Light diffusion master batch for transparent plastics and preparation method thereof

A light-diffusing masterbatch and transparent plastic technology, applied in the field of functional masterbatch, can solve problems such as difficult operation, volatile, explosive, etc., and achieve the effect of increasing the application range and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

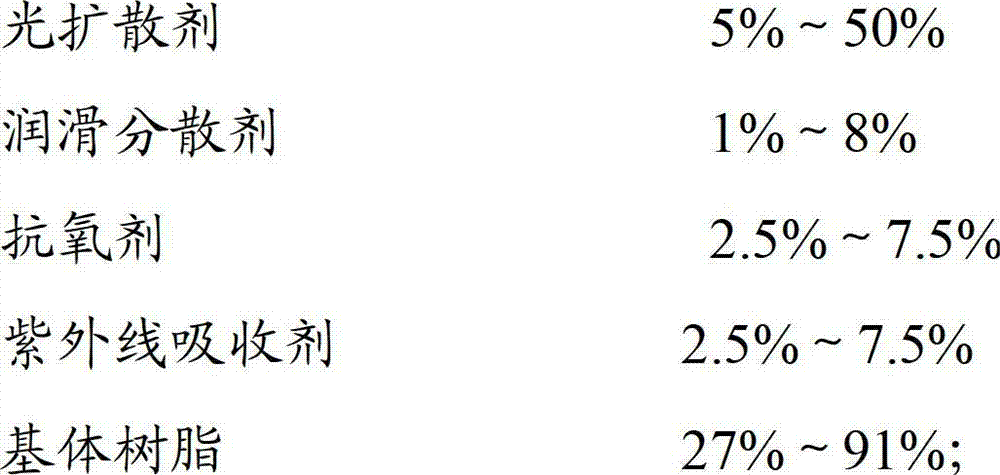

Method used

Image

Examples

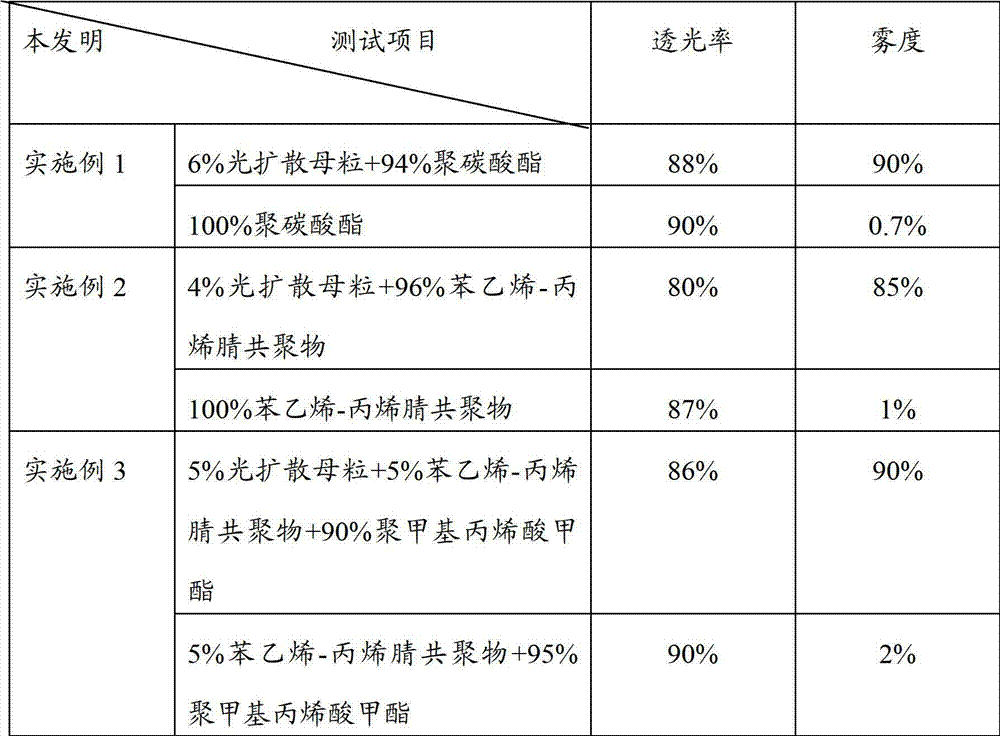

Embodiment 1

[0033] A light-diffusing masterbatch for transparent plastics, comprising the following raw materials calculated by weight percentage: cross-linked polymethyl methacrylate resin beads) 5%, pentaerythritol stearate 1%, (β[3-(3, 5-di-tert-butyl-4-hydroxyphenyl)]propionate 2.5%, 2-(2'-hydroxy-3',5'-bis[1,1-dimethylphenyl])-benzene Triazole 2.5%, polycarbonate 91%.

[0034] The average particle diameter of the organic microbeads is 1 μm; the average particle diameters of each organic microbeads are equal.

[0035] The method for preparing the light-diffusing masterbatch: First, weigh and mix the raw materials according to the above-mentioned ratio, and then put them into a parallel twin-screw extruder for melt extrusion, and the extruded product is cooled, pelletized and dried to obtain the obtained The light diffusion masterbatch.

[0036] A transparent polycarbonate plastic consisting of 6% light diffusing masterbatch and 94% polycarbonate by weight.

Embodiment 2

[0038] A light-diffusing masterbatch for transparent plastics, comprising the following raw materials calculated by weight percentage: 50% of spherical calcium carbonate particles, 8% of montan wax, β-(3,5-di-tert-butyl-4-hydroxybenzene base) stearyl propionate 7.5%, 2-(2-hydroxy-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole 7.5%, styrene-acrylonitrile copolymer 27%.

[0039] Preferably, the average particle diameter of the inorganic microbeads is 10 μm, and the average particle diameters of each inorganic microbead are equal.

[0040] The method for preparing the light-diffusing masterbatch: weigh the raw materials according to the above ratio and mix them uniformly, then put them into a reciprocating single-screw extruder for melt extrusion, and the extrudates are cooled, pelletized, and dried to obtain The light-diffusing masterbatch.

[0041] A transparent styrene-acrylonitrile plastic, composed of 4% light-diffusing masterbatch and 96% styrene-acrylonitrile copolym...

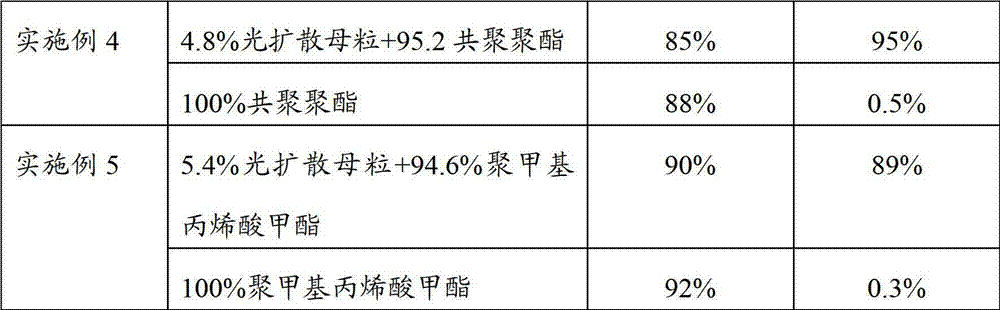

Embodiment 3

[0043] A light-diffusing masterbatch for transparent plastics, including the following raw materials calculated by weight percentage: 10% of light-diffusing agent (including 1% of cross-linked polymethyl methacrylate resin beads, cross-linked polymethyl methacrylate -1% styrene microbeads and 8% cross-linked polystyrene microbeads), 6% lubricating and dispersing agent (including 1% pentaerythritol stearate, 5% erucamide), tris(2,4- Di-tert-butylphenyl)phosphite 6.5%, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole 4.5%, base resin 96% (Among them, styrene-acrylonitrile copolymer 20% and polymethyl methacrylate resin 53%).

[0044] Preferably, the average particle diameter of the cross-linked polymethyl methacrylate resin microbeads and cross-linked polymethyl methacrylate-styrene microbeads is 1-10 μm, and the average particle diameter of each particle is different.

[0045]The method for preparing the light-diffusing masterbatch: weigh the raw materials accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com