Sewing machine

A technology for sewing machines and worktables, applied in the field of sewing machines, can solve the problems of dirty wires, unsmooth feeding of wires, and easy knocking of wires, etc., to achieve the effect of preventing throwing out and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

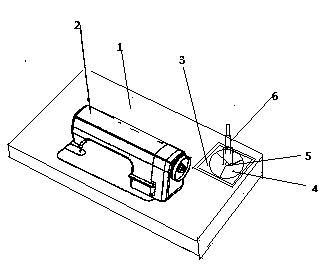

[0017] Embodiment: a sewing machine, comprising a sewing machine body 1 and a working surface 2, the sewing machine body 1 is located on the working surface 2, the working surface 1 is provided with a groove 3, and a tray 4 for placing wires is arranged in the groove 3 , the tray 4 can rotate freely. The wires needed for sewing are placed in the tray 4, and the wires can rotate together with the tray 4, so that the wires can be fed more smoothly during the sewing process, and the wires will not be broken by pulling the wires or will not be wound with the wires. The phenomenon of the barrel falling down.

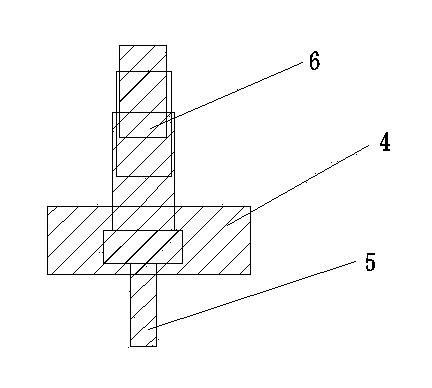

[0018] The groove 3 is provided with a fixed shaft 5 , and the tray 4 is rotatably sleeved on the fixed shaft 5 . During sewing, the wire is pulled to give a driving force to rotate the tray 4, causing the tray 4 to rotate.

[0019] The center of the tray 4 is provided with a central rod 6 for threading the wire. 6 threaded through center pole

[0020] It is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com