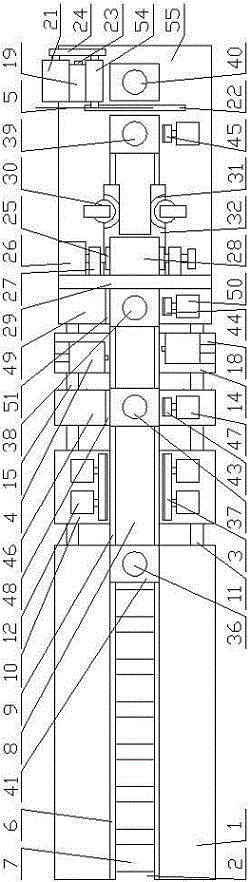

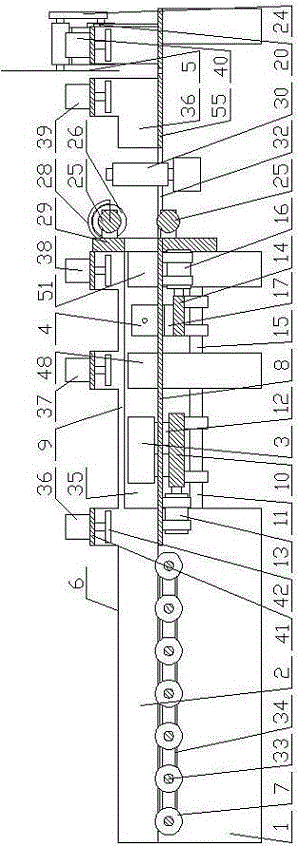

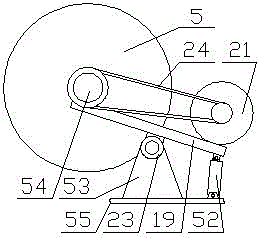

Full-automatic template foot pier nailing and cutting machine

A fully automatic, cutting machine technology, applied in sawing components, nailing tools, sawing equipment, etc., can solve the problems of high cost, waste of resources, complex equipment structure, etc., to improve surface flatness, reduce labor intensity, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] to combine Figure 1~Figure 3 As shown, the present invention includes a feeding trough, and also includes a charging device, a feeding device, a nailing device, and a cutting device arranged sequentially along the feeding trough, and the charging device is arranged at one end of the feeding chute, and the feeding device and the nailing device The nailing device is arranged on both sides of the feeding chute in turn, and the cutting device is arranged at the other end of the feeding chute.

[0055] Described charging device comprises pedestal 1, and the top of described pedestal 1 is provided with two vertical boards A6 in parallel, forms charging tank 2 between described vertical boards A6, puts multiple A template, the end face of the template faces the vertical plate A6, and the total thickness of the template in the charging tank 2 matches the groove width of the charging tank 2.

[0056] The charging chute 2 is connected to the feeding chute, and the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com