Water-based salt spray resistant gold oil and preparation method thereof

A salt-spray-resistant, water-based technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as shedding, poor salt-spray resistance, and coating film blistering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

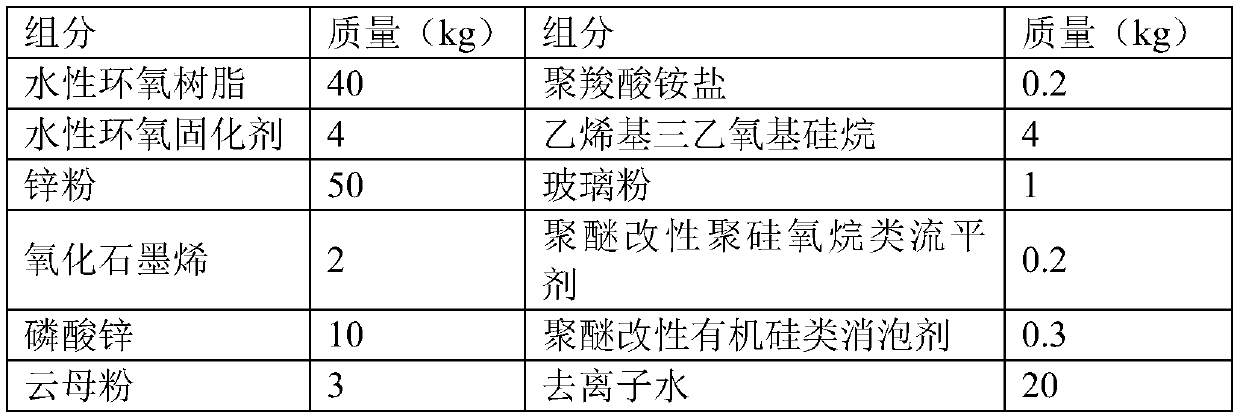

[0038] Each component and its quality of a kind of water-based salt spray resistant gold oil of table 1 embodiment 1

[0039]

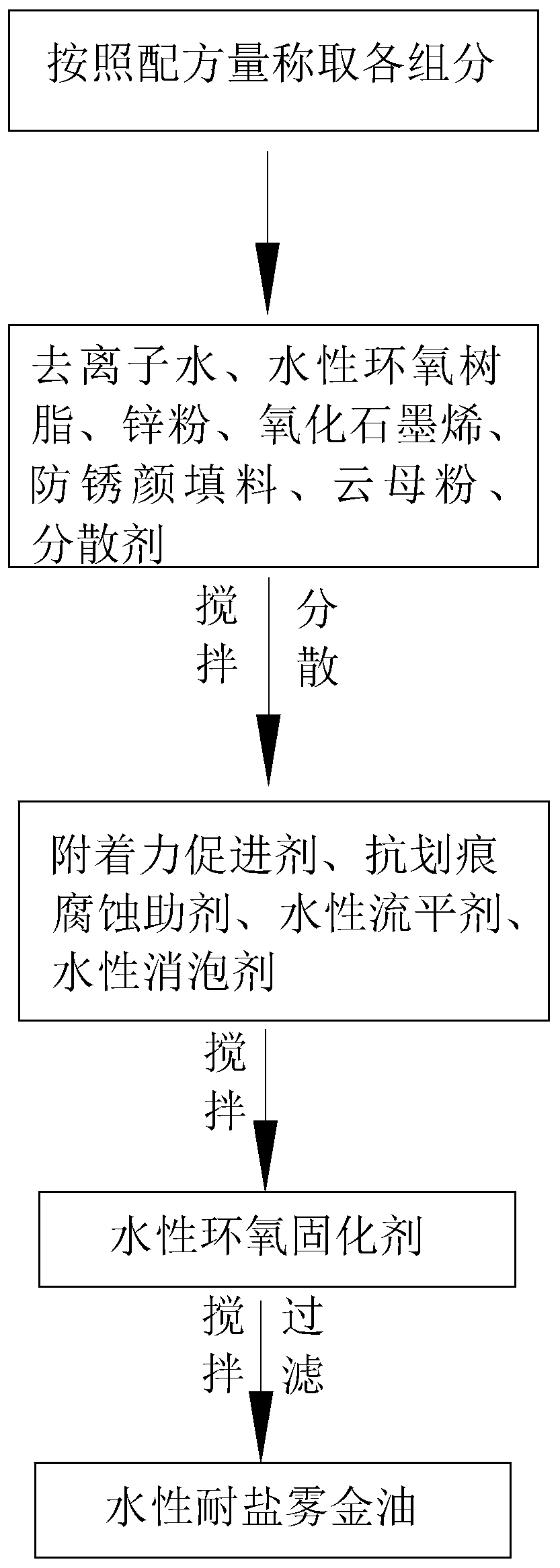

[0040] Such as figure 1 , the preparation method of the water-based salt-spray resistant gold oil specifically comprises the following steps:

[0041] Step 1, taking each component according to the formula quantity for subsequent use;

[0042] Step 2, add deionized water, water-based epoxy resin, add zinc powder, graphene oxide, zinc phosphate, mica powder and polycarboxylate ammonium salt in turn during the stirring process, stir evenly, and then disperse for 20 minutes after mixing;

[0043]Step 3, grind the mixed solution dispersed in step 2 for 5 minutes, then add vinyltriethoxysilane, glass powder, polyether modified polysiloxane leveling agent, polyether modified silicone defoaming agent Stir the agent evenly;

[0044] Step 4, add water-based epoxy curing agent to step 3 according to the formula amount, mix evenly, filter with 200-mesh gau...

Embodiment 2

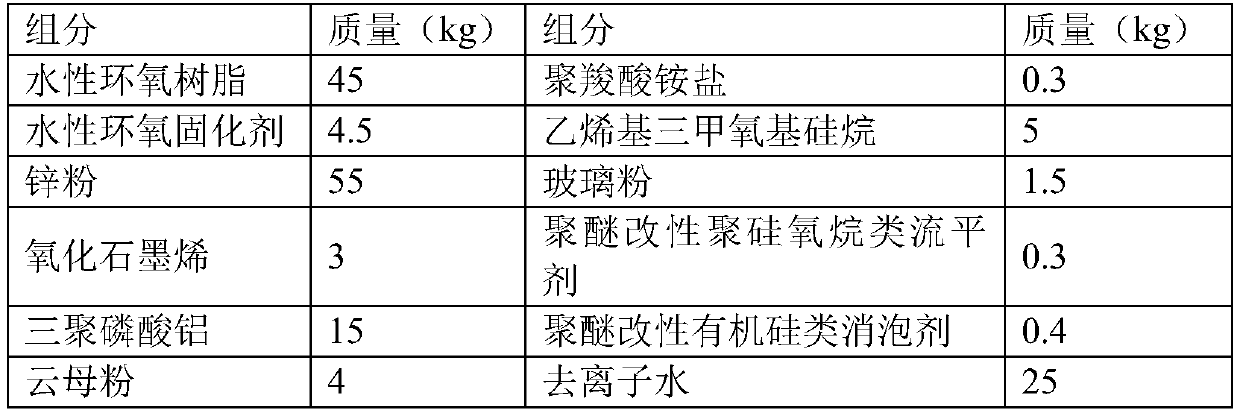

[0048] Each component and its quality of a kind of water-based salt spray resistant gold oil of table 2 embodiment 2

[0049]

[0050] The preparation method of this water-based salt spray resistant gold oil specifically comprises the steps:

[0051] Step 1, taking each component according to the formula quantity for subsequent use;

[0052] Step 2, add deionized water, water-based epoxy resin, add zinc powder, graphene oxide, aluminum tripolyphosphate, mica powder and ammonium polycarboxylate in turn during the stirring process, stir evenly, and then disperse for 30 minutes after mixing;

[0053] Step 3, grind the mixed solution dispersed in step 2 for 8 minutes, then add vinyltrimethoxysilane, glass powder, polyether modified polysiloxane leveling agent, polyether modified silicone defoamer Stir well;

[0054] Step 4, add water-based epoxy curing agent to step 3 according to the formula amount, mix evenly, filter with 200-mesh gauze, collect the filtrate and pack it to ...

Embodiment 3

[0058] Each component and its quality of a kind of water-based salt spray resistant gold oil of table 3 embodiment 3

[0059]

[0060]

[0061] The preparation method of this water-based salt spray resistant gold oil specifically comprises the steps:

[0062] Step 1, taking each component according to the formula quantity for subsequent use;

[0063] Step 2, add deionized water, water-based epoxy resin, add zinc powder, graphene oxide, zinc phosphate, mica powder and polycarboxylate ammonium salt in sequence during the stirring process, stir evenly, and then disperse for 40 minutes after mixing;

[0064] Step 3, grind the mixed liquid dispersed in step 2 for 10 minutes, then add vinyltrimethoxysilane, glass powder, polyether modified polysiloxane leveling agent, polyether modified silicone defoamer Stir well;

[0065] Step 4, add water-based epoxy curing agent to step 3 according to the formula amount, mix evenly, filter with 200-mesh gauze, collect the filtrate and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com