Preparation method of carbon microsphere/polymethyl methacrylate/polyethyleneimine nanocomposite with double shell-core structure

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of nanomaterials and can solve problems that do not conform to the concept of green development and complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

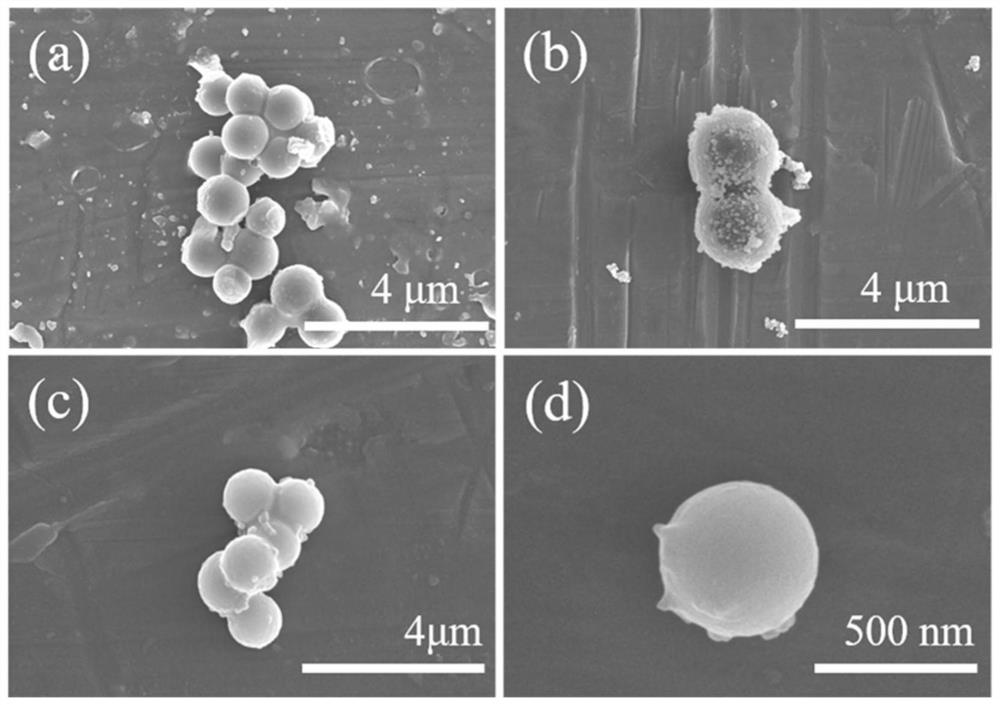

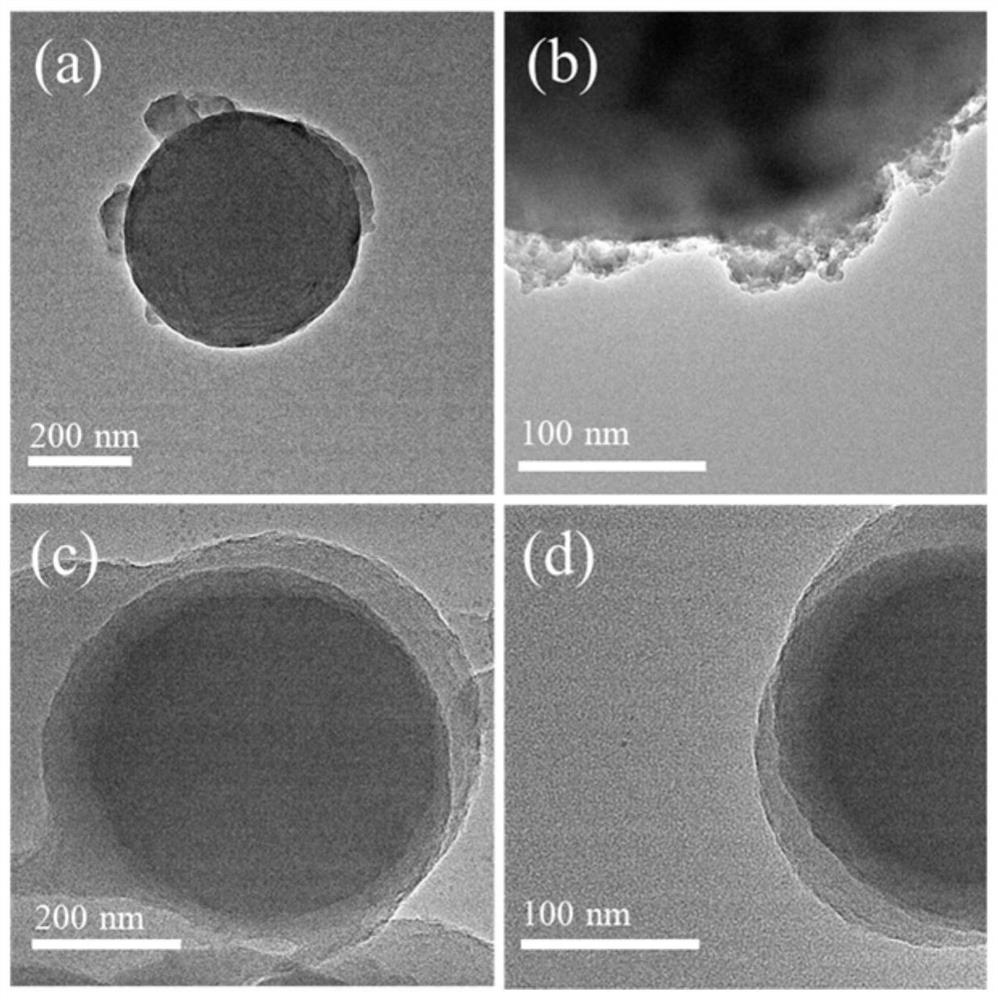

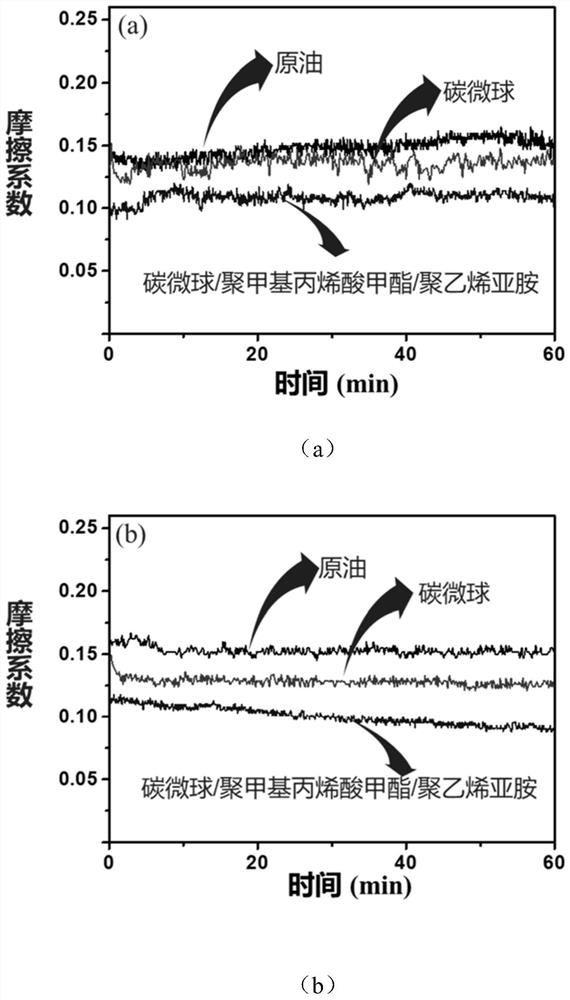

[0031] A kind of preparation method that has double shell-core structure carbon microsphere / polymethyl methacrylate / polyethyleneimine nanocomposite material, comprises the following steps:

[0032] 1) Using glucose solution as the carbon source, through hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, and the time is 12h. After the completion, the product is washed several times, suction filtered, and dried to obtain carbon microspheres. The concentration of the glucose solution is 50mg / mL;

[0033] 2) Dissolve the dry carbon microspheres in a mixed solution of deionized water and absolute ethanol (the volume ratio of deionized water and absolute ethanol is 5:4), and every 90mL of deionized water and absolute ethanol Add 0.2g of carbon microspheres into the solution, and then add the mixed solution of silane coupling agent and absolute ethanol (the silane coupling agent uses KH550, the mixed solution of silane coupling agent and absolute ethanol is...

Embodiment 1

[0040] 1) Prepare a glucose solution with a concentration of 50 mg / mL, conduct hot water thermal reaction at 180°C for 12 hours, wash the product several times, filter it with suction, and dry it in an oven at 80°C for 12 hours to obtain carbon microspheres;

[0041] 2) Dissolve 0.2g of dry carbon microspheres in a mixed solution of 50ml of deionized water and 40ml of absolute ethanol, add 5ml of silane coupling agent and 20ml of absolute ethanol to prepare the mixed solution, and react at 60°C under reflux conditions After 12 hours, the product was washed several times, filtered with suction, and dried in an oven at 80°C for 12 hours to obtain modified carbon microspheres;

[0042] 3) The dried modified carbon microspheres, water and methyl methacrylate were formulated into solution A, wherein the concentration of modified carbon microspheres in solution A was 5 mg / mL, and the amount of methacrylic acid mechanism added was modified 0.25wt% of the mass of carbon microspheres, ...

Embodiment 2

[0046] 1) Prepare a glucose solution with a concentration of 50 mg / mL, conduct hot water thermal reaction at 180°C for 12 hours, wash the product several times, filter it with suction, and dry it in an oven at 80°C for 12 hours to obtain carbon microspheres;

[0047] 2) Dissolve 0.2g of dry carbon microspheres in a mixed solution of 50ml of deionized water and 40ml of absolute ethanol, add 5ml of silane coupling agent and 20ml of absolute ethanol to prepare the mixed solution, and react at 60°C under reflux conditions After 12 hours, the product was washed several times, filtered with suction, and dried in an oven at 80°C for 12 hours to obtain modified carbon microspheres;

[0048] 3) The dried modified carbon microspheres, water and methyl methacrylate were formulated into solution A, wherein the concentration of modified carbon microspheres in solution A was 6 mg / mL, and the amount of methacrylic acid mechanism added was modified 0.25wt% of the mass of carbon microspheres, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com