High-voltage power cable laying device

A high-voltage cable and wiring device technology, which is applied in cable laying equipment, transportation and packaging, and thin material processing, etc., can solve the problems of unsatisfactory cable multi-line laying and backward laying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

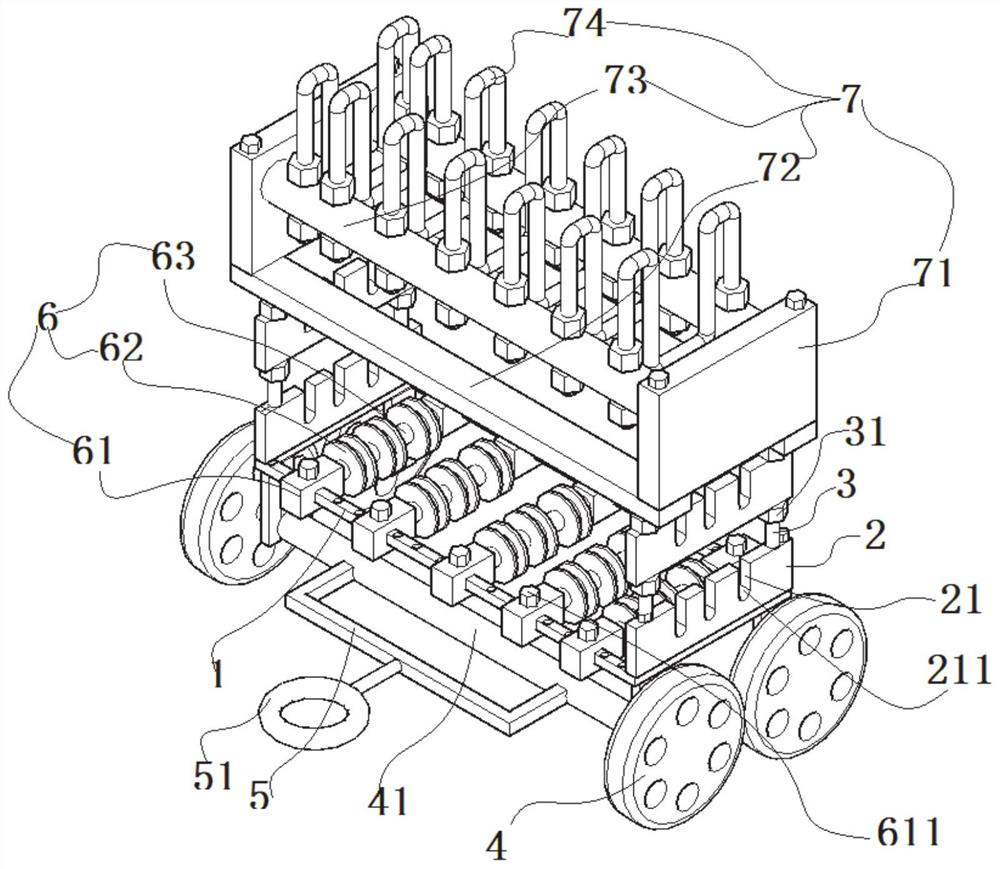

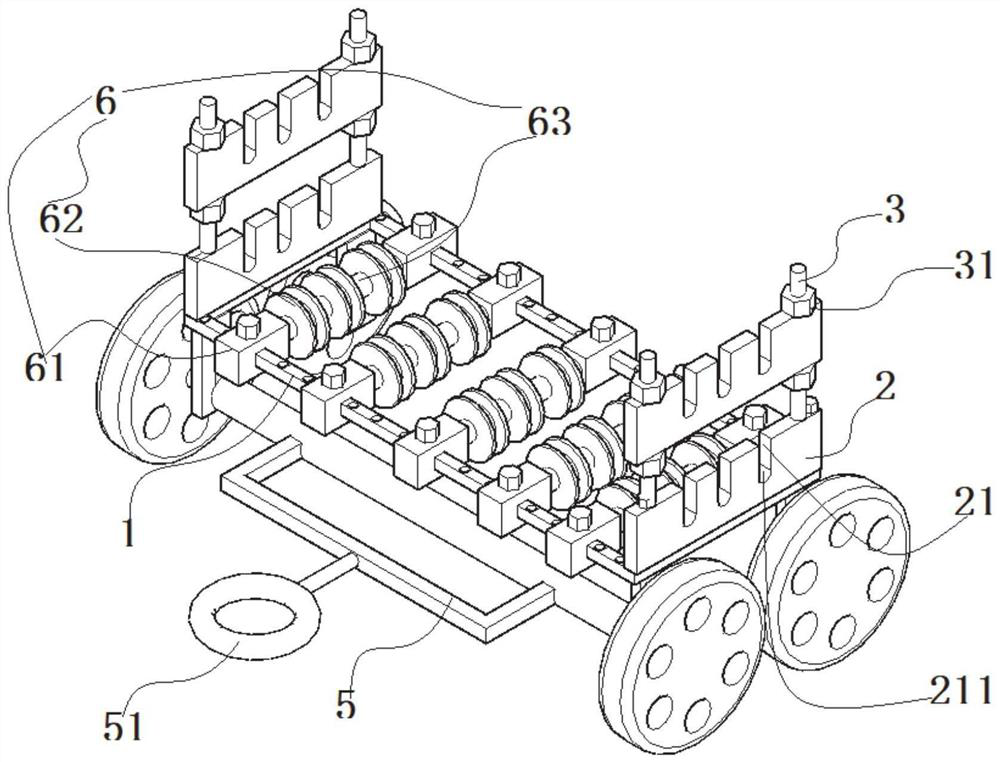

[0043] Example 1 Power high voltage cable wiring device

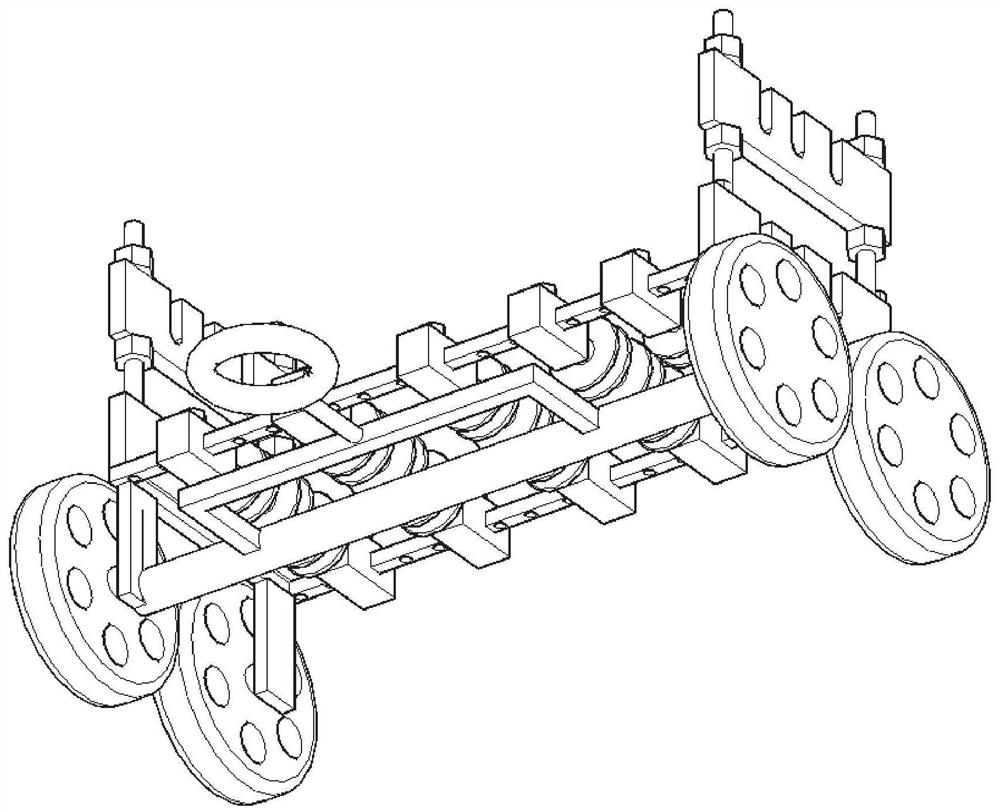

[0044] Such as Figure 1-7 As shown, a power high voltage cable wiring device includes a rectangular unit rod 1; a rectangular machine lever 1 slides to connect a plurality of left and right intervals set up a cable shaping member 6;

[0045] The cable discharge member 6 includes a sliding connection to a rectangular machine lever 1, a bearing mount 61 on the rear sides, and the bearing mount 61 is rotated between the connecting shaft 63 (the bearing mount 61 is fitted) The bearing, the arranging shaft 63 is rotated in the bearing), and a plurality of front and rear spacer disposed on the bearing shaft 63 are fixed; the discharge wheel 62 is opened on the platen 621;

[0046] The bearing mount 61 is threaded and connected to the positioning bolt 611, and the rectangular machine rod 1 is opened on the rectangular housing rod 1.

[0047] The left and right ends of the rectangular machine holder 1 are fixedly connected to the w...

Embodiment 2

[0067] Example 2 laying method

[0068] Such as Figure 1-7 As shown, the present embodiment is based on the apparatus structure disclosed in Example 1, and the laying method of the power high voltage cable wiring device is disclosed. Specifically, the specific structure of the power high voltage cable wiring apparatus is as follows:

[0069] A power high voltage cable wiring device includes a rectangular machine lever 1; a rectangular machine frame rod 1 slides to connect a plurality of left and right intervals set up a cable shaping member 6;

[0070] The cable discharge member 6 includes a sliding connection to a rectangular machine lever 1, a bearing mount 61 on the rear sides, and the bearing mount 61 is rotated between the connecting shaft 63 (the bearing mount 61 is fitted) The bearing, the arranging shaft 63 is rotated in the bearing), and a plurality of front and rear spacer disposed on the bearing shaft 63 are fixed; the discharge wheel 62 is opened on the platen 621;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com