Suspension type water chestnut digging machine

A mining excavator and hanging technology, applied in the field of water chestnut mining equipment, can solve the problems of high labor intensity, damage of water chestnuts, large mechanical crushing of water chestnuts, etc., and achieve the effect of convenient power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

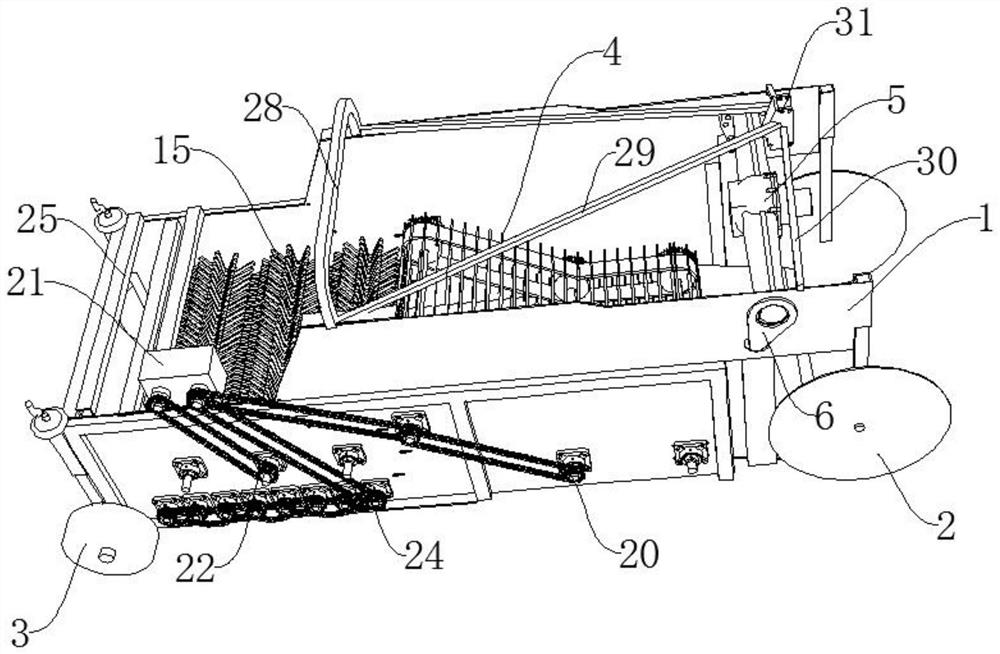

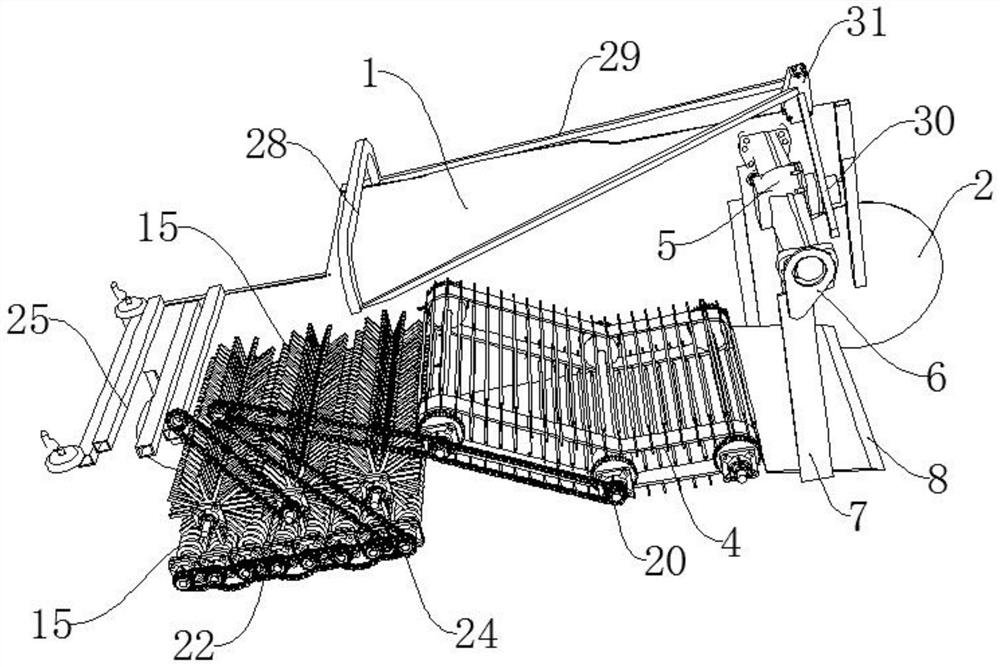

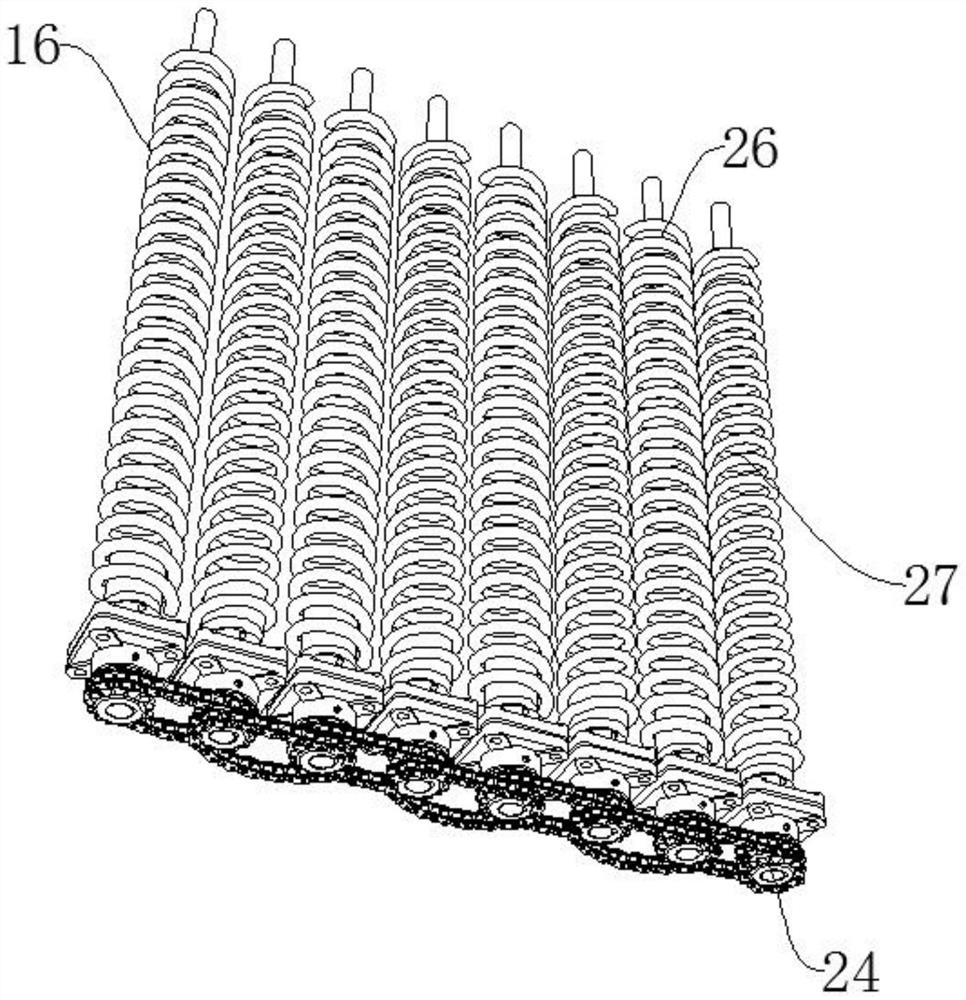

[0037] see Figure 1-9 , the present invention provides a technical solution: a suspended water chestnut excavator, comprising a frame 1, two sets of depth-gauge wheels 2 and two sets of ground wheels 3, the top, bottom and both sides of the frame 1 are of open design , the depth-limiting wheel 2 is symmetrically rotated and installed on both sides of the head of the lower surface of the frame 1, and the ground wheel 3 is symmetrically rotated and installed on both sides of the tail of the lower surface of the frame 1. A power unit is installed on the frame 1, a lifting chain component 4 is installed in the frame 1 on one side of the vibration lifting component, and a kneading treatment component is installed in the frame 1 on one side of the lifting chain component 4;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com