Sewing machine frame with real-time monitoring function used for necktie sewing

A real-time monitoring and rack device technology, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of serious human injury, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

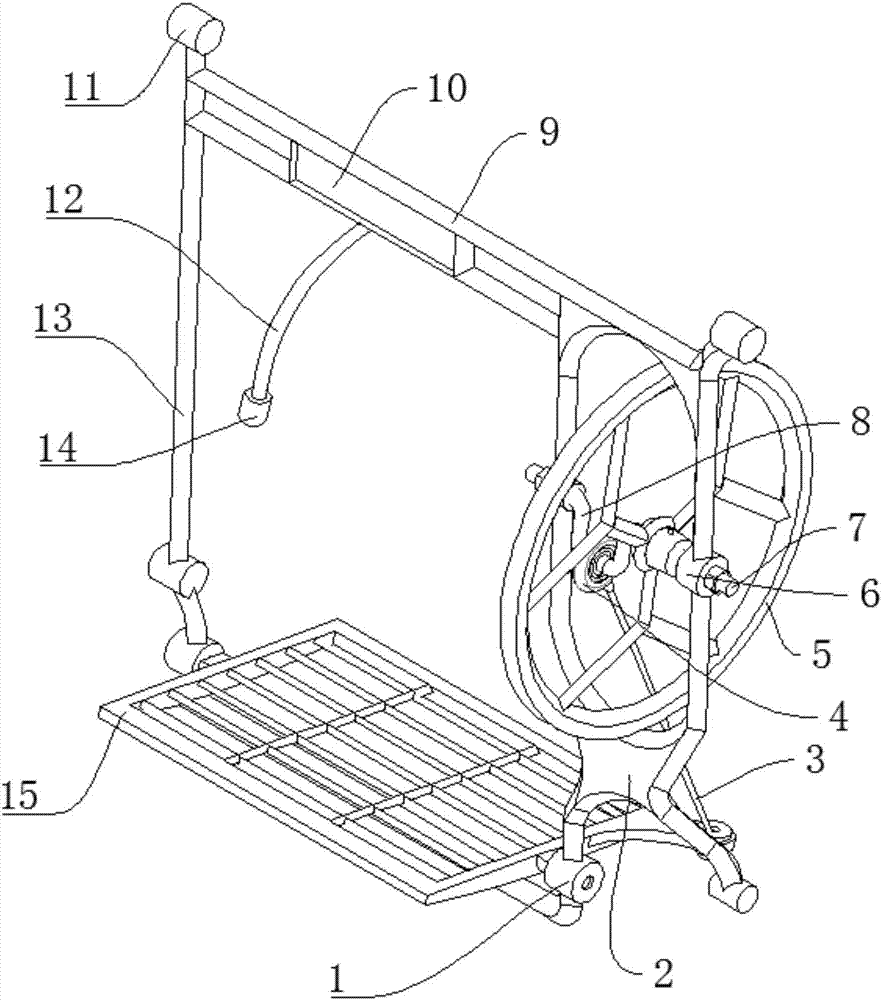

[0015] like figure 1 As shown, a sewing machine frame device capable of real-time monitoring for tie sewing includes a base body 2, a connecting rod 3, a beam 9 and a display screen 10, and a support frame 1 is arranged beside the base body 2, and the support frame 1 is used to install feet. Pedal 15, connecting rod 3 is arranged beside support frame 1, and connecting rod 3 is in order to transmit power to driving rod 8, and bearing seat 4 is arranged beside connecting rod 3, and bearing seat 4 is used for installing main shaft 7, and bearing seat 4 is next to There is a main shaft 7, the main shaft 7 is used to install the driving wheel 5, and the shaft sleeve 6 is arranged beside the main shaft 7, and the shaft sleeve 6 is used to install the main shaft 7, and the driving wheel 5 is arranged next to the shaft sleeve 6, and the driving wheel 5 is used to maintain the norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com