Serger for tie production

A side machine and necktie technology, which is applied in the direction of cloth pressing mechanism, sewing machine components, sewing machine housing, etc., can solve the problems that the production line cannot work continuously, and achieve the effect of high yield, good quality and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

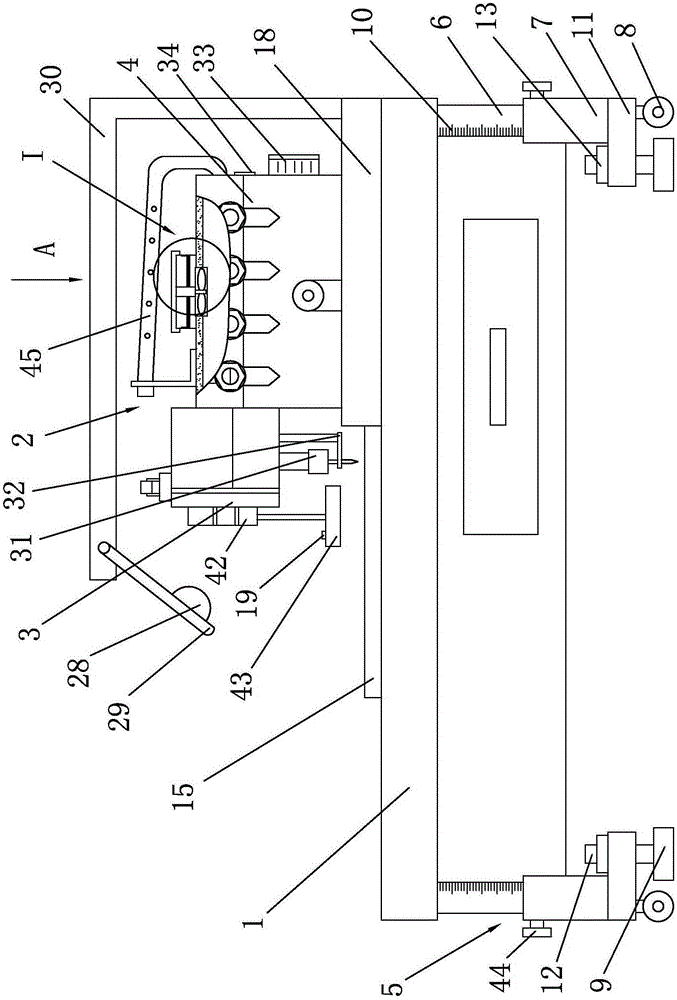

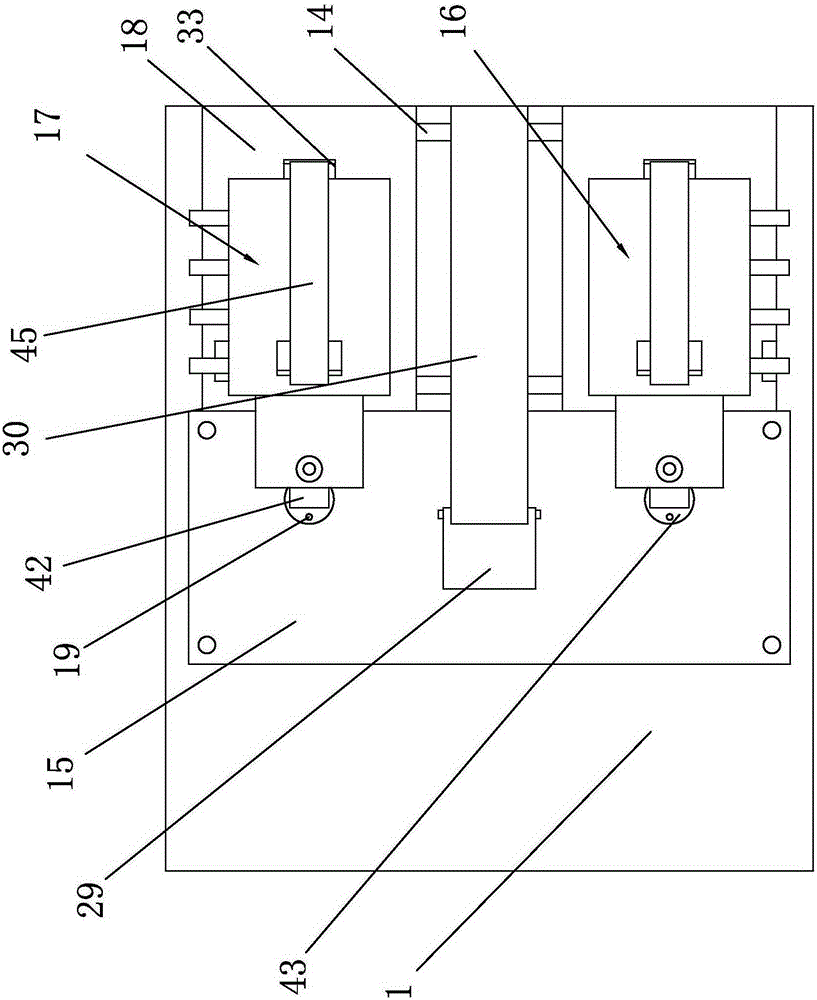

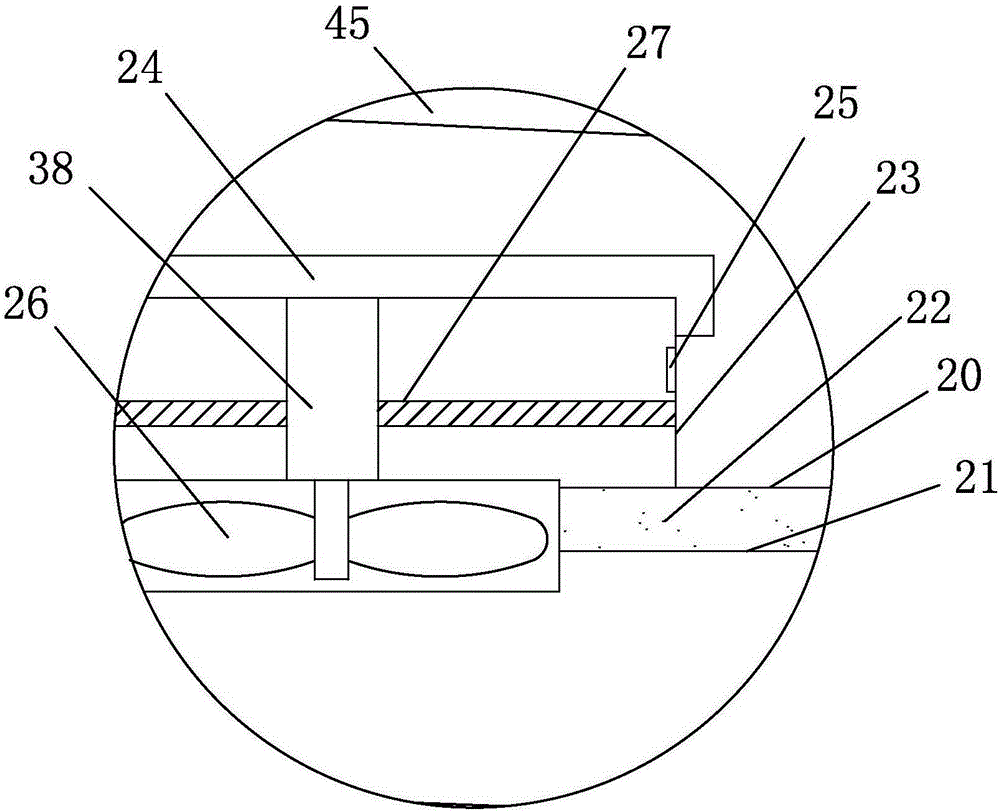

[0029] Such as Figure 1 to Figure 5 As shown, it is an edge machine for necktie production, including a workbench 1, an edge body 2 and a lighting device. The edge body 2 includes a machine head 3 and a chassis 4, and a walking machine is installed at the lower end of the machine head 3. The thread needle 31 is provided with a pressing plate 32 on the threading needle 31, and the pressing plate 32 is connected with the machine head 3 through a telescopic rod. The design of the pressing plate 32 plays a guiding and stabilizing effect, so that the movement of the threading needle 31 is more stable and constant, avoiding The stitching needle 31 deviates during the downward movement, which affects the edge overlay effect. A hand wheel 33 and an air outlet 34 are arranged on the right end surface of the cabinet 4. The number of rotations of the hand wheel 33 is proportional to the moving distance of the cloth. Adjusting and reading the readings on the hand wheel 33 can scientifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com