Formula and treatment method of abrasion-resisting, anti-friction and life-prolonging nano plating layer of mechanical parts

A technology for mechanical parts and nano-coatings, applied in nano-technology, coatings, electrolytic coatings, etc., can solve the problems of increased internal stress, affecting the mechanical properties of the coating, and brittleness of the coating, achieving low internal stress and excellent mechanical properties of the coating. , The effect of coating crystal fine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

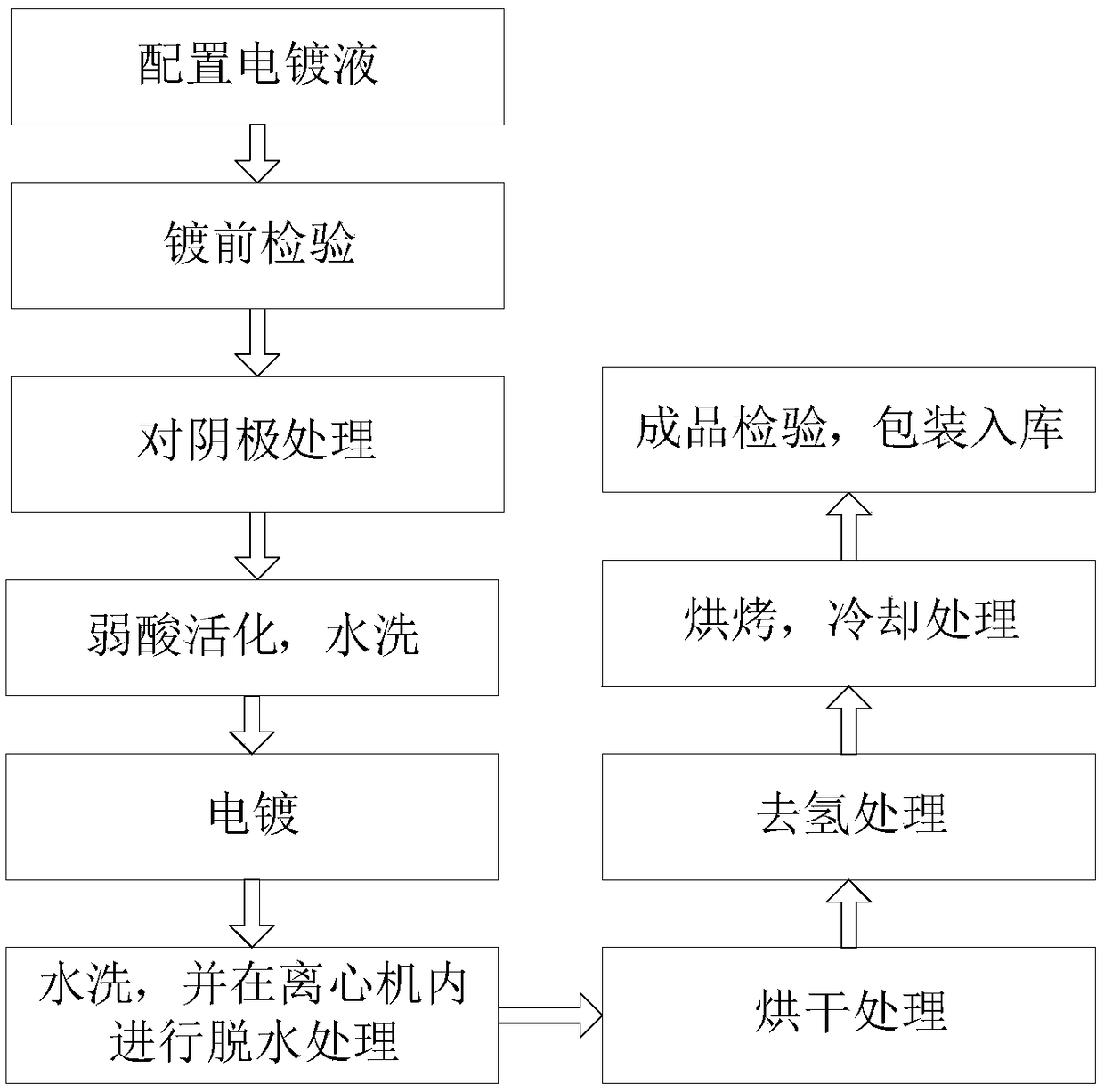

Method used

Image

Examples

no. 1 example

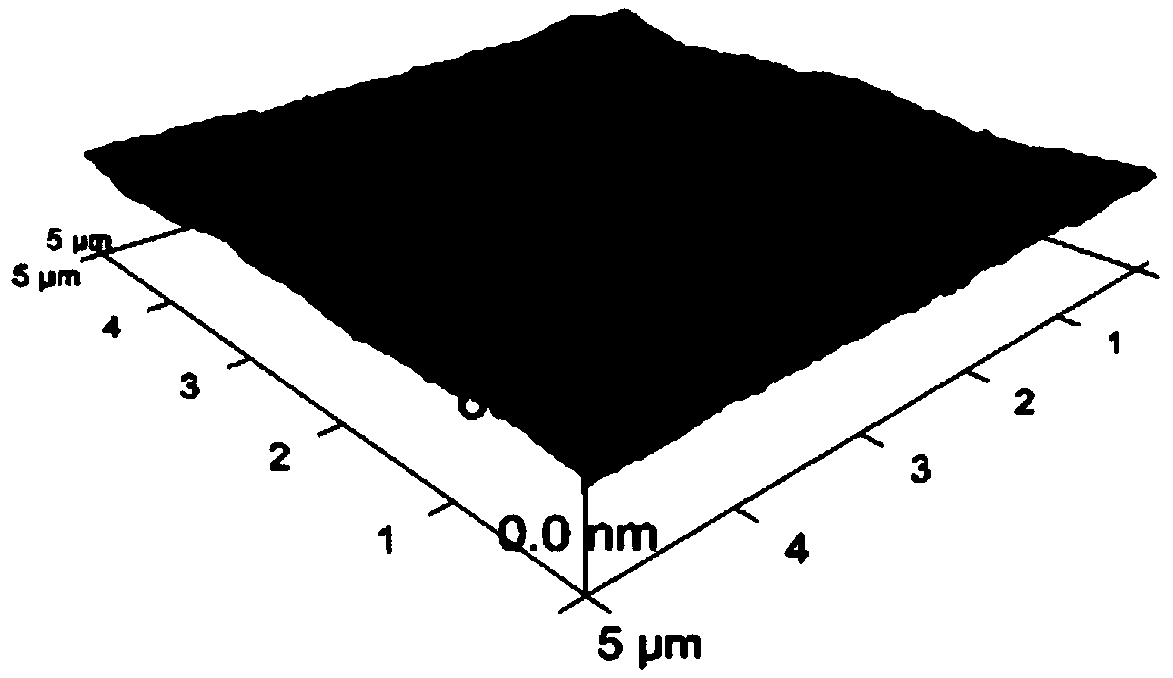

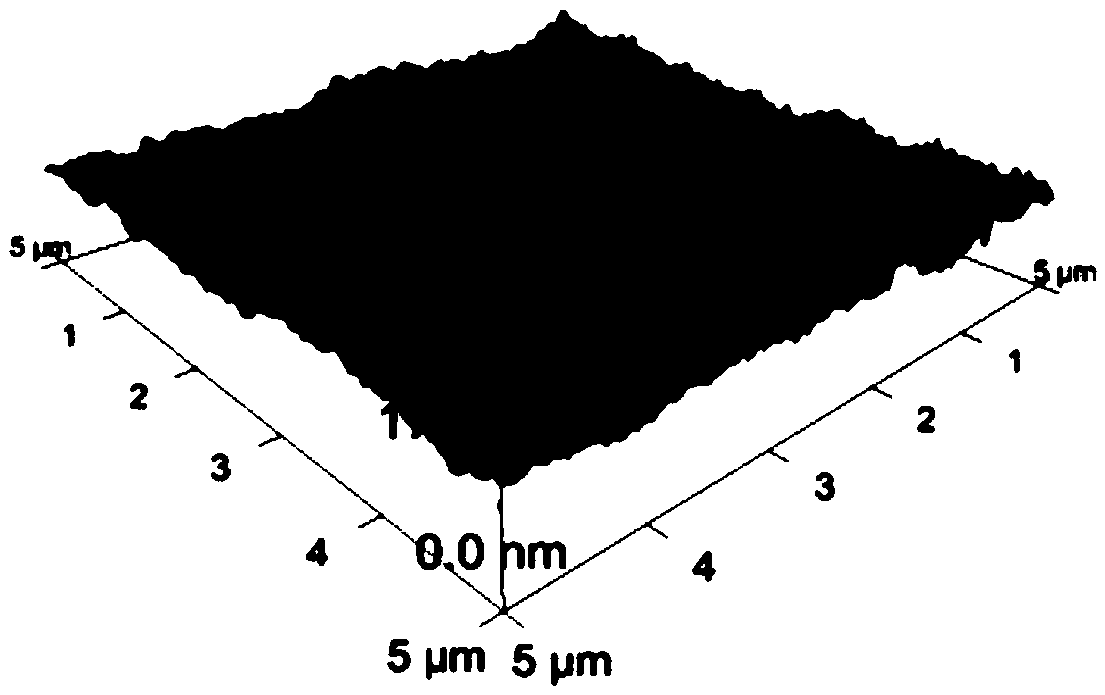

[0043] Moreover, adding 0.5-3g / l of cerium sulfate to the electroplating solution can improve the dispersion ability and deep plating ability of the plating solution, improve the current efficiency of electroplating, and increase the hardness and corrosion resistance of the coating. The addition of cerium sulfate also plays a role in stabilizing the plating solution. Through analysis, it is found that the addition of cerium sulfate increases the cathodic polarization of nickel-cobalt-tungsten sulfide alloy electrodeposition, and makes the grains of the obtained coating more fine, uniform and dense. , thereby improving the corrosion resistance of the coating. According to the test of its actual performance, its bending strength, hardness and impact toughness have been greatly improved, and the porosity has been significantly reduced. After adding cerium sulfate to the plating solution, the bonding strength between the plating layer and the substrate is obviously improved. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com