Polyethylene and polyvinyl formal composite material, preparation method thereof, and bionic rattan chair

A technology of polyvinyl formal and composite materials, applied in chairs, other seating furniture, applications, etc., can solve the problems of short service life of bionic rattan chairs, aging and damage of bionic rattan chairs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

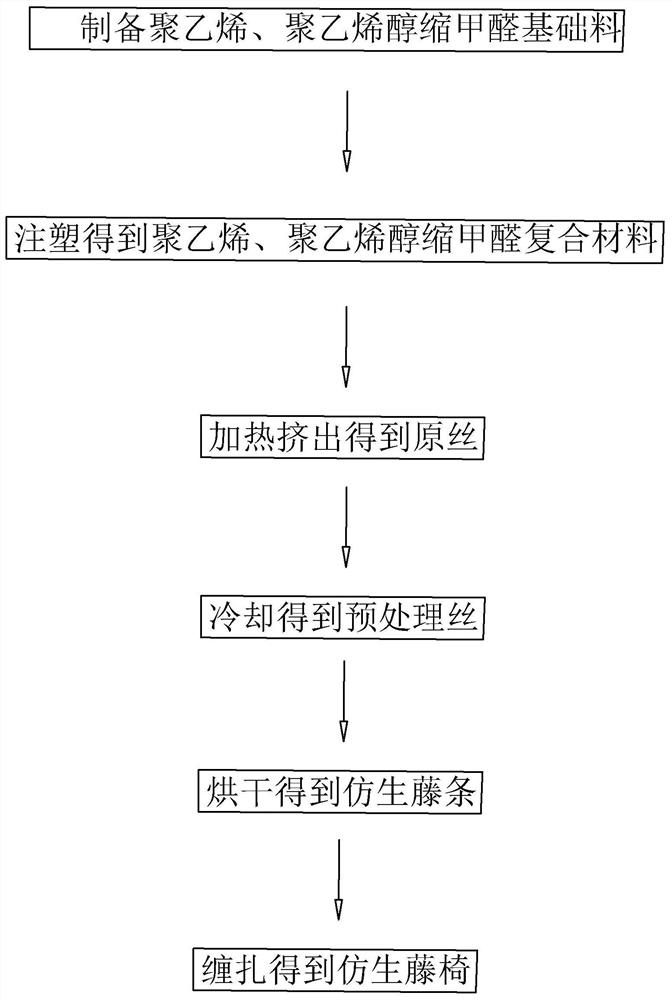

Method used

Image

Examples

preparation example

[0041] In this application, each raw material component is as table 1:

[0042] Table 1 The source of each raw material component

[0043] raw material factory Specification Polyethylene (Low Density) Shanghai McLean Biochemical Technology Co., Ltd. Item No.: P816883-35g Polyvinyl formal Shanghai McLean Biochemical Technology Co., Ltd. Item No.: P865736-5g Maleic anhydride polyethylene Sigma Aldrich Trading Ltd Item No.: 456624-250g talcum powder Shanghai McLean Biochemical Technology Co., Ltd. Item No.: T819386-1kg carbon black Shanghai McLean Biochemical Technology Co., Ltd. Item No.: C806276-80g Titanium dioxide Shanghai Yuanye Biotechnology Co., Ltd. Item No.: S28322-100g Bagasse fiber Hangzhou Hanpu Plastic Products Co., Ltd. / glass fiber Shanghai Yuanye Biotechnology Co., Ltd. Item No.: S30527-500g Polyacrylonitrile-based carbon fiber Lianyungang Rui Innovative Materials Co., Ltd. ...

preparation example 1

[0045] A kind of color master batch adopts following preparation method:

[0046] Step 1. Stir and mix 11kg maleic anhydride polyethylene and 7kg talcum powder at a stirring speed of 300r / min to obtain the masterbatch raw material;

[0047] Step 2. Add the masterbatch raw materials into the injection molding machine, and then extrude and granulate to obtain the masterbatch.

[0048] Among them, the specific process parameters of the above-mentioned injection molding machine are: the temperature of the first zone is 130-140°C, the temperature of the second zone is 150-160°C, the temperature of the third zone is 160-170°C, the temperature of the fourth zone is 160-170°C, and the temperature of the fifth zone is 160-170°C. 170-180℃, 180-200℃ in the sixth zone, 170-180℃ in the seventh zone, 160-170℃ in the eighth zone, 150-160℃ in the ninth zone, 150-160℃ in the tenth zone , the screw speed is 400r / min.

preparation example 2-3

[0050] The difference from Preparation Example 1 is that the proportions of the raw materials in Preparation Examples 2-3 are different, as shown in Table 2.

[0051] Table 2 The composition and weight (kg) of each raw material in Preparation Example 1-3

[0052] Raw material composition Preparation Example 1 Preparation example 2 Preparation example 3 Maleic anhydride polyethylene 11 14 8 talcum powder 7 6 8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com