Oilseed rape two-side and rear laying cutter-rower

A windrowing machine and laying technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, etc., can solve problems such as low operating efficiency, disorderly laying, and conveying blockage, and achieve small machine vibration, save space, and The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

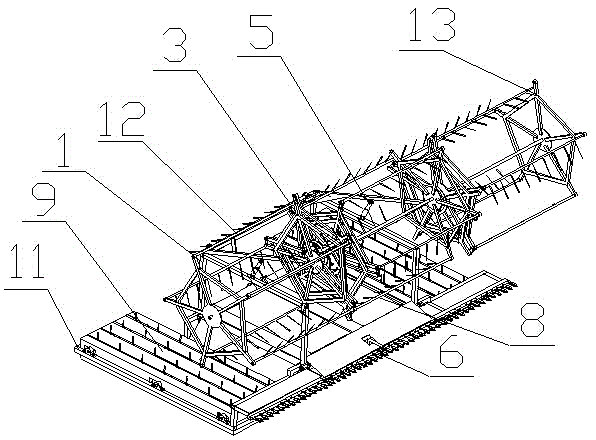

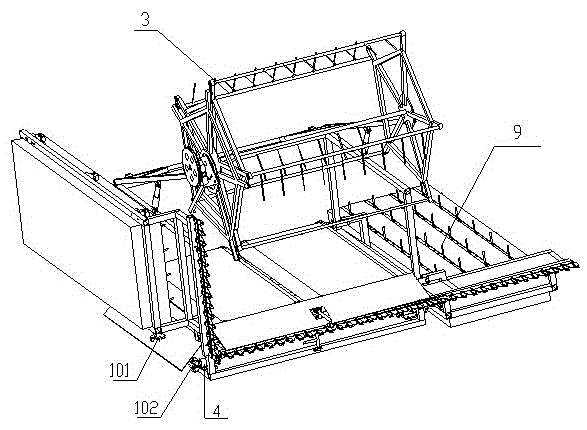

[0032] like Figure 1 to Figure 6 As shown, a kind of windrower embodiment of canola double-side rear laying of the present invention includes a main header 1, the main header 1 is connected to work by a three-point suspension device and a walking chassis, and the top of the main header 1 is installed There is a lifting reel, the main cutter 6 is installed in front of the bottom of the main header 1, and two sets of horizontal conveying devices 8 are installed on the bottom of the main header 1 directly behind the main cutter 6. The conveying device 8 is symmetrical along the center of the main header 1, and the two outer sides of the main header 1 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com