Mold-proof and antibacterial photovoltaic back plate and preparation method thereof

A photovoltaic backplane, anti-mildew and antibacterial technology, which is applied in the field of anti-mildew and antibacterial photovoltaic backplane and its preparation, can solve the problems of the backplane's water vapor barrier performance plummeting, mildew spots, and affecting the long-term durability of components, etc., to achieve guaranteed The effect of long-term performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

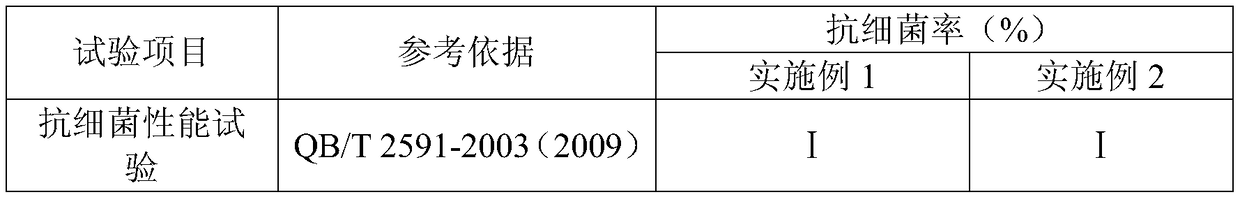

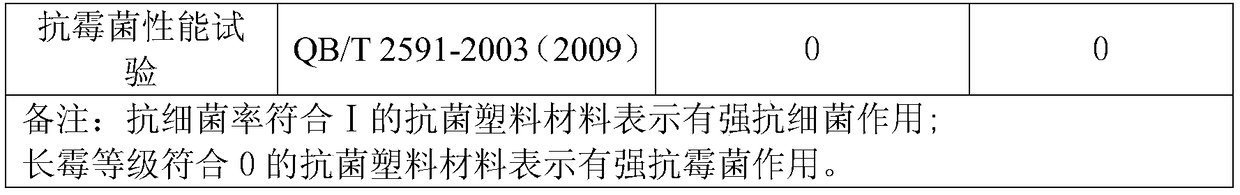

Examples

specific Embodiment 1

[0037] A preparation process for an anti-mildew and antibacterial photovoltaic backboard, comprising the following steps:

[0038] Put 50 parts of anti-mold and antibacterial agent and 50 parts of polypropylene into a high-mixer and mix for 30 minutes, then put it into a twin-screw extruder, melt and extrude at 180°C to obtain anti-mold and anti-bacterial masterbatches and store them dry;

[0039] Mix 4 parts of the above-mentioned antifungal and antibacterial masterbatch, 88 parts of polypropylene, 4 parts of titanium dioxide, 2 parts of octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 2,2 2 parts of '-tetramethylenebis(3,1-benzoxazin-4-one) were thrown into a high mixer and mixed, then melt-extruded at 180°C to granulate and dry;

[0040] Put the dried particles into the casting machine, cast them at 190°C to form a film, cool, trim and roll to obtain an antibacterial and mildew-proof polyolefin film;

[0041] The glue is coated on the PET by extrusion coating gl...

specific Embodiment 2

[0042] A preparation process for an anti-mildew and antibacterial photovoltaic backboard, comprising the following steps:

[0043] Put 60 parts of anti-mold and anti-bacterial agent and 40 parts of high-density polyethylene into a high-density mixer and mix for 20 minutes, then put them into a twin-screw extruder, melt and extrude at 190°C to obtain anti-mold and anti-bacterial masterbatches and store them dry ;

[0044] 3 parts of above-mentioned mildew-resistant and antibacterial masterbatches, 15 parts of linear low-density polyethylene, 73 parts of polypropylene, 4 parts of aluminum oxide, 3 parts of pentaerythritol tetrakis (bis-T-butyl hydroxyhydrocinnamic acid) ester, bis-( Put 2 parts of 2-methoxy-4-hydroxy-5-benzoylphenyl)methane into a high mixer for mixing, then melt extrusion at 170°C to granulate and dry;

[0045] Put the dried particles into the casting machine, cast at 185°C to form a film, cool, trim and roll to obtain an antibacterial and mildew-proof polyole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com