Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

a technology of paperboard and insulation properties, which is applied in the field of coated paperboards and paperboard containers having improved tactile and bulk insulation properties, can solve the problems of environmental unfriendly, styrofoam containers are often brittle, and containers suffer a number of drawbacks, and achieve excellent insulation properties and high gm taber stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

Coated Plate Formation

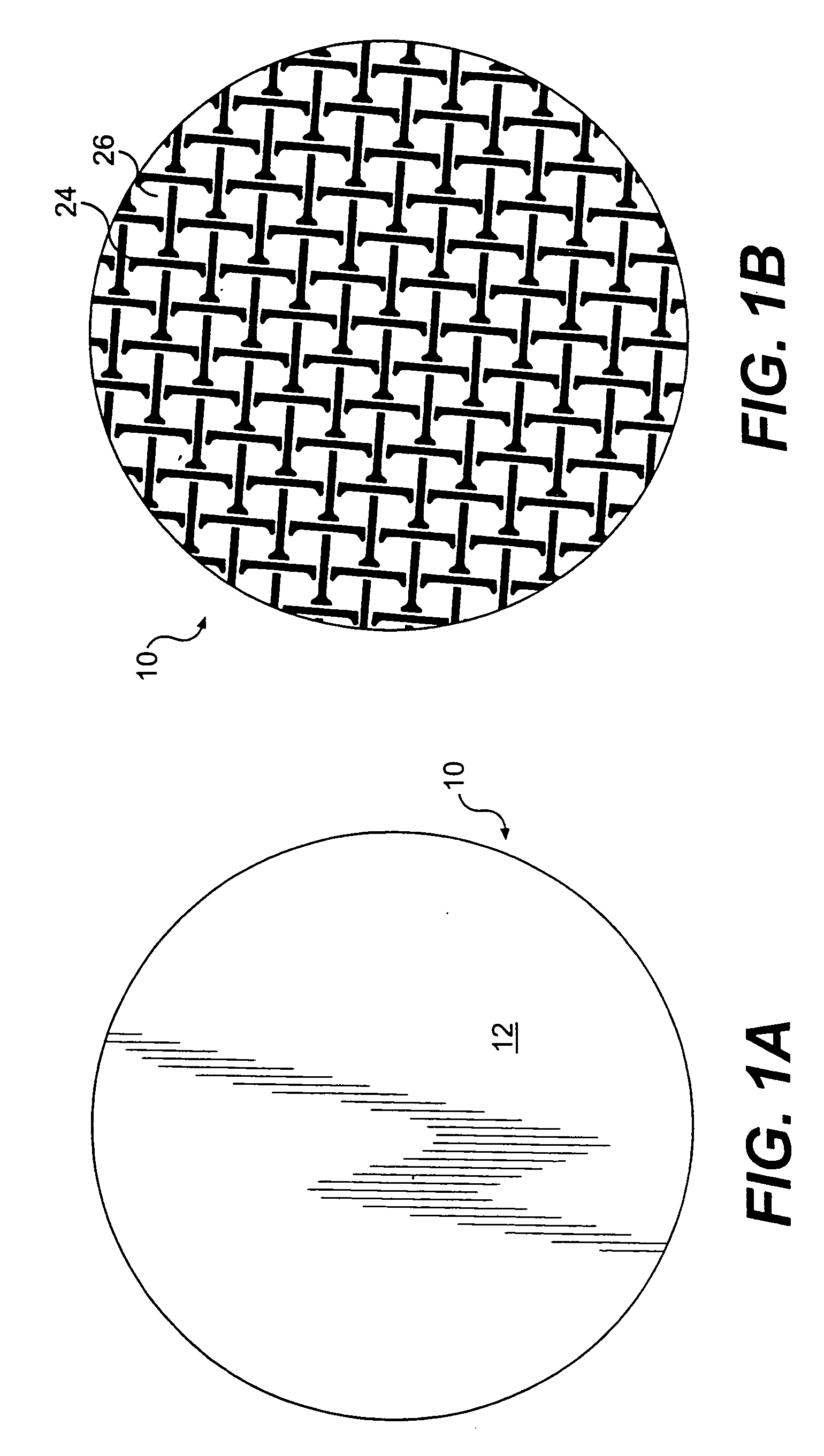

[0253] Below is a description of the process for applying textured coating using a Neenah Technical Center Faustel coater rotogravure deck and subsequent product formation. A commercially available coating sold by Industrial Adhesive Corporation of Chicago, Ill., under designation DB-333-DS was used. This coating comprises an acrylic binder to which have been charged a blend of adhesives and 16-30% microspheres. The coating delivers a textured coating with a height of approximately 0.001″-0.010″. Applied coating can not be removed from the paper substrate without effort. The coating is applied using the design illustrated in FIG. 4C with a coverage area of 55%. Three pounds of the coating were applied to a 3000 square foot ream of paperboard.

[0254] The roll was chemically etched by Gravure, Inc., of Lymon, S.C., using an 85-line screen with a 10-12 pitch wall, 80-85 microns in depth. A 12-inch wide pattern was etched continuously around the roll face. Coating...

example 3

Preparation of Texture Coated Hamburger and Sandwich Wrap

[0256] Hamburger and sandwich wrap specimens of 14 mil and 19 mil depths were screen-printed with a textured coating comprising 30% Expancel 820 microspheres, 50% Acronal S504 latex binder, and 20% clay pigment. Thickener (Alcogum L-29) was added to facilitate screen-printing. A coating weight of thirteen pounds per 3000 square foot ream was applied generating 8 mils of coating caliper. FIG. 4E design was used for the pattern for the screen-printed hamburger or sandwich wrap textured pattern. The coated wrap had a significantly greater thermal insulation for the hand touching the surface, and the wrap had also much improved friction resistance. The thermal and friction resistance is comparable to that obtained when textured plates or cups are produced.

example 4

Sample of Texture Coated Hamburger Wrap

[0257] Hamburger wrap specimens of 14 mil and 19 mil depths were screen printed as disclosed in Example 3. The solids formulation were as follows:

TABLE 4Expancel Coating for Hamburger Graphic on Quilt Wrap% DryCompoundAdditionSolidsSolidsorder29.0Expancel 820 microspheres45%248.0BASF Acronal 504 latex50%119.0Hydrafine Clay70%3As desiredAlcogum L-29 Thickener30%74 Glycerin100%5Drewplus L407 Antifoam28%4As desiredNotox Ink100%6

[0258] The resulting texture coated hamburger wrap is shown in FIG. 37 which is a photograph of a section of the hamburger wrap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com