Method for producing synthetic leather by using solvent-free double-component polyurethane scraping and coating method

A two-component polyurethane and synthetic leather technology, which is applied in textiles and papermaking, can solve the problems of high cost, complex technology, and high equipment requirements, and achieve the effects of reduced energy consumption, wide application range, and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

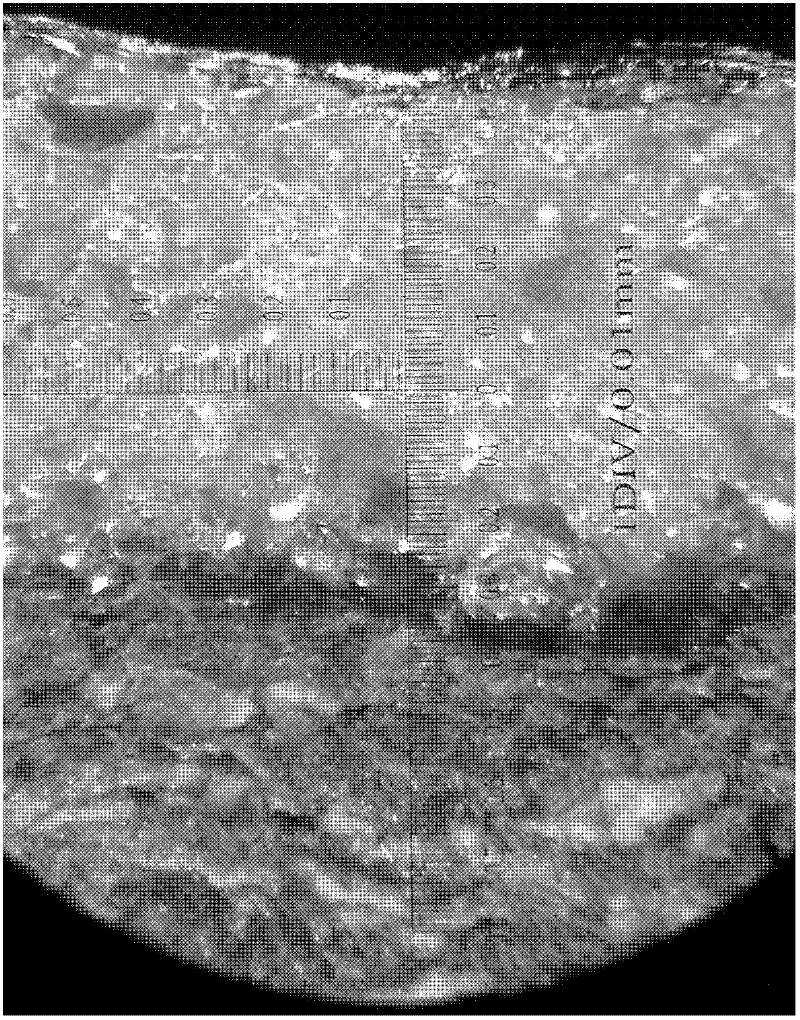

[0046] (1) Scratch-coat the fabric on the release paper, the coating amount is 120 g / square meter, first dry at 80°C for 60 seconds, and then dry at 110°C for 120 seconds to obtain the fabric layer; the fabric is made of 100 parts by weight of oily polyurethane HU-8550D (purchased from Shanghai Xinyu Resin Co., Ltd.), 30 parts by weight of butanone, 40 parts by weight of ethyl acetate and 5 parts by weight of pigment are mixed;

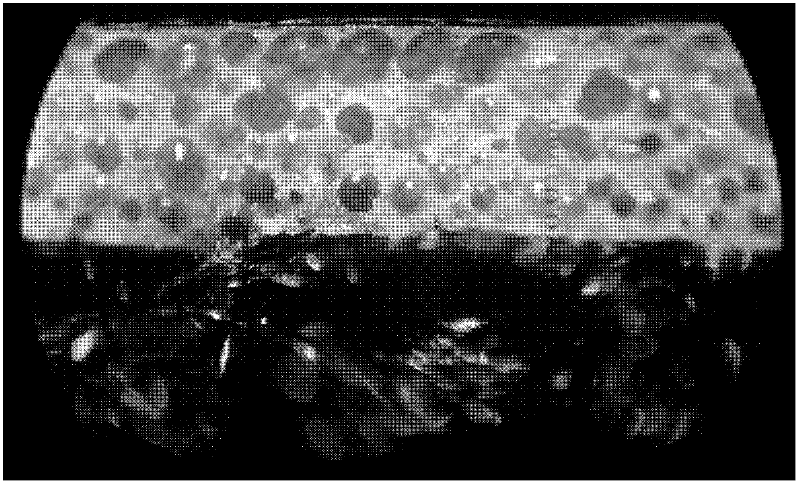

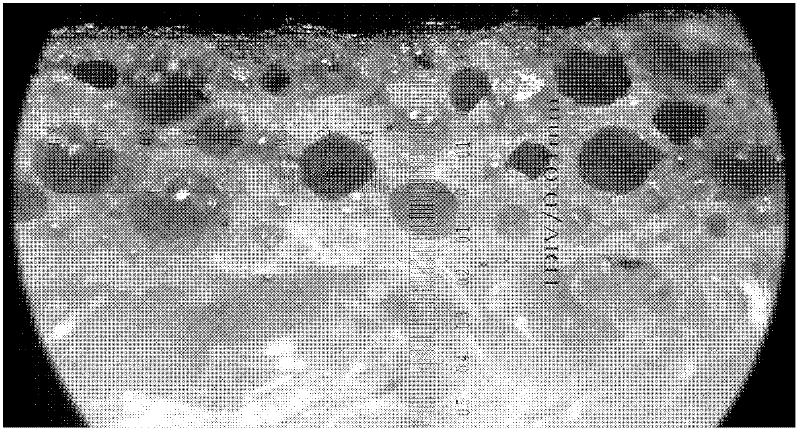

[0047] (2) Control the flow rate of the feeding machine so that the material M and SF-93N (purchased from Foshan Feiling Leather Chemical Co., Ltd.) are mixed in the mixing chamber of the feeding machine at a weight ratio of 161.1:28, poured and scraped onto the fabric layer and then dried at 90°C for 60 seconds to obtain a foamed material layer; the coating amount of the foamed material layer is 266 g / m2; the M material consists of the following components in parts by weight : SF-93H (purchased from Foshan Feiling Leather Chemical Co., Ltd.) 90 parts...

Embodiment 2

[0053] (1) Scratch-coat the fabric on the release paper, the coating amount is 130 g / square meter, first dry at 100°C for 60 seconds, and then dry at 130°C for 150 seconds to obtain the fabric layer; the fabric is made of 100 parts by weight of oily polyurethane DU-S1050 (purchased from Guangdong Daying Chemical Co., Ltd.), 30 parts by weight of water, 0.5 parts by weight of water-based thickener HEUR-A (produced by Hefei Anke Fine Chemical Co., Ltd.) and 15 parts by weight a mixture of pigments;

[0054] (2) Control the flow rate of the feeding machine so that the material M and SF-93N (purchased from Foshan Feiling Leather Chemical Co., Ltd.) are mixed in the mixing chamber of the feeding machine at a weight ratio of 161.1:28, poured and scraped onto the fabric layer and then dried at 70°C for 60 seconds to obtain a foamed material layer; the coating amount of the foamed material layer is 400 g / m2; the M material is composed of the following components in parts by weight : ...

Embodiment 3

[0060] (1) Scratch-coat the fabric on the release paper, the coating amount is 150 g / square meter, first dry at 80°C for 60 seconds, and then dry at 130°C for 120 seconds to obtain the fabric layer; the fabric is made of 100 parts by weight of oily polyurethane HU-8550D (purchased from Shanghai Xinyu Resin Co., Ltd.), 30 parts by weight of butanone, 40 parts by weight of ethyl acetate and 5 parts by weight of pigment are mixed;

[0061] (2) Control the flow rate of the feeding machine so that the material M and SF-97N (purchased from Foshan Feiling Leather Chemical Co., Ltd.) are mixed in the mixing chamber of the feeding machine at a weight ratio of 101.2:28, poured and scraped onto the fabric layer and then dried at 110°C for 60 seconds to obtain a foam material layer; the layer coating amount of the foam material is 374 g / m2; the M material is composed of the following components in parts by weight : SF-97H (purchased from Foshan Feiling Leather Chemical Co., Ltd.) 90 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com