Packing material and preparation method thereof

A technology of packaging materials and mixing materials, which is applied in transportation and packaging, chemical instruments and methods, thin material processing, etc., and can solve problems such as wear, poor cushioning capacity, and scratches on the product surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] see figure 1 and figure 2 According to the preferred embodiment of the present invention, the packaging material 10 includes a base layer 11 and a buffer layer 13 formed on a surface of the base layer 11 .

[0018] The base layer 11 is composed of polystyrene and additives, the mass ratio of the additives to polystyrene is 1:12-1:8, and the preferred mass ratio is 1:10. The additive is calcium carbonate.

[0019] The buffer layer 13 is made of silica gel. The silica gel is aminopropyl silica gel, such as aminopropyl silica gel of BS320929750G model. Generally, the thickness of the buffer layer 13 should be smaller than that of the base layer, so the mass ratio of silica gel to polystyrene can be 4:110~6:90, and the preferred mass ratio is 5:100.

[0020] The packaging material 10 can be subjected to blister processing.

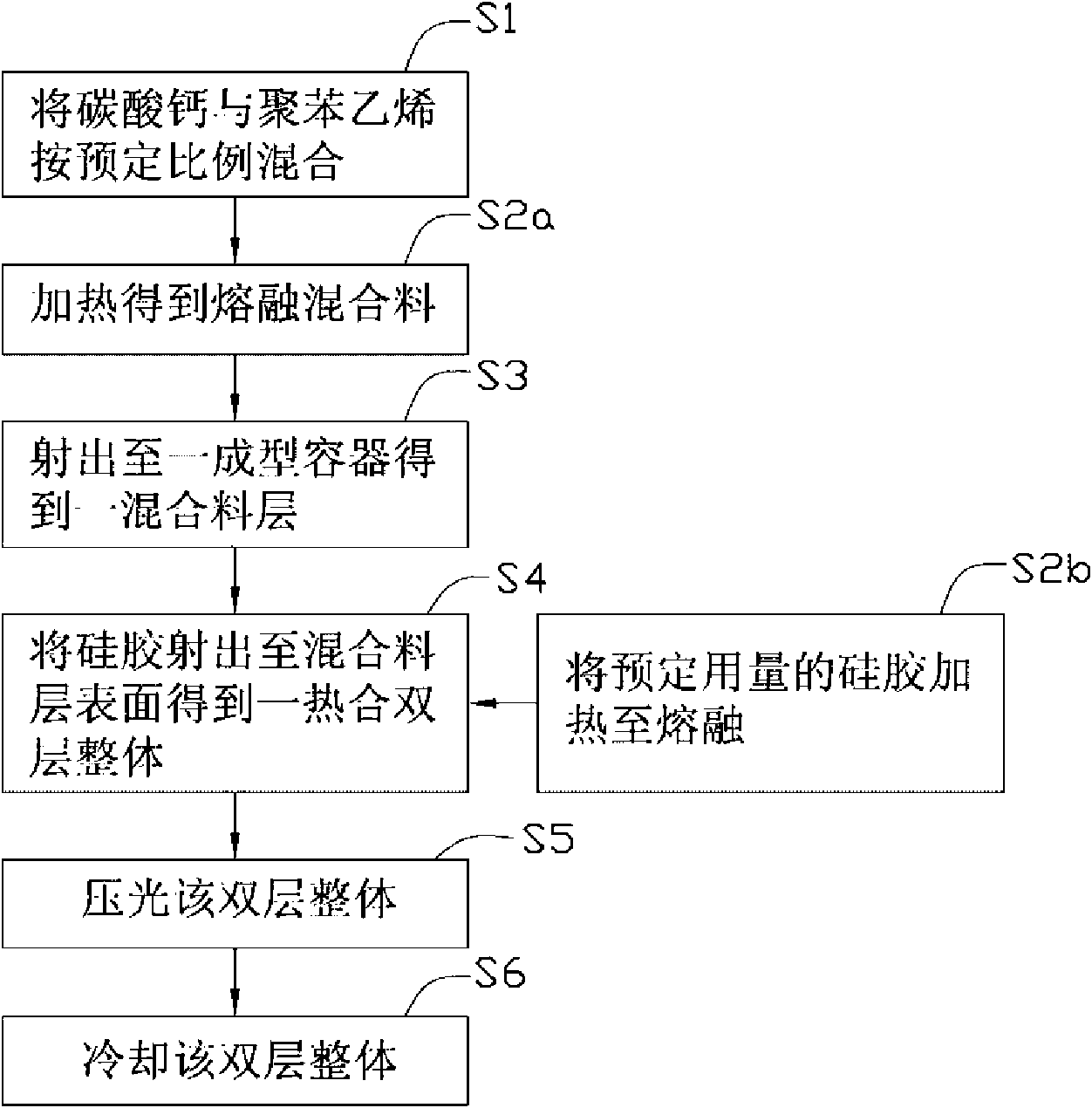

[0021] The preparation method of above-mentioned packaging material 10 comprises the following steps:

[0022] Step S1: uniformly mix calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com