Method for preparing organosilicon modified acrylic resin

A technology of acrylic resin and silicone, which is applied in the field of preparation of acrylic resin, can solve the problems of low surface of silicone polymer, poor compatibility of acrylic resin, increase of surface roughness of paint film, etc., and achieve excellent aging resistance and excellent mechanical properties Performance, compatibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

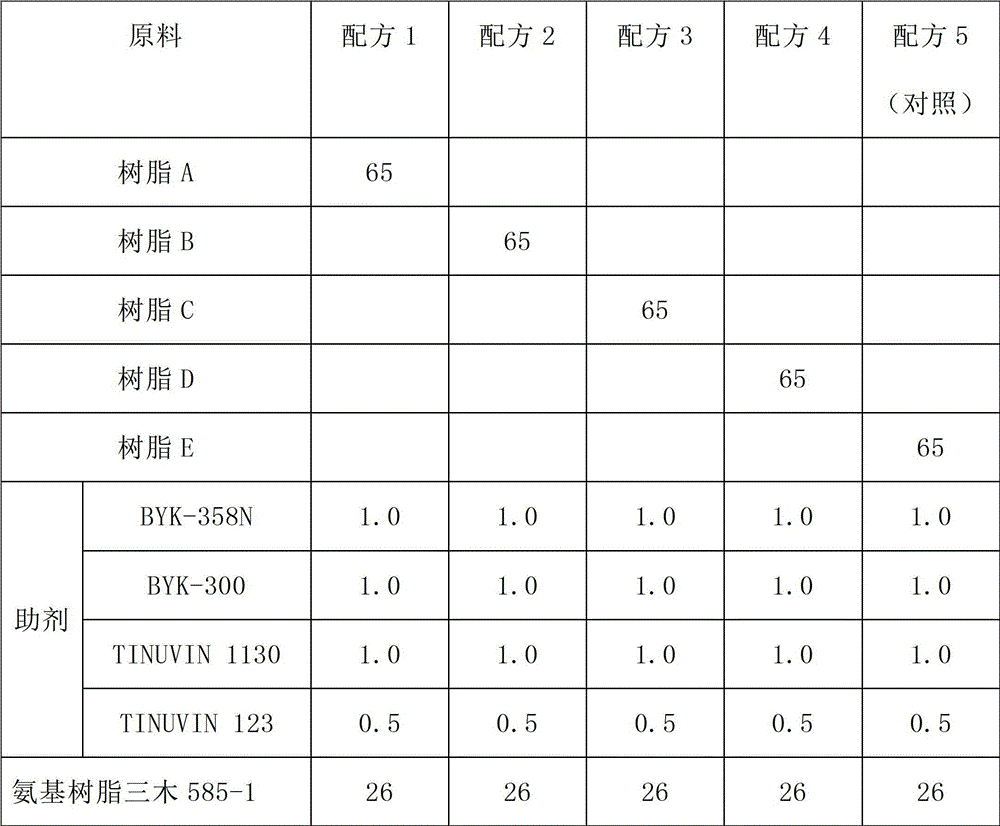

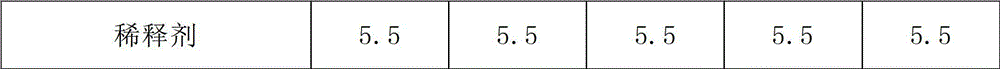

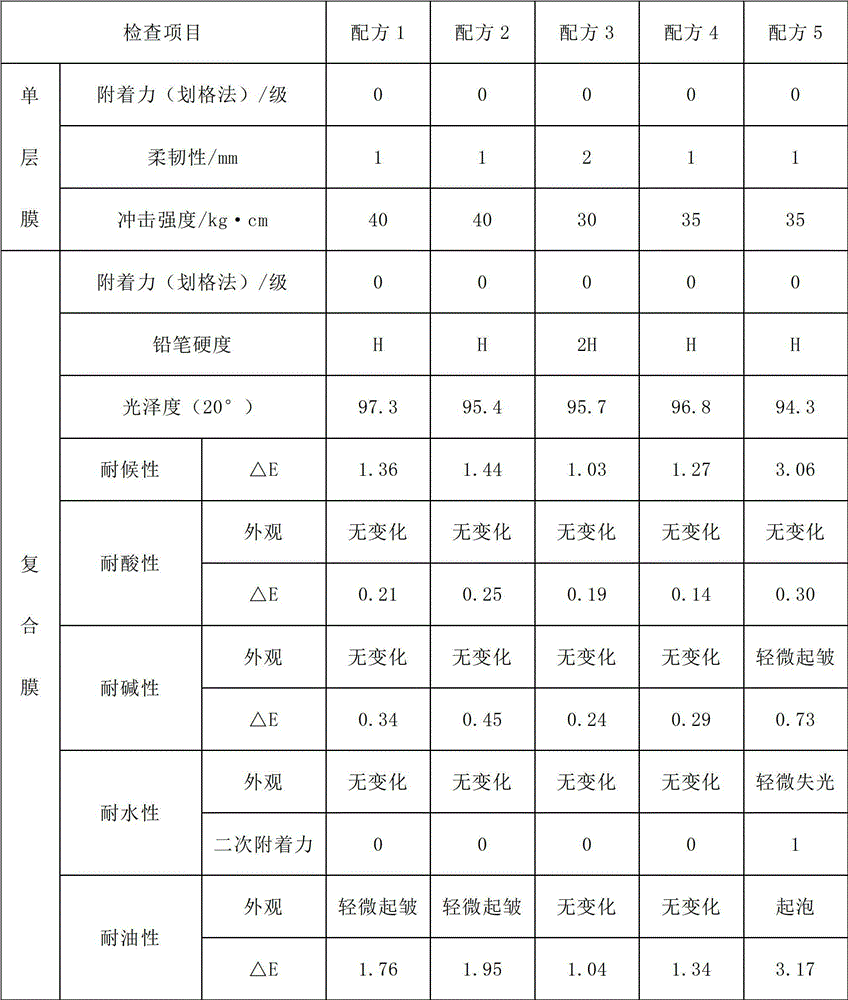

Examples

Embodiment 1

[0021] Put 10 parts of xylene and 70 parts of trimethylbenzene mixture in a four-necked flask equipped with a stirrer and a condenser, stir and raise the temperature to 140°C, then slowly add 80 parts of styrene and 20 parts of butyl acrylate dropwise , 30 parts of hydroxyethyl methacrylate, 10 parts of γ-methacryloxypropyl trimethoxysilane and 10 parts of benzoyl tert-butyl peroxide, and control the dropping time for about 3 hours, and then keep warm 2 hours. Then lower the temperature to 100°C, add 0.5 parts of dibutyltin dilaurate, and drop 50 parts of hydroxyl-terminated silicone oil within 0.5 hours, then keep it warm for 6 hours, cool down and discharge, and obtain silicone-modified acrylic resin A.

Embodiment 2

[0023] Put 40 parts of ethyl acetate and 40 parts of butyl acetate mixture into a four-necked flask equipped with a stirrer and a condenser, stir and raise the temperature to 80°C, then slowly add 30 parts of styrene, 45 parts of formaldehyde methyl acrylate, 20 parts butyl acrylate, 40 parts hydroxyethyl methacrylate, 5 parts tetramethyldivinyl disiloxane and 10 parts dibenzoyl peroxide, and the dropping time is controlled to be 3 hours About, and then keep warm for 4 hours. Then lower the temperature to 60°C, add 0.5 parts of hydrochloric acid, and dropwise add 50 parts of hydroxyl-terminated silicone oil within 0.5 hours, then keep it warm for 4 hours, add ammonia water for neutralization, cool down and discharge to obtain silicone-modified acrylic resin B.

Embodiment 3

[0025] Put 40 parts of xylene, 30 parts of butyl acetate and 10 parts of ethylene glycol monoethyl ether acetate mixture into a four-necked flask equipped with a stirrer and a condenser, stir and raise the temperature to 100°C, and then slowly drop Add 80 parts of styrene, 20 parts of butyl methacrylate, 30 parts of hydroxyethyl methacrylate, 5 parts of methylvinyldiethoxysilane and 10 parts of benzoyl tert-butyl peroxide, and add them dropwise The time is about 3 hours, and then keep warm for 3 hours. Then lower the temperature to 100°C, add 0.5 parts of tetraisopropyl titanate, and drop 50 parts of hydroxyl-terminated silicone resin within 0.5 hours, then keep it warm for 6 hours, cool down and discharge, and obtain silicone-modified acrylic acid Resin C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com