Railroad internal combustion engine car oil complexing agent composition and application thereof

A technology for diesel locomotives and oil compositions, which is applied in the direction of lubricating compositions, additives, and the petroleum industry. It can solve the problems of technical lag, failure to solve oil products that are prone to oxidation and failure, and no way to meet the needs of locomotives to increase the working temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

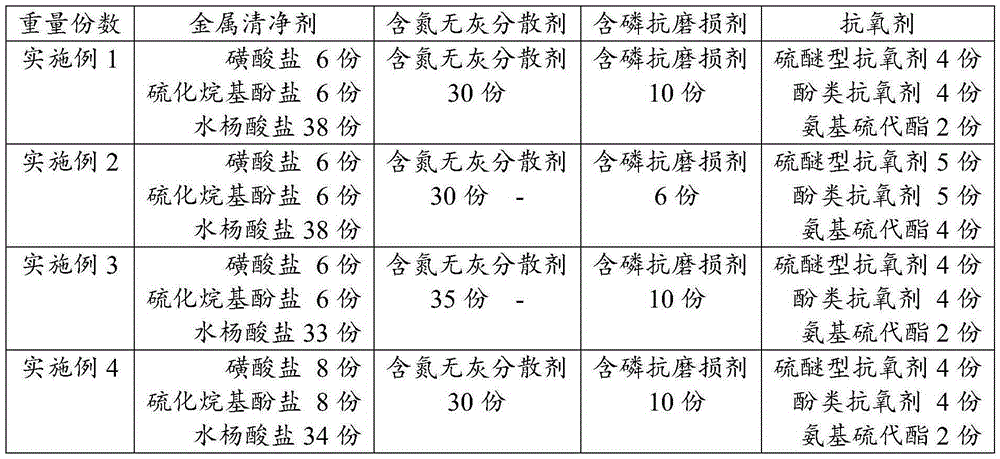

[0027] Add each component according to the parts by weight in Table 1, and mix uniformly to obtain a compound agent composition for railway diesel locomotive oil.

[0028] The composition obtained in [Example 1-4] was added to the base oil at 65°C with the dosage shown in Table 2, wherein the nitrogen-containing ashless dispersant used was T154 double polyisobutylene succinimide, and the phosphorus-containing The anti-wear agent is T203 bis-octyl zinc thiophosphor, stirred for 3 hours, made into a sample, and carried out performance evaluation. The results are shown in Table 2.

[0029] Table 1

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com