Test method applicable to measurement of static friction coefficient of engineering components

A technology of static friction coefficient and test method, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of excessive safety factor, industrial production economy, unfavorable safety, no standardized test methods, etc., to achieve reliable results, The effect of the simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

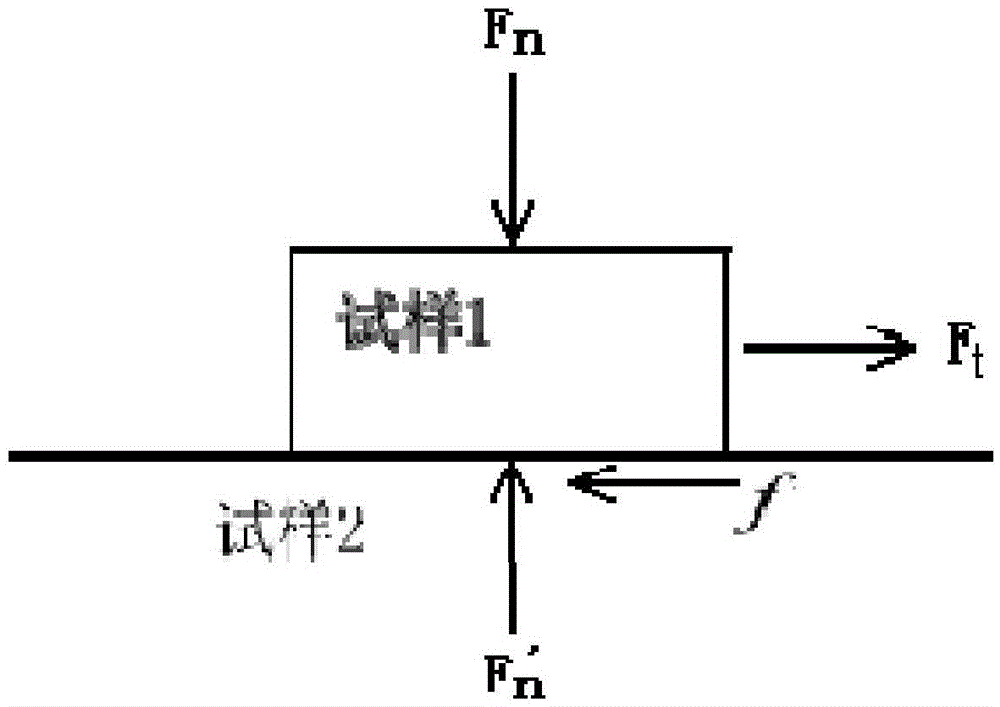

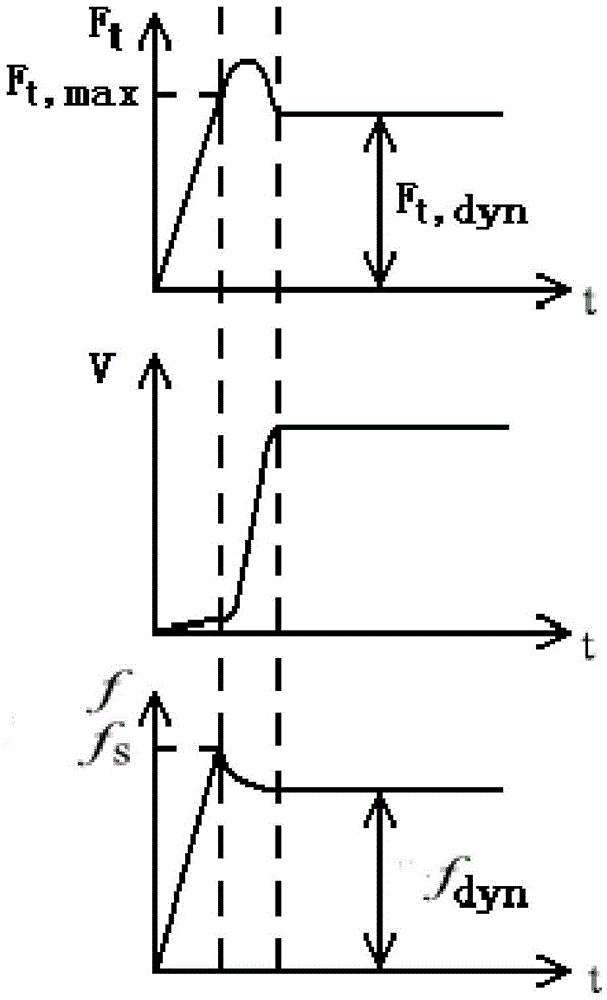

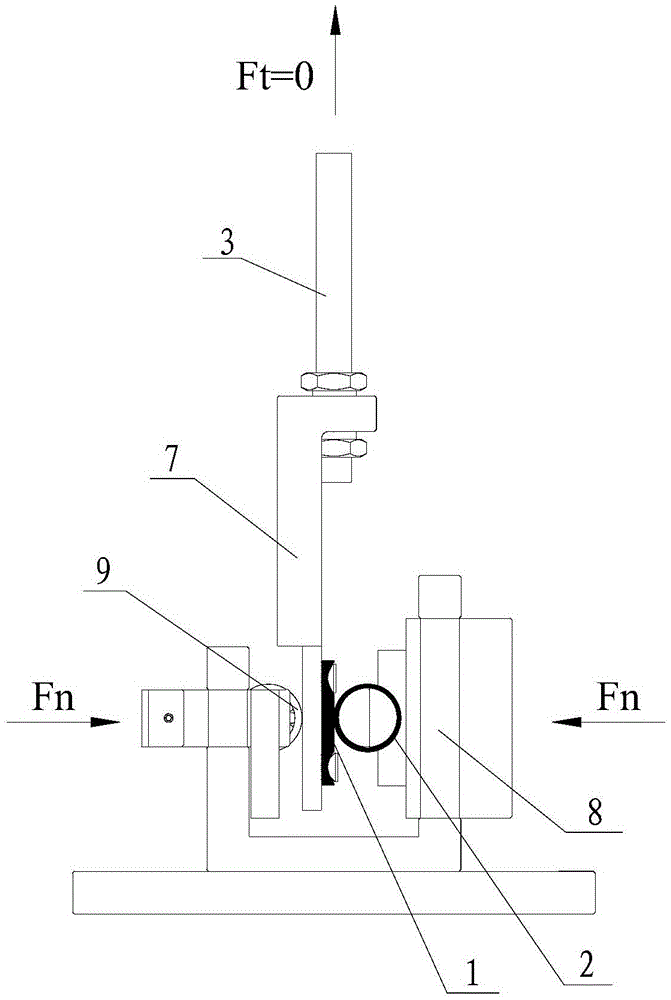

[0031] see Figure 3 to Figure 5 As shown, in this embodiment, the measurement method and principle of the static friction coefficient in this application are illustrated by taking the measurement of the static friction coefficient of the most common flat plate and pipe line contact in engineering applications as an example, wherein the flat plate is the first sample 1, and the pipe is the first sample 1. Second sample 2, the measurement test of the static friction force is carried out on a conventional tensile testing machine.

[0032] see Figure 3 to Figure 5 As shown, the sample and test device need to be installed before the test. First, prepare the first sample 1 and the second sample 2, and after cleaning both, fix the flat plate of the first sample 1 to the tensile shaft 3 of the tensile testing machine 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com