Fan lamp of self-generating sewing machine

A sewing machine and fan lamp technology, which is applied to sewing machine components, sewing equipment, machines/engines, etc., can solve the problems of high use cost, insufficient wind power, and operator sultry heat, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

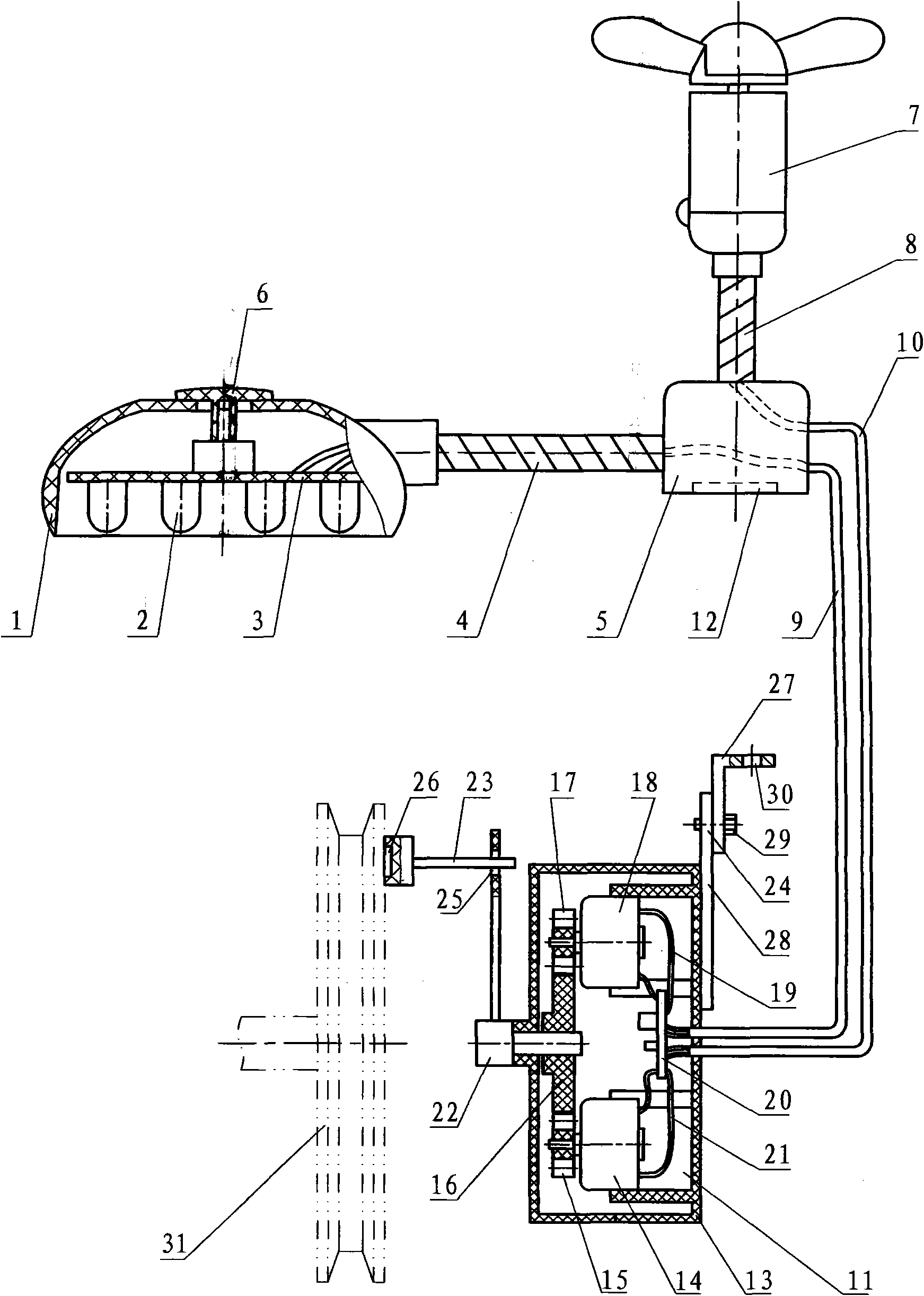

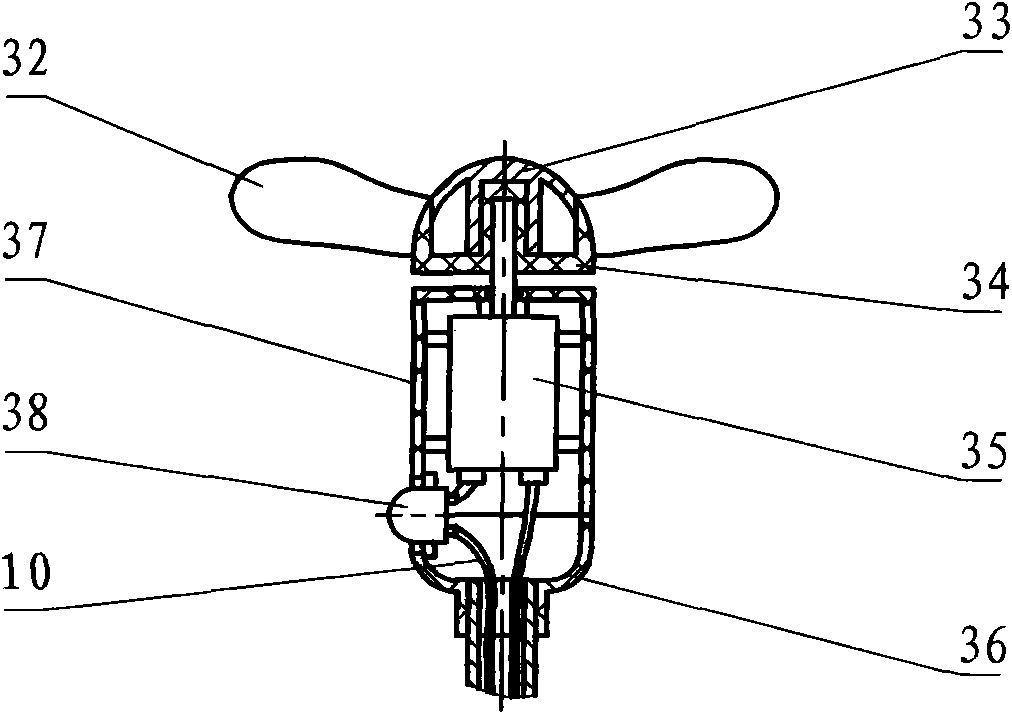

[0021] Combine below Figure 1 to Figure 6 A detailed description will be made to the specific embodiment of the present invention. Embodiment 1: as figure 1 , a self-generating sewing machine fan lamp, including a lamp housing 1, a light-emitting diode group 2, a circuit board 3, a metal hose 4, a lamp holder 5, a fan 7, a metal hose 8, a power cord 9, an electric wire 10, and a lamp housing 1 There is a circuit board 3 inside, the LED group 2 is installed on the circuit board 3, the slide switch 6 is installed on the circuit board 3, the bottom of the lamp holder 5 is provided with a magnet 12, and the lamp holder 5 is provided with a metal hose 4 and a metal Flexible hose 8, one end of electric wire 9 is connected with light-emitting diode group 2, one end of electric wire 10 is connected with micromotor 35 in fan 7, it is characterized in that: the other end of described electric wire 9 and electric wire 10 is provided with power generation device 11. The metal hose 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com