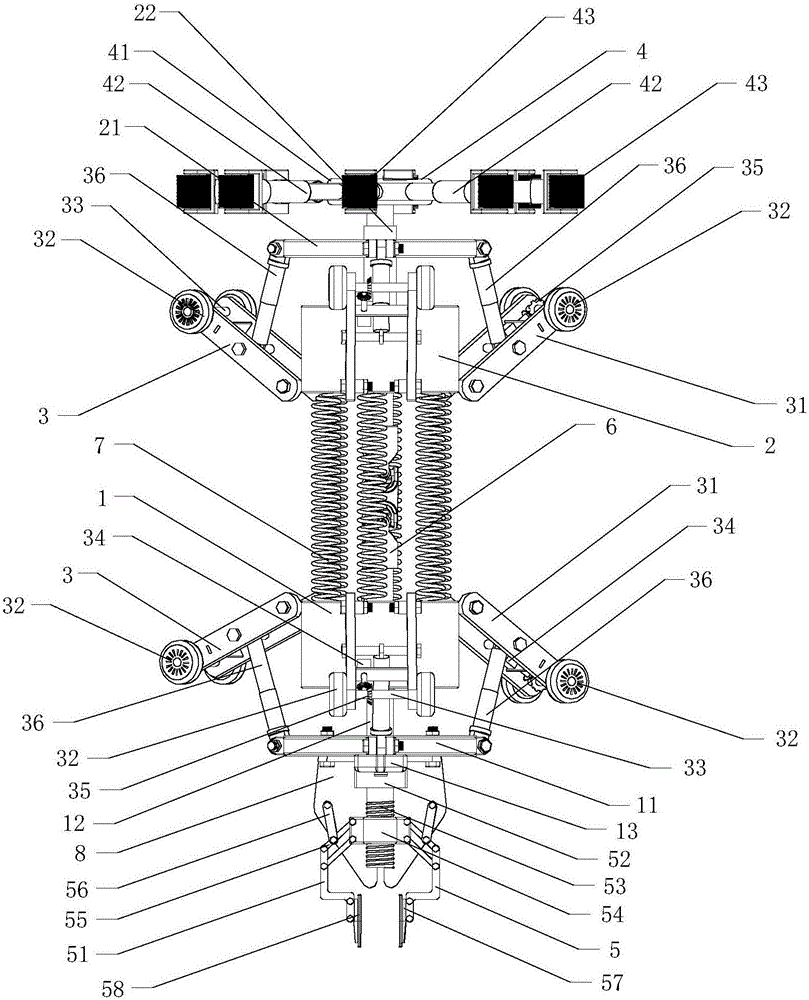

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] combine figure 1 and figure 2 , a new type of telescopic pipe cleaning robot, including a first body 1, a second body 2, a traveling mechanism 3, a cleaning device 4 and a manipulator 5, the first body 1 and the second body 2 are cylindrical structures, and The two are arranged in a front-to-back and positively opposite manner. The first body 1 and the second body 2 are connected together by a double-joint universal joint 6 , and the double-joint universal joint 6 The front end is fixedly connected with the rear part of the first body 1, and its rear end is fixedly connected with the front part of the second body 2. The double-joint universal joint 6 can make the first body 1 and the second body 2 realize larger Angular range of steering. Six springs 7 are arranged between the first body 1 and the second body 2. In the state of natural elongation, all the springs 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com