Protective Agent for Ozone Oxidation Catalyst Used in Degradation of Organic Wastewater

A technology for ozone oxidation and organic wastewater, applied in catalyst protection, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of rising bed pressure in the tower and lack of catalytic function , tower operation resistance increase and other problems, to achieve the effect of reducing tower operation resistance, reducing pressure drop, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

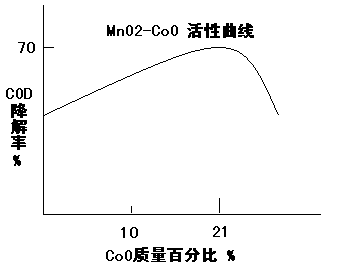

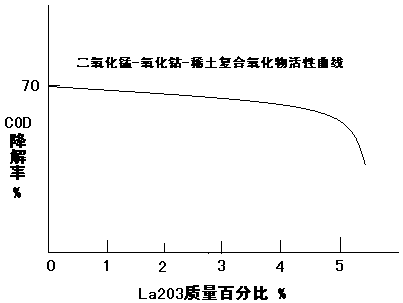

Embodiment 1

[0020] Example 1, the raw material is composed of 6wt% composite active component (manganese dioxide-cobalt oxide-rare earth oxide), 43wt% fly ash, 2wt% activated carbon powder pore-forming agent, 47wt% kaolin, 2wt% methyl cellulose viscose It is composed of a binder, and an ozone oxidation catalyst protective agent for degrading organic wastewater is prepared through processes such as synthesis, kneading, pelletization, drying, sieving, and calcination. The composite active component is synthesized by the following co-precipitation method: prepare a precursor mixed solution with manganese nitrate, cobalt nitrate, lanthanum nitrate, and pure water, use sodium hydroxide solution as a precipitant, adjust the pH value to make the precursor co-precipitate completely, Wash with pure water and filter the coprecipitate to filtrate Na + Until the concentration reaches 40mg / L, the co-precipitate is dried at 110°C to obtain a composite active component. The protective agent meets the pe...

Embodiment 2

[0022] Example 2: The raw material is composed of 7wt% composite active component (manganese dioxide-cobalt oxide-rare earth oxide), 41wt% fly ash, 3wt% activated carbon powder pore-forming agent, 48wt% kaolin, 1wt% methyl cellulose viscose It is composed of a binder, and an ozone oxidation catalyst protective agent for degrading organic wastewater is prepared through processes such as synthesis, kneading, pelletization, drying, sieving, and calcination. The protective agent reaches the following performance indicators in Table 2:

[0023] Protective agent model

Embodiment 3

[0024] Embodiment 3: The raw material is composed of 8wt% composite active component (manganese dioxide-cobalt oxide-rare earth oxide), 40wt% fly ash, 4wt% activated carbon powder pore-forming agent, 45wt% kaolin, 3wt% methyl cellulose viscose It is composed of a binder, and an ozone oxidation catalyst protective agent for degrading organic wastewater is prepared through processes such as synthesis, kneading, pelletization, drying, sieving, and calcination. The protective agent reaches the following performance indicators in Table 3:

[0025] Protective agent model

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com