Novel modified prefabricated body carbon ceramic brake pad material and manufacturingmethod thereof

A manufacturing method and prefabricated body technology, applied in the direction of friction linings, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of unstable friction performance, uneven friction, poor automatic performance, etc., and achieve no attenuation of friction performance, Effect of improving anti-oxidation and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

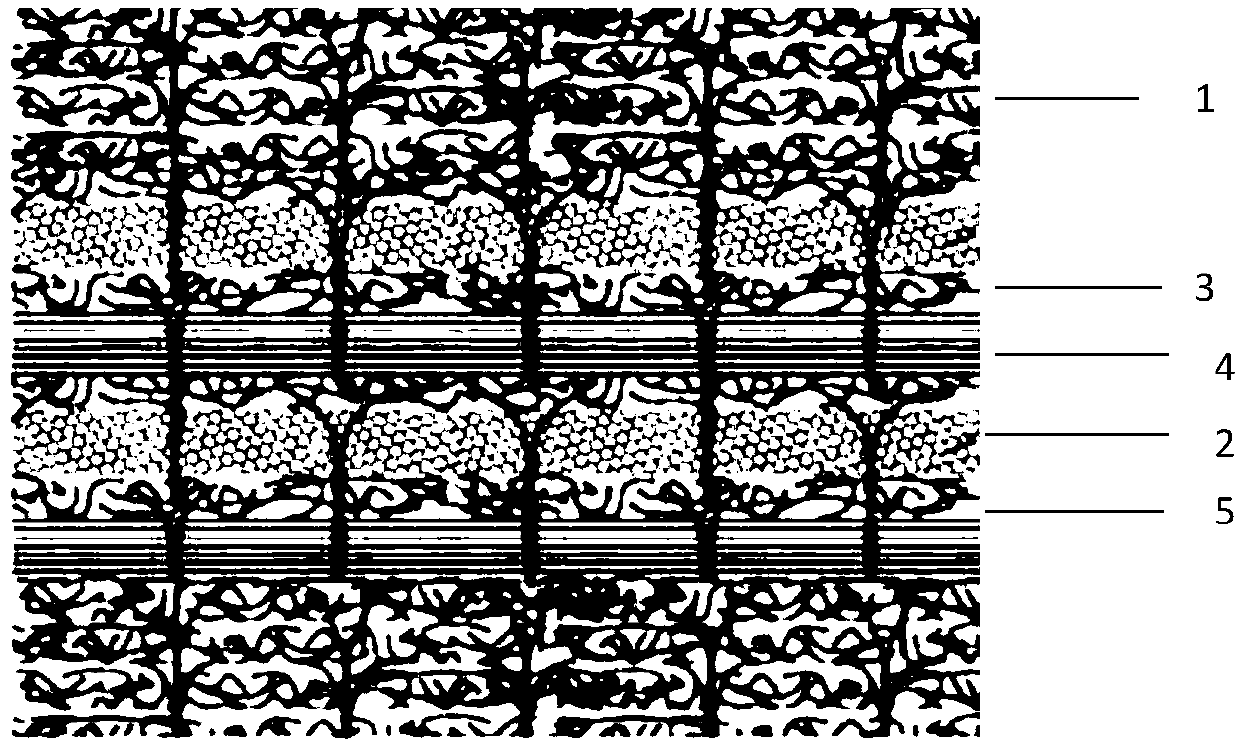

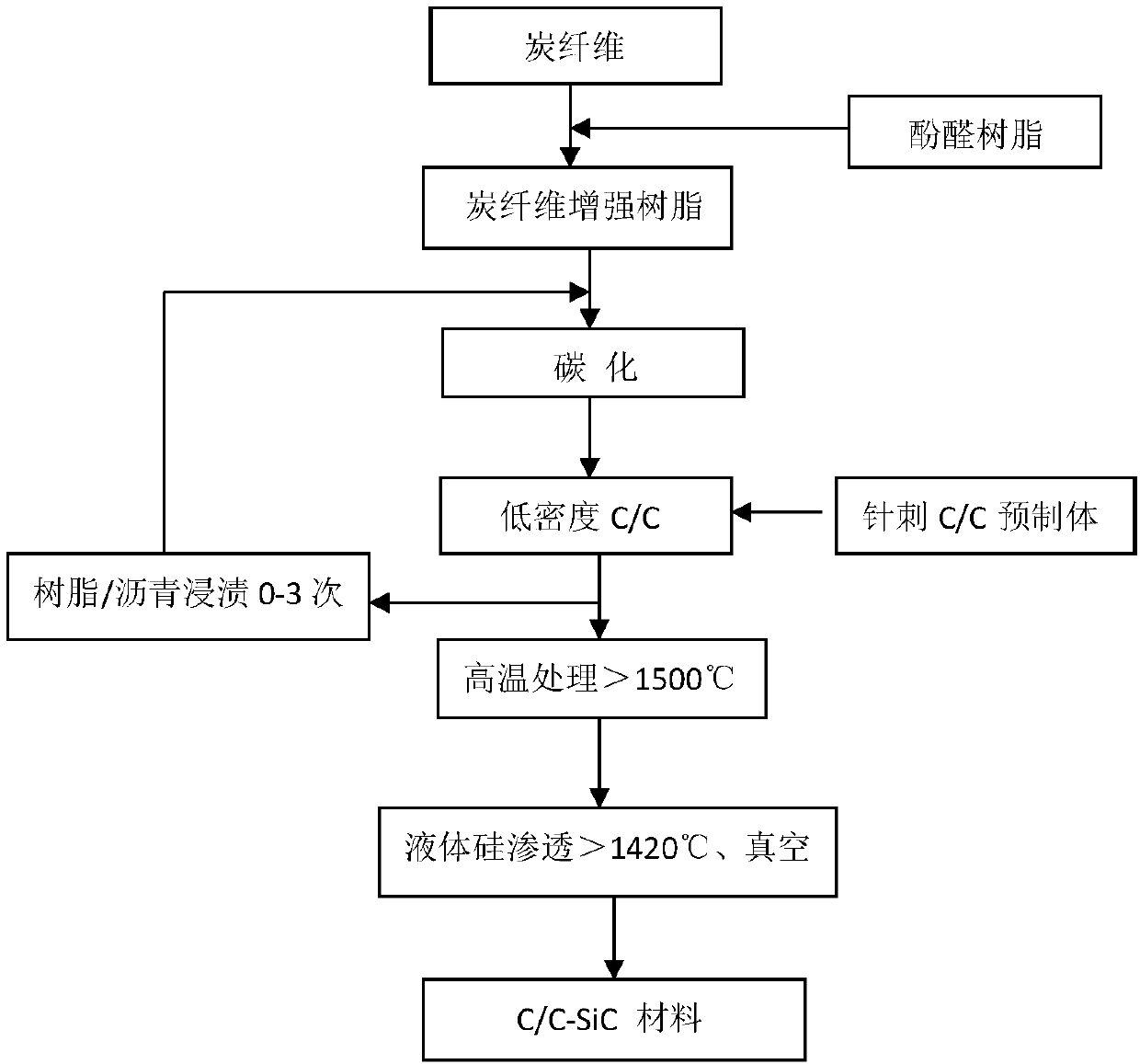

[0026] 1. To improve the structural design of the prefabricated body, the present invention adopts a new carbon fiber prefabricated body with a "sandwich" structure. The "sandwich" C / C composite consists of a friction functional layer and a structural functional layer. The structural functional layer is a three-dimensional acupuncture structure, the structural functional layer is located in the middle of the material, and the frictional functional layer is located on the periphery of the material, and the two are connected as a whole through the relay acupuncture method. Among them, the structural functional layer is a typical three-dimensional needle-punched structure, which is the same as the structure of the three-dimensional needle-punched C fiber preform, and the frictional functional layer is a pure tire mesh structure, such as figure 1 Layers of "sandwich" structure shown.

[0027] , Fiber preparation and treatment, the fiber used in this experiment is the 3K twill car...

Embodiment 2

[0039] 1. The prefabricated body structure design adopts a carbon fiber prefabricated body with a "sandwich" sandwich structure. The C / C composite material with "sandwich" sandwich structure consists of a friction functional layer and a structural functional layer. The structural functional layer is a three-dimensional acupuncture structure, the structural functional layer is located in the middle of the material, and the frictional functional layer is located on the periphery of the material, and the two are connected as a whole through the relay acupuncture method. Among them, the structural functional layer is a typical three-dimensional needle-punched structure, which is the same as the structure of the three-dimensional needle-punched C fiber preform, and the frictional functional layer is a pure tire mesh structure, such as figure 1 Layers of "sandwich" sandwich structure shown.

[0040] 2. The preparation and treatment of needle-punched structural fibers. The fibers us...

Embodiment 3

[0052] 1. The prefabricated body structure design adopts a carbon fiber prefabricated body with a "sandwich" sandwich structure. The C / C composite material with "sandwich" sandwich structure consists of a friction functional layer and a structural functional layer. The structural functional layer is a three-dimensional acupuncture structure, the structural functional layer is located in the middle of the material, and the frictional functional layer is located on the periphery of the material, and the two are connected as a whole through the relay acupuncture method. Among them, the structural functional layer is a typical three-dimensional needle-punched structure, which is the same as the structure of the three-dimensional needle-punched C fiber preform, and the frictional functional layer is a pure tire mesh structure, such as figure 1 Layers of "sandwich" sandwich structure shown.

[0053] 2. Preparation and treatment of needle-punched structural fibers. The fibers used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com