Facial line detection mechanism, facial line detection device and sewing machine provided with facial line detection device

A detection mechanism and detection device technology, which is applied in the direction of sewing machine components, sewing equipment, thread breakage detectors, etc., can solve problems such as inability to detect abnormalities, no upper thread supply abnormality detection, thread breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

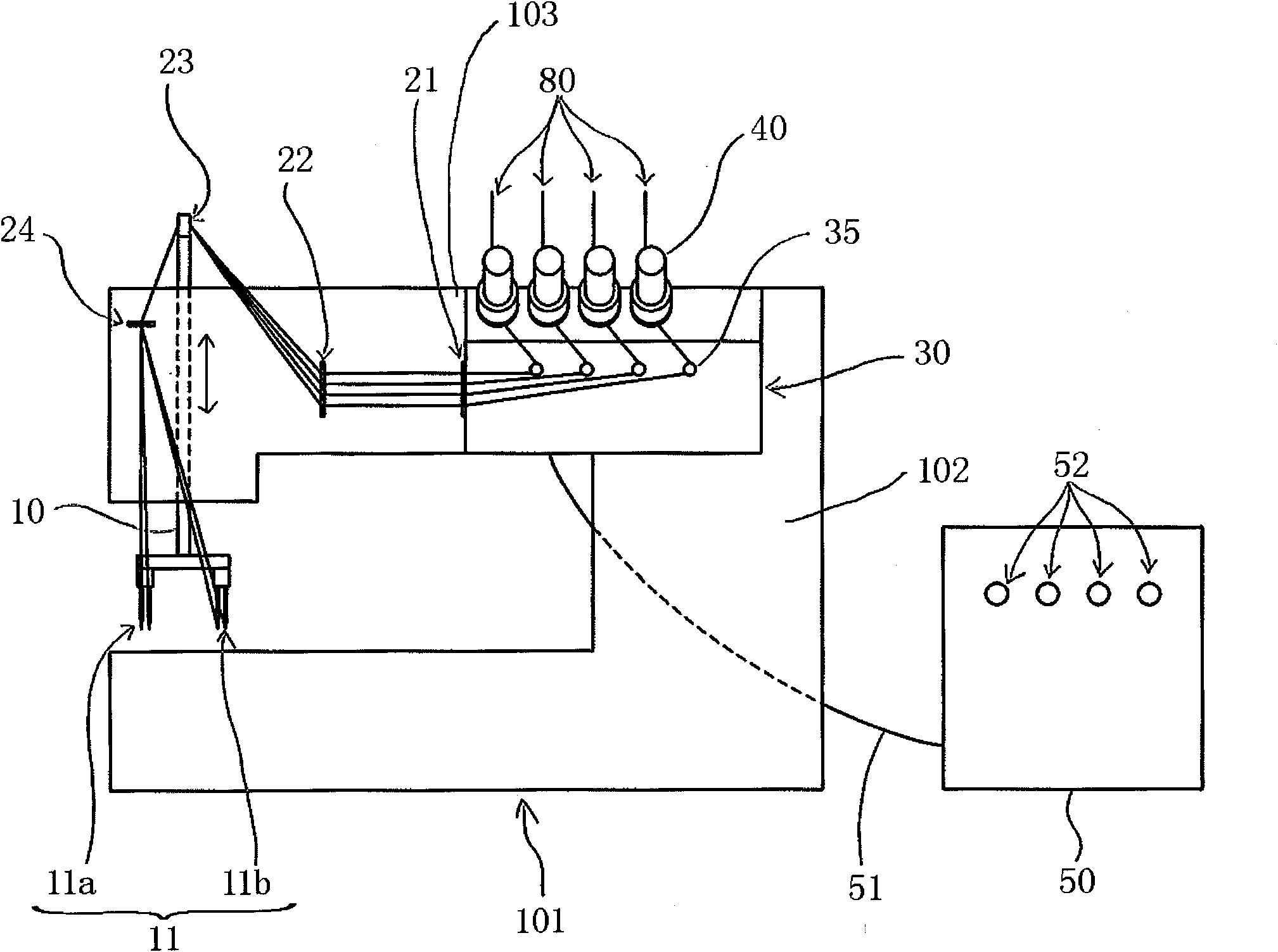

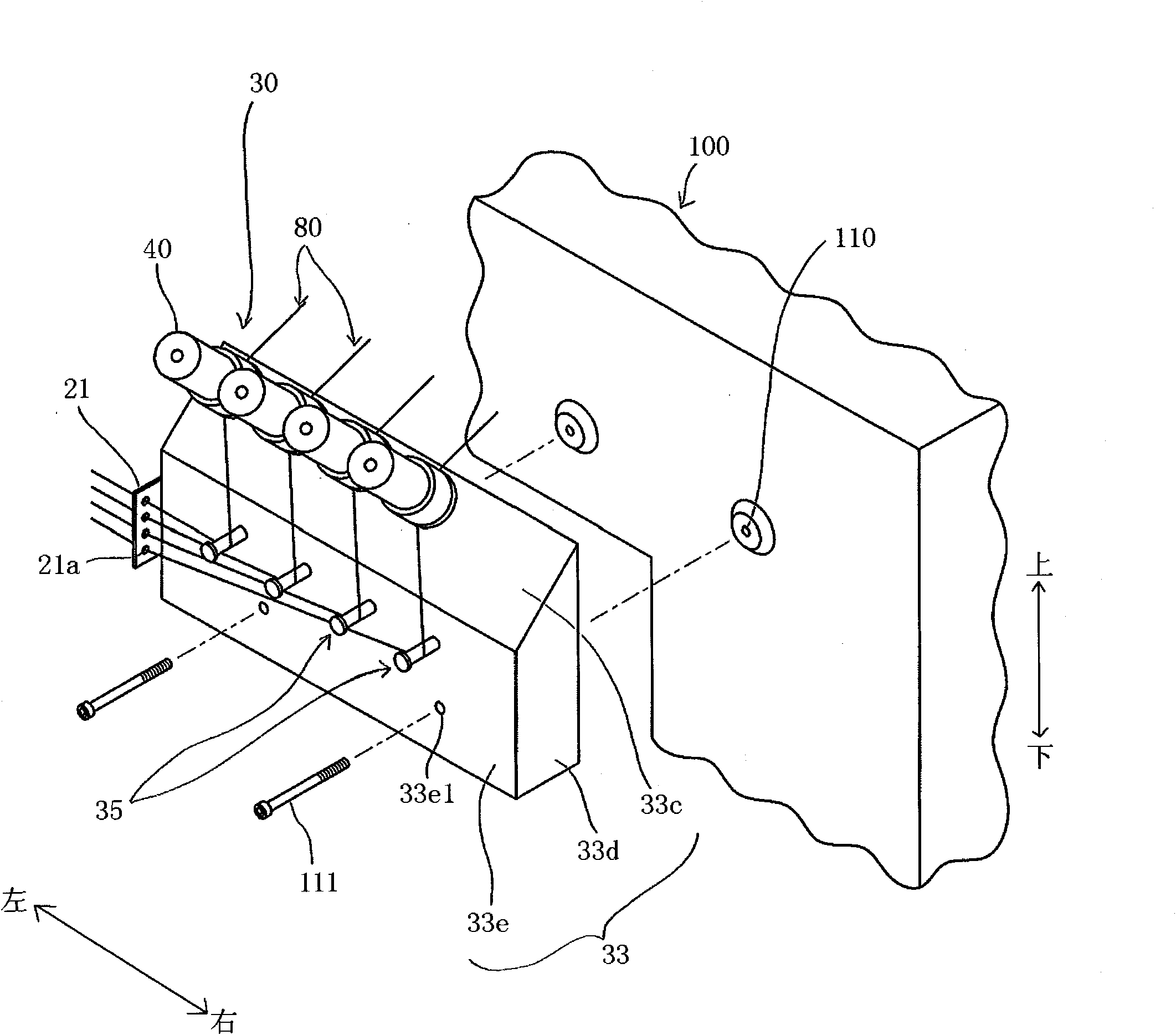

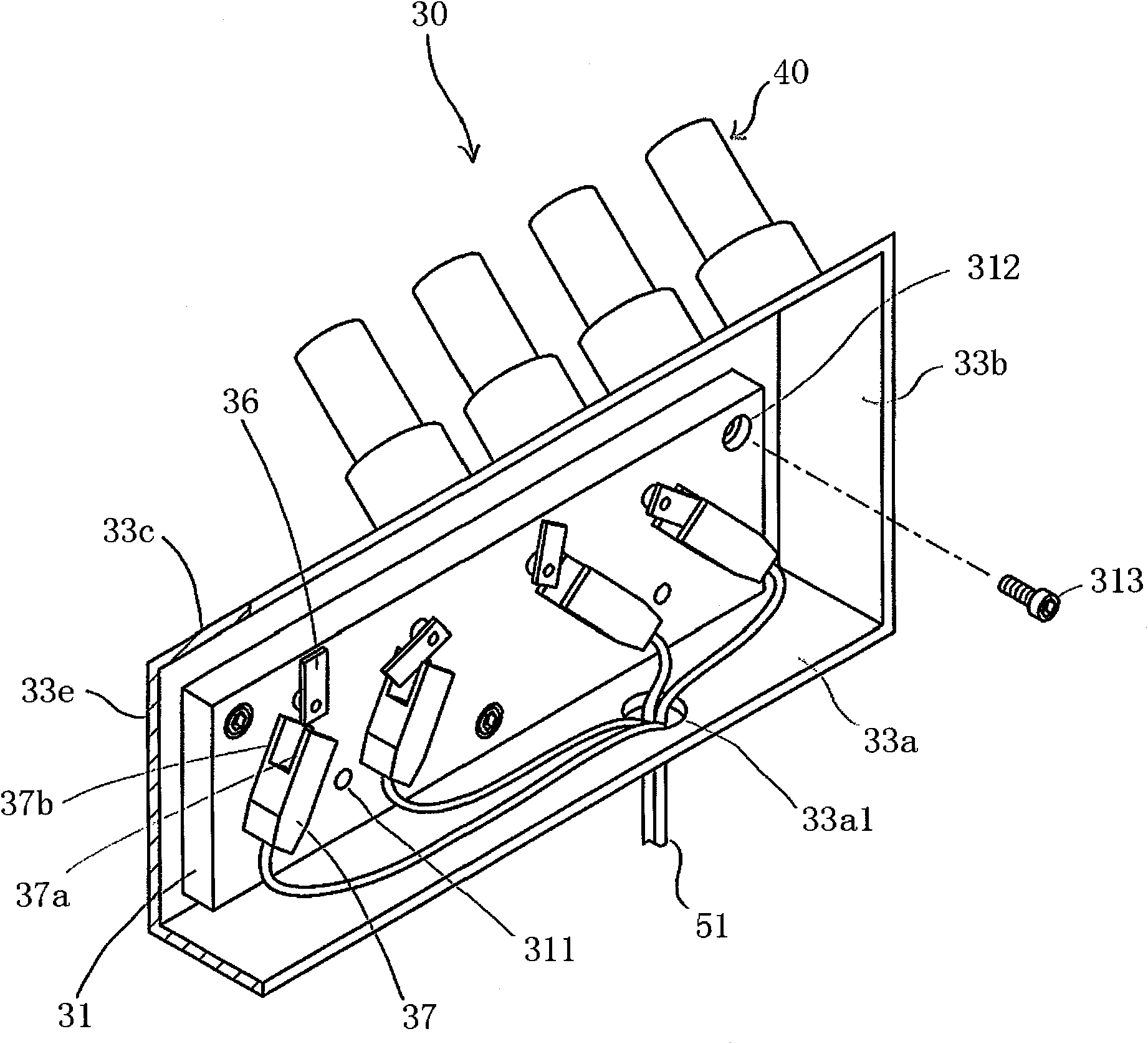

[0030] Hereinafter, best embodiments of the present invention will be described with reference to the drawings. In the following description, the up-down direction and the left-right direction refer to the up-down direction and the left-right direction shown in the drawings, respectively.

[0031] Before describing the needle thread detecting mechanism and the needle thread detecting device having the needle thread detecting mechanism of the present invention, a loop slide fastener which is one of slide fasteners will be described.

[0032] Figure 9 It is a cross-sectional view showing a fastener chain sewn with a sewing needle. Figure 10 is the front view of the sliding zipper, indicating the use of Figure 9 The zipper fastener chain 210 shown makes a sliding zipper. Such as Figure 10 As shown, the coil slide fastener 200 is configured such that ribs 202, 202 are respectively provided at the opposite ends of the left and right bands 201, 201, and the edge portions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com