Patents

Literature

69 results about "Minimum latency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Minimum latency = 45. The people involved in the turnaround are interested only in the time it takes for their individual tasks. When all of the tasks are done at the same time, however, it is possible to reduce the latency to the length of the longest task. If some steps have prerequisites, it becomes more difficult to perform all steps in ...

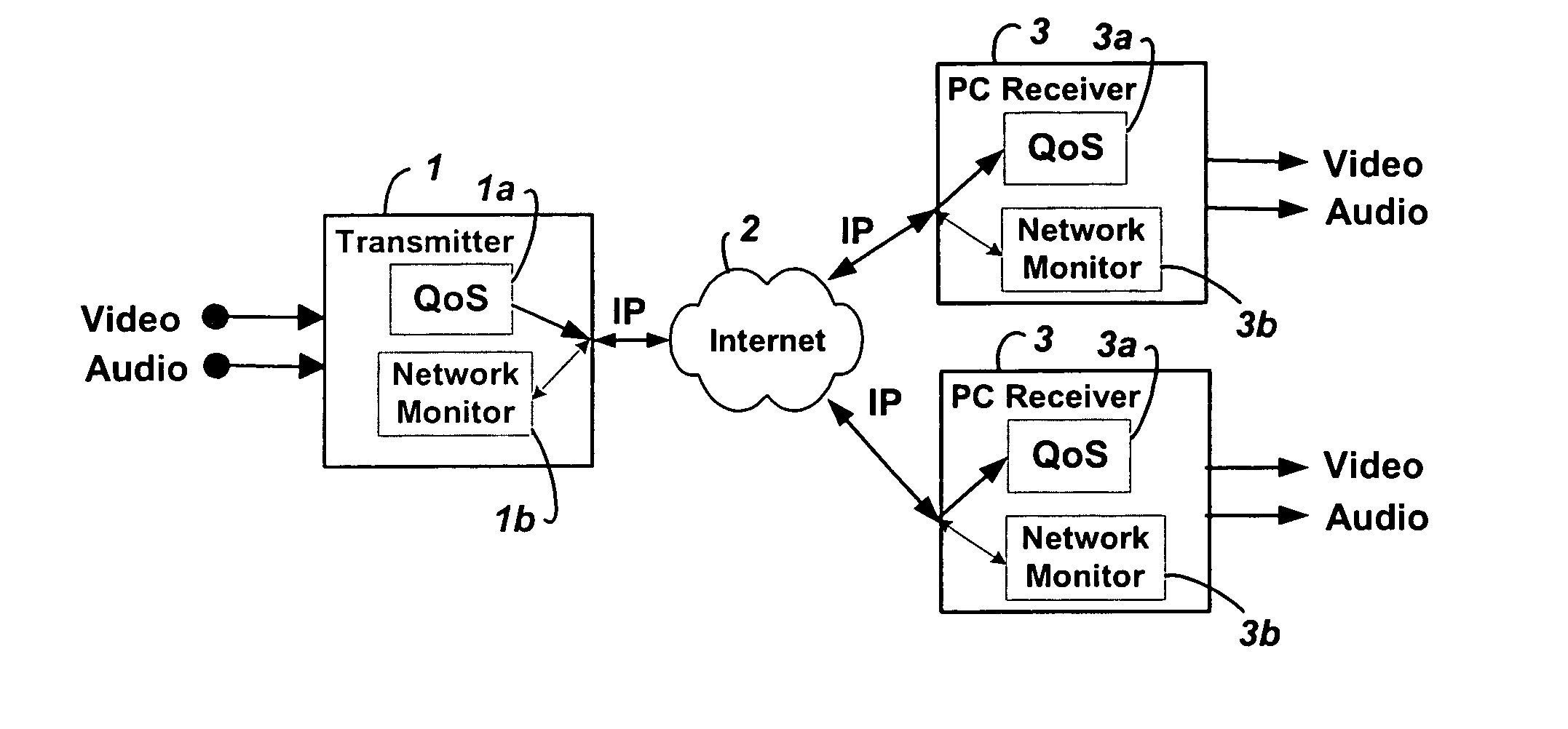

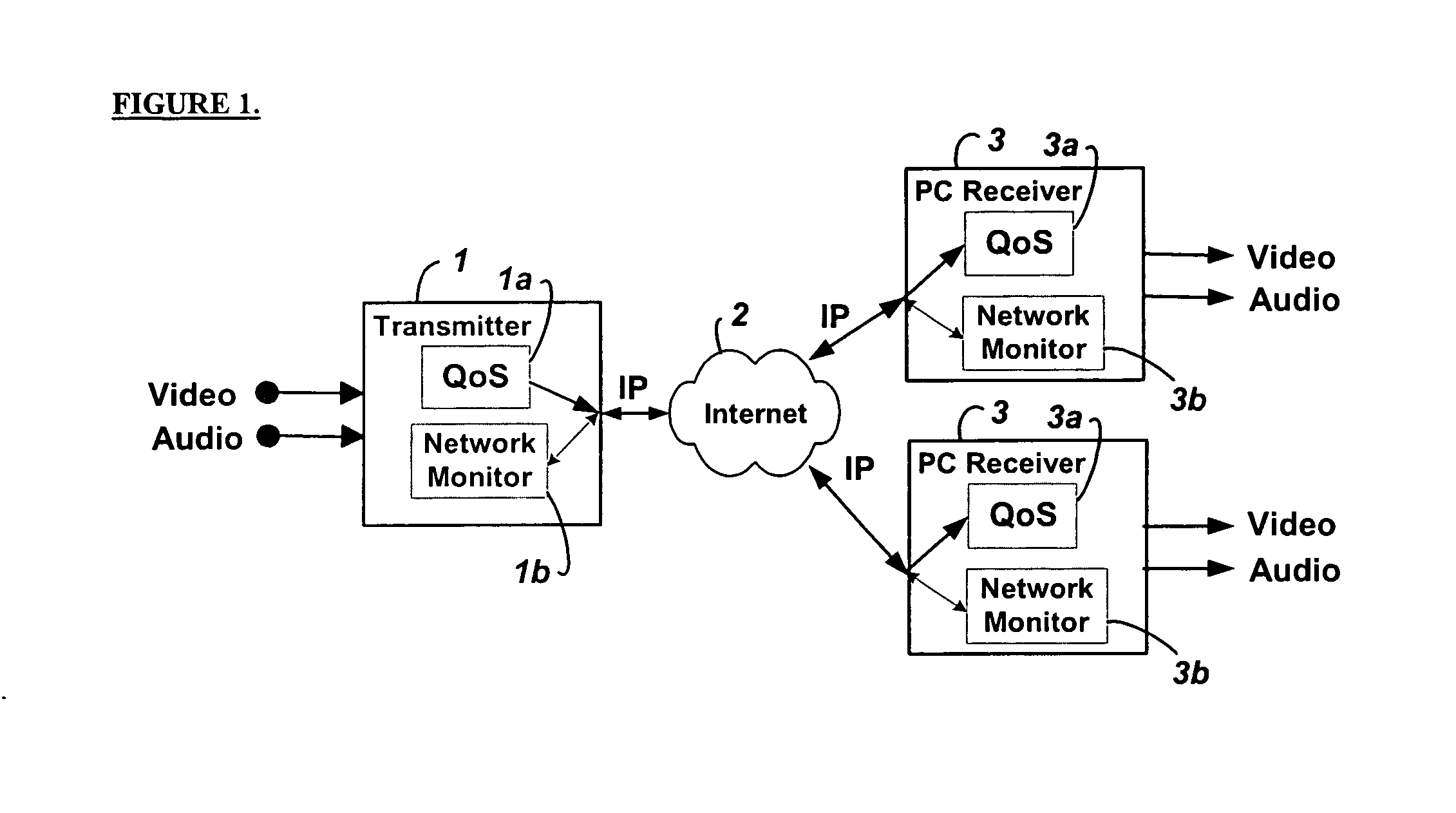

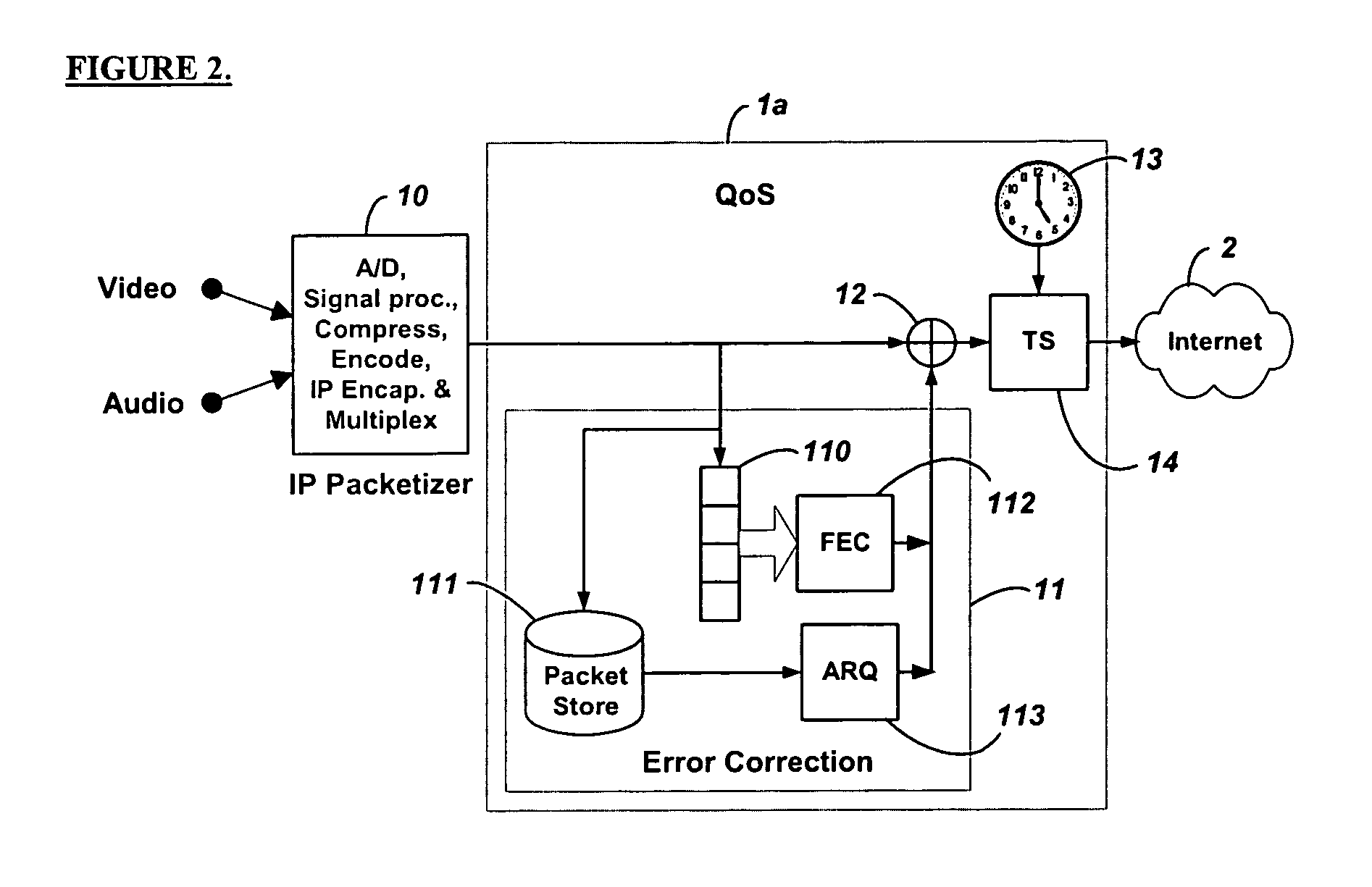

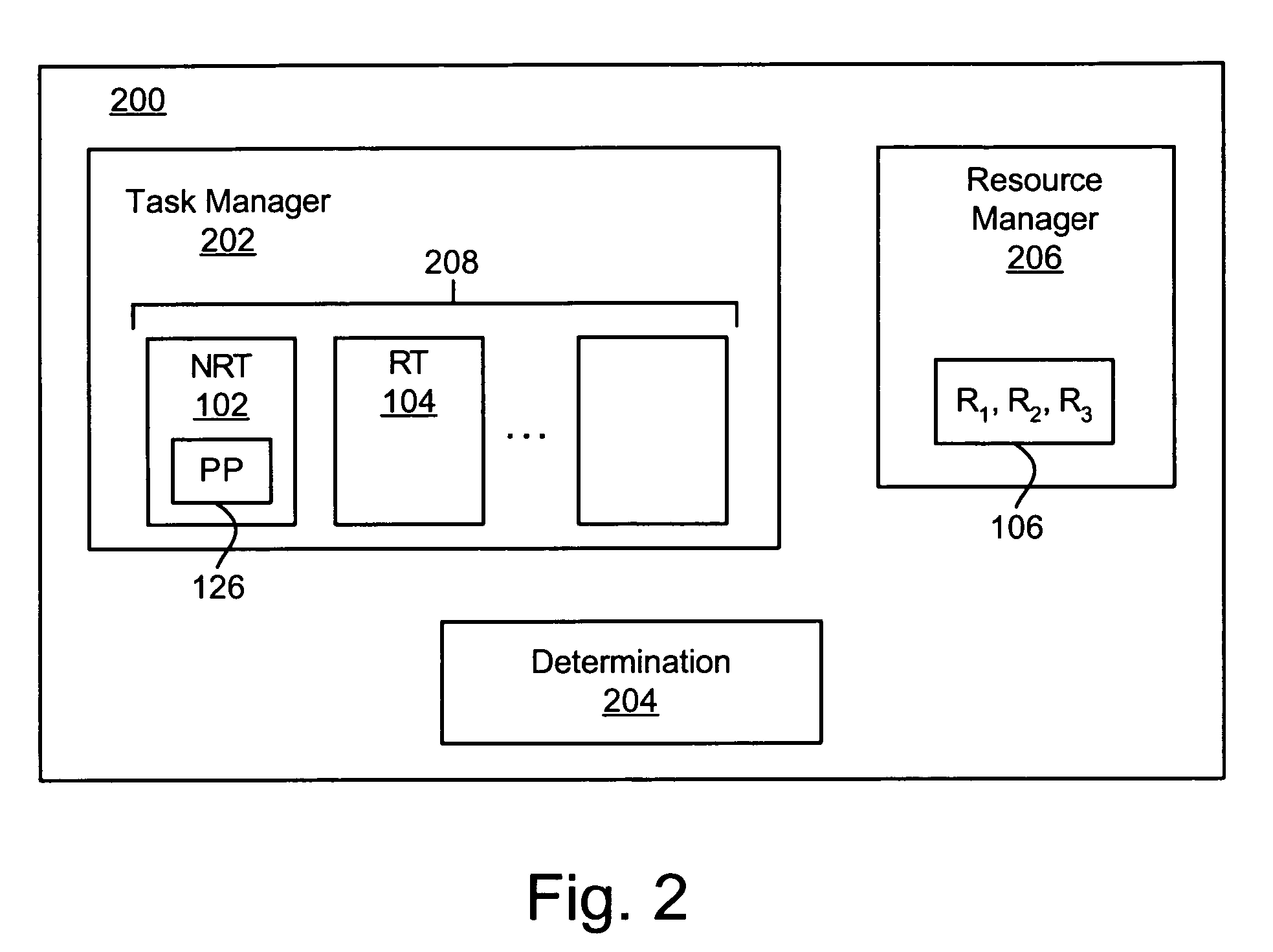

Method and system for providing site independent real-time multimedia transport over packet-switched networks

InactiveUS20060007943A1Minimal latency site-independenceAchieve independenceTime-division multiplexData switching by path configurationData packTimestamp

Embodiments of the invention enable minimum latency site independent real-time video transport over packet switched networks. Some examples of real-time video transport are video conferencing and real-time or live video streaming. In one embodiment of the invention, a network node transmits live or real-tine audio and video signals, encapsulated as Internet Protocol (IP) data packets, to one or more nodes on the Internet or other IP network. One embodiment of the invention enables a user to move to different nodes or move nodes to different locations thereby providing site independence. Site independence is achieved by measuring and accounting for the jitter and delay between a transmitter and receiver based on the particular path between the transmitter and receiver independent of site location. The transmitter inserts timestamps and sequence numbers into packets and then transmits them. A receiver uses these timestamps to recover the transmitter's clock. The receiver stores the packets in a buffer that orders them by sequence number. The packets stay in the buffer for a fixed latency to compensate for possible network jitter and / or packet reordering. The combination of timestamp packet-processing, remote clock recovery and synchronization, fixed-latency receiver buffering, and error correction mechanisms help to preserve the quality of the received video, despite the significant network impairments generally encountered throughout the Internet and wireless networks.

Owner:QVIDIUM TECH

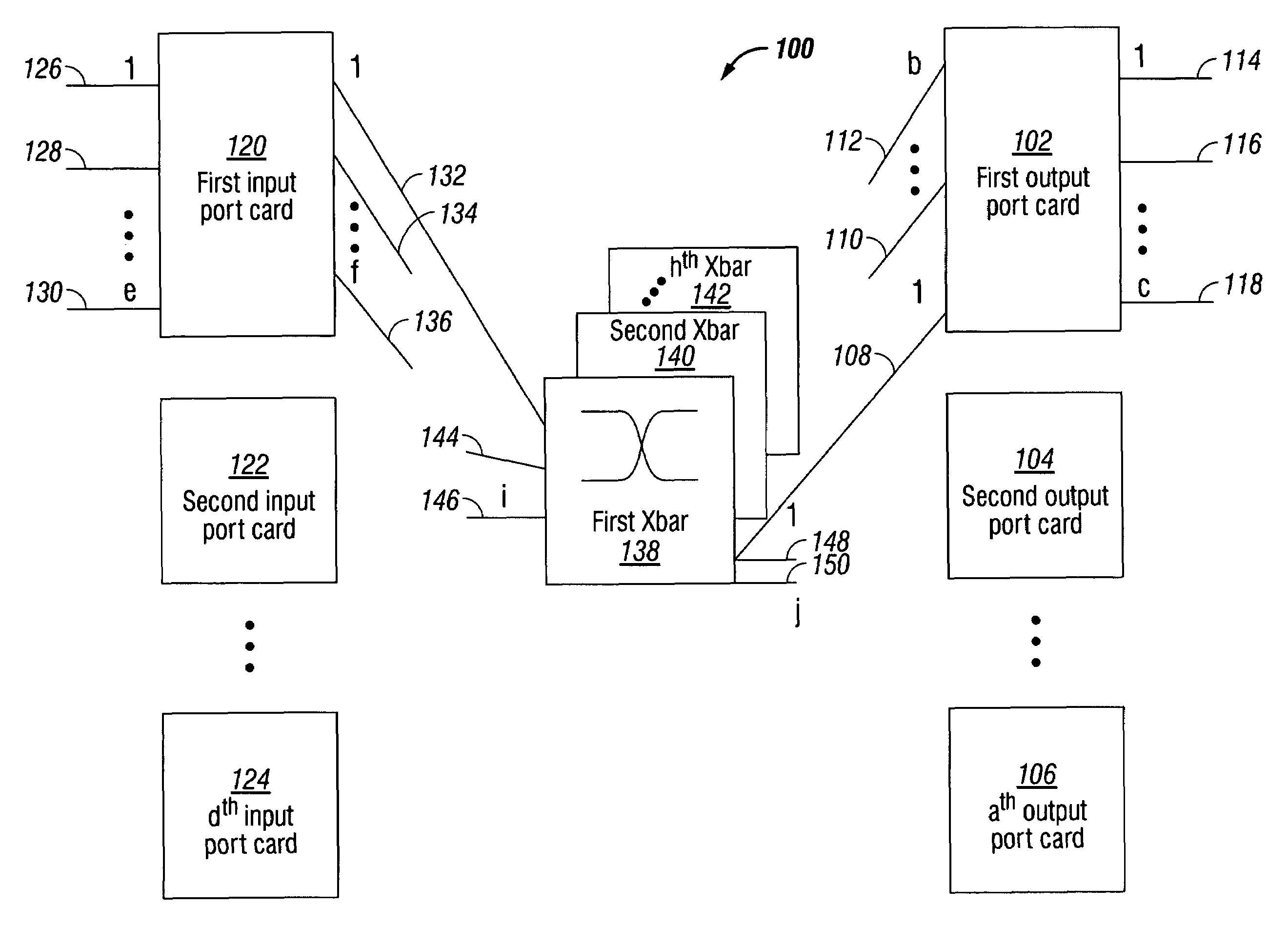

Minimum latency cut-through switch fabric

InactiveUS7230947B1Multiplex system selection arrangementsData switching by path configurationPacket communicationCut-through switching

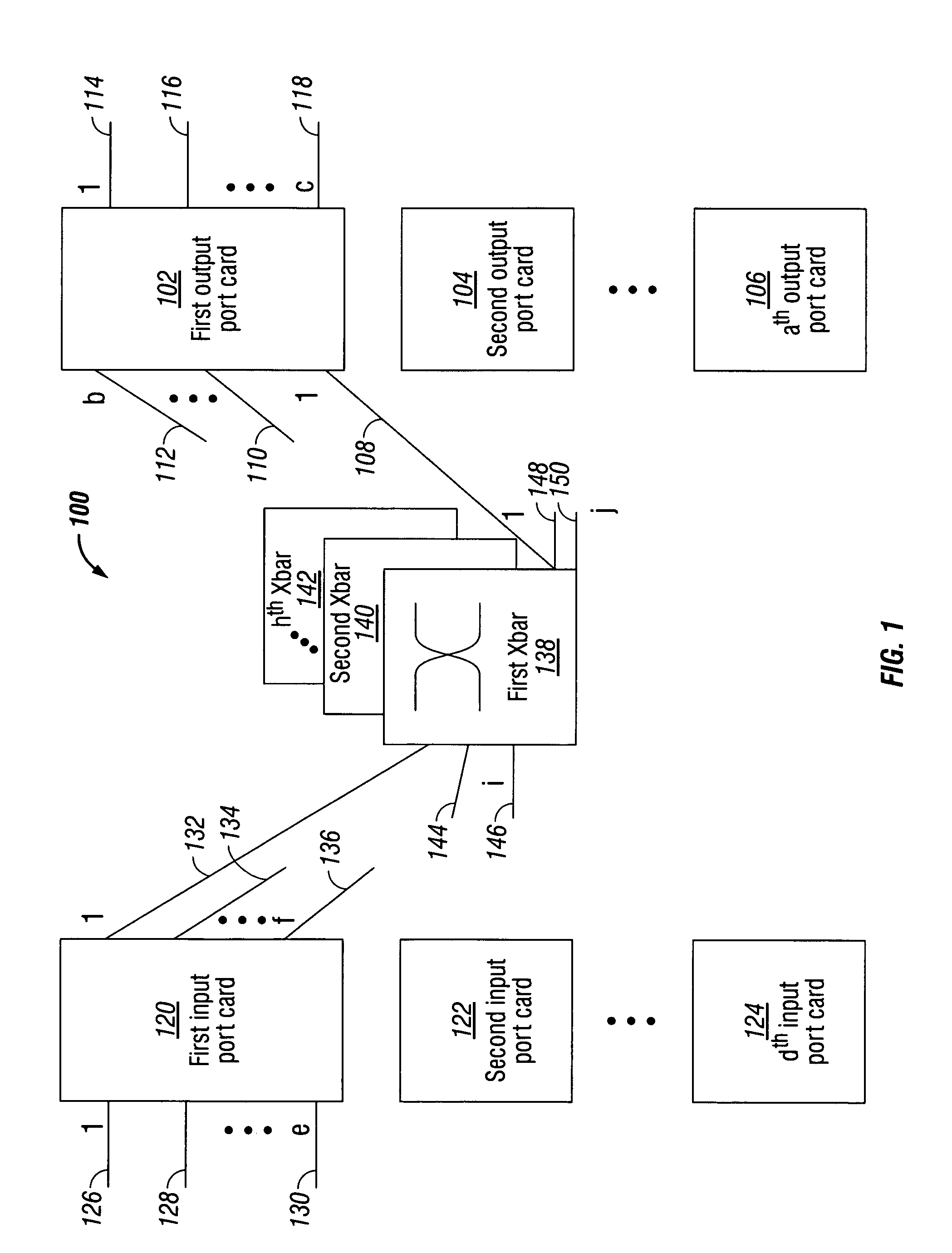

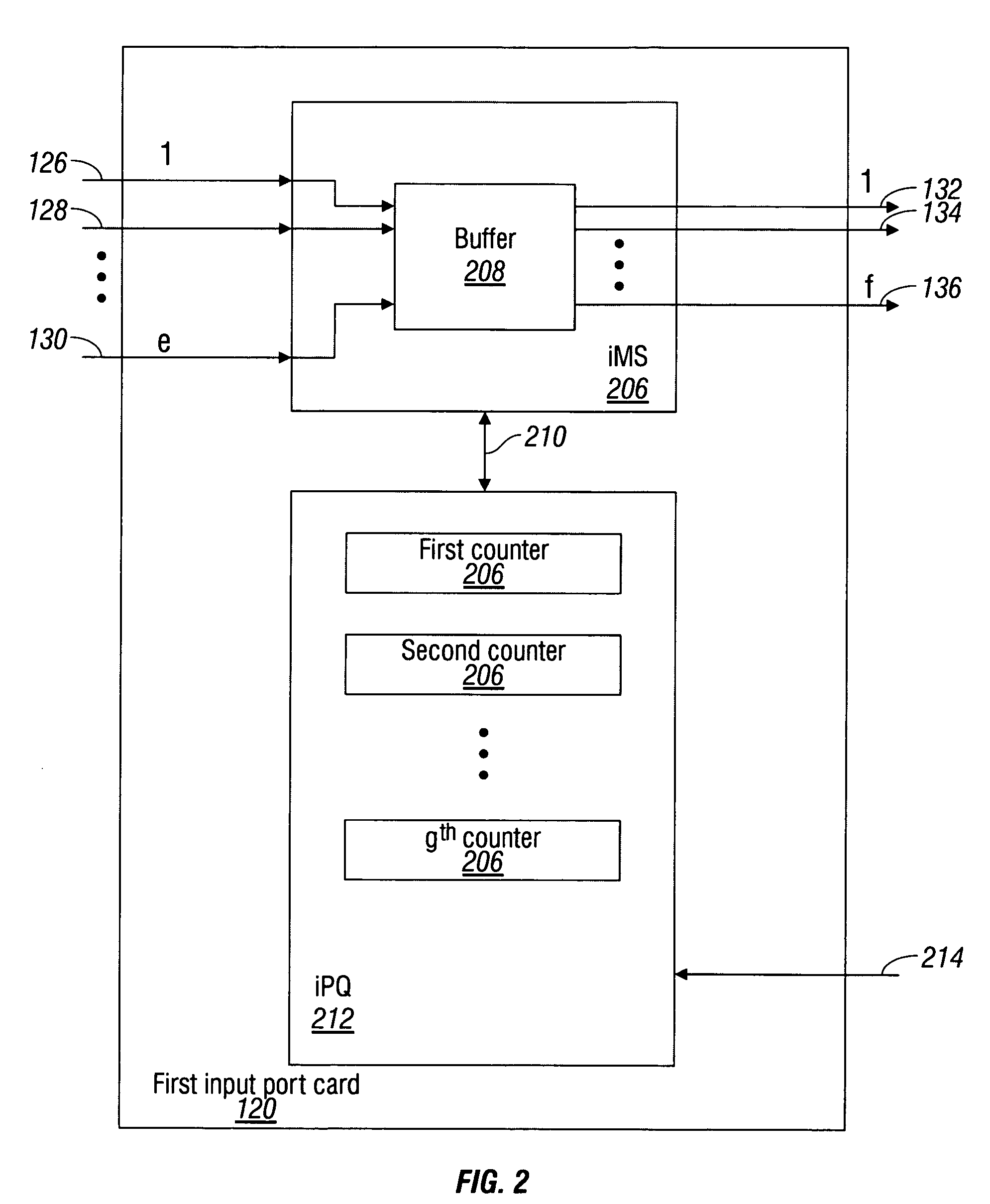

A system and method are provided for cut-through packet routing in a packet communications switch fabric. The method comprises: accepting information packets addressed to a plurality of output port card egress ports at an input port card ingress port; routing information packets between port cards on backplane data links through an intervening crossbar; maintaining a credit counter for each port card egress destination, at the input port card; decrementing the counter in response to transmitting cells in a packet from the input port card; and, incrementing the counter in response to transmitting cells from the packet at the output port card. In some aspects of the method, accepting information includes buffering the packets in an ingress memory subsystem (iMS). Routing information includes the iMS transmitting buffered packets on a selected backplane data link. Decrementing the counter includes the iMS communicating with the iPQ in response to transmitting a cell.

Owner:QUALCOMM INC

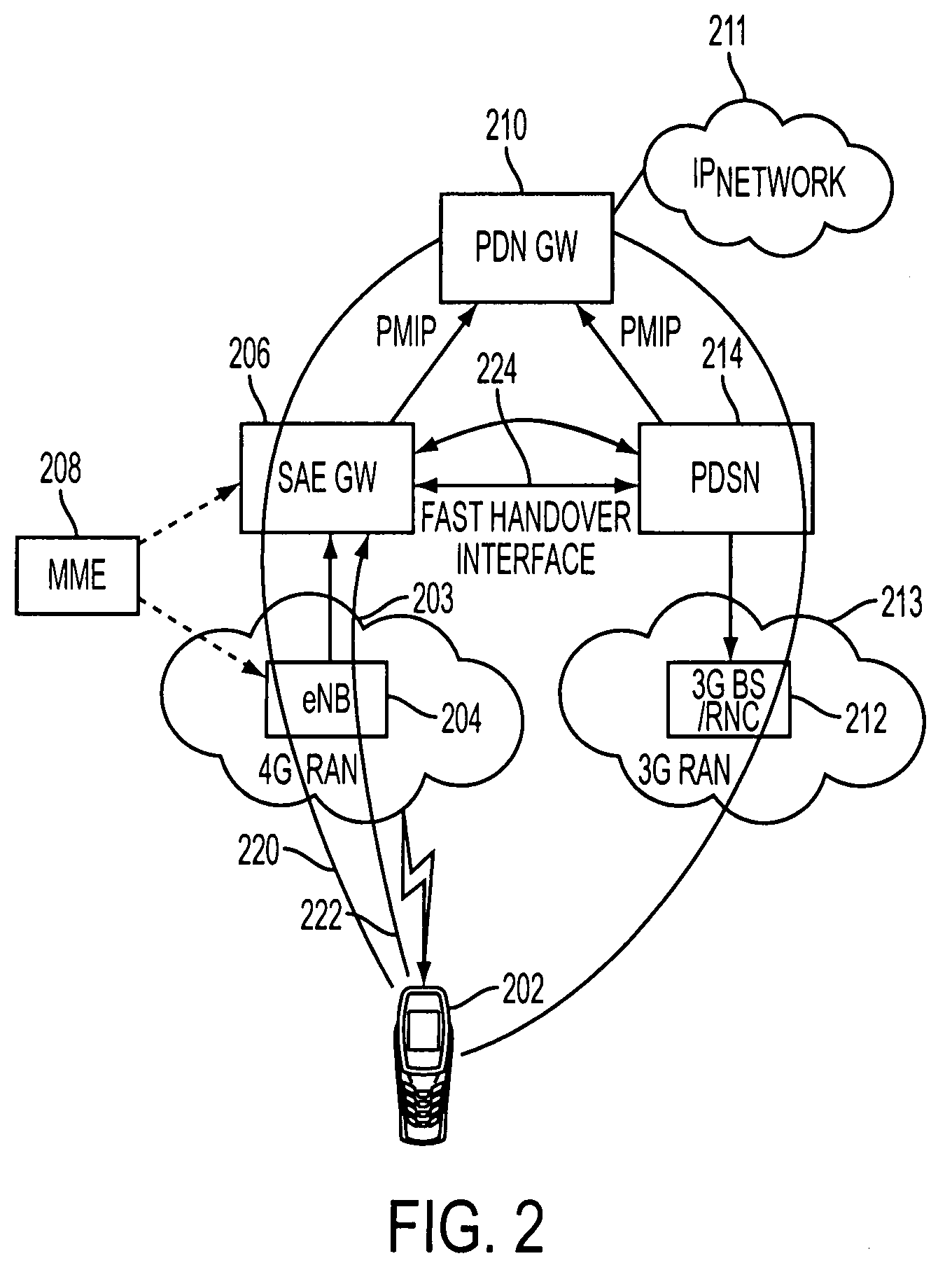

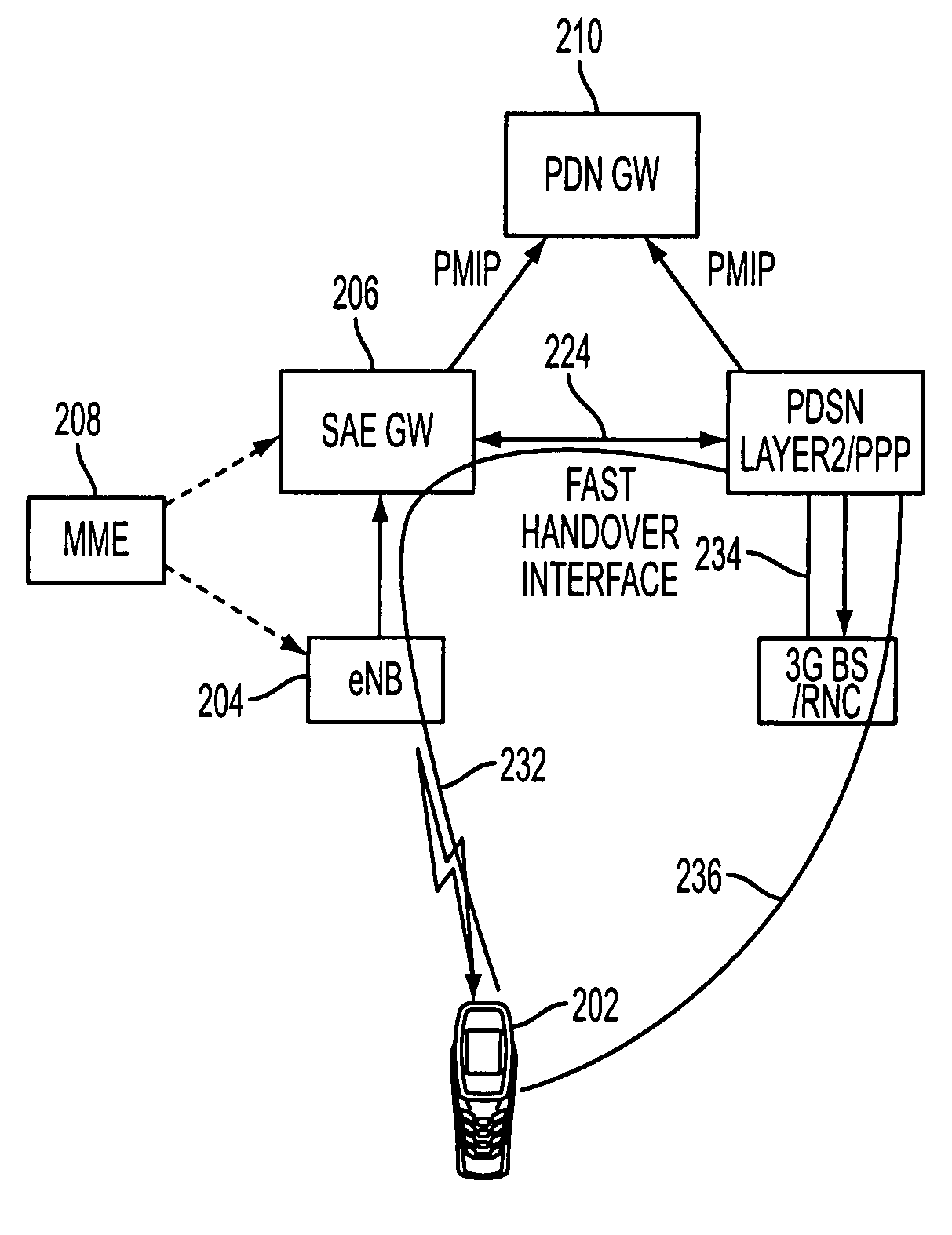

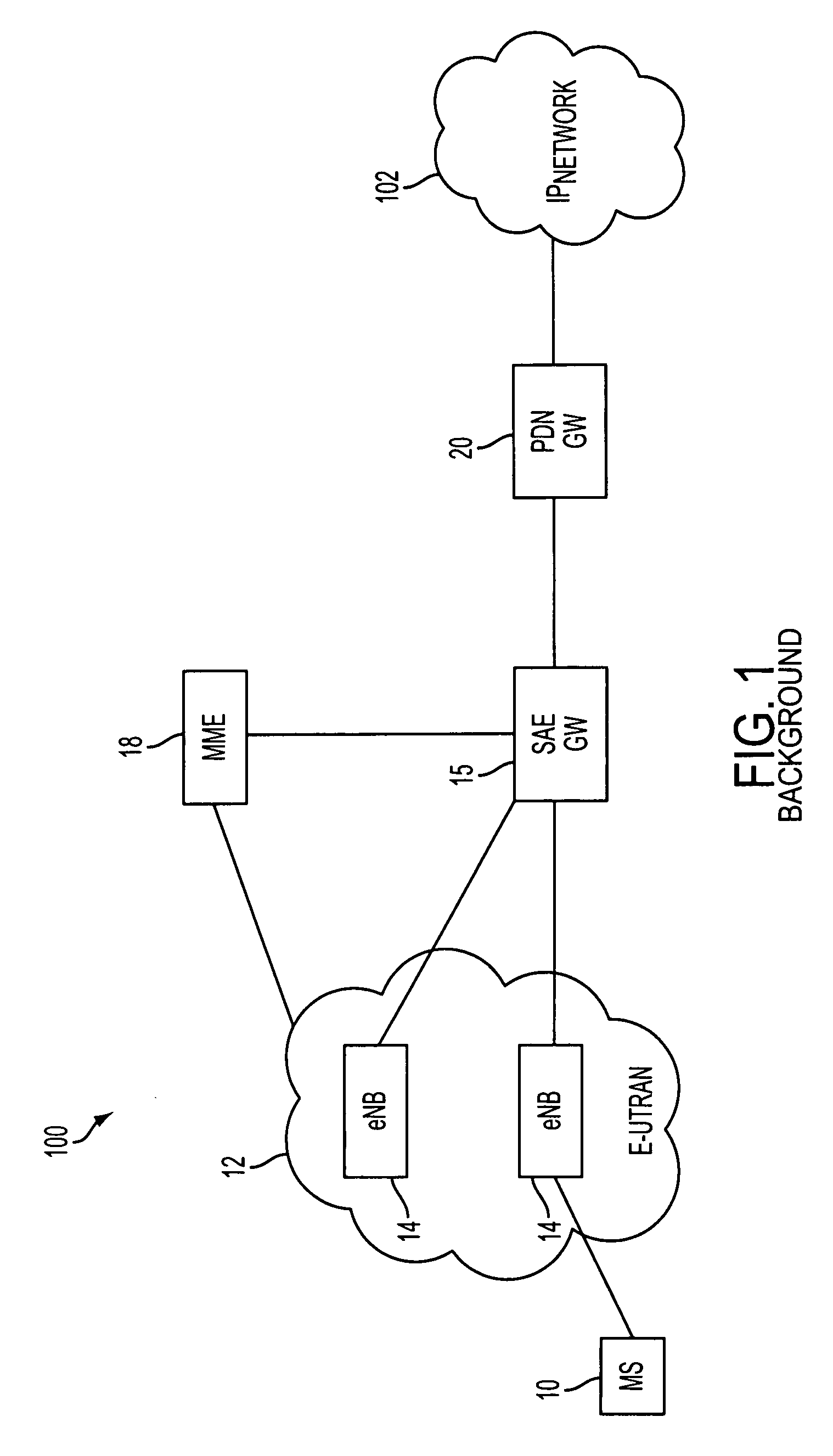

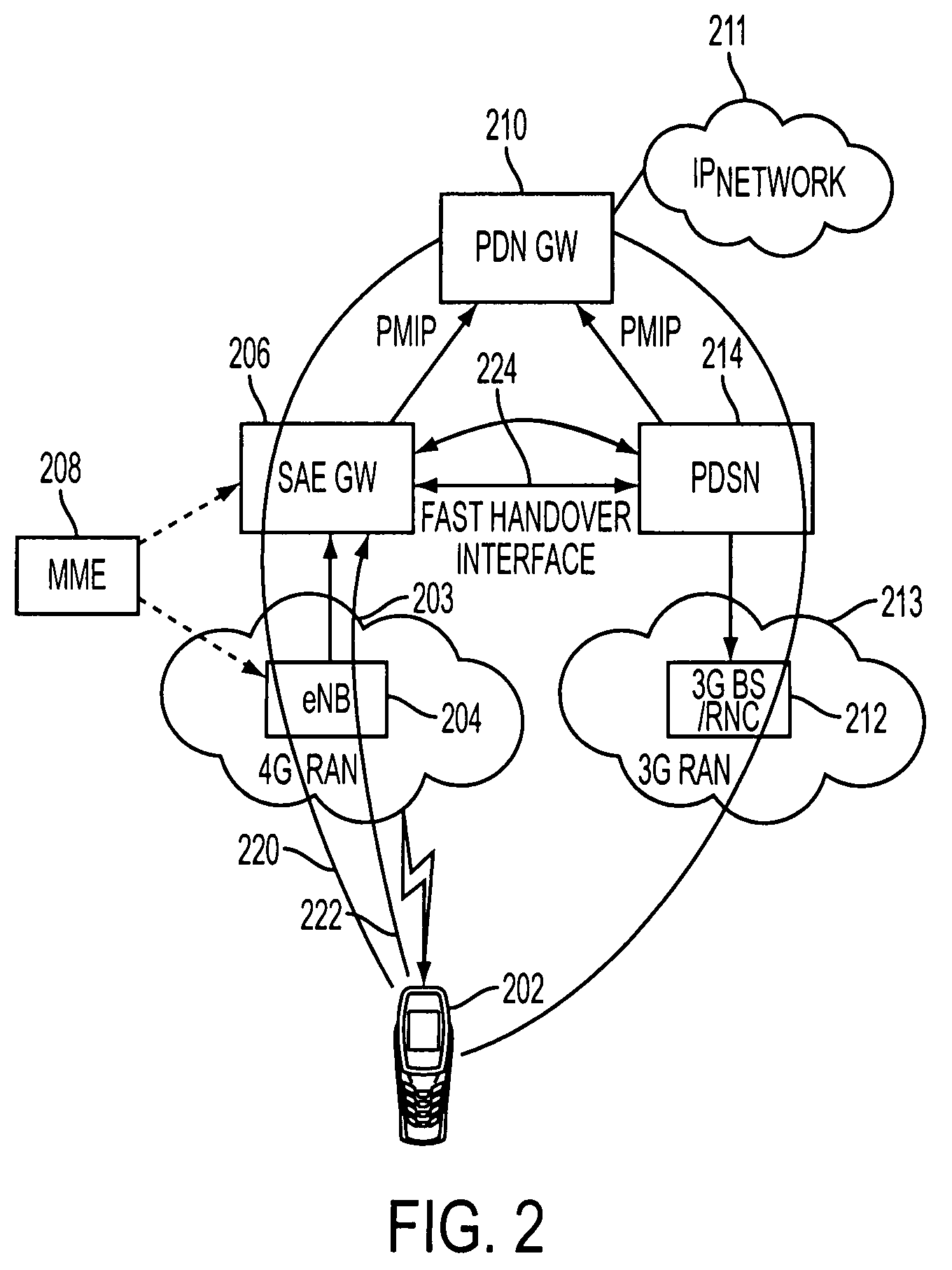

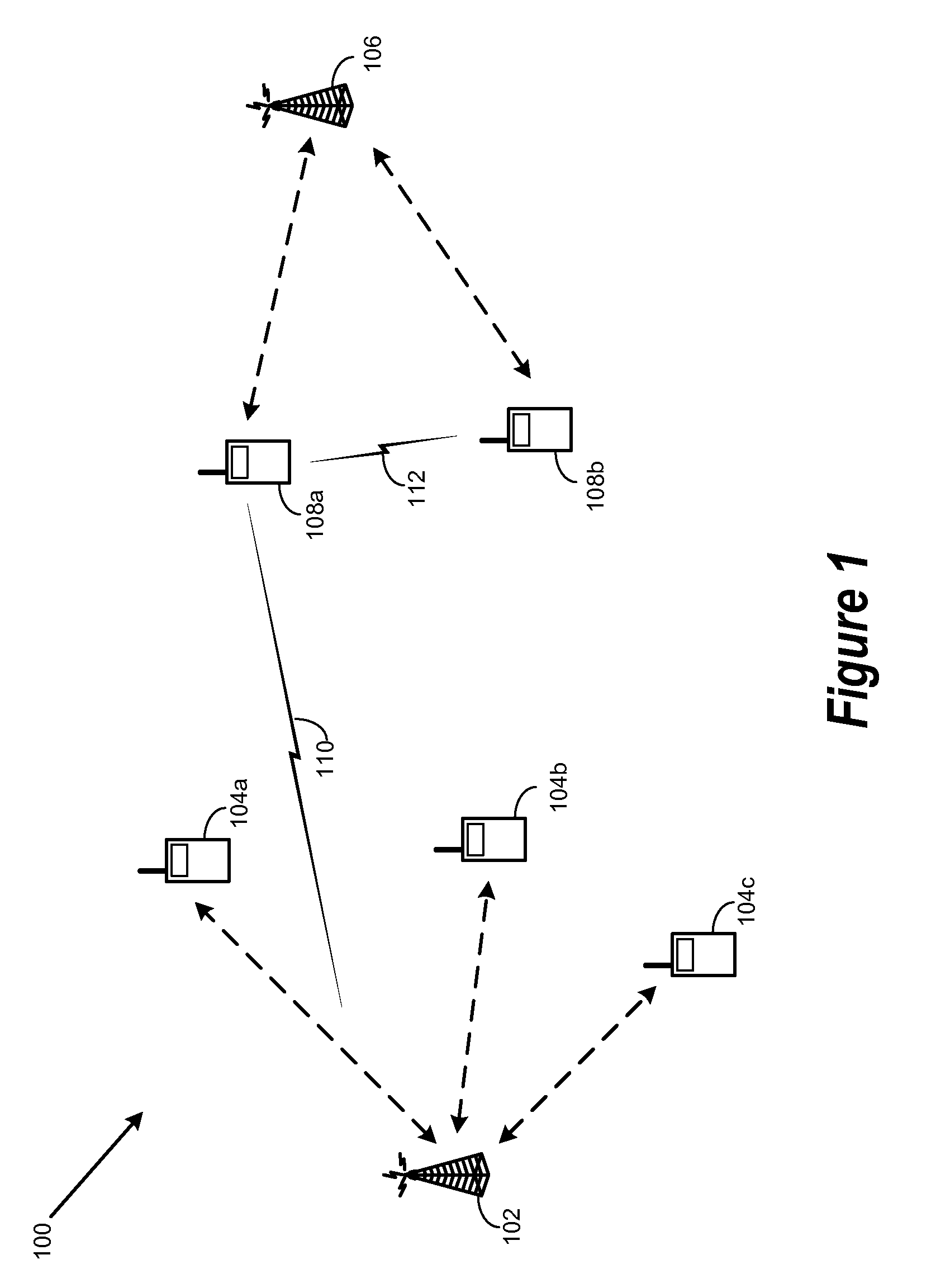

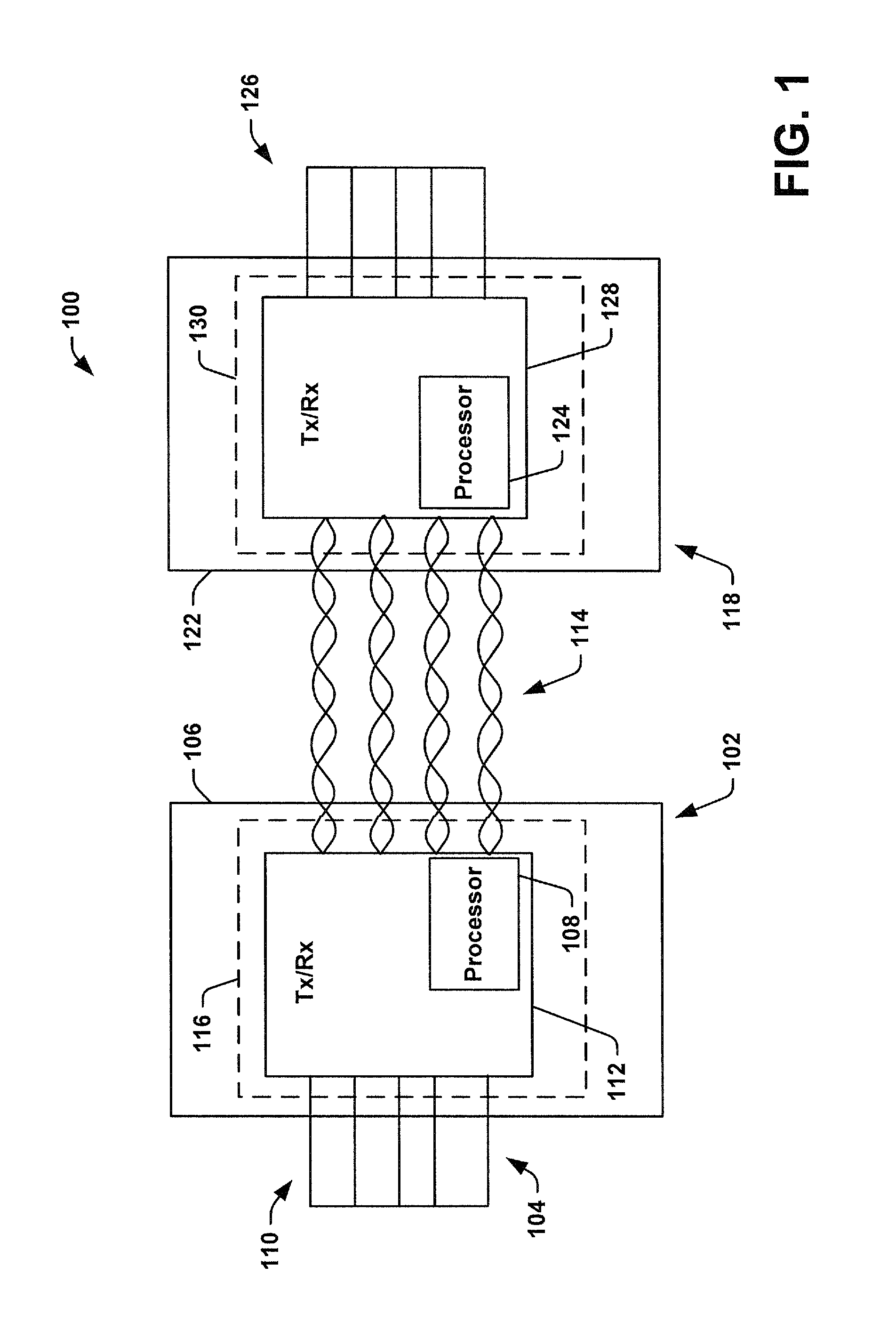

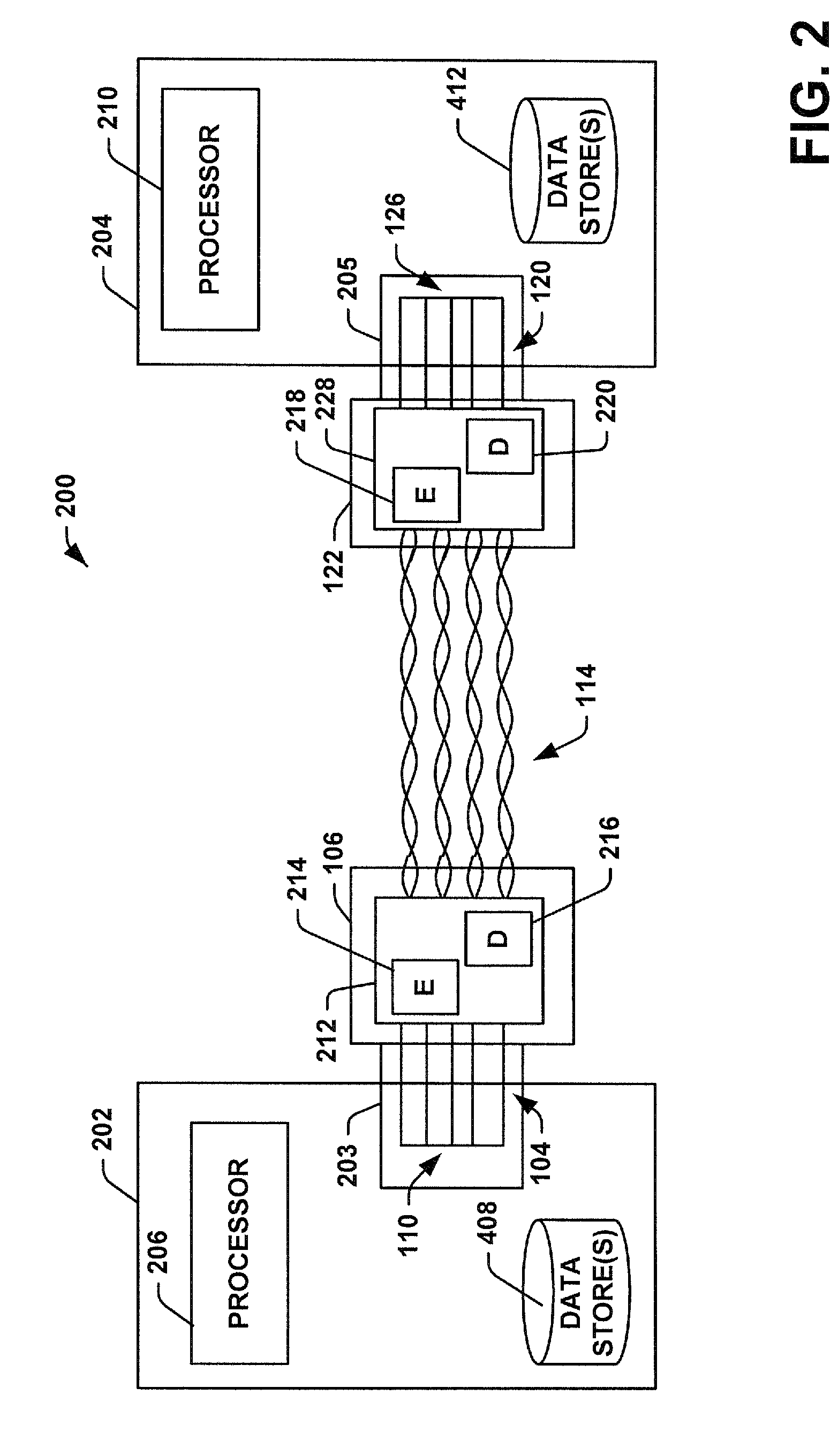

Low latency handover between wireless communication networks using different radio access technologies

ActiveUS20090201878A1Minimum delayRadio/inductive link selection arrangementsWireless commuication servicesRadio access technologyAccess network

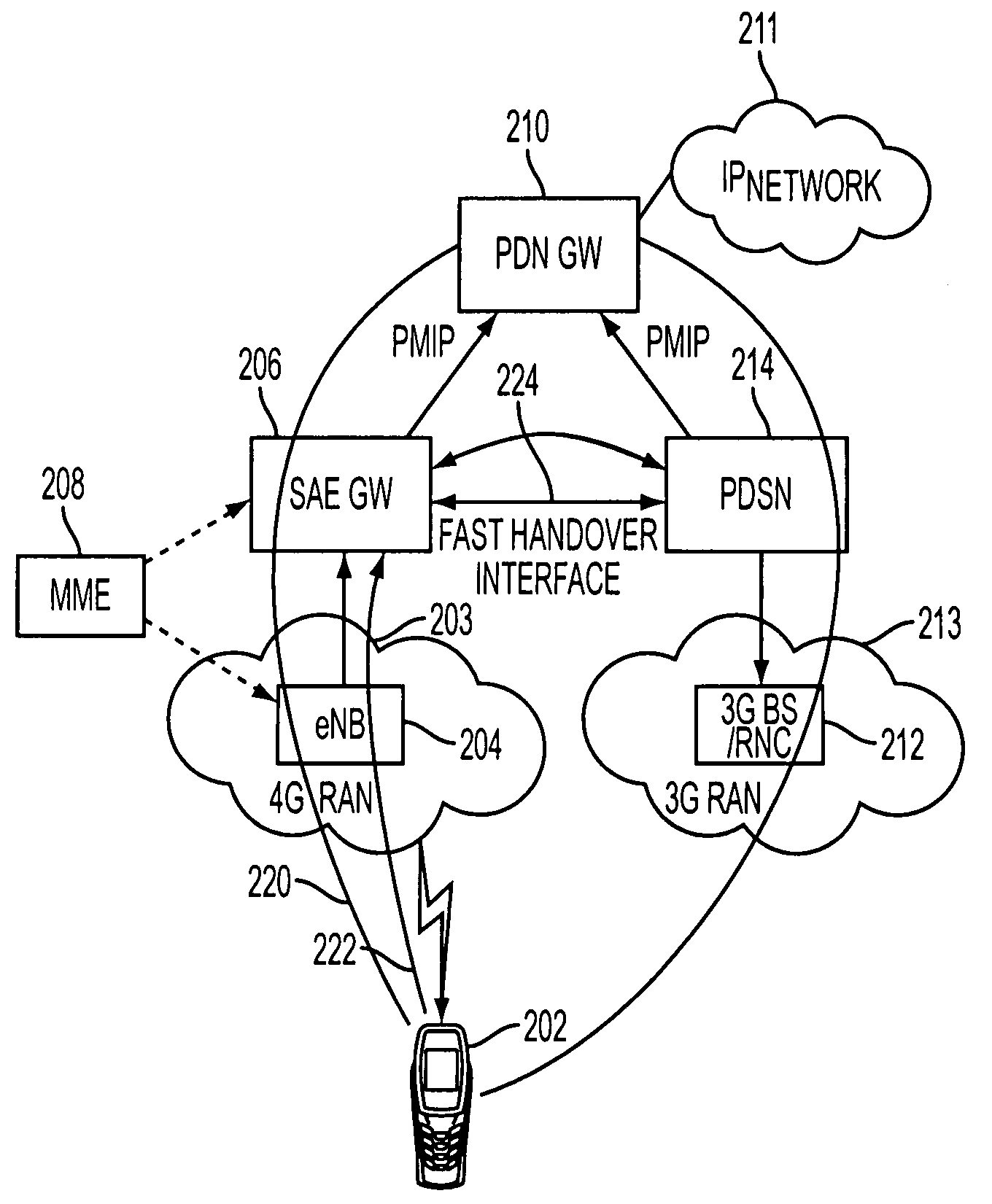

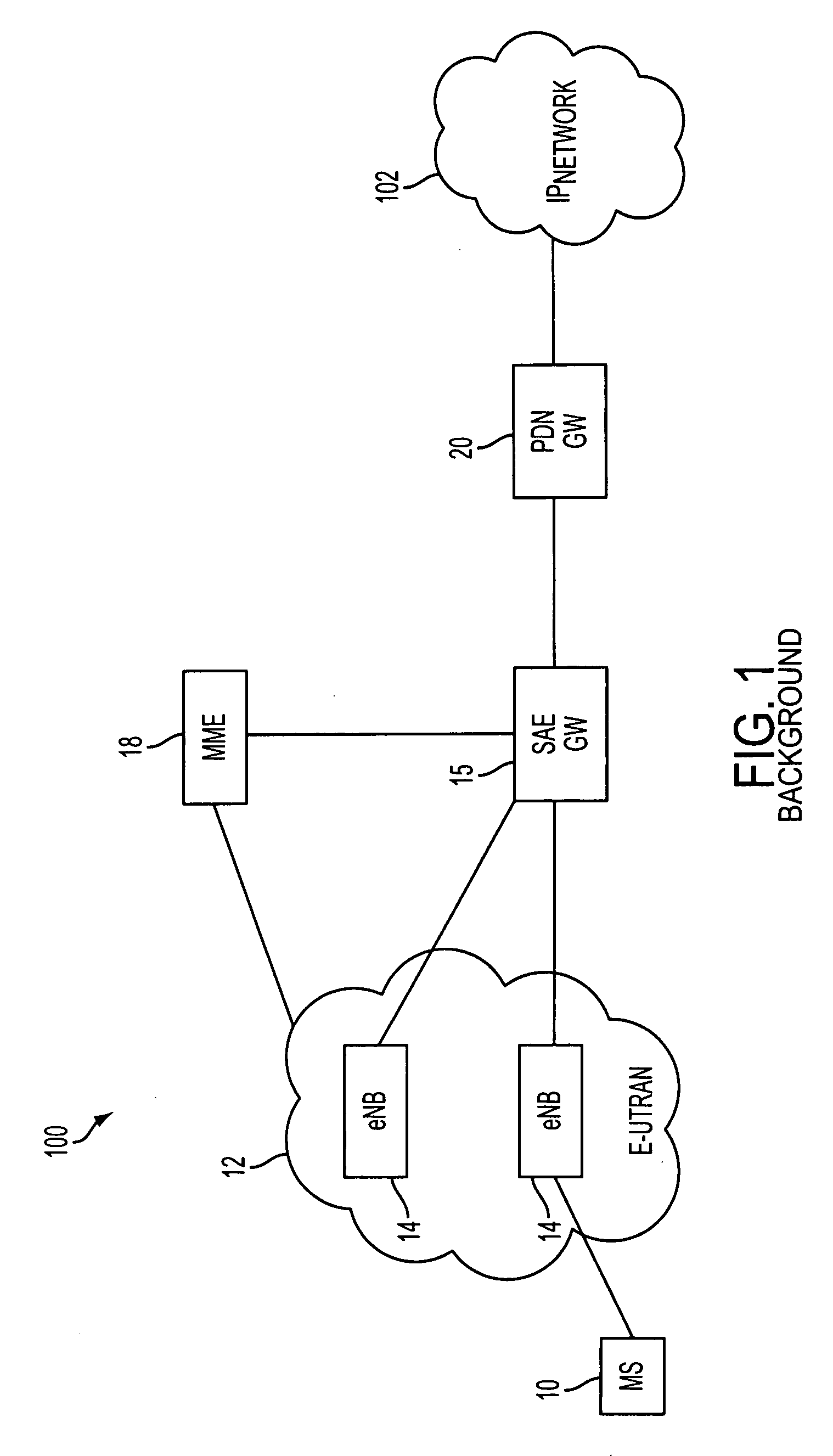

A communications system for providing a user's mobile station (MS) with an Internet Protocol (IP) connectivity, has an IP network gateway for allocating an IP address to the MS to enable it to access an IP network. First and second base stations are respectively configured to support communications of the MS over first and second radio access networks using different radio access technologies. A first access gateway provides an interface between the IP network gateway and the first radio access network, whereas a second access gateway provides an interface between the IP network gateway and the second radio access network. A handover interface is provided between the first access gateway and the second access gateway for enabling the MS to switch between the first and second radio access networks with minimum latency.

Owner:CELLO PARTNERSHIP DBA VERIZON WIRELESS

Method and apparatus for fail-safe resynchronization with minimum latency

InactiveUS20060022724A1Guaranteed uptimeMinimizes shiftingSynchronisation information channelsPulse automatic controlData latencyVoltage shift

Owner:RAMBUS INC

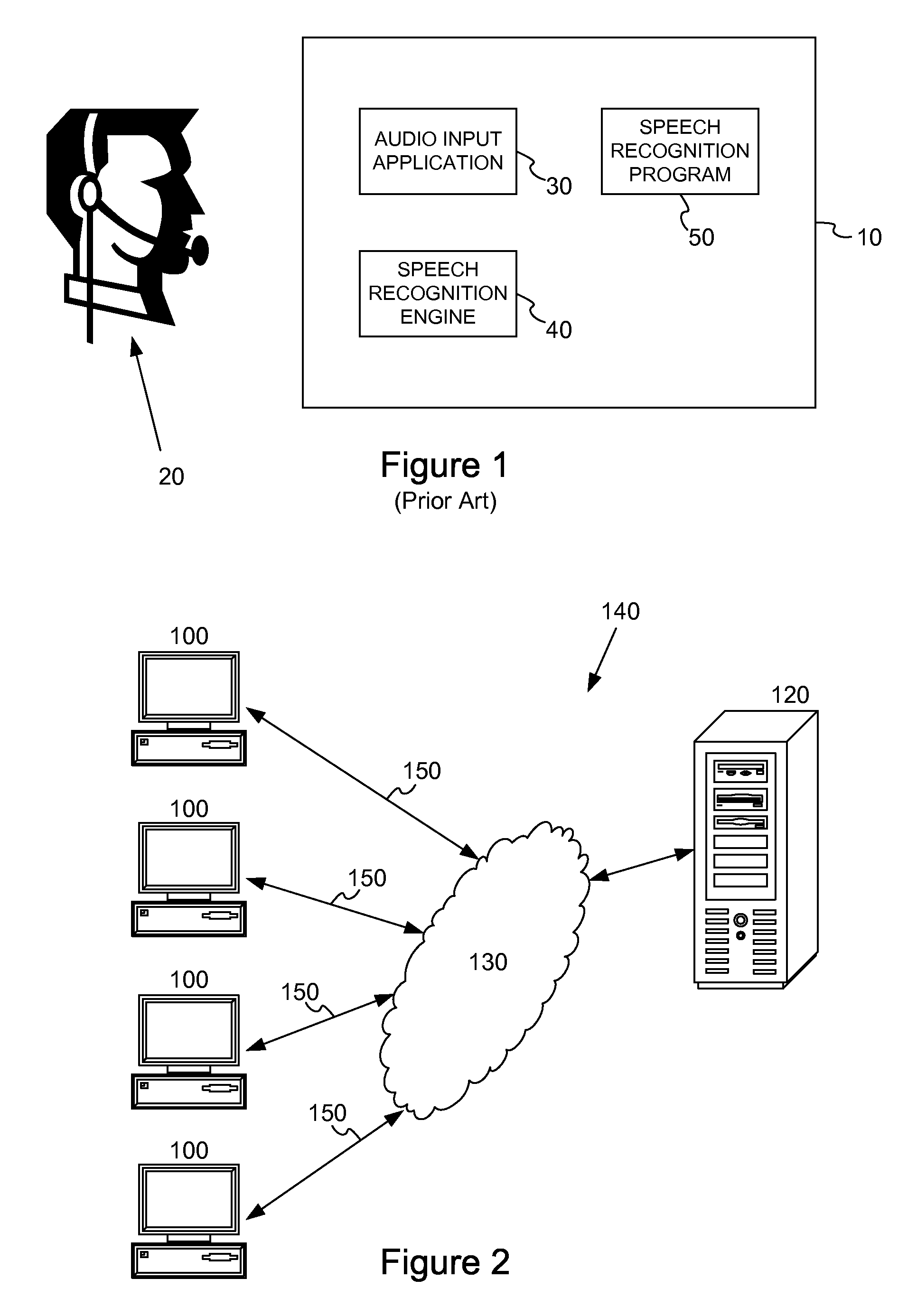

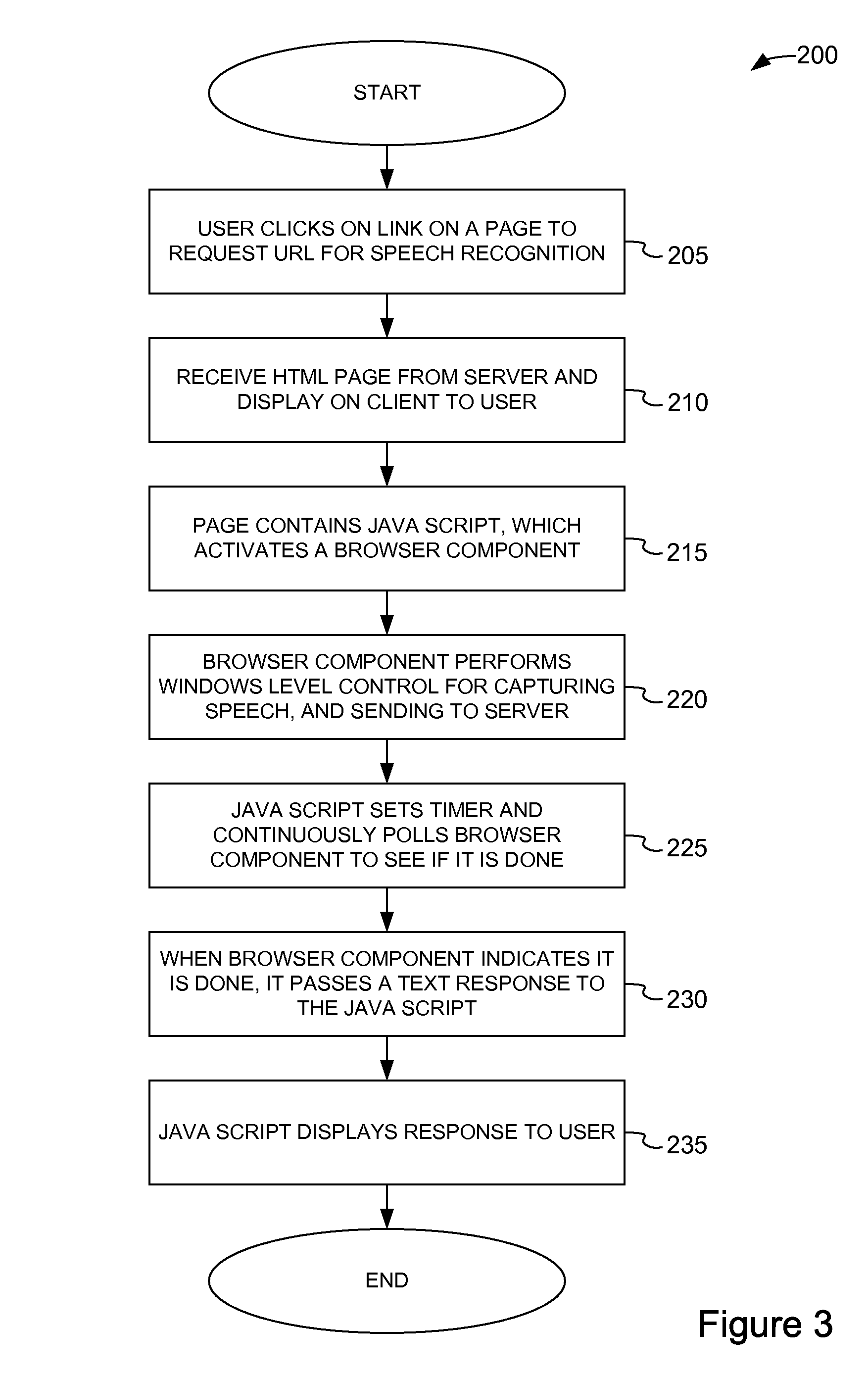

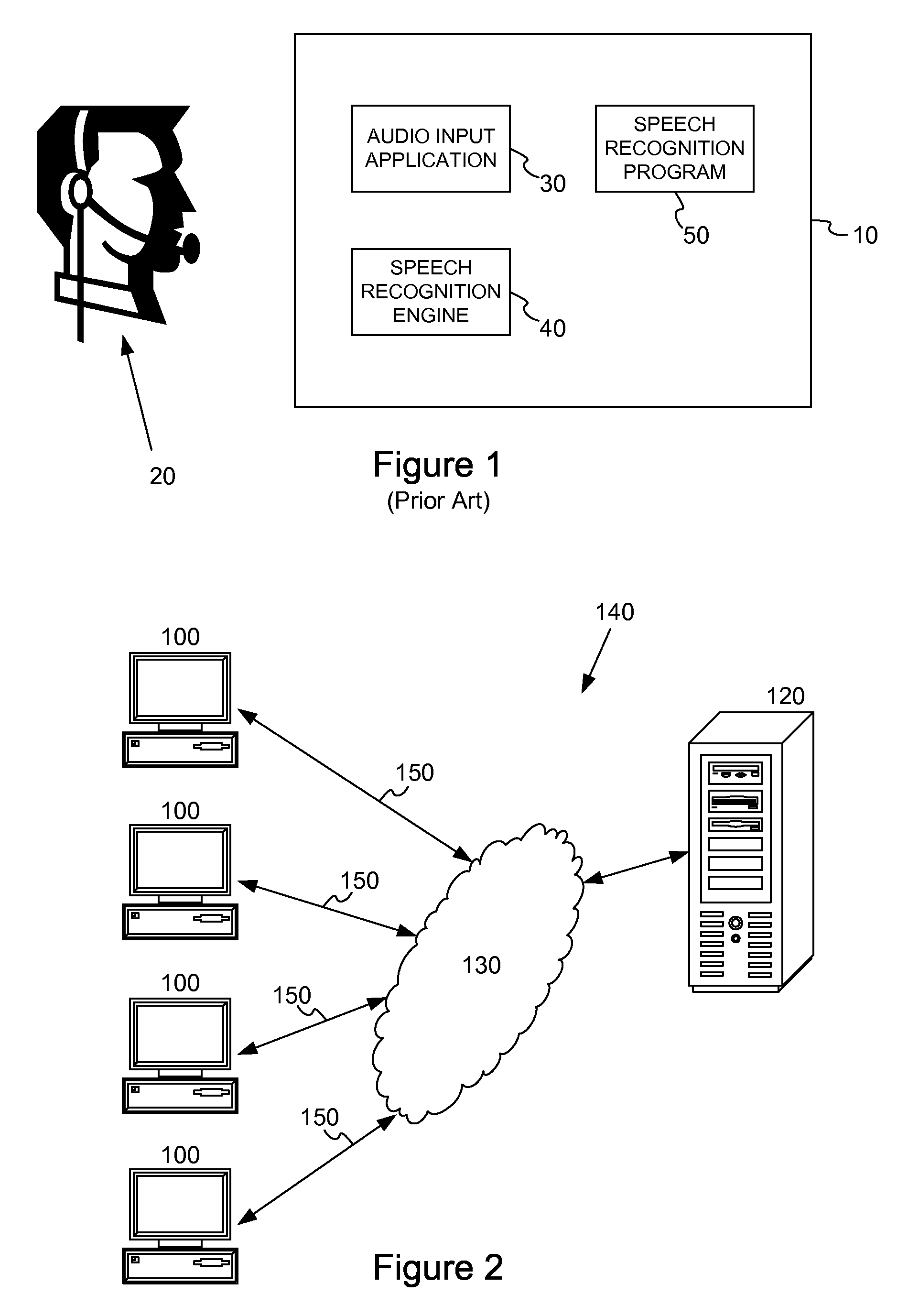

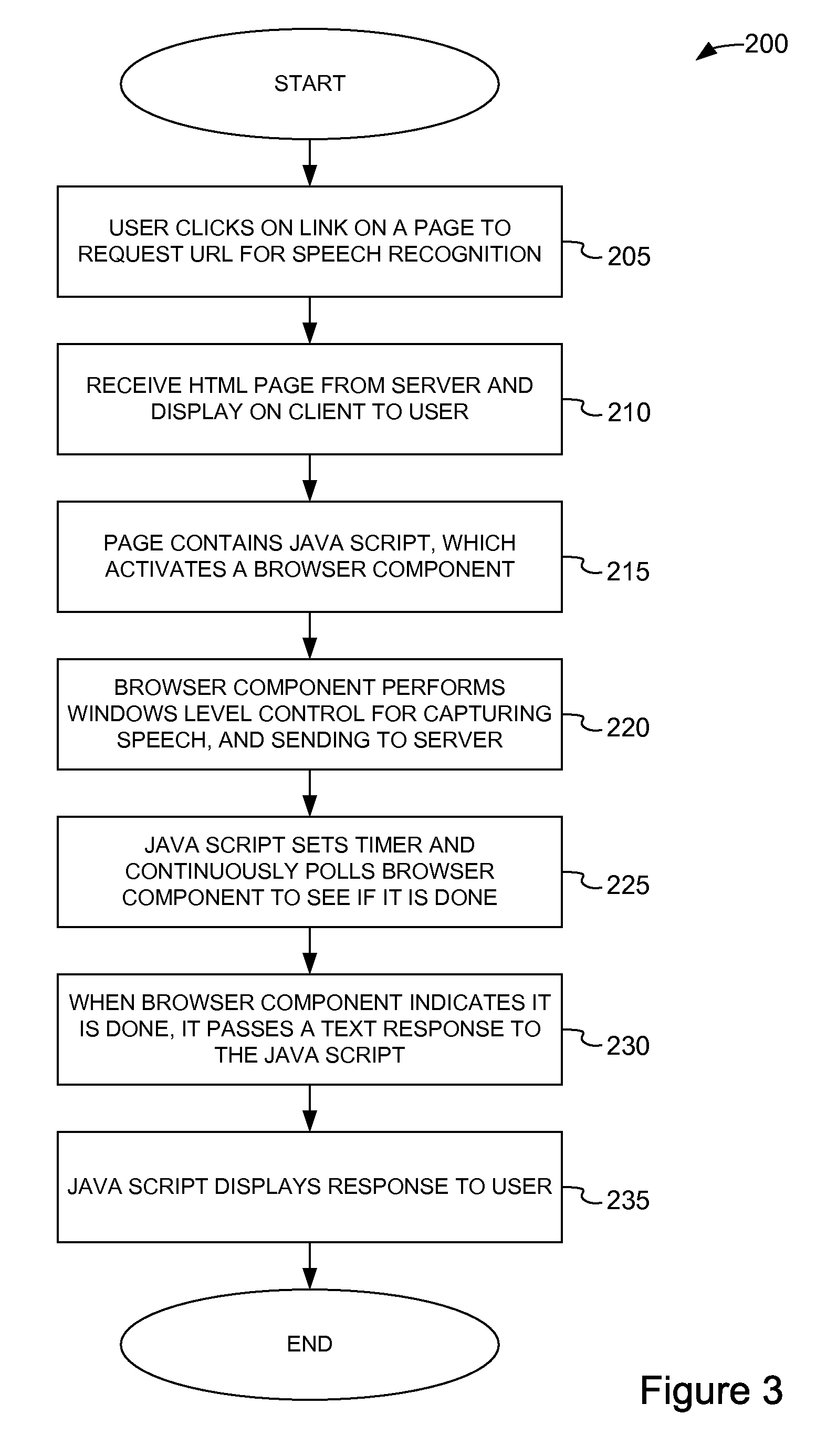

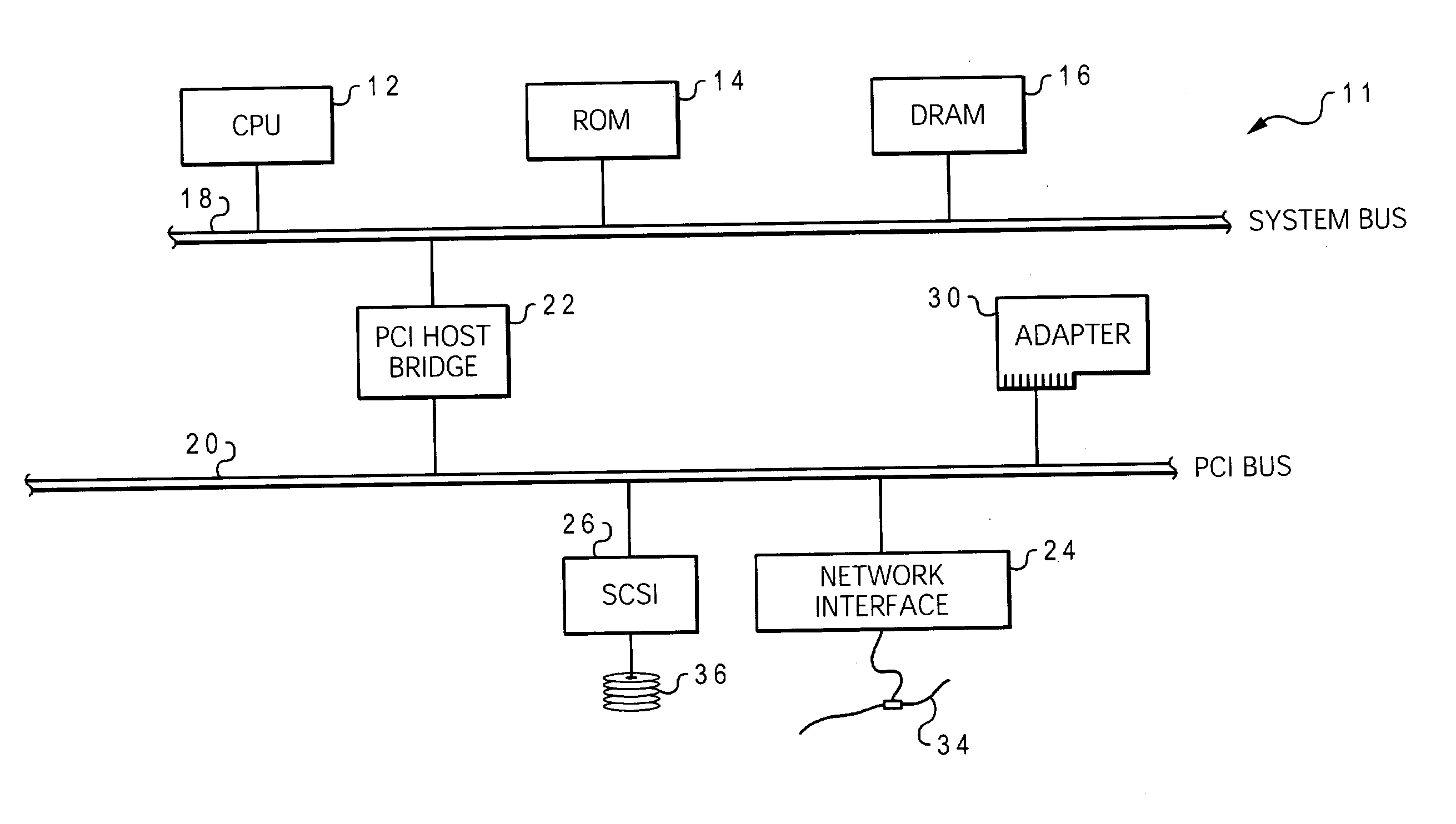

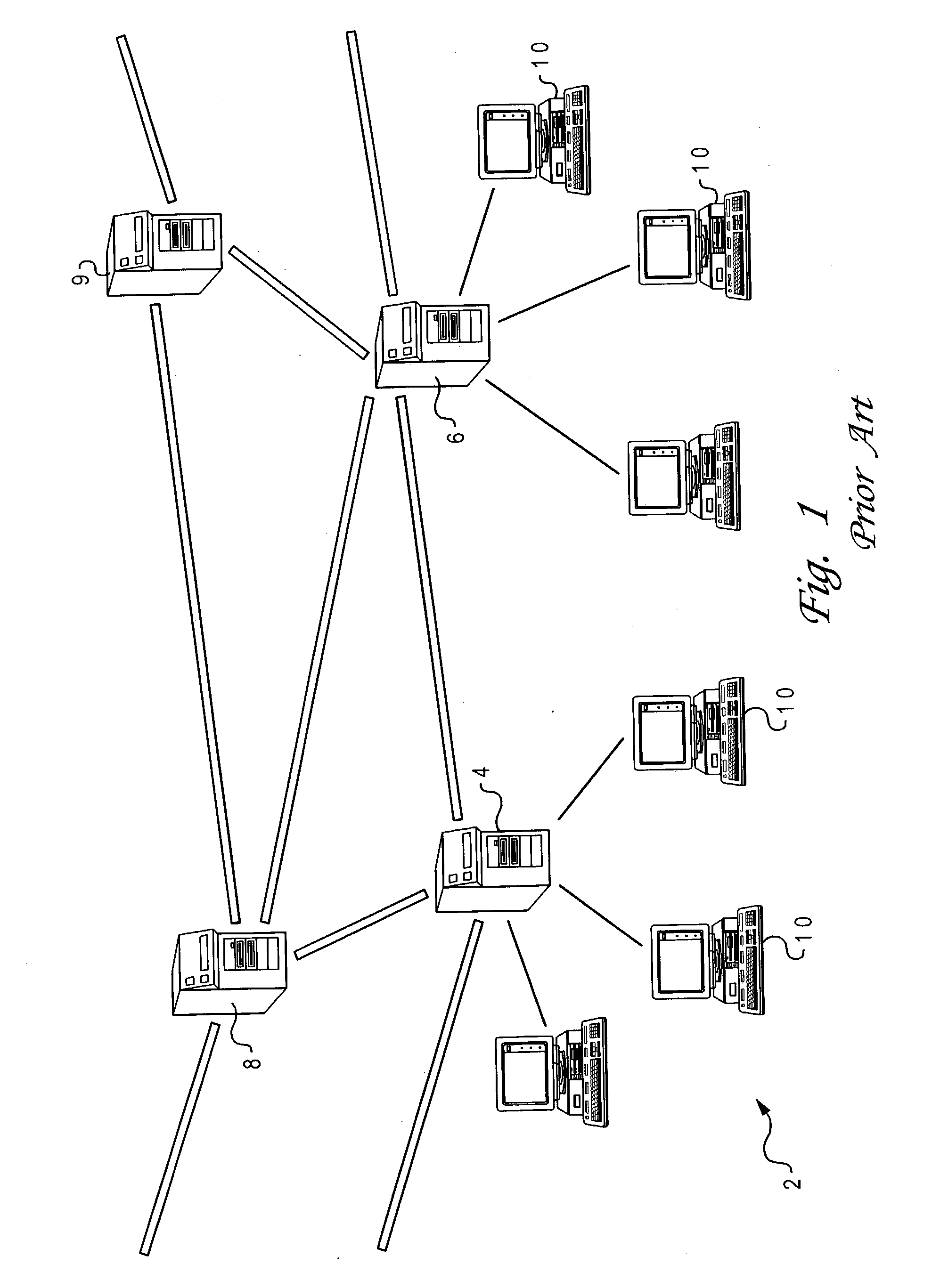

Method and system for network-based speech recognition

Methods and systems for handling speech recognition processing in effectively real-time, via the internet, in order that users do not experience noticeable delays from the start of an exercise until they receive responsive feedback. A user uses a client to access the internet and a server supporting speech recognition processing, e.g., for language learning activities. The user inputs speech to the client, which transmits the user speech to the server in approximate real-time. The server evaluates the user speech in context of the current speech recognition exercise being executed, and provides responsive feedback to the client, again, in approximate real-time, with minimum latency delays. The client upon receiving responsive feedback from the server, displays, or otherwise provides, the feedback to the user.

Owner:PEARSON EDUCATION

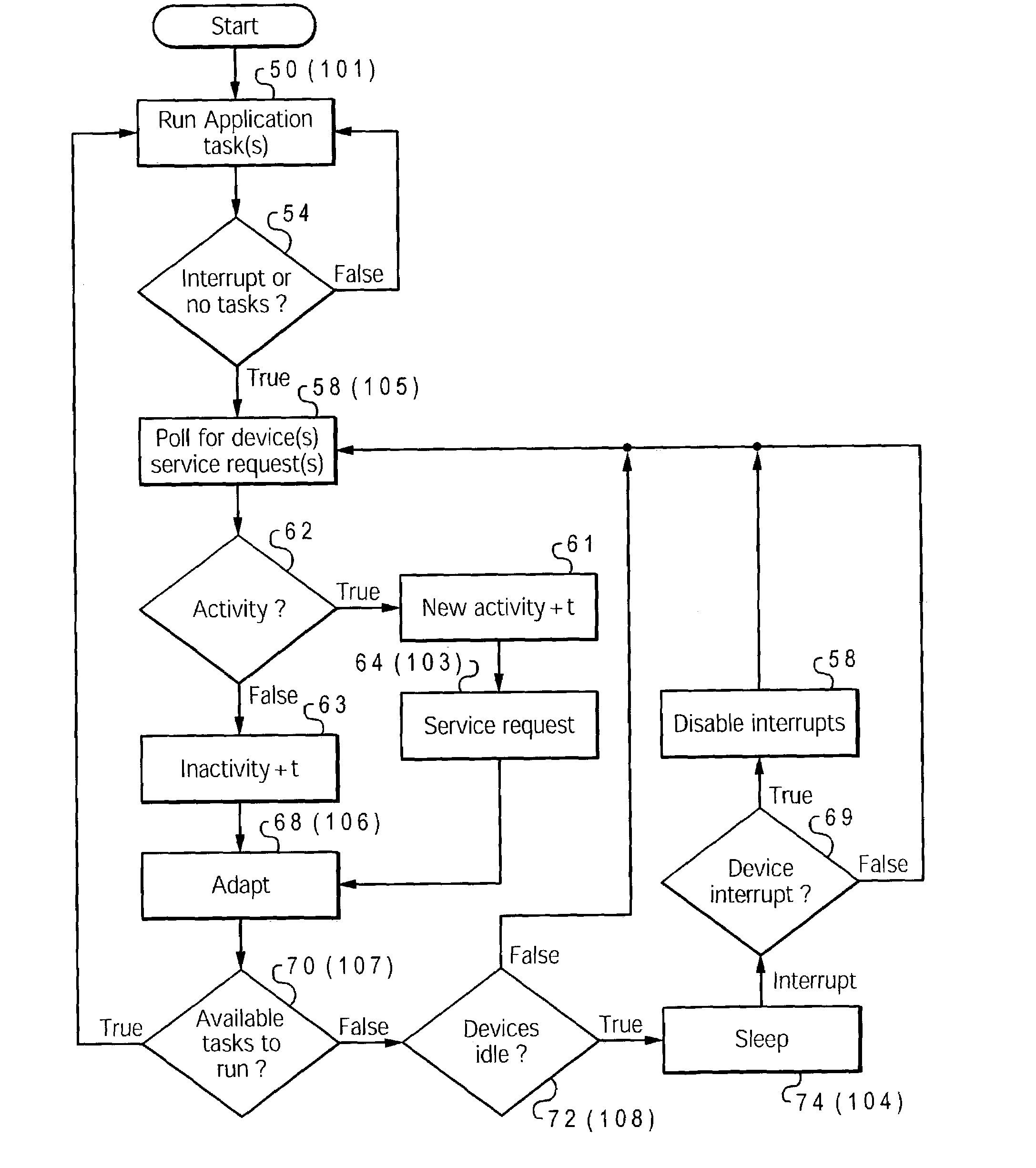

Power aware adaptive polling

ActiveUS7093141B2Simple methodEasy to handleVolume/mass flow measurementMultiple digital computer combinationsTime segmentPolling system

A method for adapting the periodicity of polling for pending service requests, by polling system devices for pending service requests, recording whether or not there was a pending service request and, based on accumulated data, determining whether or not the system devices are idle. Based on this determination, the system may elect to enter a power conservation mode until device activity is signaled, or an adjustable period of time elapses. The adaptation mechanism may alter the periodicity of the timer interrupt, disable or enable device interrupts, and modify variables used to determine system idleness (including minimum latency and minimum idleness thresholds). In this manner, the system can conserve power while maintaining system performance and responsiveness.

Owner:IBM CORP

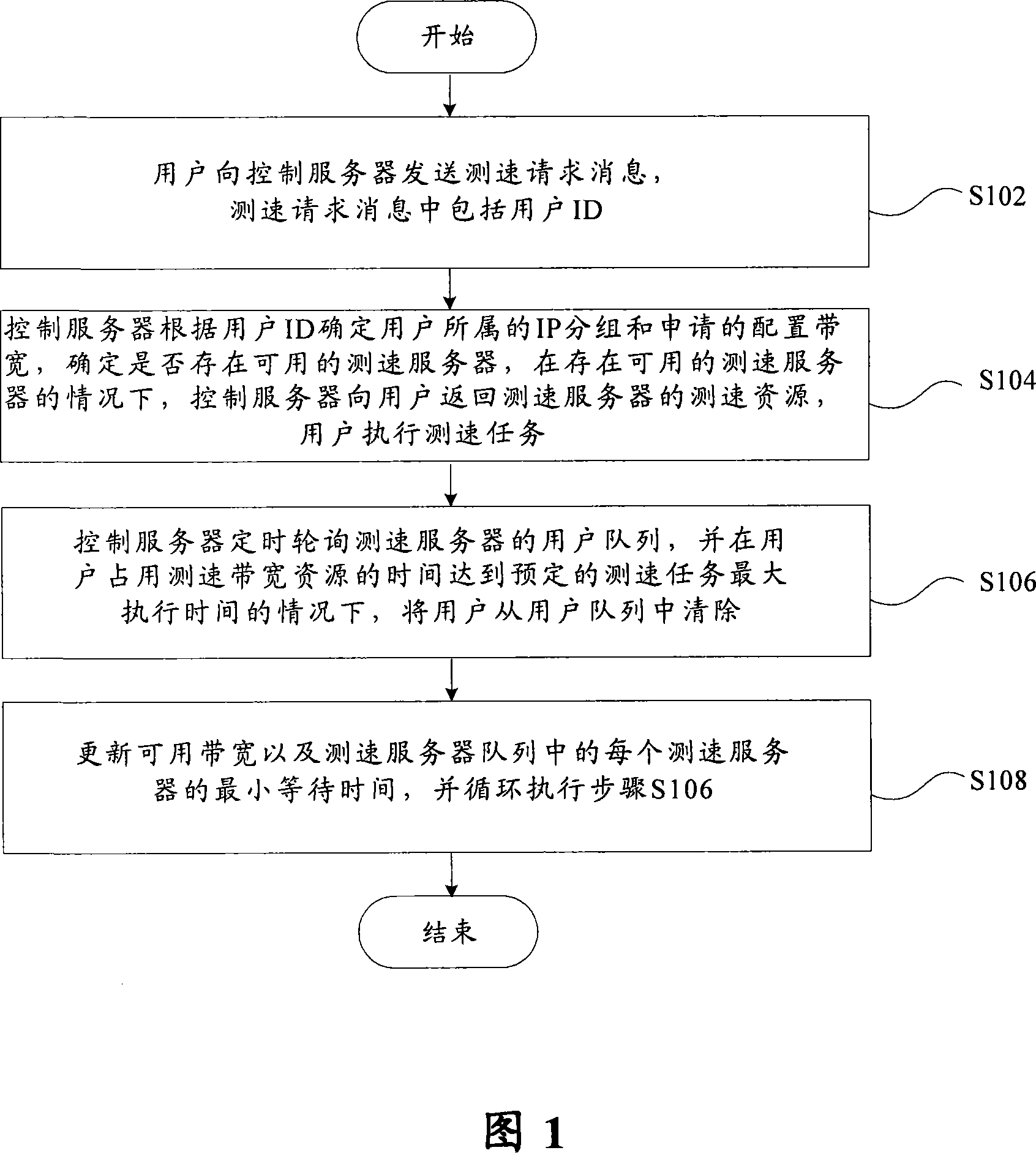

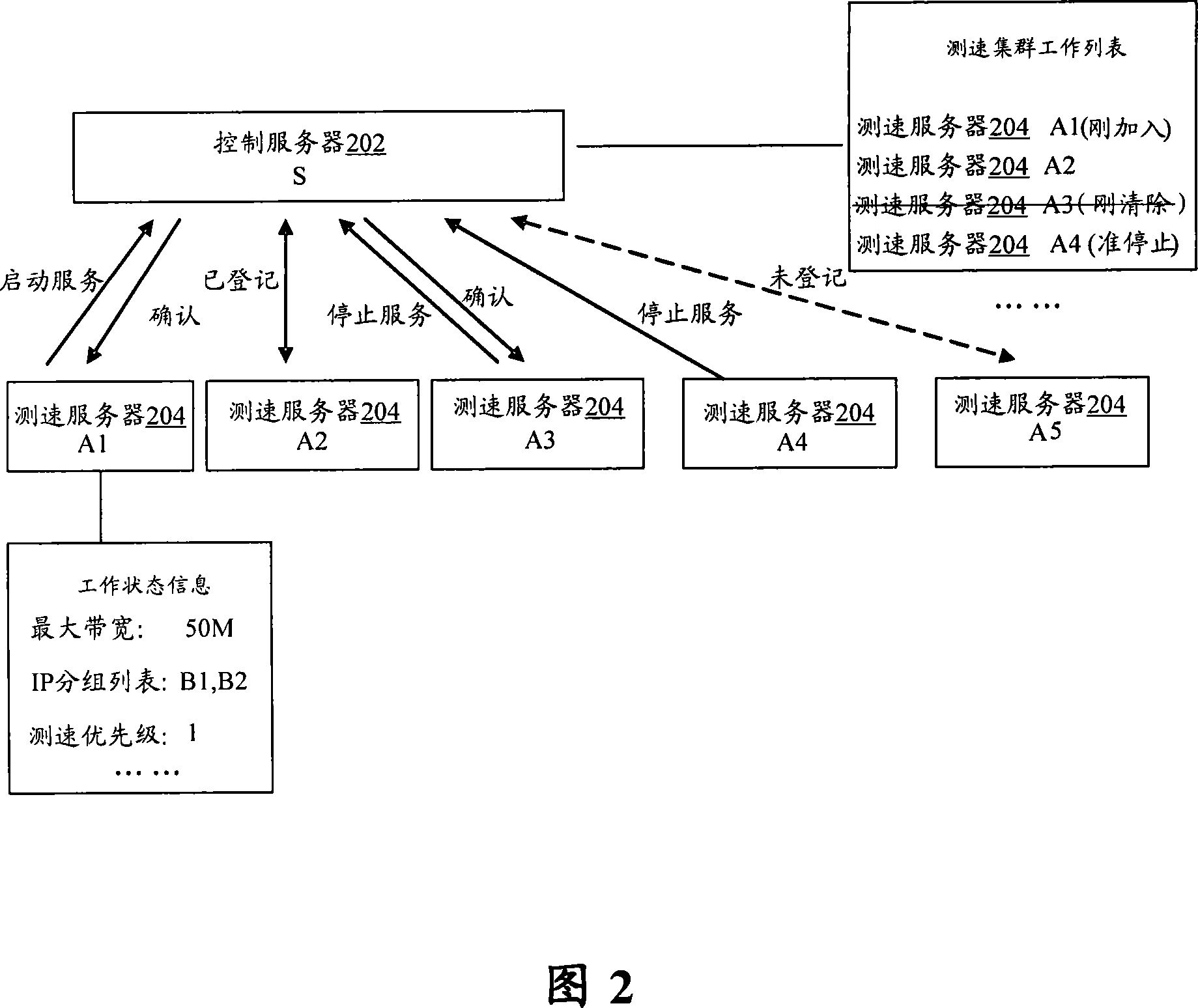

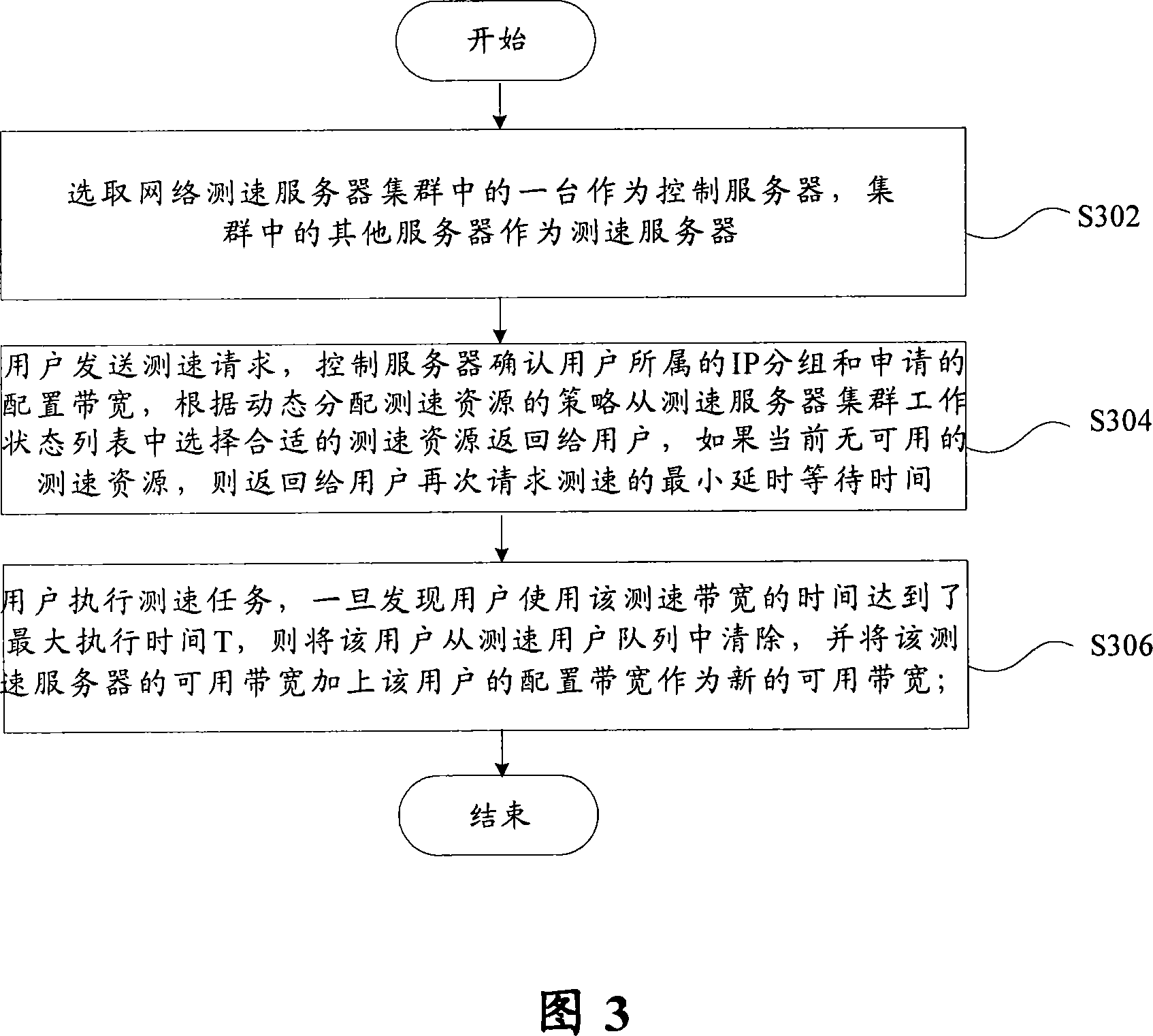

Speed-measuring resource dynamic distributing method and system for network speed-measuring system

InactiveCN101068171AGuaranteed credibilityGuaranteed accuracyData switching networksUser identifierWaiting time

Owner:GLOBAL INNOVATION AGGREGATORS LLC

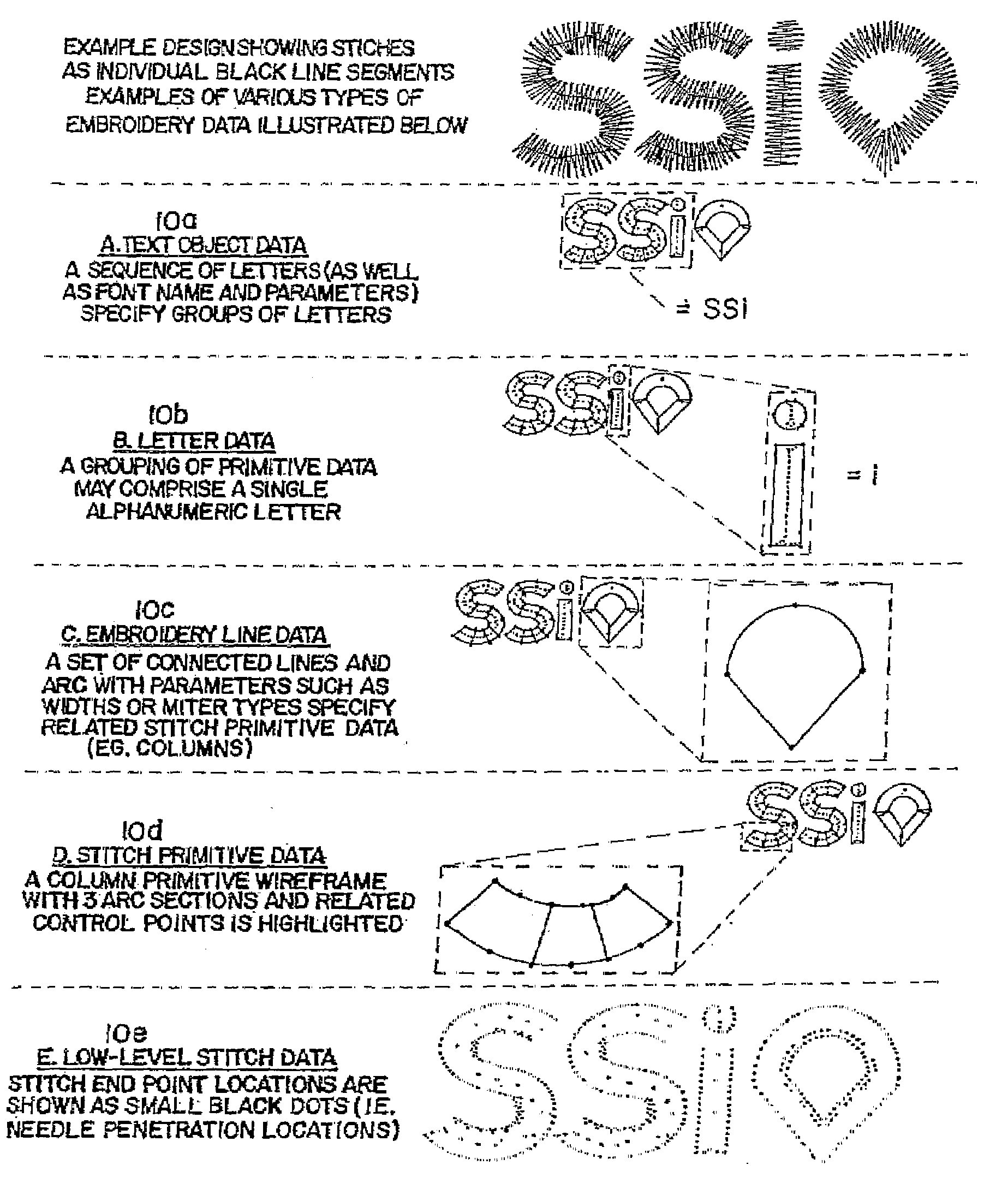

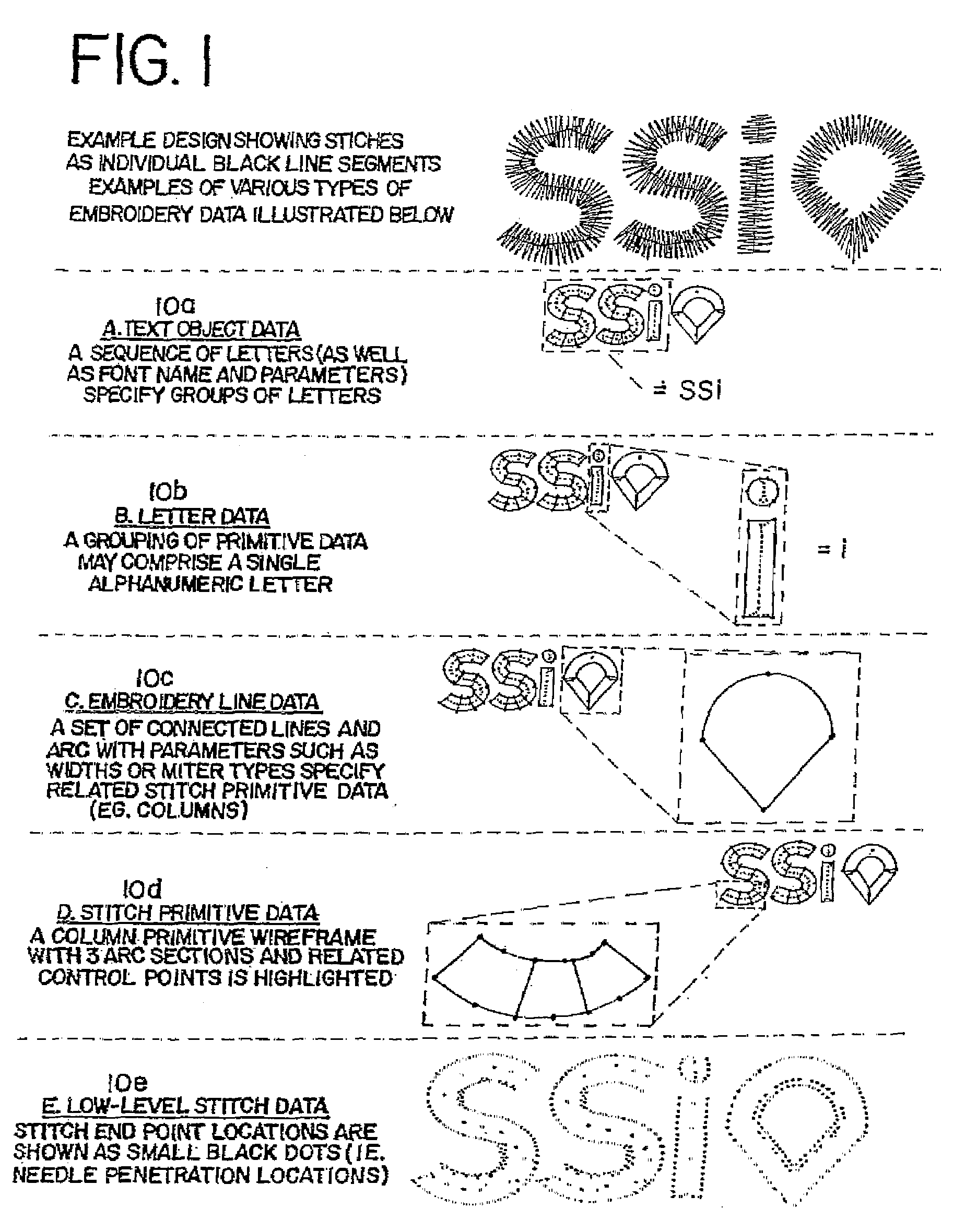

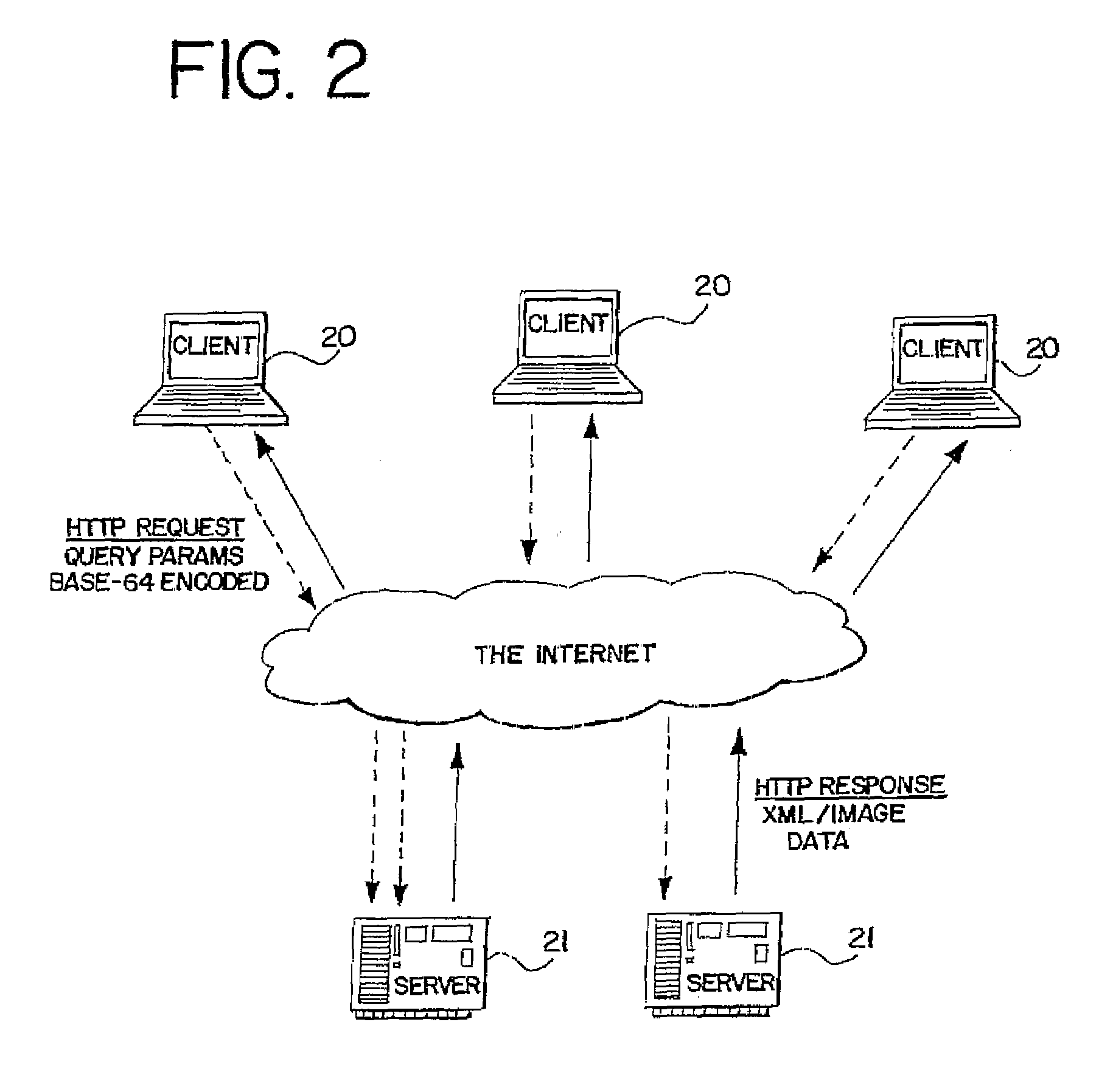

Method and System for Creating and Manipulating Embroidery Designs Over a Wide Area Network

ActiveUS20080079727A1Easy to displayDrawing from basic elementsImage data processing detailsClient-sideUser interface

A method and system are disclosed for creating and manipulating embroidery designs over a wide area network. The method includes steps to transmit various embroidery design data over a wide area network between a client and a server The manner in which the embroidery design data is created, manipulated, and transmitted allows a user to preview photo realistic renderings of possible finished products, and more precisely adjust interpretations through a provided user interface with minimum latency.

Owner:CIMPRESS SCHWEIZ

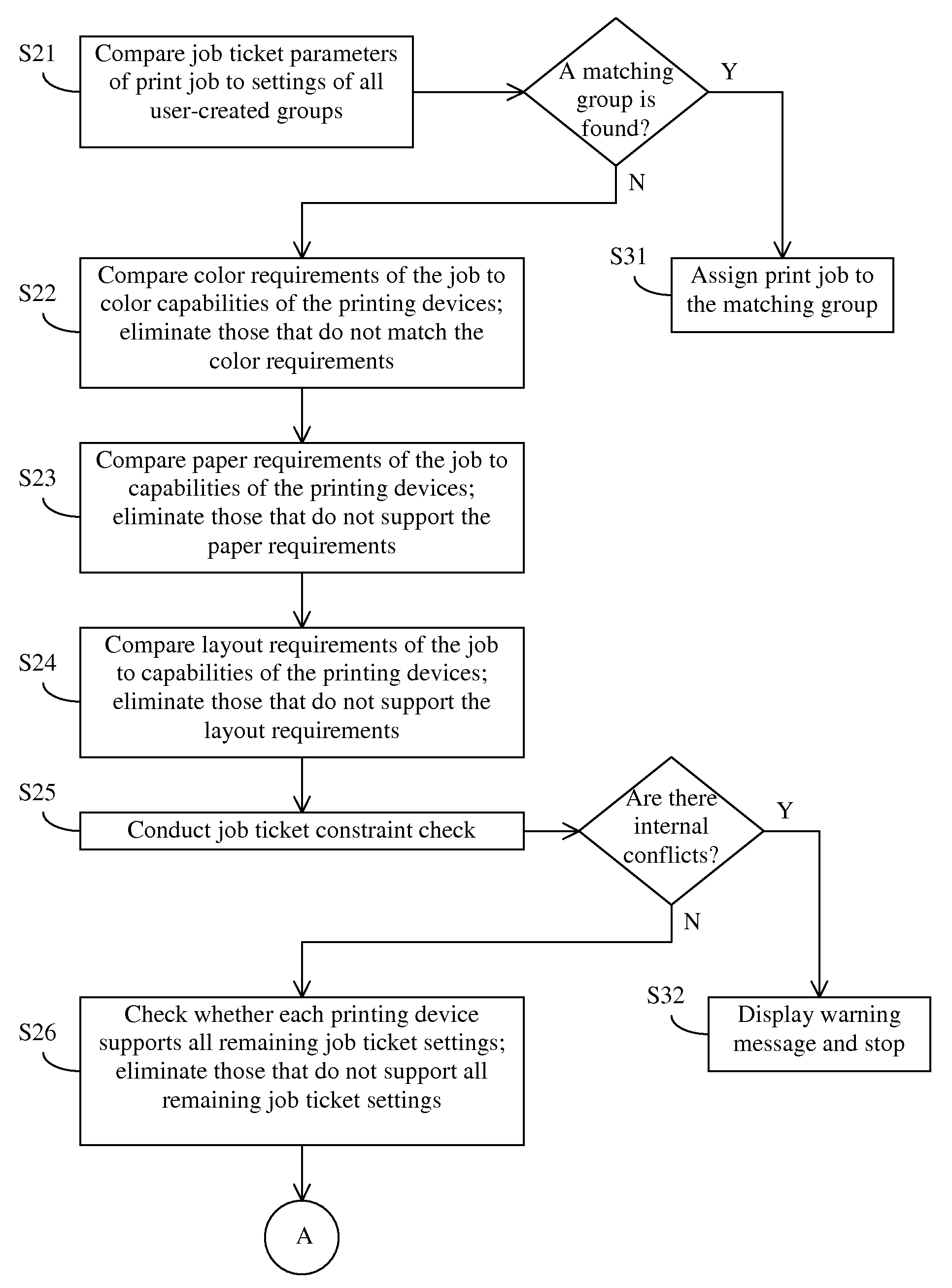

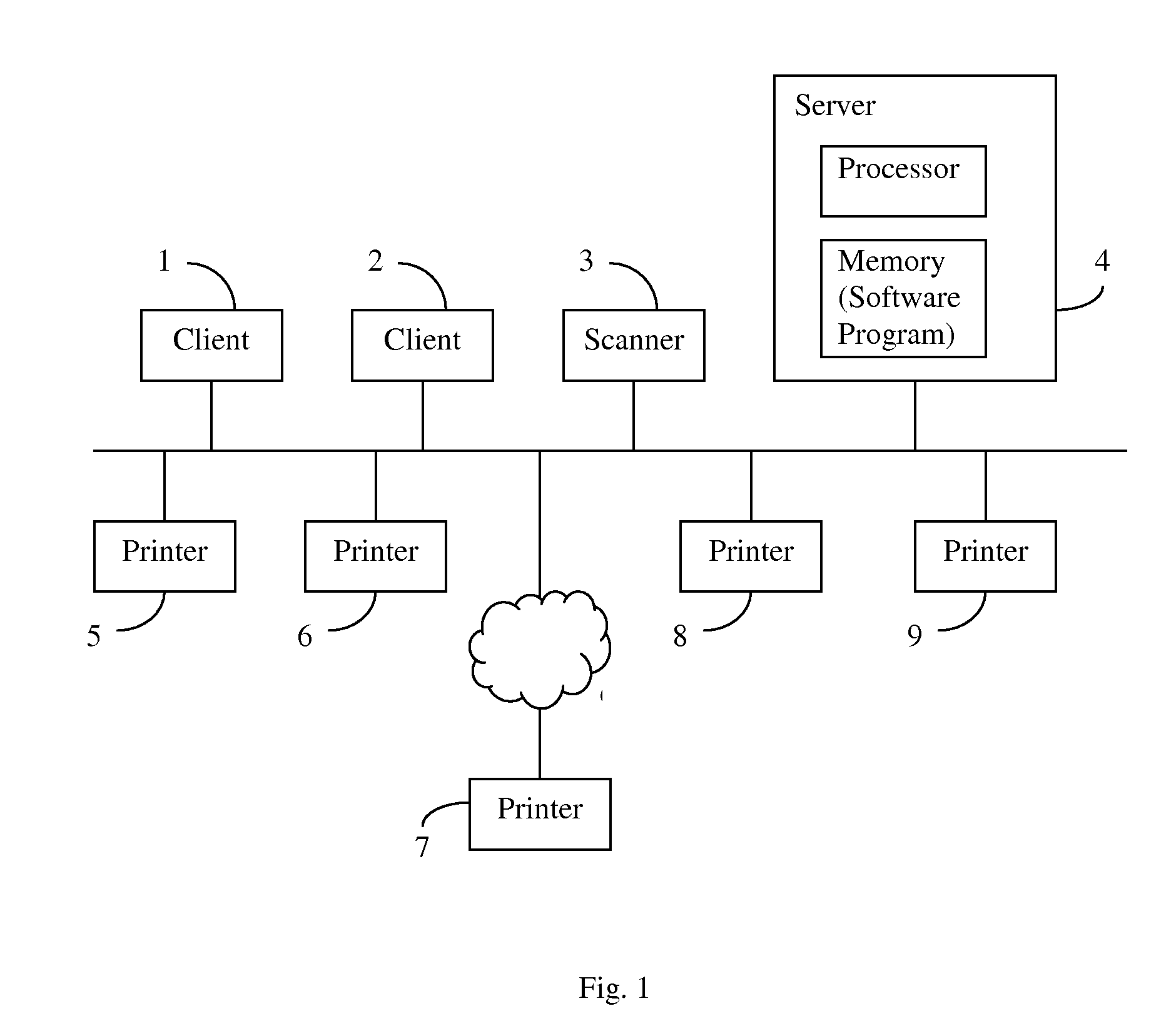

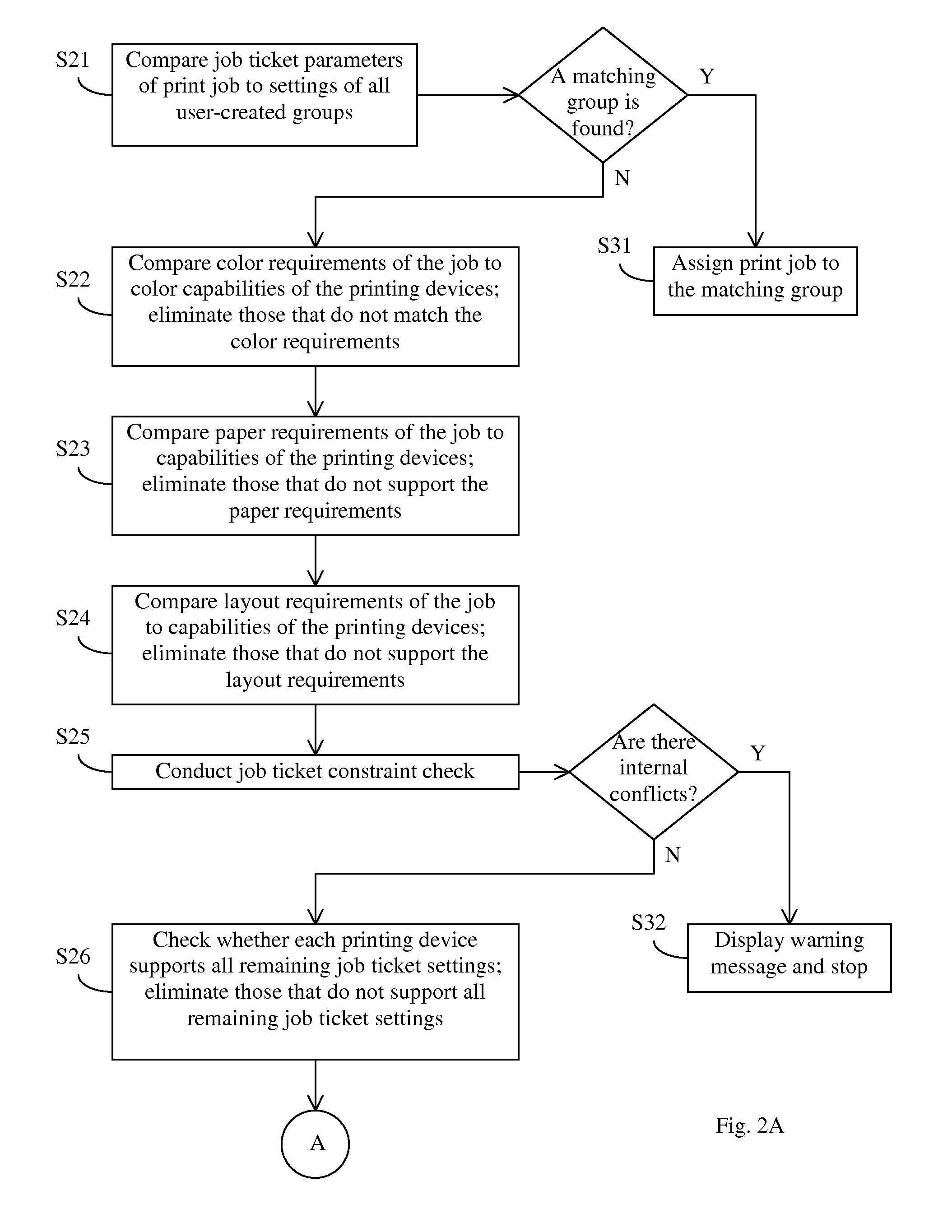

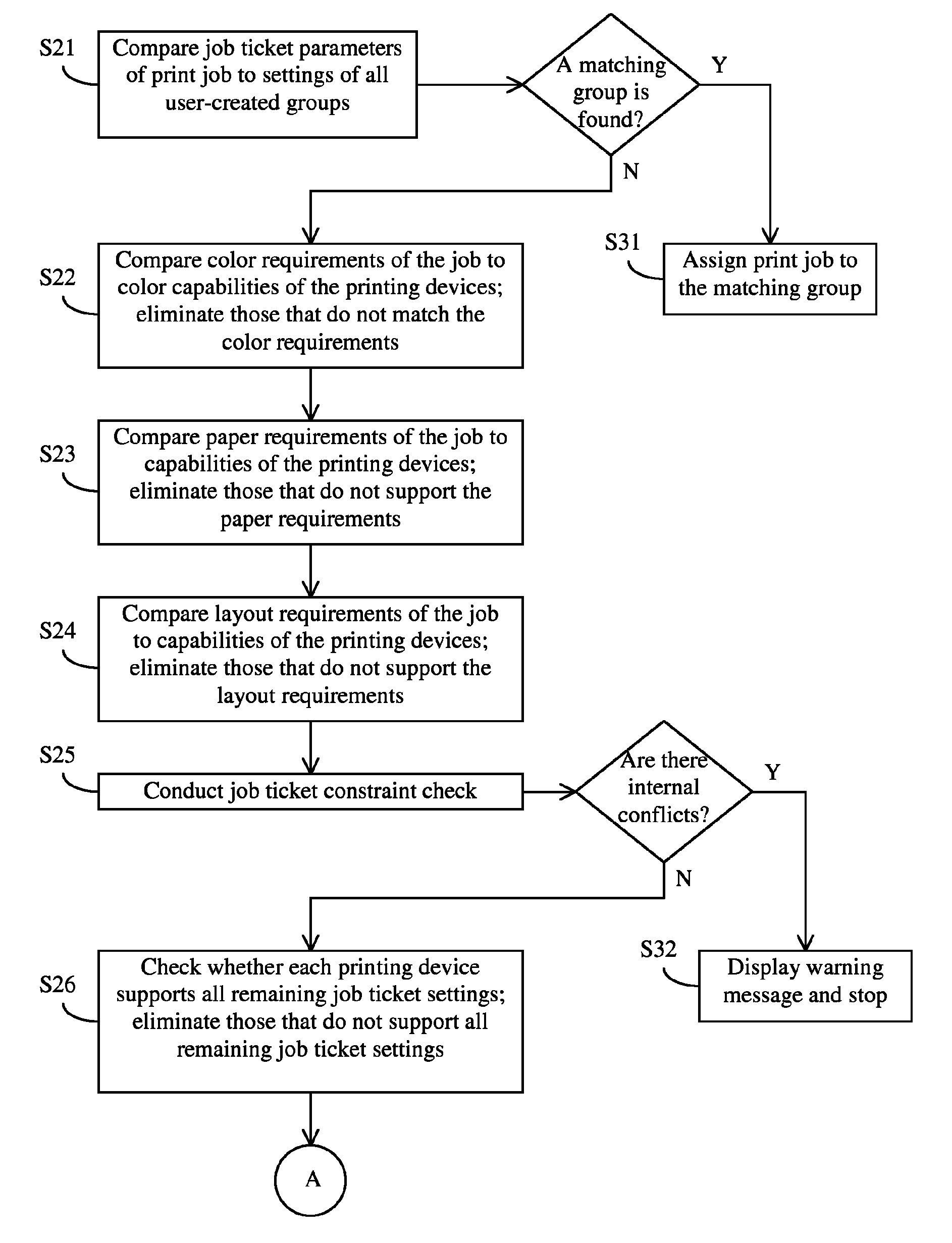

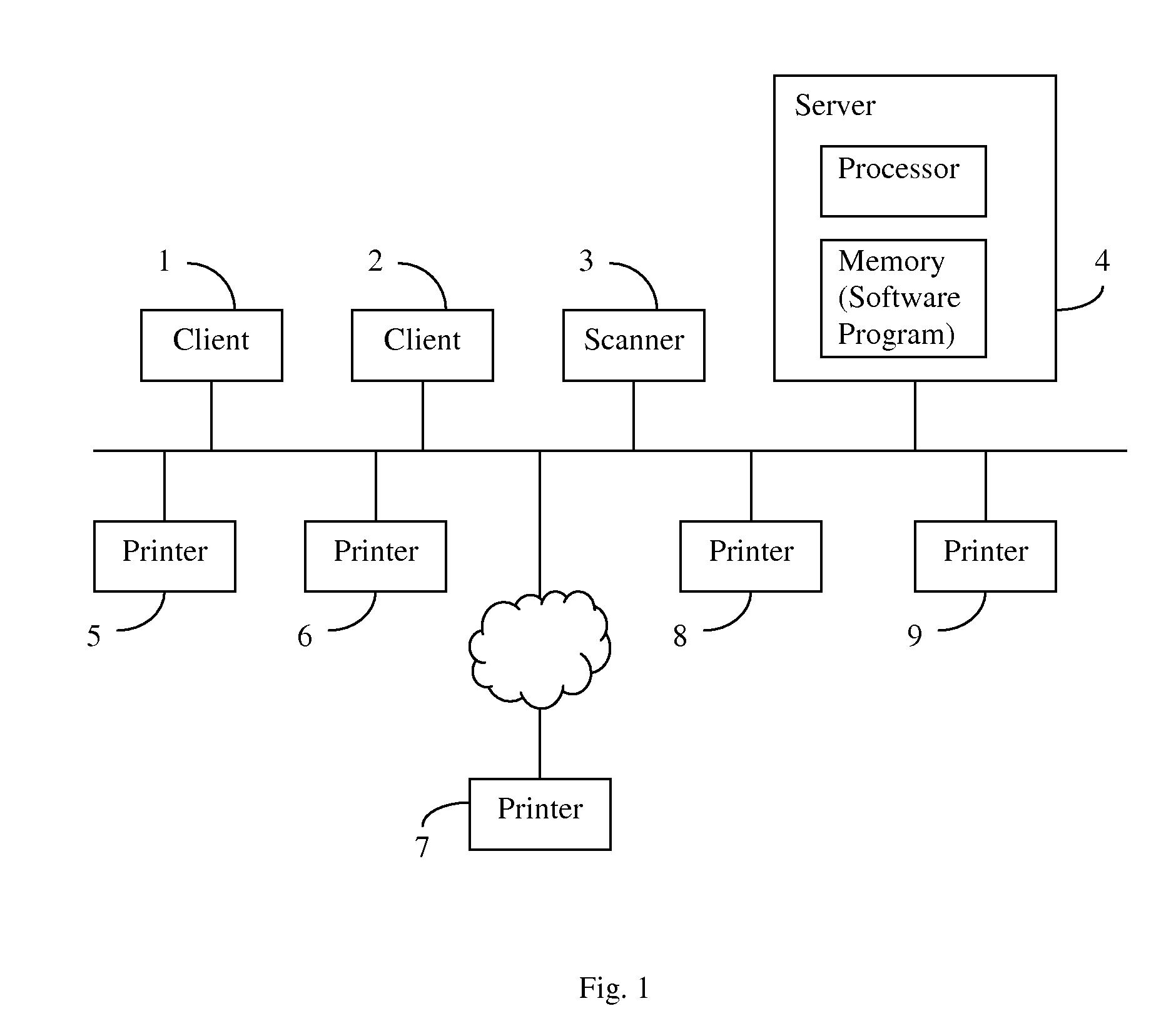

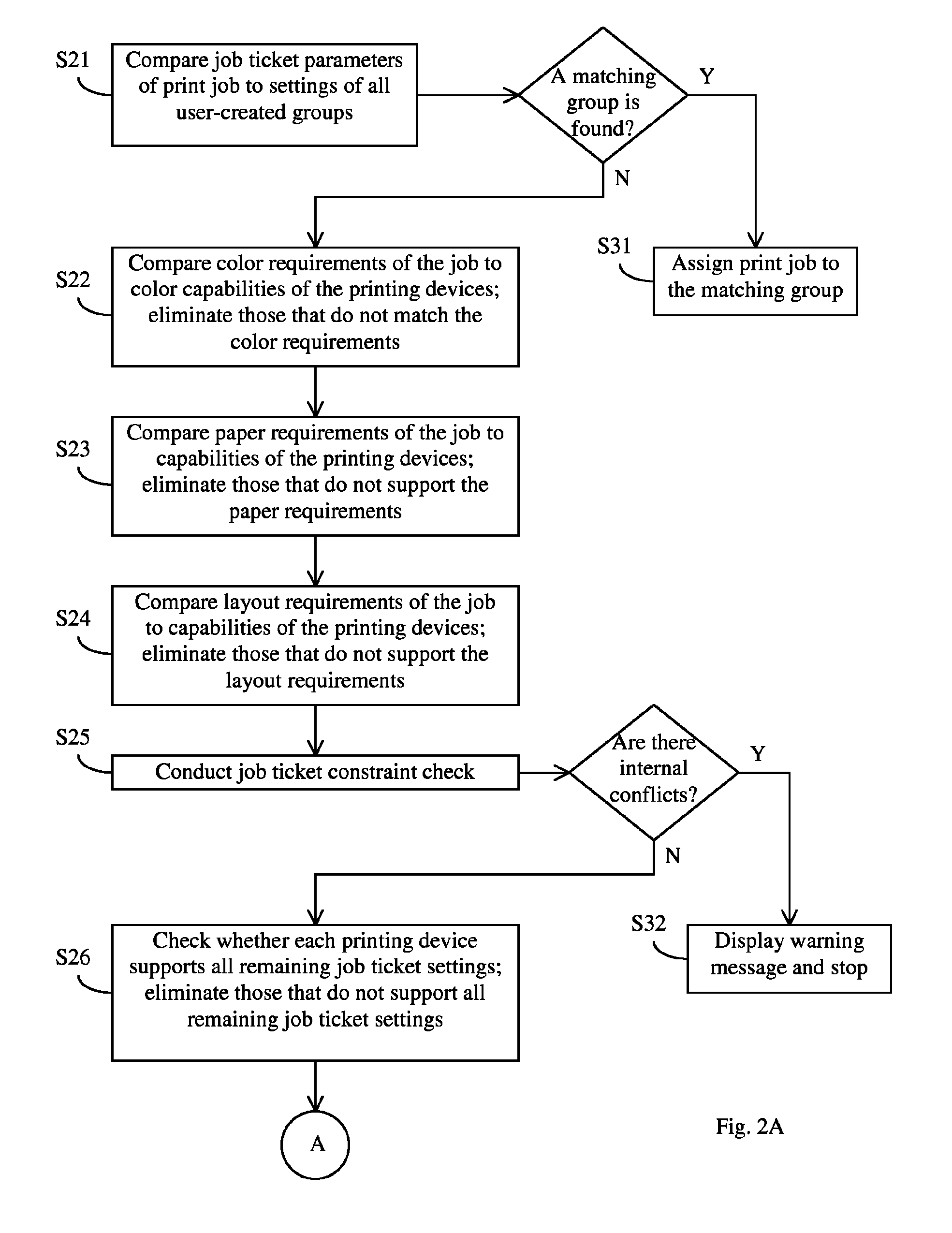

Print job assignment method allowing user-prioritization

ActiveUS20090201531A1Extended processing methodDigitally marking record carriersCharacter printing data arrangement from carrierComputer scienceJob assignment

A method implemented in a print job management apparatus for processing print jobs in a multiple-printer print shop environment is described. Each print job specifies job ticket parameters representing printing requirements. Each received job is processed by comparing the printing requirements of the job with capabilities of the printers. If a printer cannot satisfy all printing requirements of the job, it is eliminated as a candidate printer. Then, from all printers that can satisfy all printing requirements of the job, one printer is selected based on a pre-defined priority preference and the job is submitted to the selected printer. The printer priority preference is created by the operator based on cost and other factors. The operator can also select an alternative execution mode where, among all printers that can satisfy all requirements of the job, the one with minimum wait time is selected.

Owner:KONICA MINOLTA LAB U S A INC

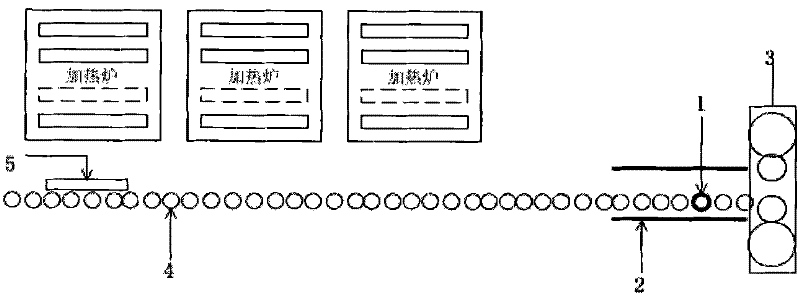

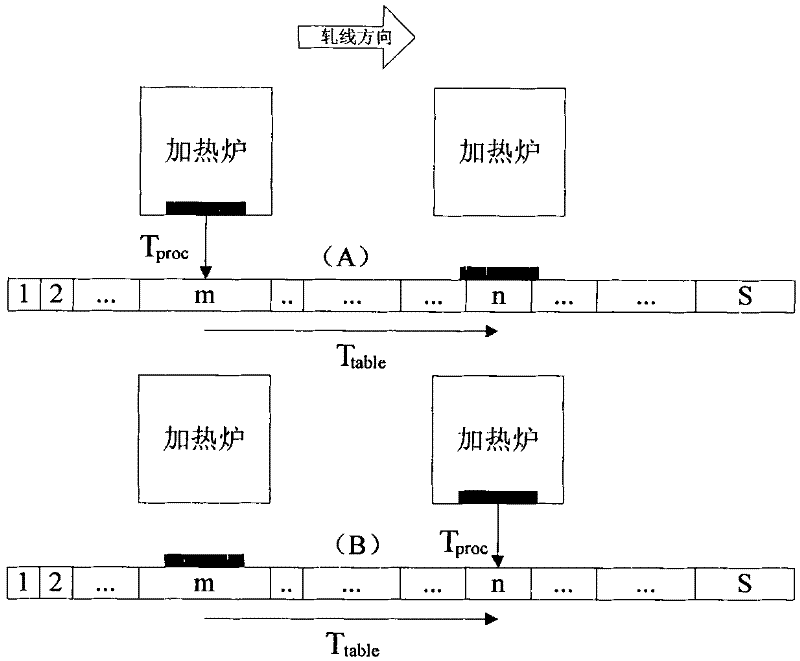

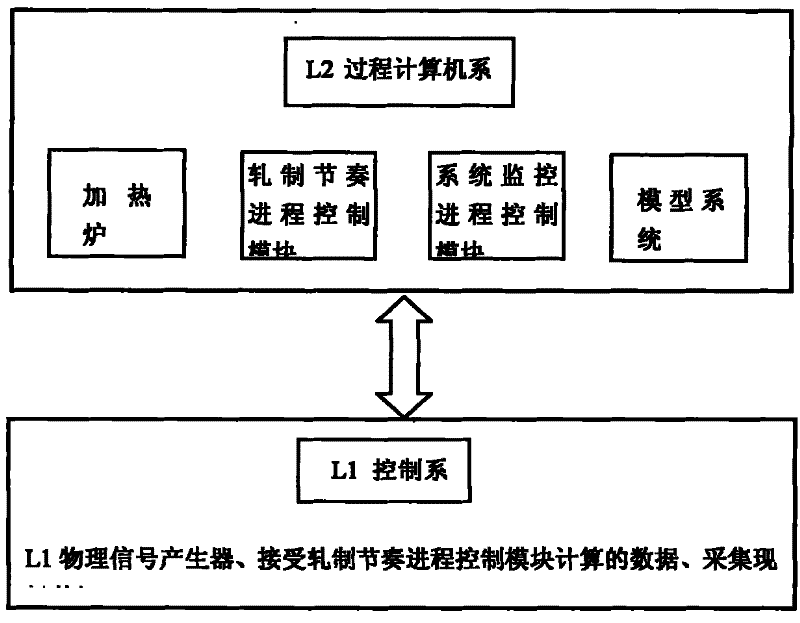

A control method for equal-gap steel rolling

InactiveCN102294361AImprove efficiencyImprove stabilityRoll mill control devicesMetal rolling arrangementsComputer control systemHeating furnace

The invention relates to a method for controlling equal-gap steel rolling, belonging to the technical field of metallurgy. In the method, a computer control system is used. The method comprises the following control steps of: judging a current steel extraction heating furnace and a next steel extractable heating furnace; reading the action time of a steel extraction machine transmitted by a monitoring sensor of the next steel extractable steel heating furnace as well as a roller table running speed and a practical time interval between the reach of two front adjacent plate blanks to a rollingmill transmitted by a speed senor and a time sensor on a roller table; retrieving a store formula and calculating corresponding waiting time of the next steel extractable heating furnace; when the waiting time is reached, controlling the heating furnace to extract steel; and calculating the next steel extraction waiting time every time steel extraction is finished and determining a next steel extraction heating furnace according to a minimum waiting time principle. Due to the adoption of the method, the tendency to equal-interval rolling is automatically realized by dynamic adjustment, self-adaptation to various complex environments can be realized, the organized production efficiency of a steel rolling line is increased, the stability of the rolling tempo is improved, the energy consumption is lowered, and the problem of the influence on coiled sheet quality caused by unreasonable production organization is solved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

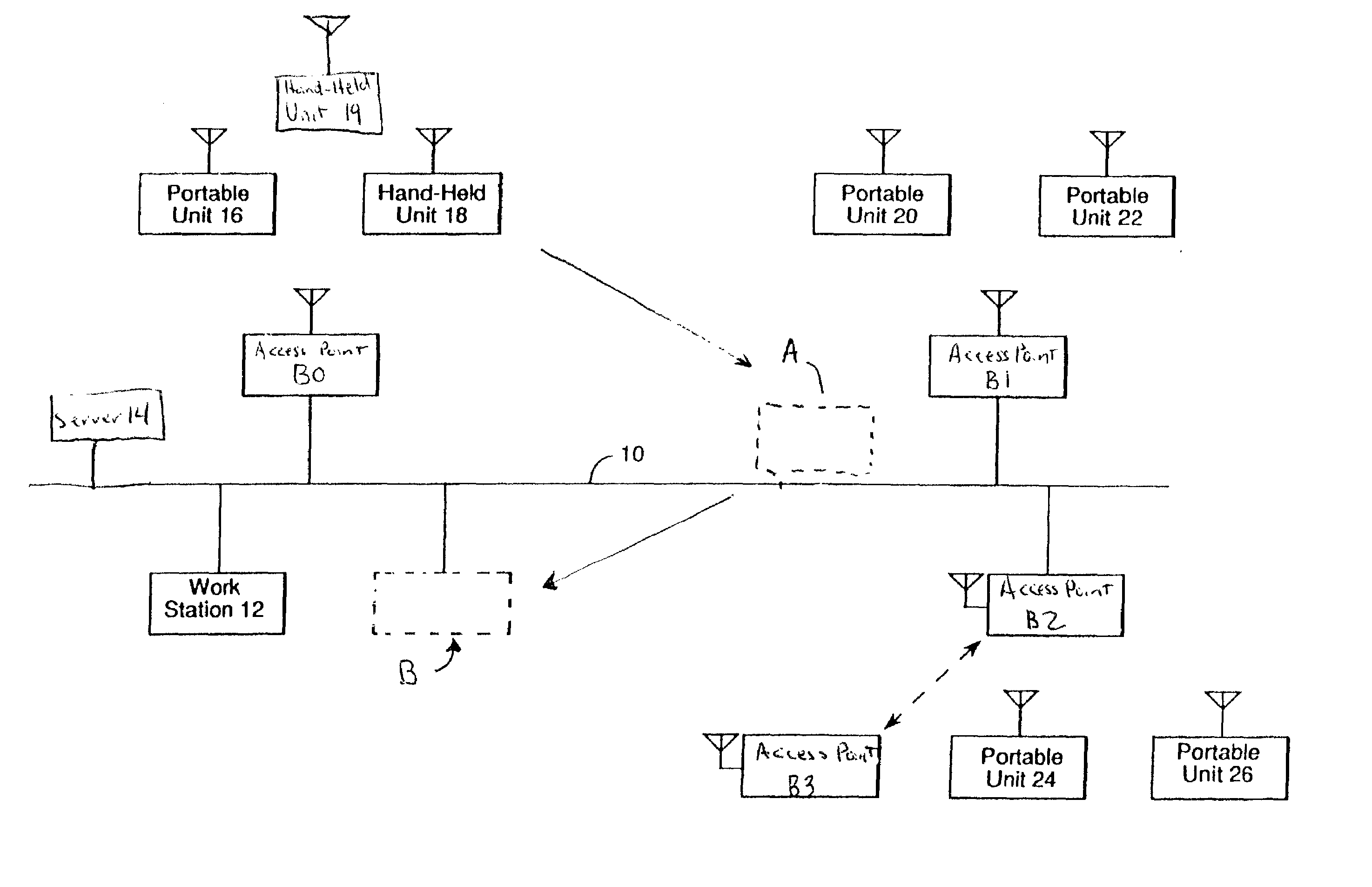

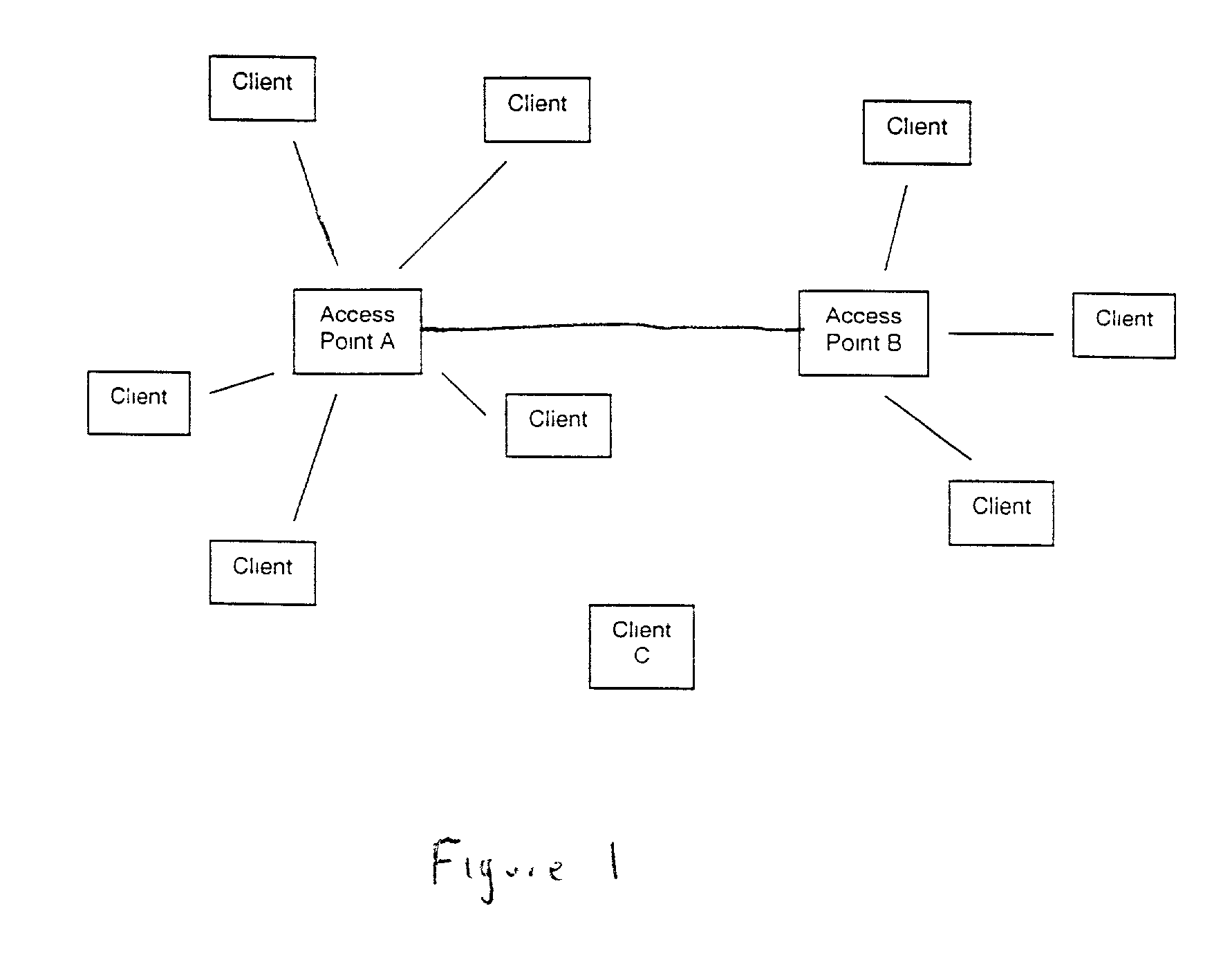

System and method for optimizing throughput using response time as a metric

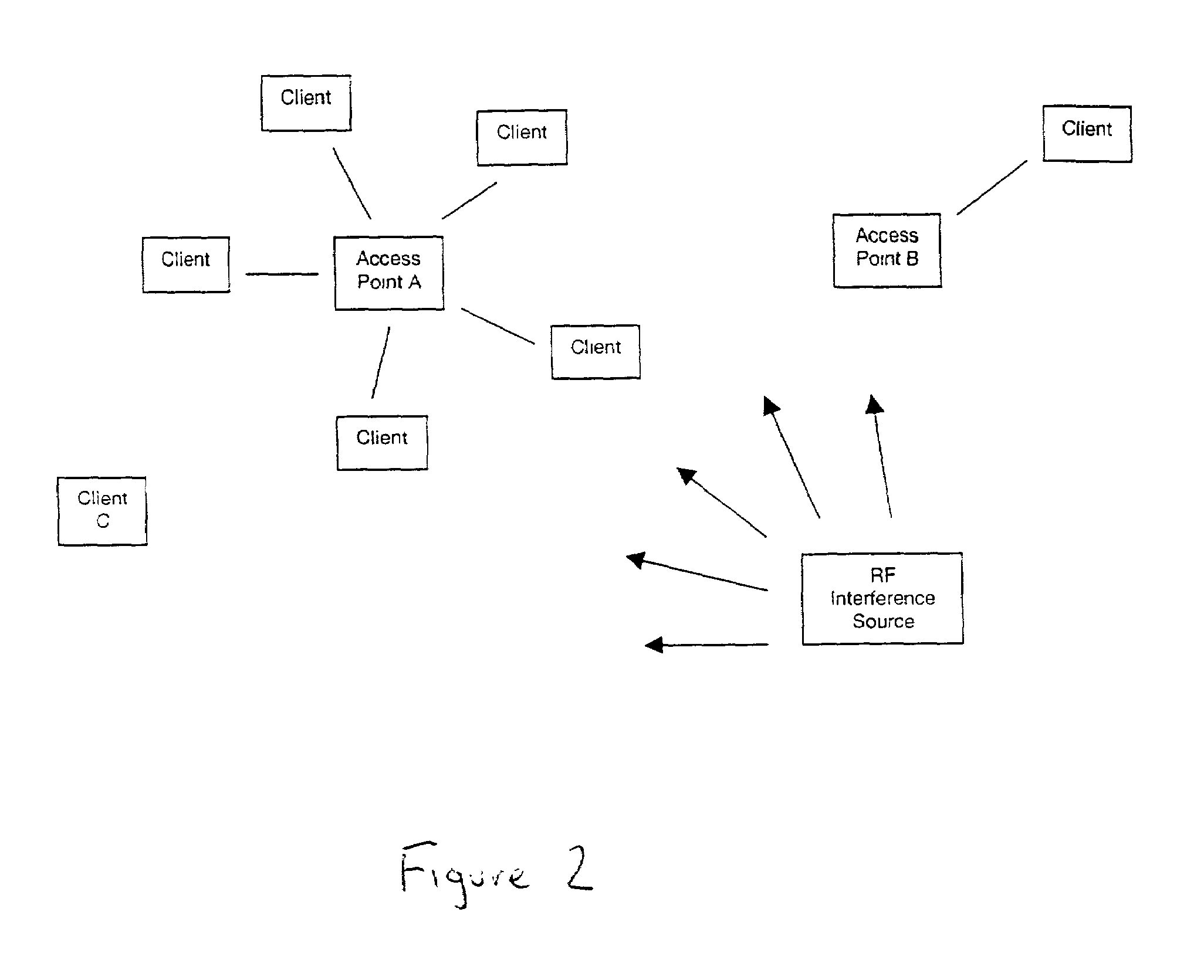

In a wireless local area network, a system and method for association between access points and clients based upon measuring the response time of packets and selecting the access point with the least latency. The present invention also contemplates taking the average response time of several packets between an access point and client and selecting the access point for association with the least amount of latency based upon the average response time. The present invention is further directed to optimizing throughput by user selectable or dynamically allocable trigger events which causes the client of an associated access point to seek other access points meeting the threshold limits. Finally, since the present invention causes the a client to seek an access point based on measuring the response time of packets, an effective and efficient system and method is disclosed to overcome external radio frequency interference.

Owner:CISCO TECH INC

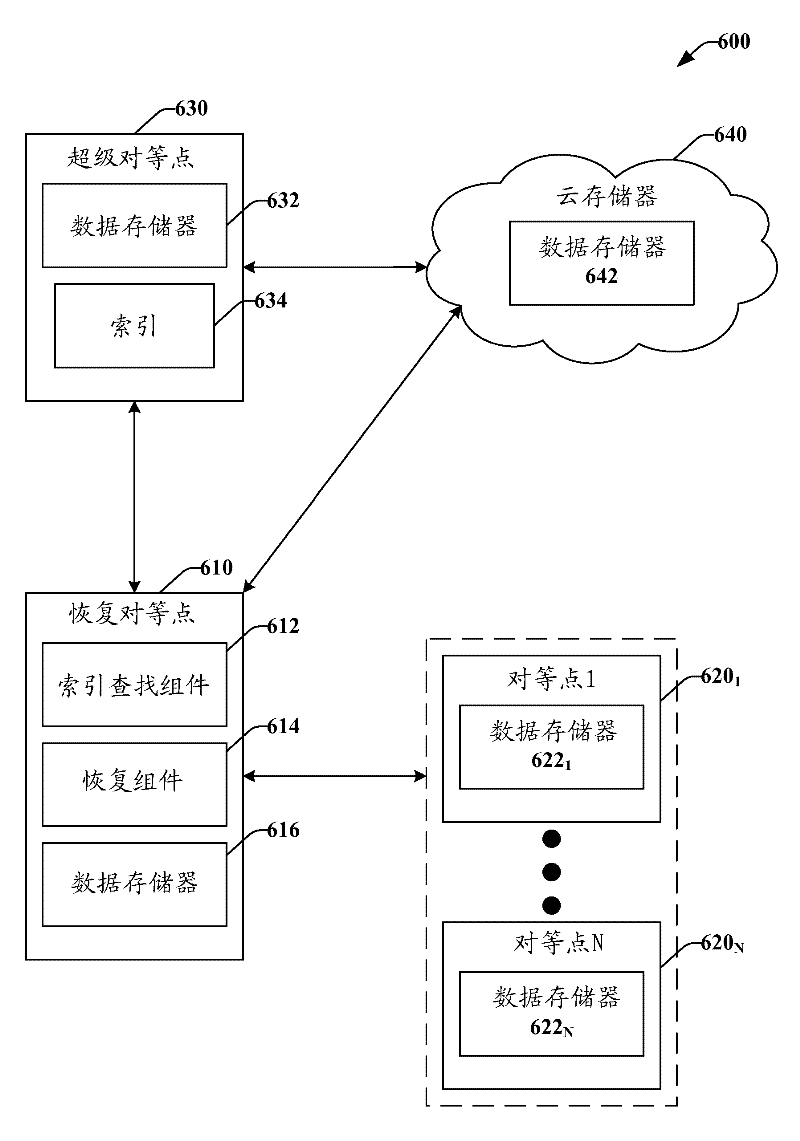

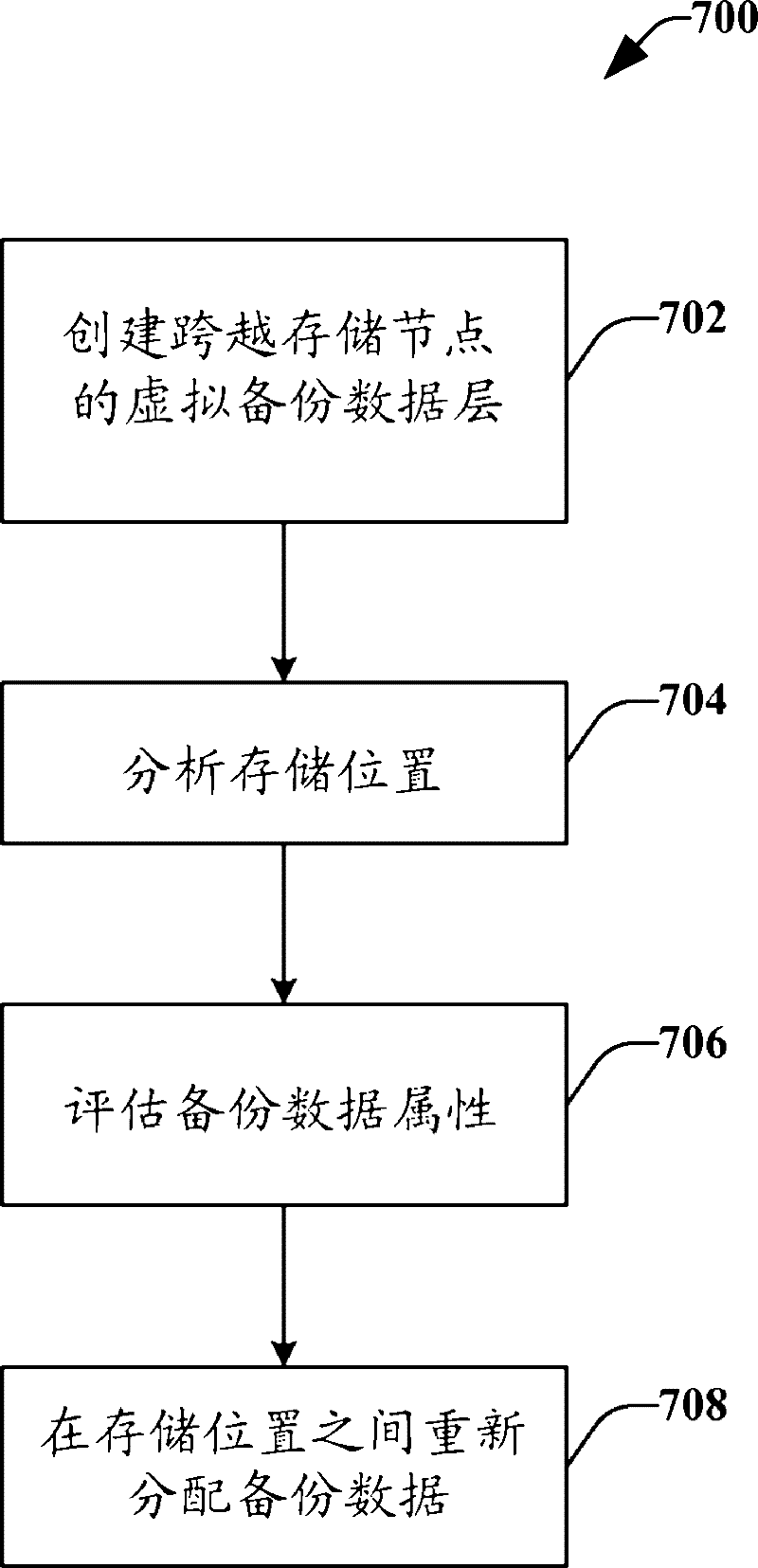

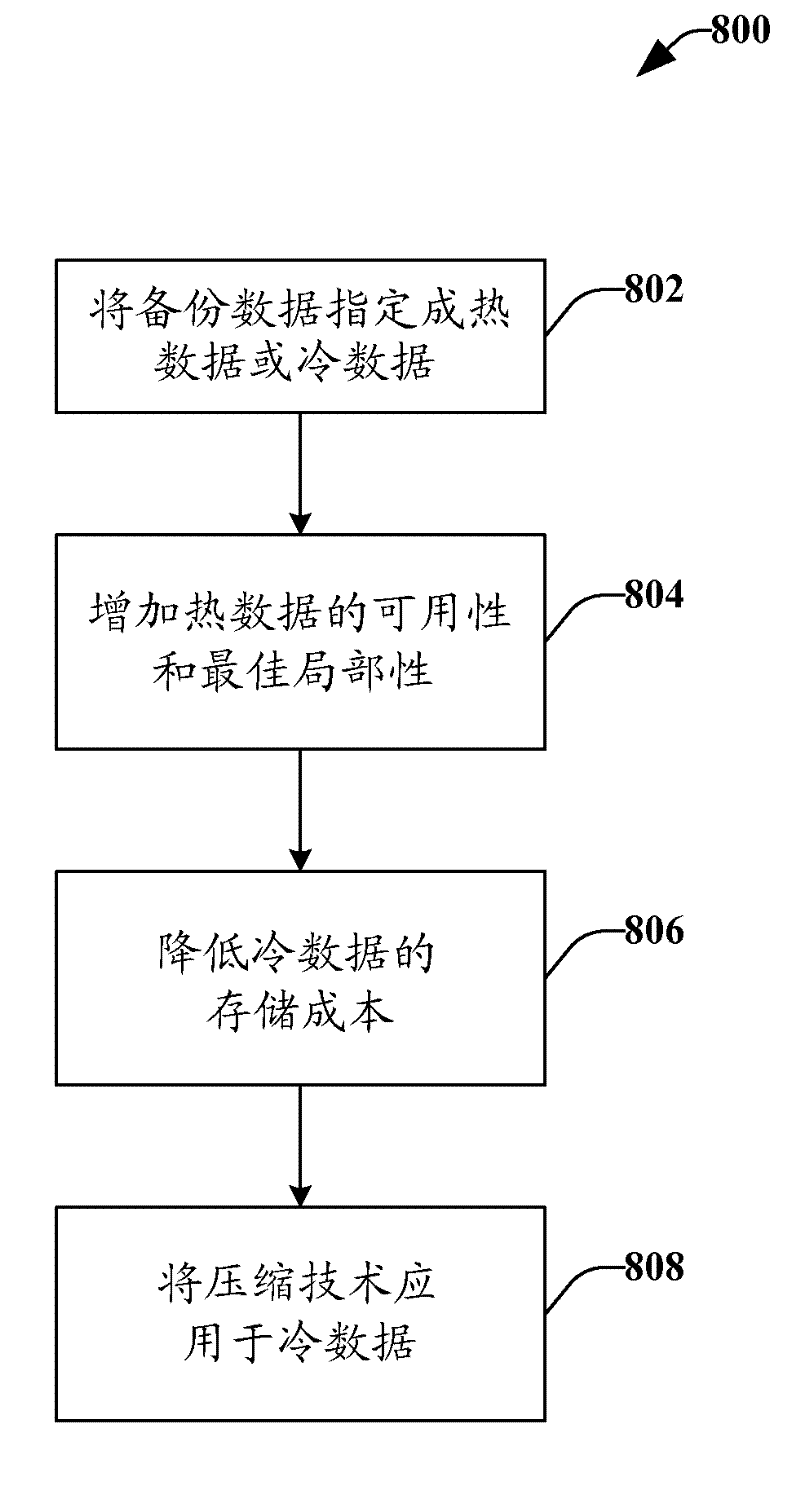

Intelligent tiers of backup data

ActiveCN102414673AInput/output to record carriersProgram control using stored programsSubject matterHeuristic

The claimed subject matter relates to systems and / or methodologies that facilitate intelligent distribution of backup information across storage locations in network-based backup architectures. A virtual layering of backup information across storage locations in the backup architecture can be implemented. Statistical models are utilized to dynamically re-allocate backup information among storage locations and / or layers to ensure availability of data, minimum latency upon restore, and minimum bandwidth utilization upon restore. In addition, heuristics or machine learning techniques can be applied to proactively detect failures or other changes in storage locations such that backup information can be reallocated accordingly prior to a failure.

Owner:MICROSOFT TECH LICENSING LLC

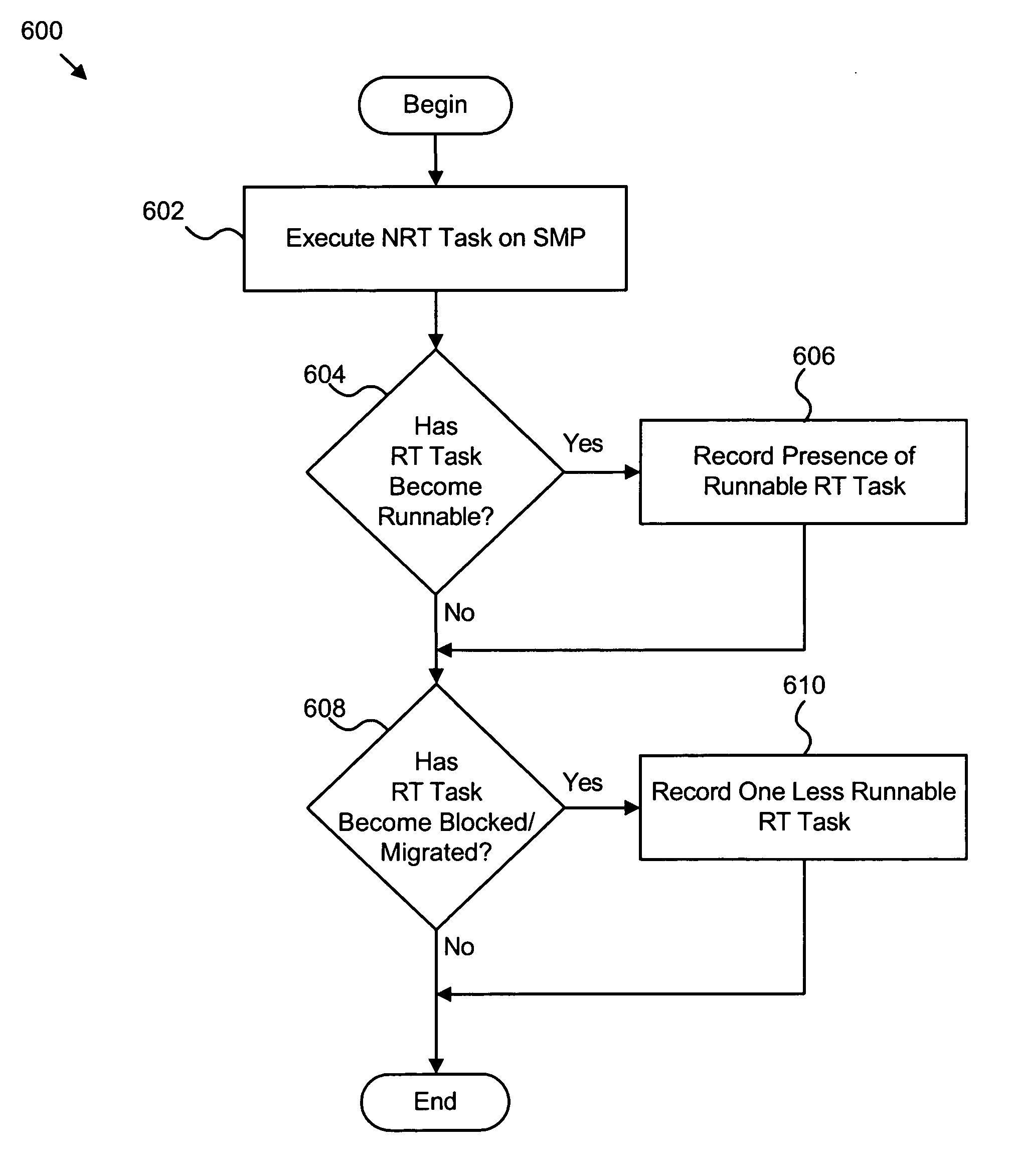

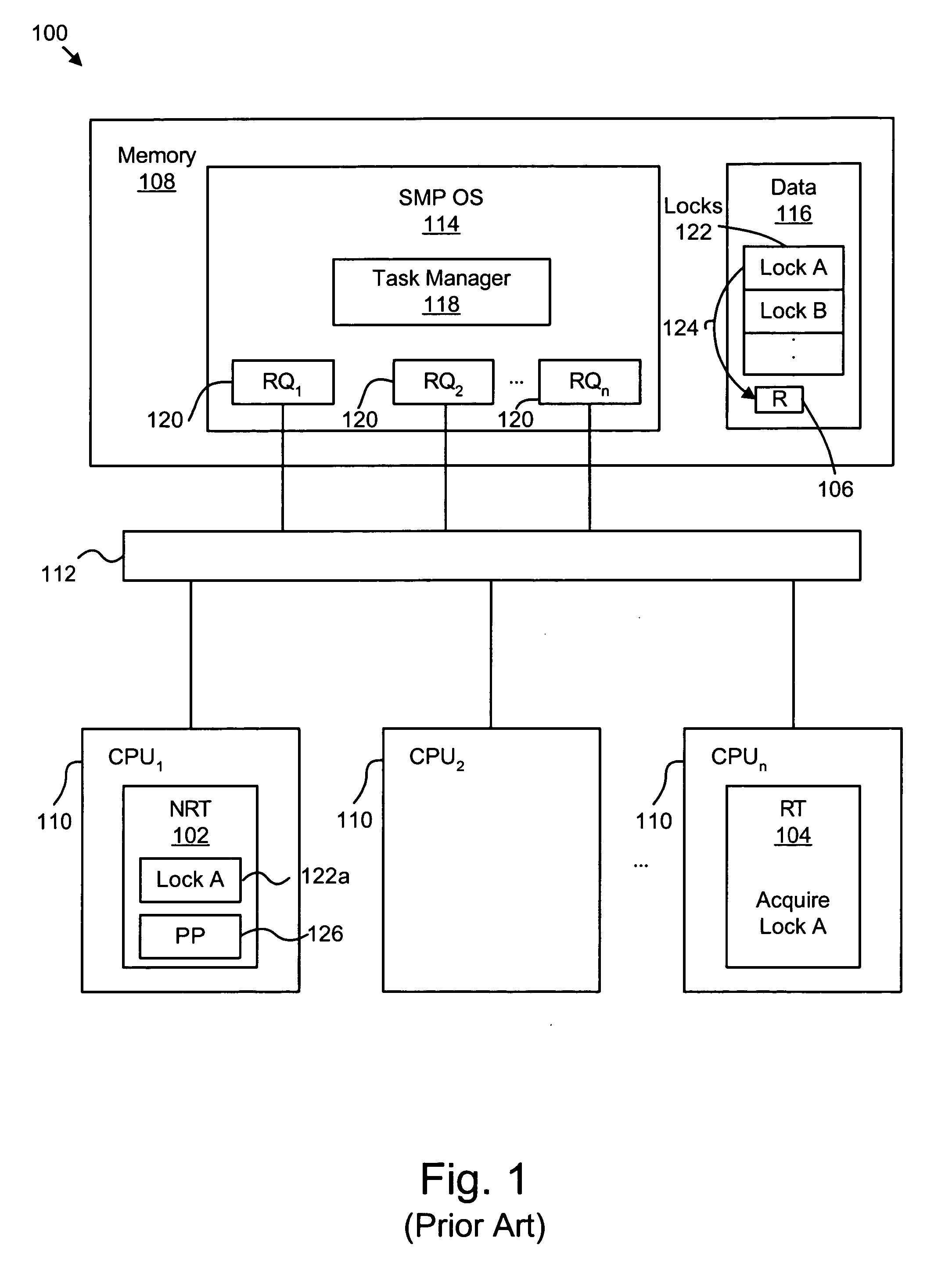

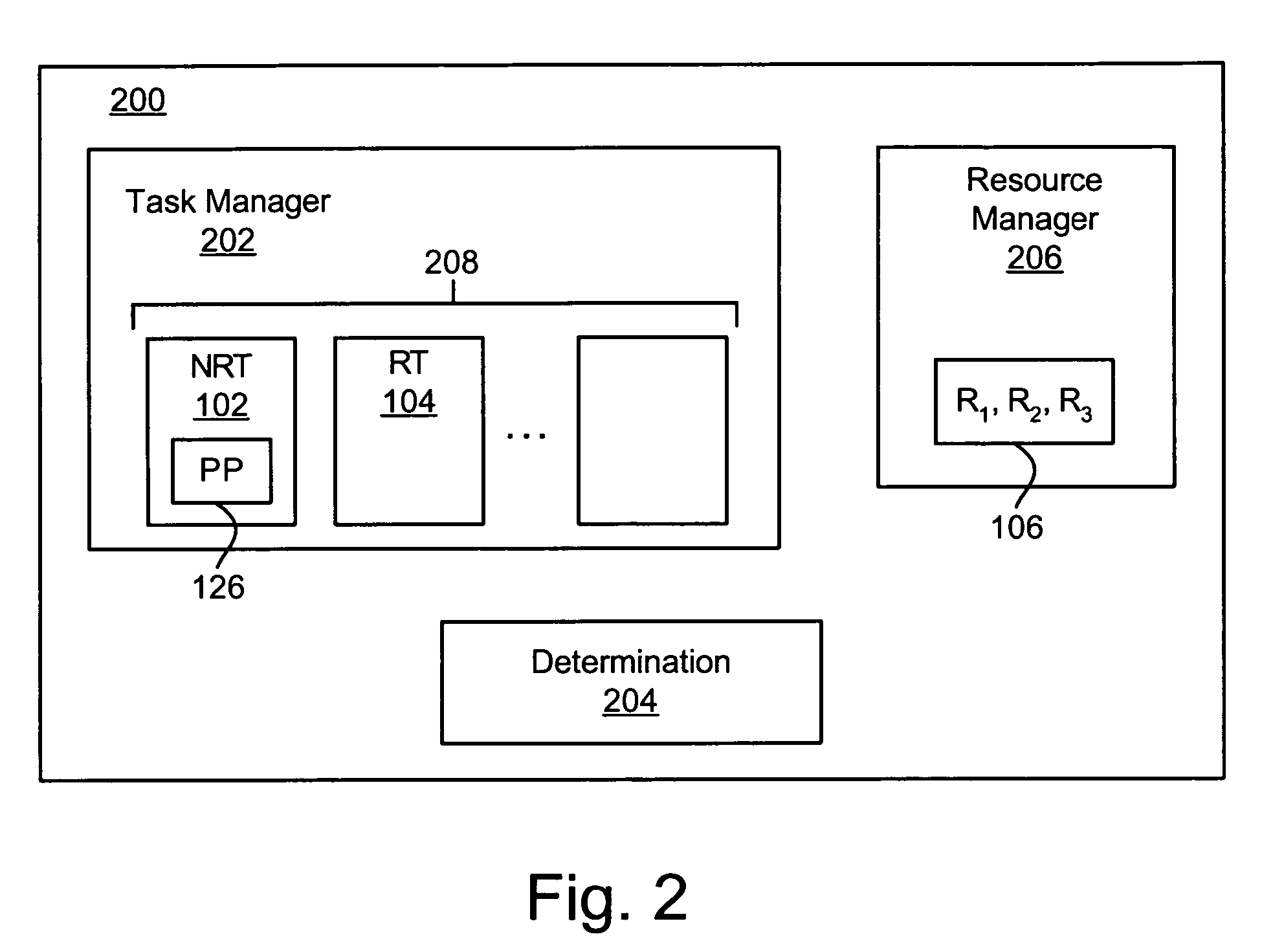

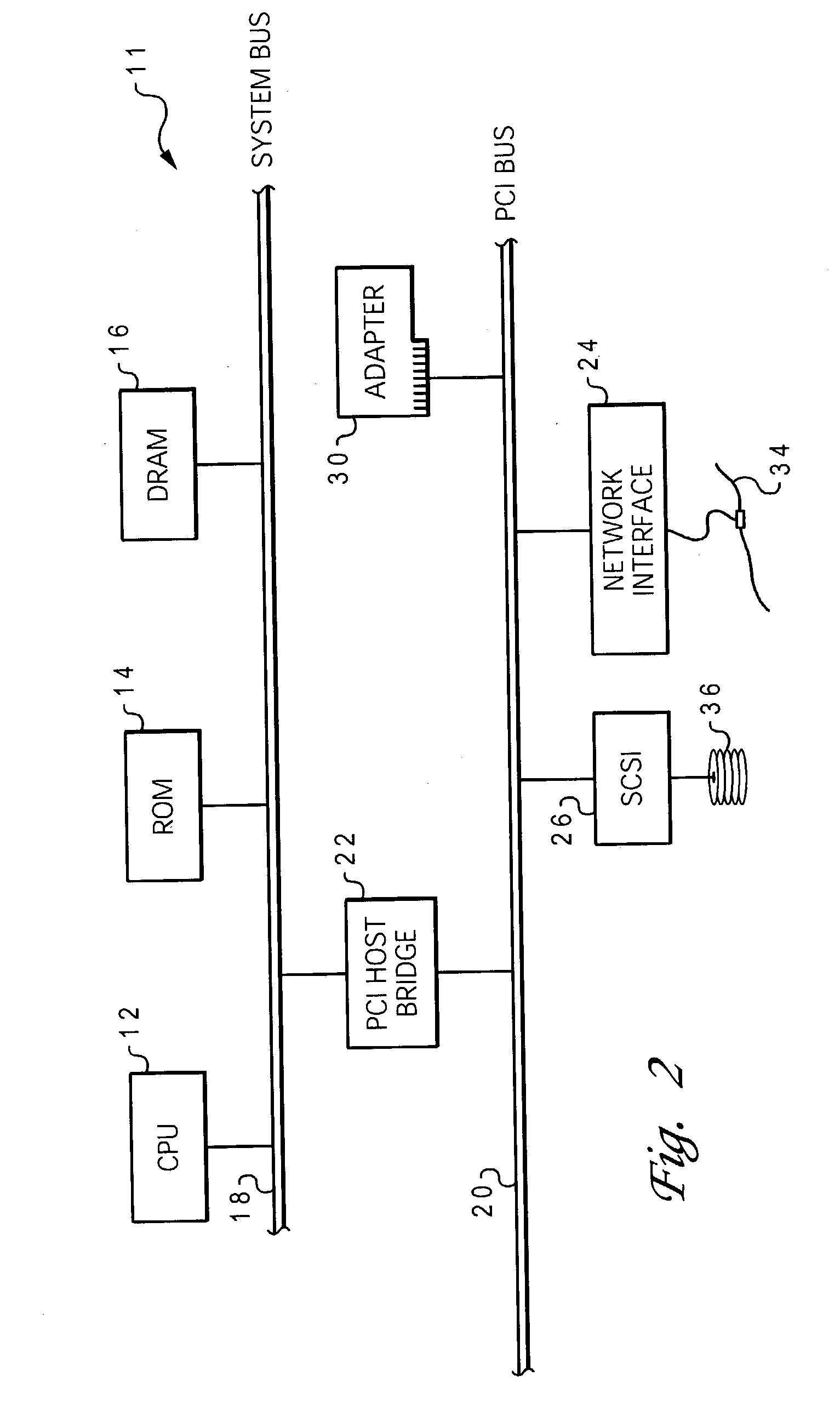

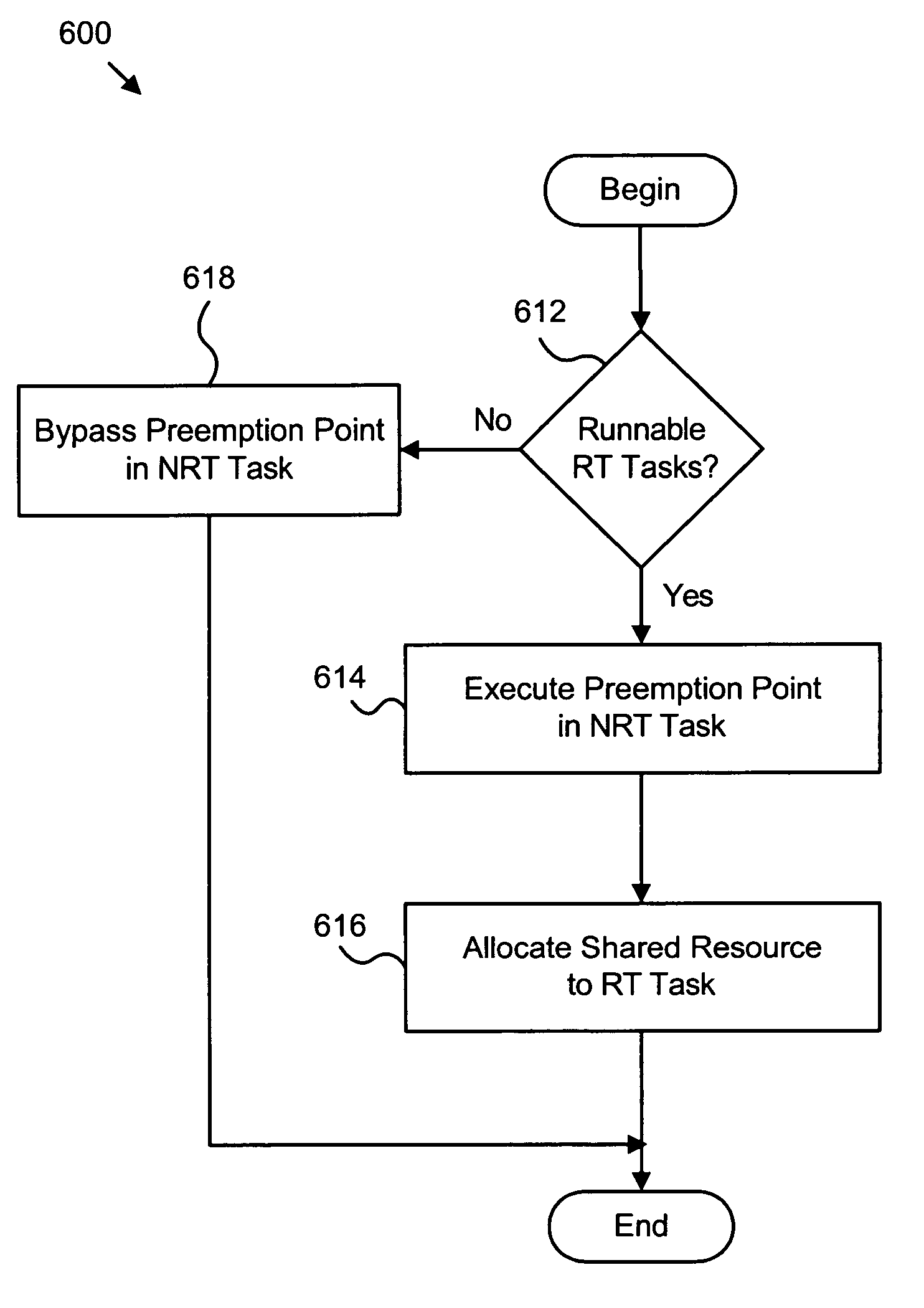

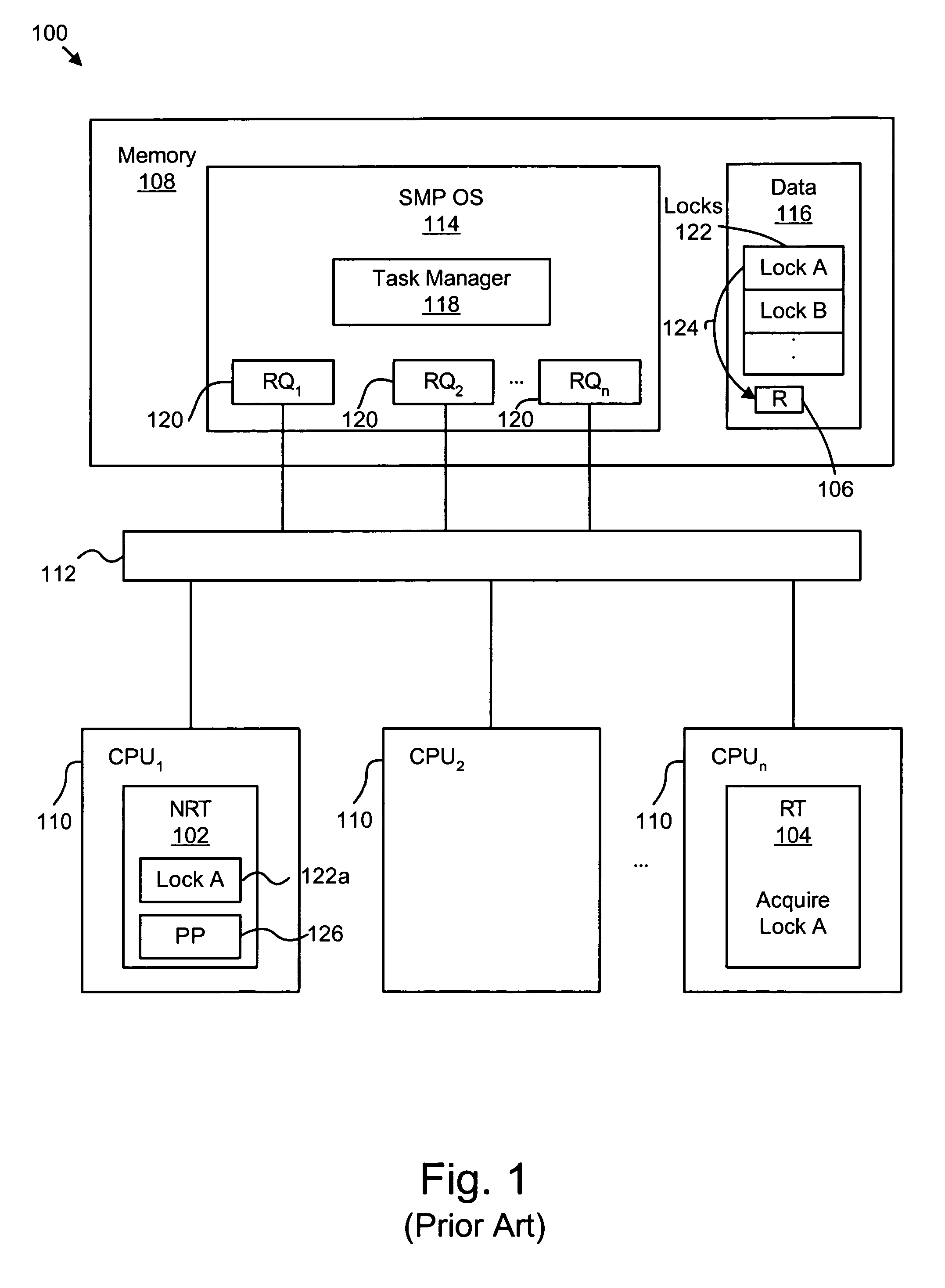

Apparatus, system, and method for automatically minimizing real-time task latency and maximizing non-real time task throughput

ActiveUS20060085793A1Minimizing RT task latencyMaximizing NRT throughputMultiprogramming arrangementsMemory systemsNon real timeMulti processor

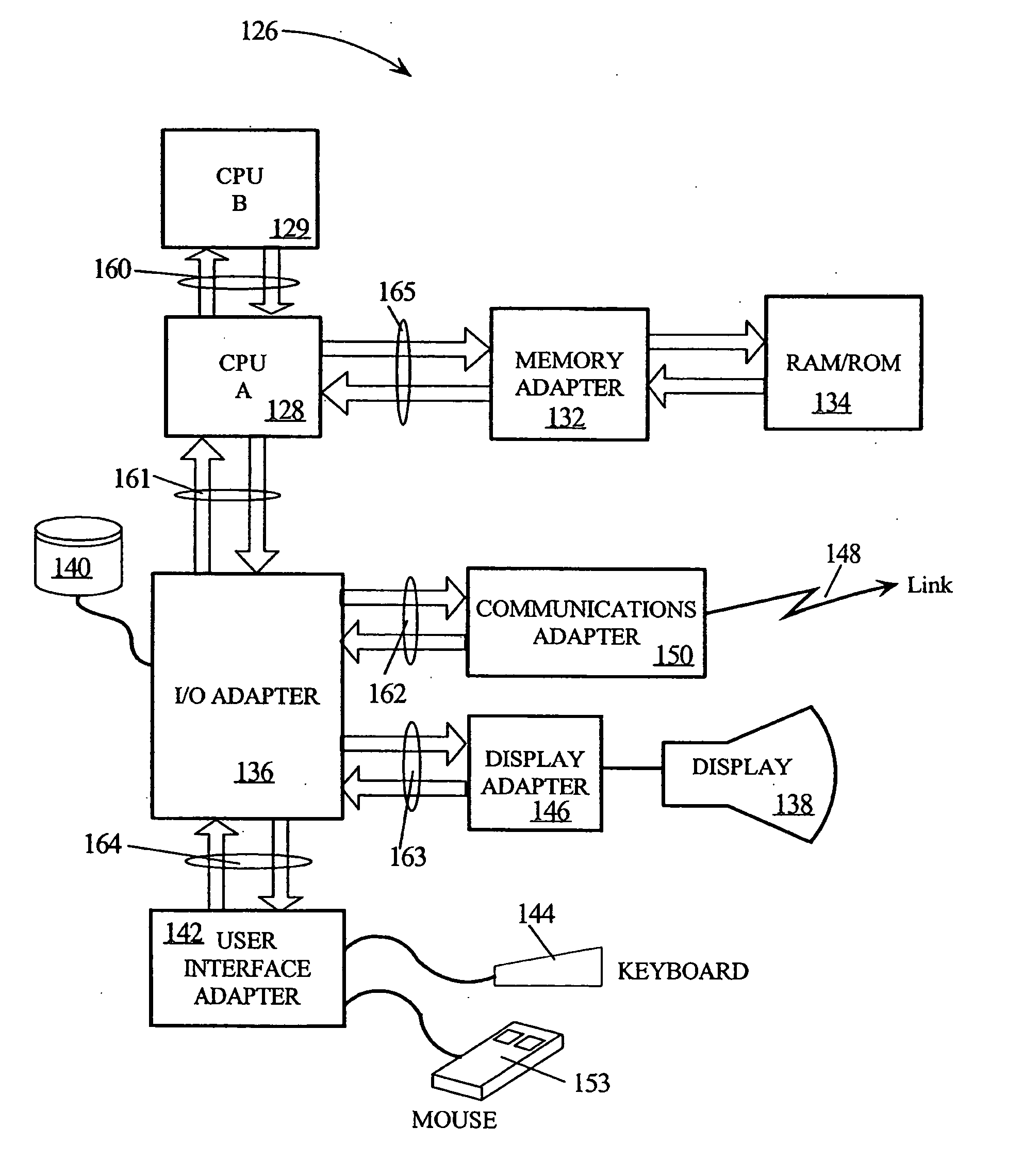

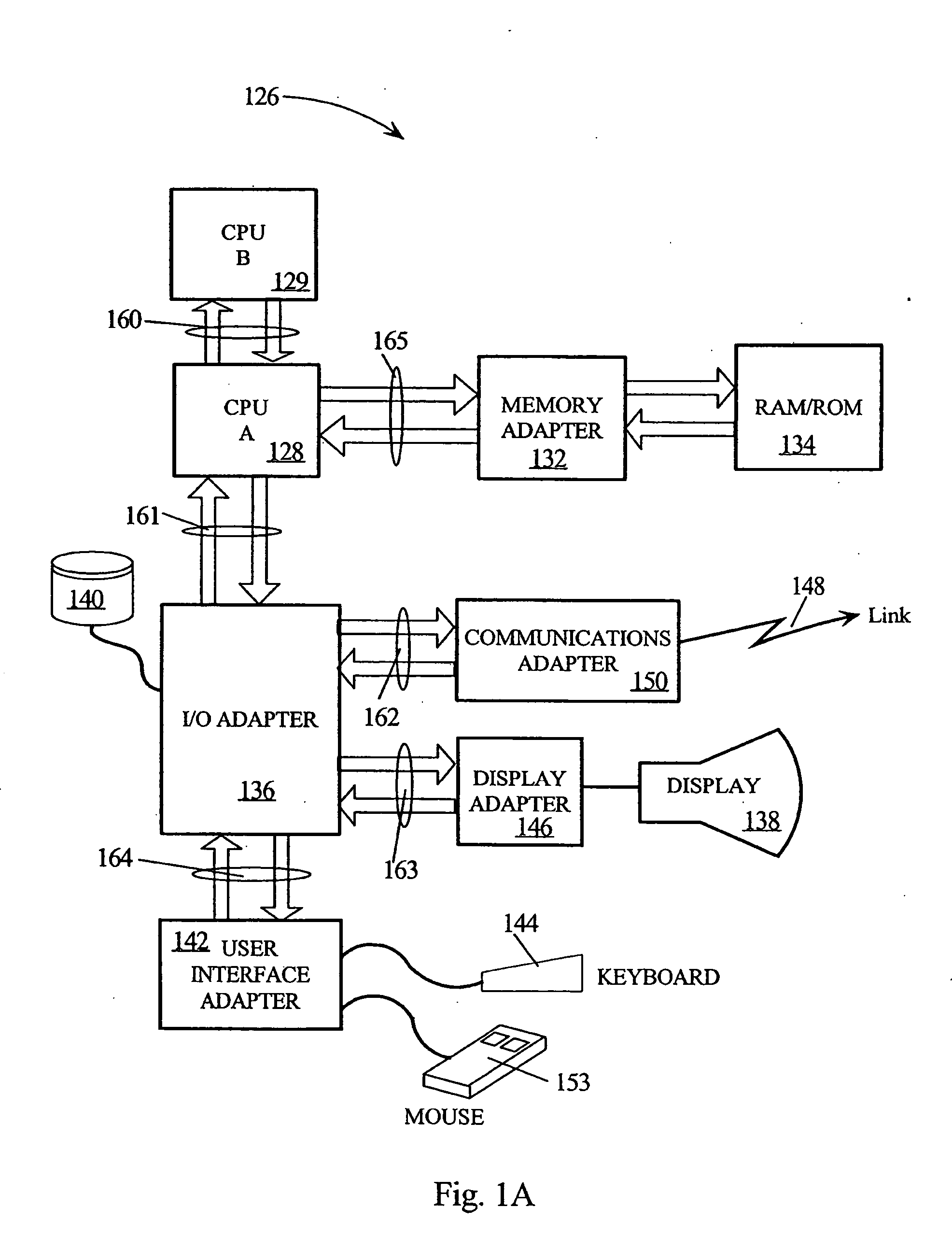

An apparatus, system, and method are provided for automatically minimizing Real-Time (RT) task latency and maximizing Non-Real Time (NRT) task throughput. The apparatus may include a task manager, a determination module, and optionally a tracking module. The task manager may execute a NRT task configured to obtain exclusive access to a resource within a multi-processor environment. The determination module identifies a RT task within the multi-processor environment that shares exclusive access to the resource with the NRT task. Optionally, the tracking module selectively executes or bypasses a preemption point associated with the NRT task in response to the RT task becoming runnable. Alternatively, the NRT task selectively executes or bypasses a predefined preemption point in response to the RT task becoming runnable. In this manner, RT tasks on any processor of the multi-processor environment meet minimum latency thresholds and NRT tasks automatically provide maximum throughput in the multi-processor environment.

Owner:TWITTER INC

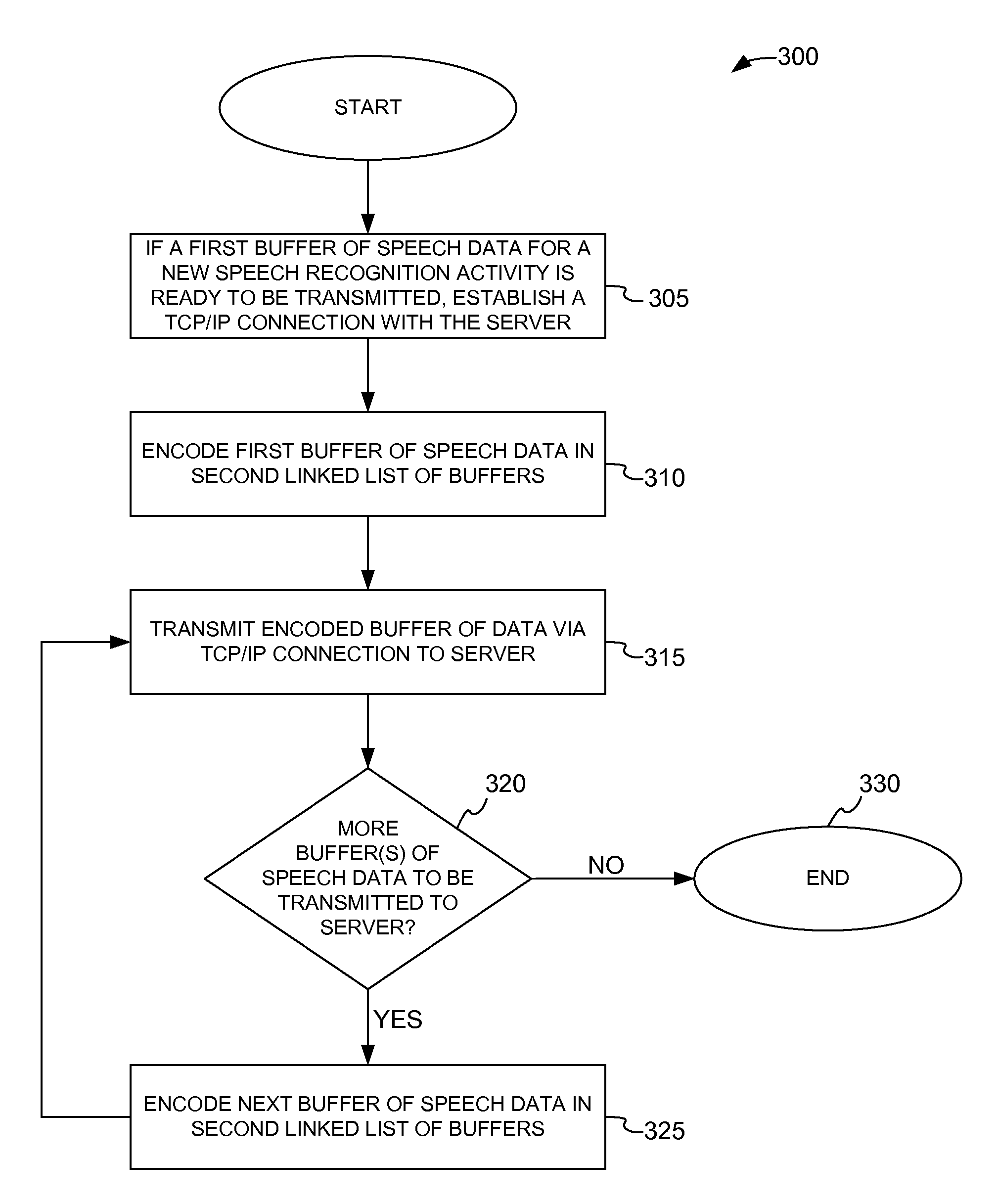

Real-time speech recognition over the internet

Methods and systems for handling speech recognition processing in effectively real-time, via the Internet, in order that users do not experience noticeable delays from the start of an exercise until they receive responsive feedback. A user uses a client to access the Internet and a server supporting speech recognition processing, e.g., for language learning activities. The user inputs speech to the client, which transmits the user speech to the server in approximate real-time. The server evaluates the user speech in context of the current speech recognition exercise being executed, and provides responsive feedback to the client, again, in approximate real-time, with minimum latency delays. The client upon receiving responsive feedback from the server, displays, or otherwise provides, the feedback to the user.

Owner:PEARSON EDUCATION

Power aware adaptive polling

ActiveUS20040123169A1Easy to handleImprove performanceVolume/mass flow measurementMultiple digital computer combinationsPolling systemTime segment

A method for adapting the periodicity of polling for pending service requests, by polling system devices for pending service requests, recording whether or not there was a pending service request and, based on accumulated data, determining whether or not the system devices are idle. Based on this determination, the system may elect to enter a power conservation mode until device activity is signaled, or an adjustable period of time elapses. The adaptation mechanism may alter the periodicity of the timer interrupt, disable or enable device interrupts, and modify variables used to determine system idleness (including minimum latency and minimum idleness thresholds). In this manner, the system can conserve power while maintaining system performance and responsiveness.

Owner:IBM CORP

Apparatus, system, and method for automatically minimizing real-time task latency and maximizing non-real time task throughput

ActiveUS7721291B2Minimizing real-time (RT) task latencyMaximize throughputMultiprogramming arrangementsMemory systemsNon real timeMulti processor

An apparatus, system, and method are provided for automatically minimizing Real-Time (RT) task latency and maximizing Non-Real Time (NRT) task throughput. The apparatus may include a task manager, a determination module, and optionally a tracking module. The task manager may execute a NRT task configured to obtain exclusive access to a resource within a multi-processor environment. The determination module identifies a RT task within the multi-processor environment that shares exclusive access to the resource with the NRT task. Optionally, the tracking module selectively executes or bypasses a preemption point associated with the NRT task in response to the RT task becoming runnable. Alternatively, the NRT task selectively executes or bypasses a predefined preemption point in response to the RT task becoming runnable. In this manner, RT tasks on any processor of the multi-processor environment meet minimum latency thresholds and NRT tasks automatically provide maximum throughput in the multi-processor environment.

Owner:TWITTER INC

Low latency handover between wireless communication networks using different radio access technologies

ActiveUS8027309B2Minimum delayTime-division multiplexData switching by path configurationIp addressGeneric Access Network

A communications system for providing a user's mobile station (MS) with an Internet Protocol (IP) connectivity, has an IP network gateway for allocating an IP address to the MS to enable it to access an IP network. First and second base stations are respectively configured to support communications of the MS over first and second radio access networks using different radio access technologies. A first access gateway provides an interface between the IP network gateway and the first radio access network, whereas a second access gateway provides an interface between the IP network gateway and the second radio access network. A handover interface is provided between the first access gateway and the second access gateway for enabling the MS to switch between the first and second radio access networks with minimum latency.

Owner:CELLCO PARTNERSHIP INC

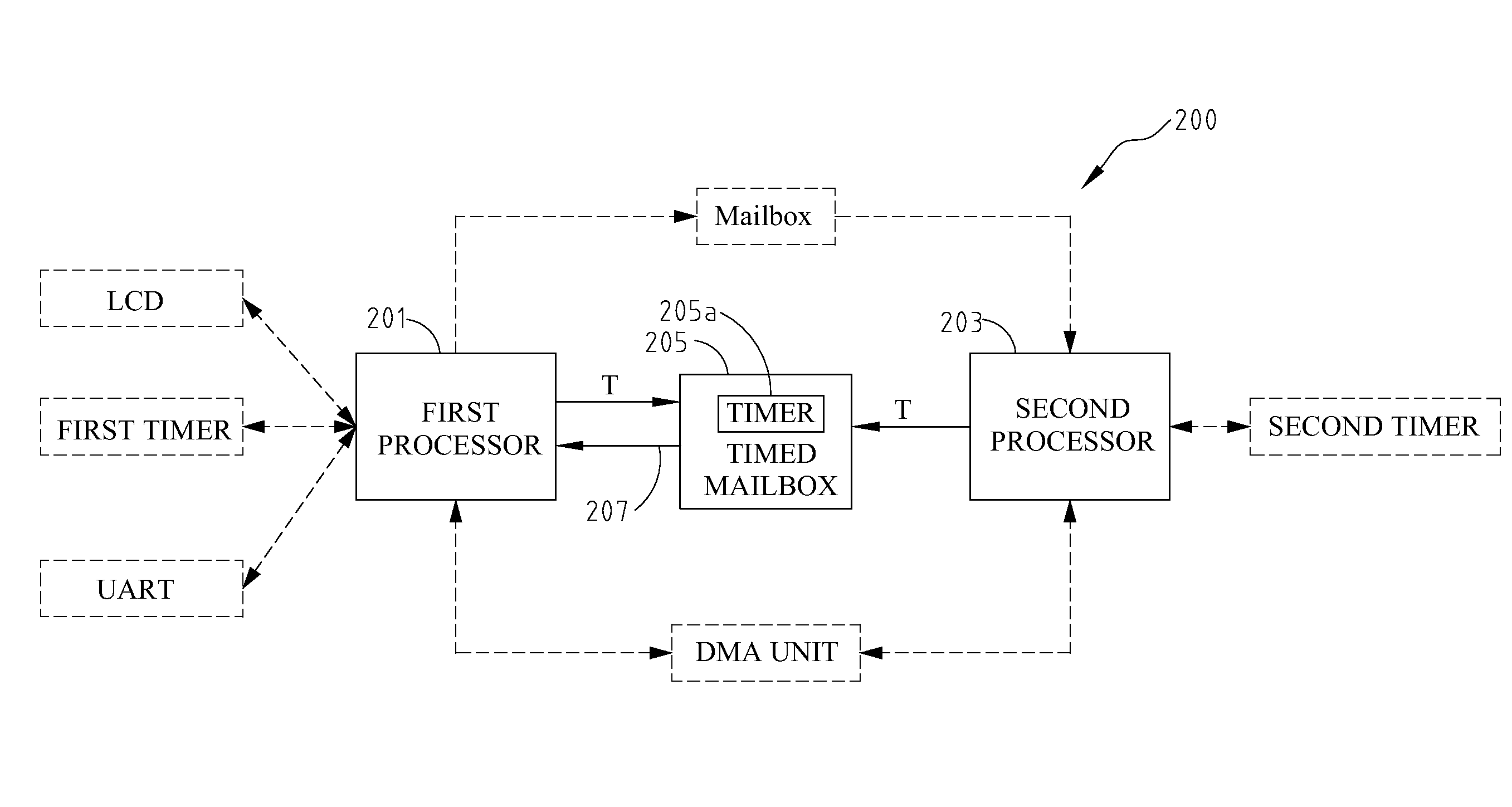

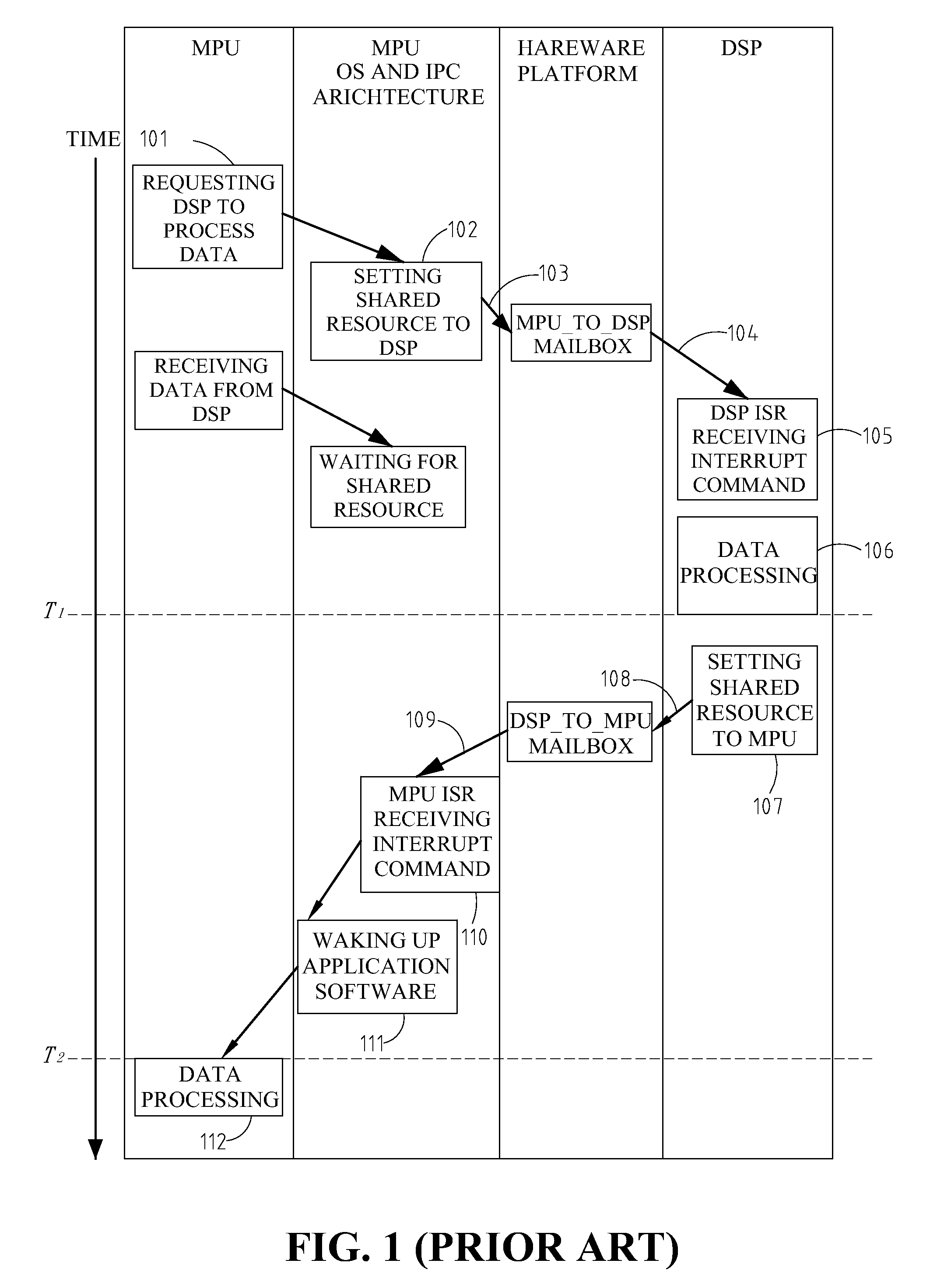

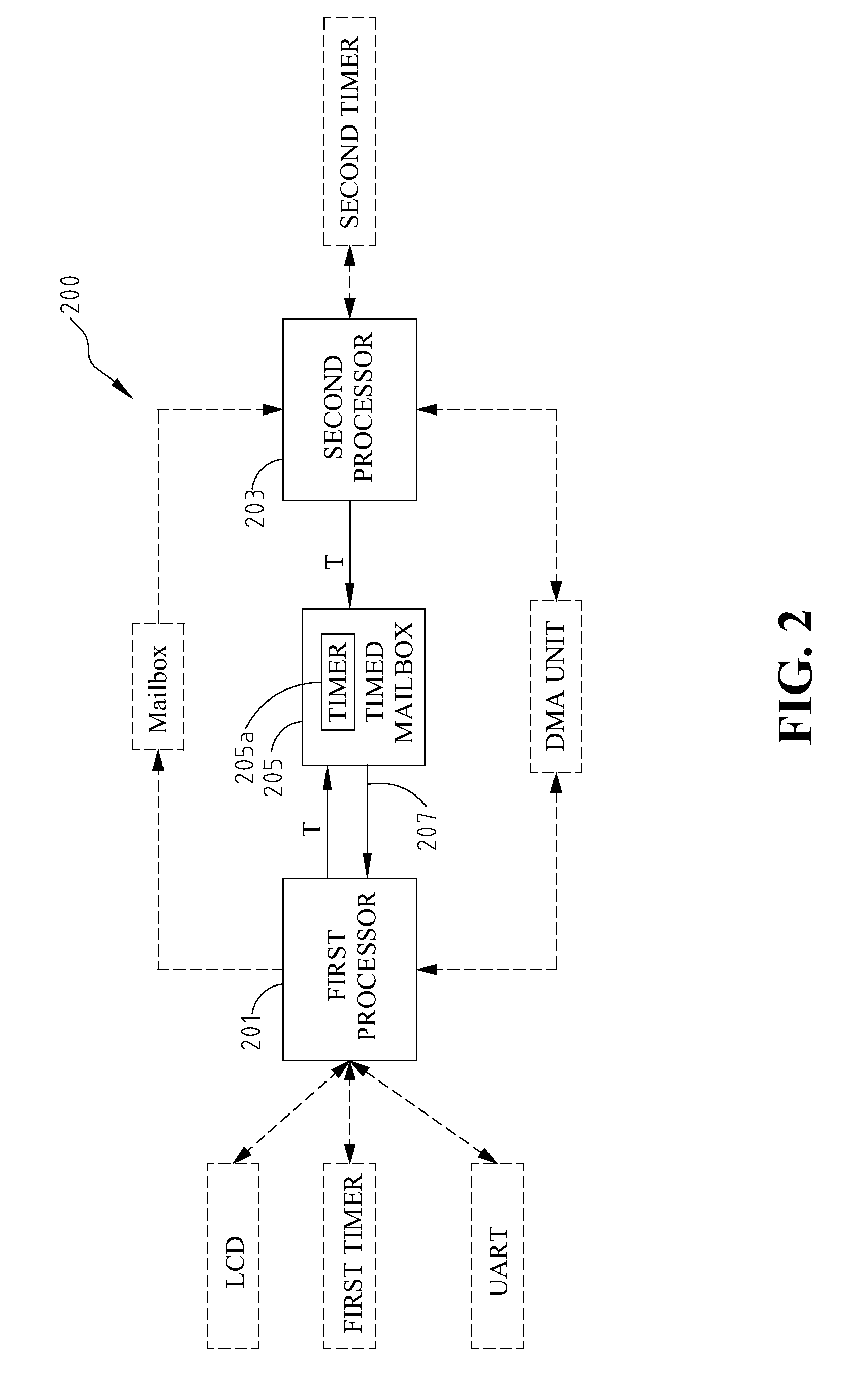

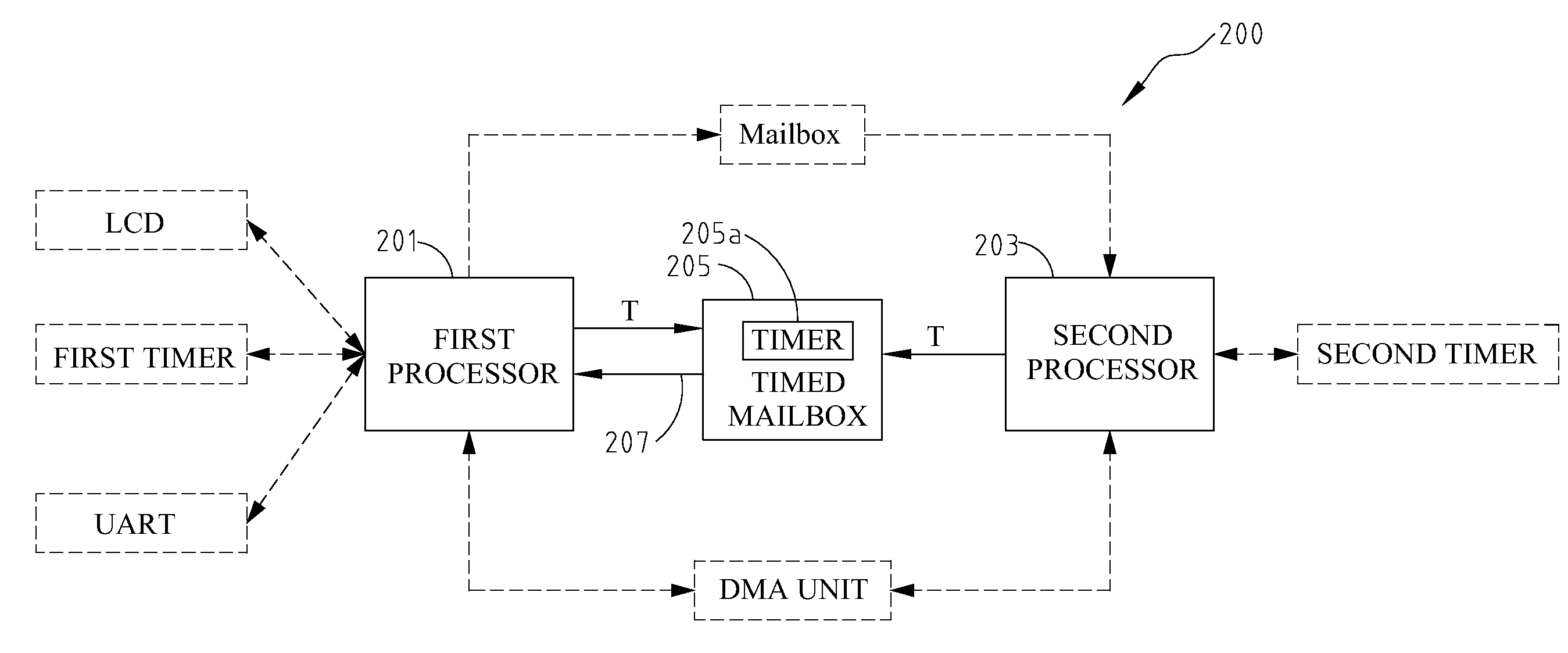

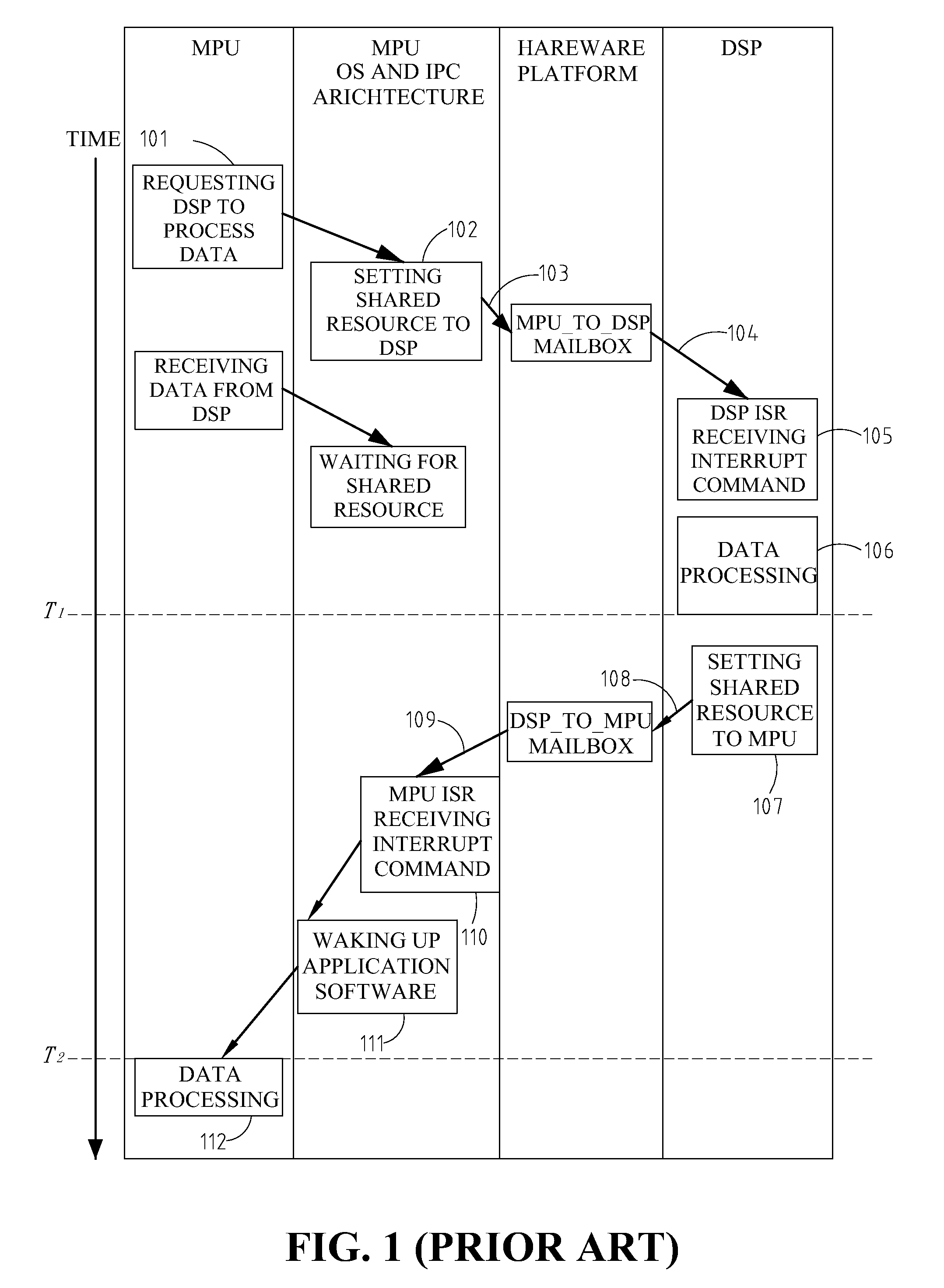

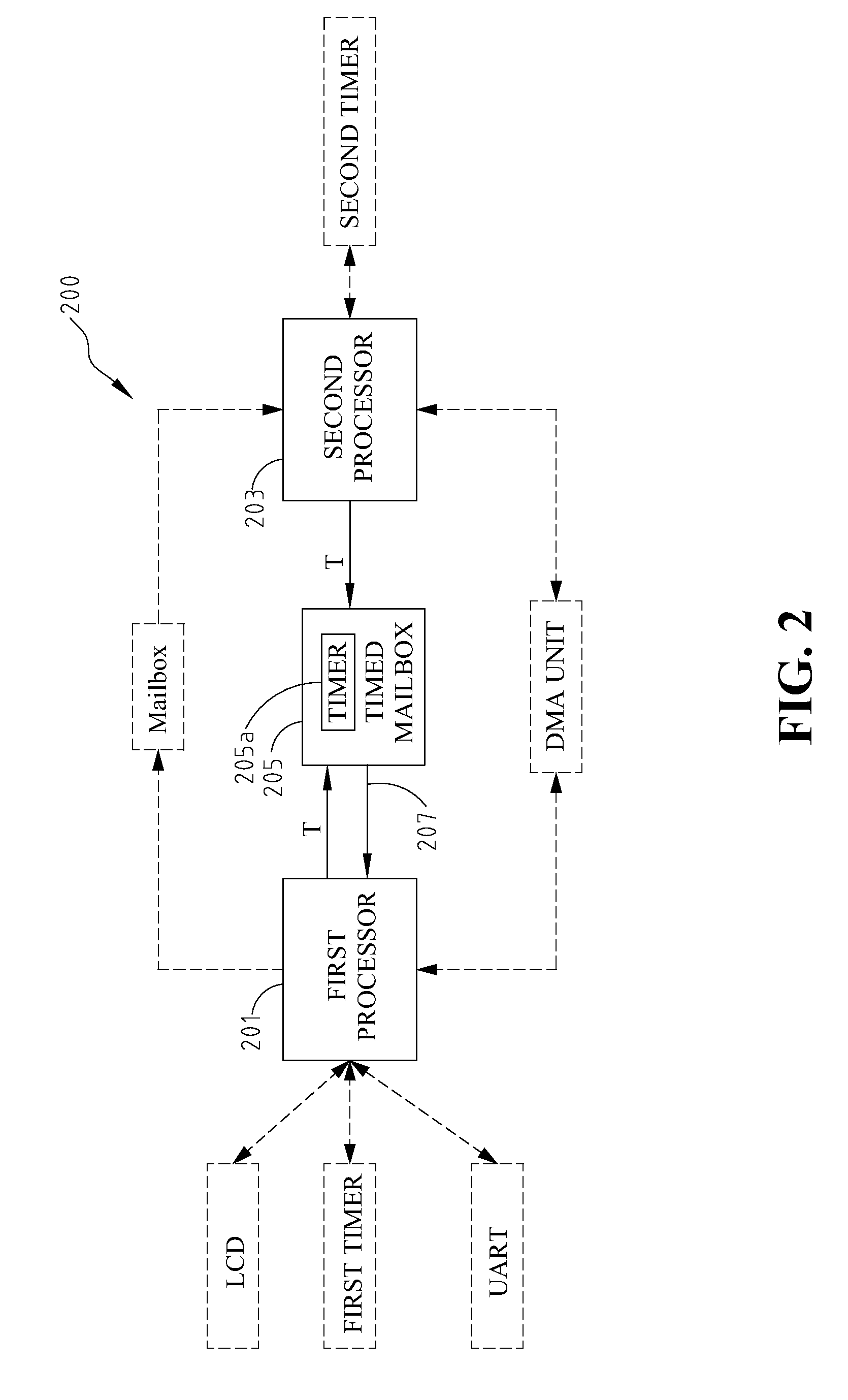

System having minimum latency using timed mailbox to issue signal in advance to notify processor of the availability of the shared resources

ActiveUS8099731B2Increase profitOvercomes drawbackMultiprogramming arrangementsMultiple digital computer combinationsMulti processorTimer

Owner:IND TECH RES INST

Print job assignment method allowing user-prioritization

ActiveUS8270007B2Extended processing methodDigitally marking record carriersCharacter printing data arrangement from carrierComputer scienceJob assignment

A method implemented in a print job management apparatus for processing print jobs in a multiple-printer print shop environment is described. Each print job specifies job ticket parameters representing printing requirements. Each received job is processed by comparing the printing requirements of the job with capabilities of the printers. If a printer cannot satisfy all printing requirements of the job, it is eliminated as a candidate printer. Then, from all printers that can satisfy all printing requirements of the job, one printer is selected based on a pre-defined priority preference and the job is submitted to the selected printer. The printer priority preference is created by the operator based on cost and other factors. The operator can also select an alternative execution mode where, among all printers that can satisfy all requirements of the job, the one with minimum wait time is selected.

Owner:KONICA MINOLTA LAB U S A INC

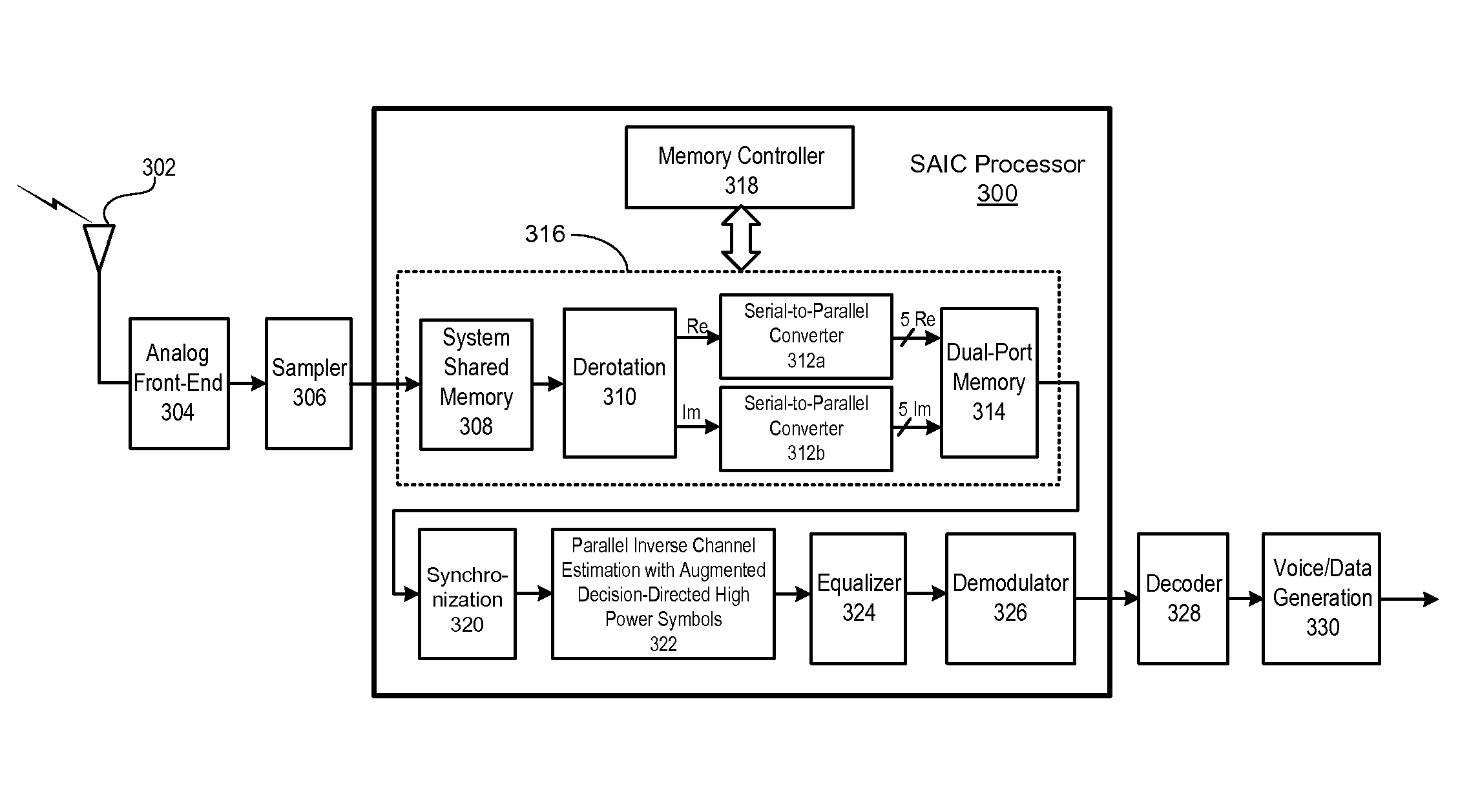

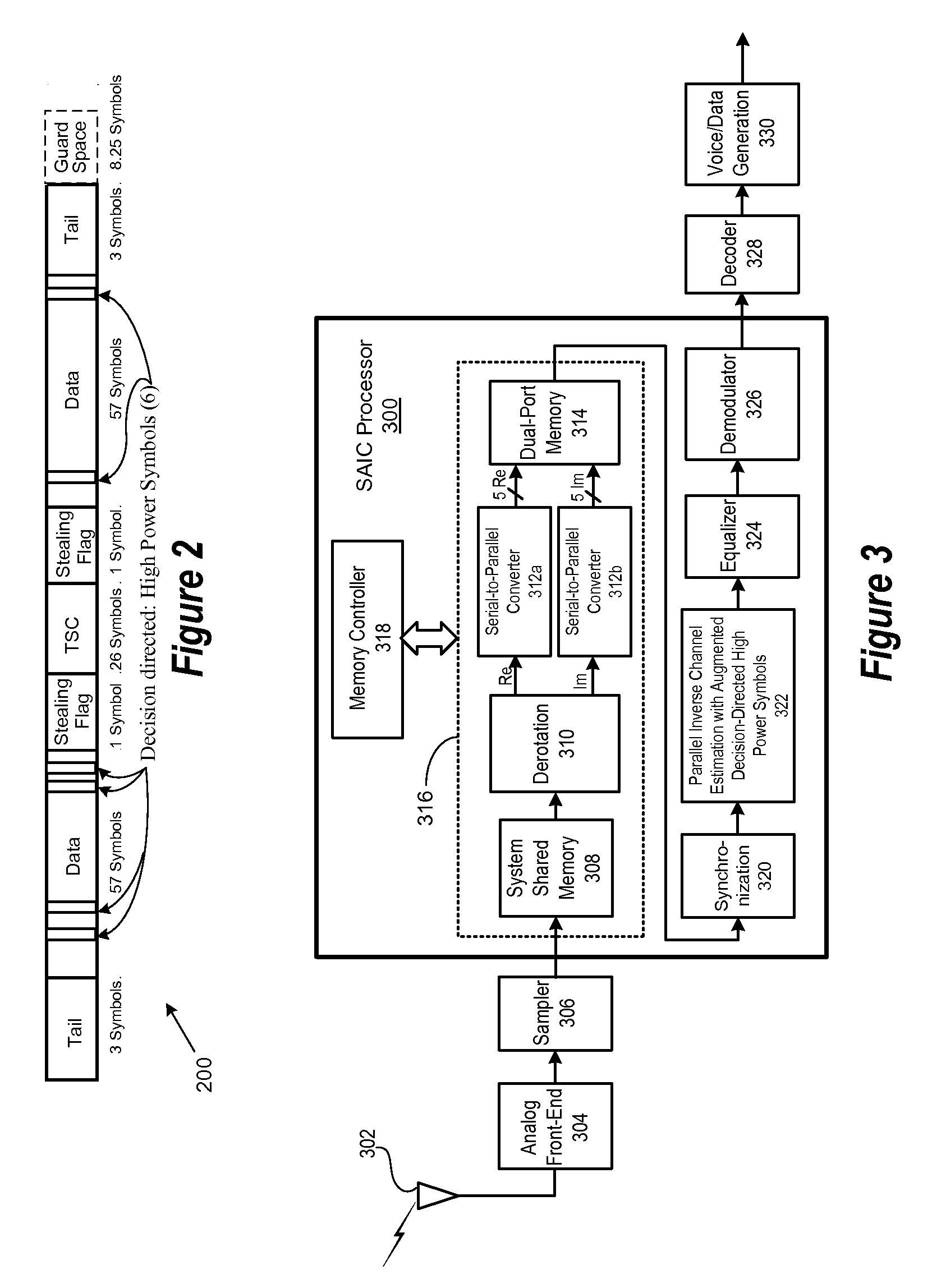

Parallel processing for single antenna interference cancellation

A system and method is disclosed for providing single antenna interference cancellation processing with minimum latency. Incoming data frames are processed to generate a plurality of parallel data streams which are then further processed using a parallel single antenna interference cancellation algorithm to reject the signals and to generate a data stream containing only the desired symbols. In various embodiments of the invention, the parallel data streams are processed using a parallel arithmetic logic unit that is capable of operating in single-cycle mode in response to a first control stream and a multi-cycle mode in response to a second control stream. Embodiments of the invention comprise a three port memory interface operable to receive the parallel data streams and to generate a virtual three-dimensional data structure therefrom. In some embodiments of the invention, the virtual three-dimensional data representation comprises a plurality of segmented matrices, with the segmented matrices comprising data corresponding to portions of the incoming data frames. Data elements within the individual segments of the virtual three dimensional data structure can be calculated using data elements contained in a predetermined row and predetermined column of a segment.

Owner:APPLE INC

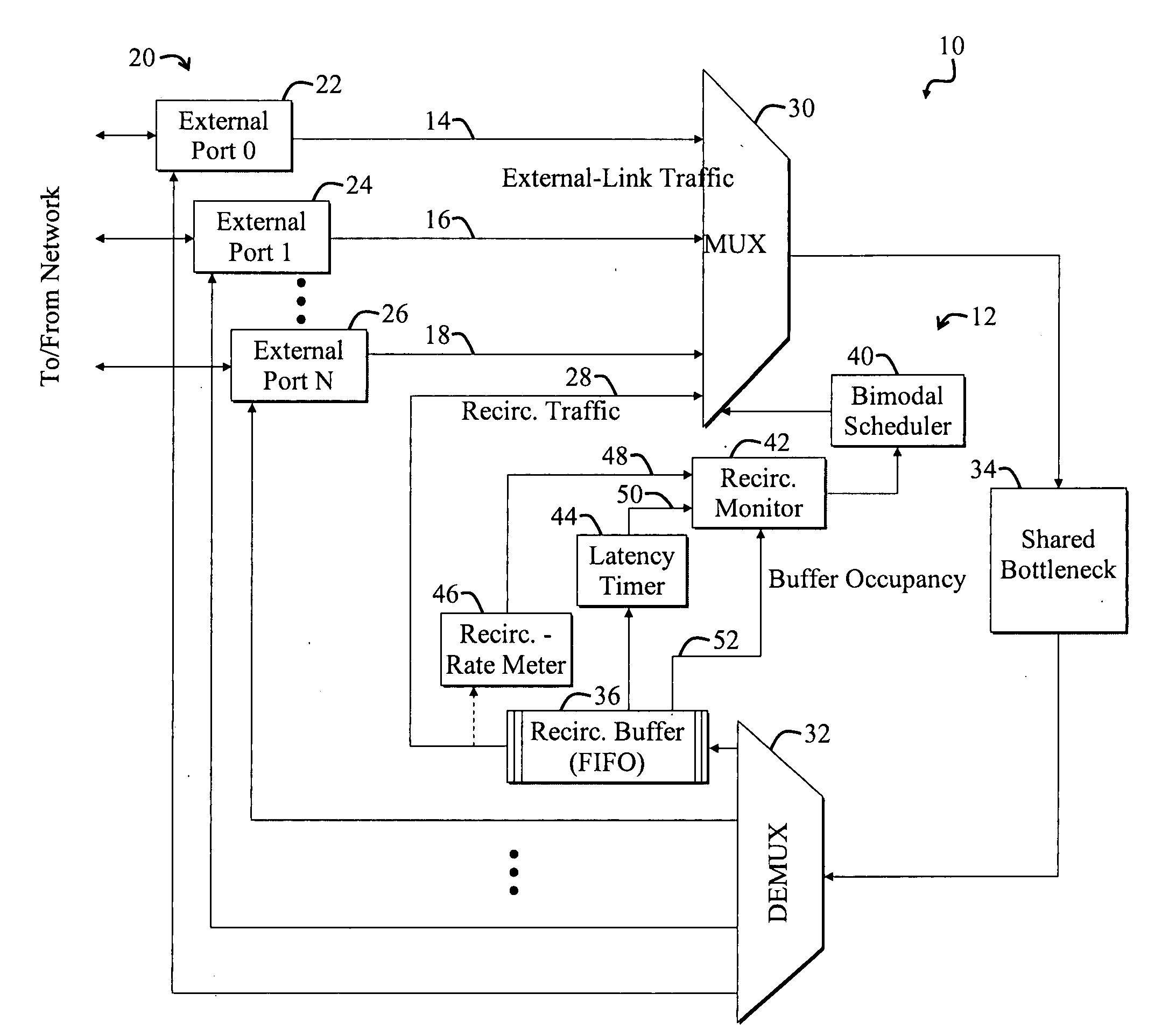

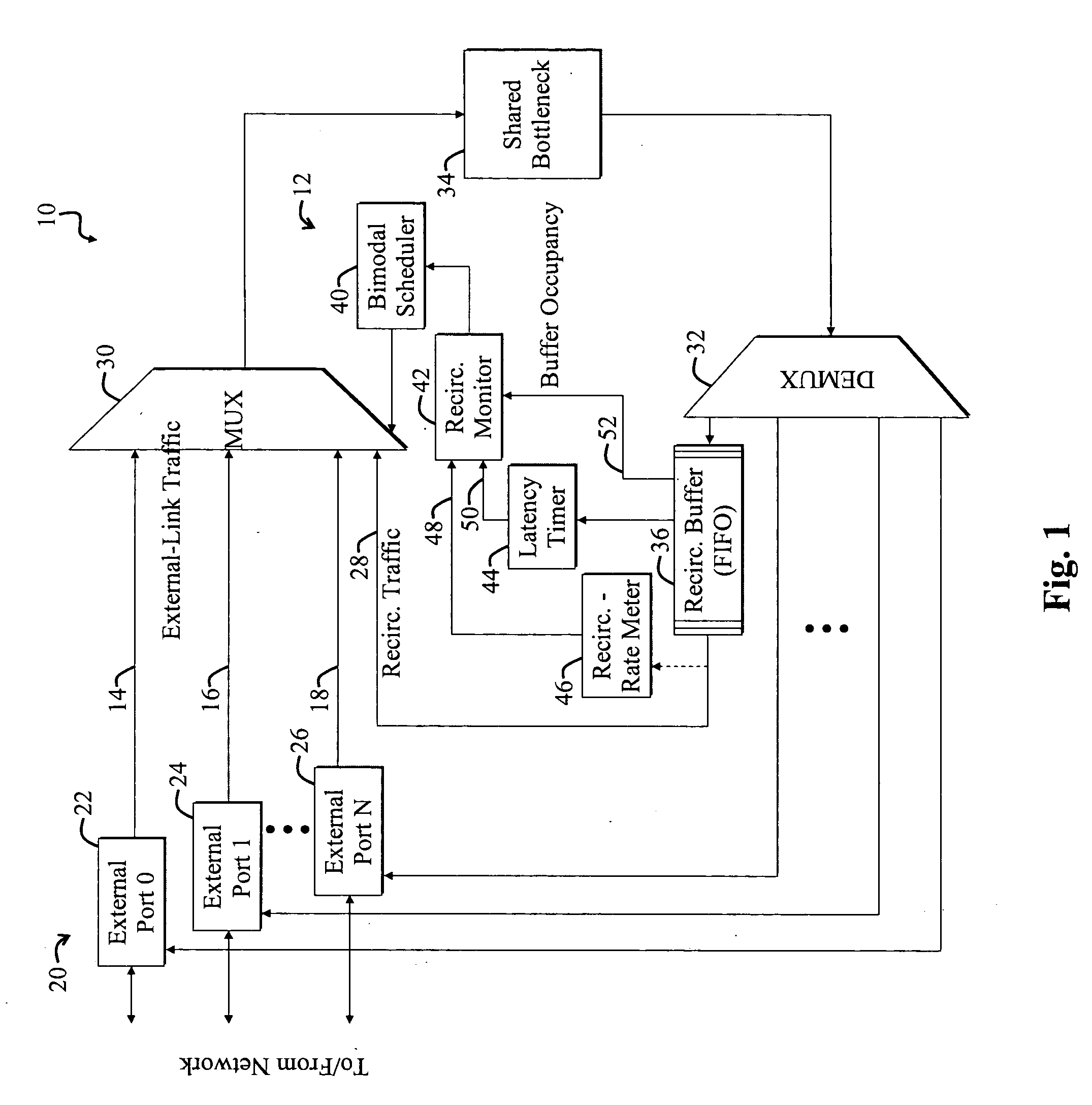

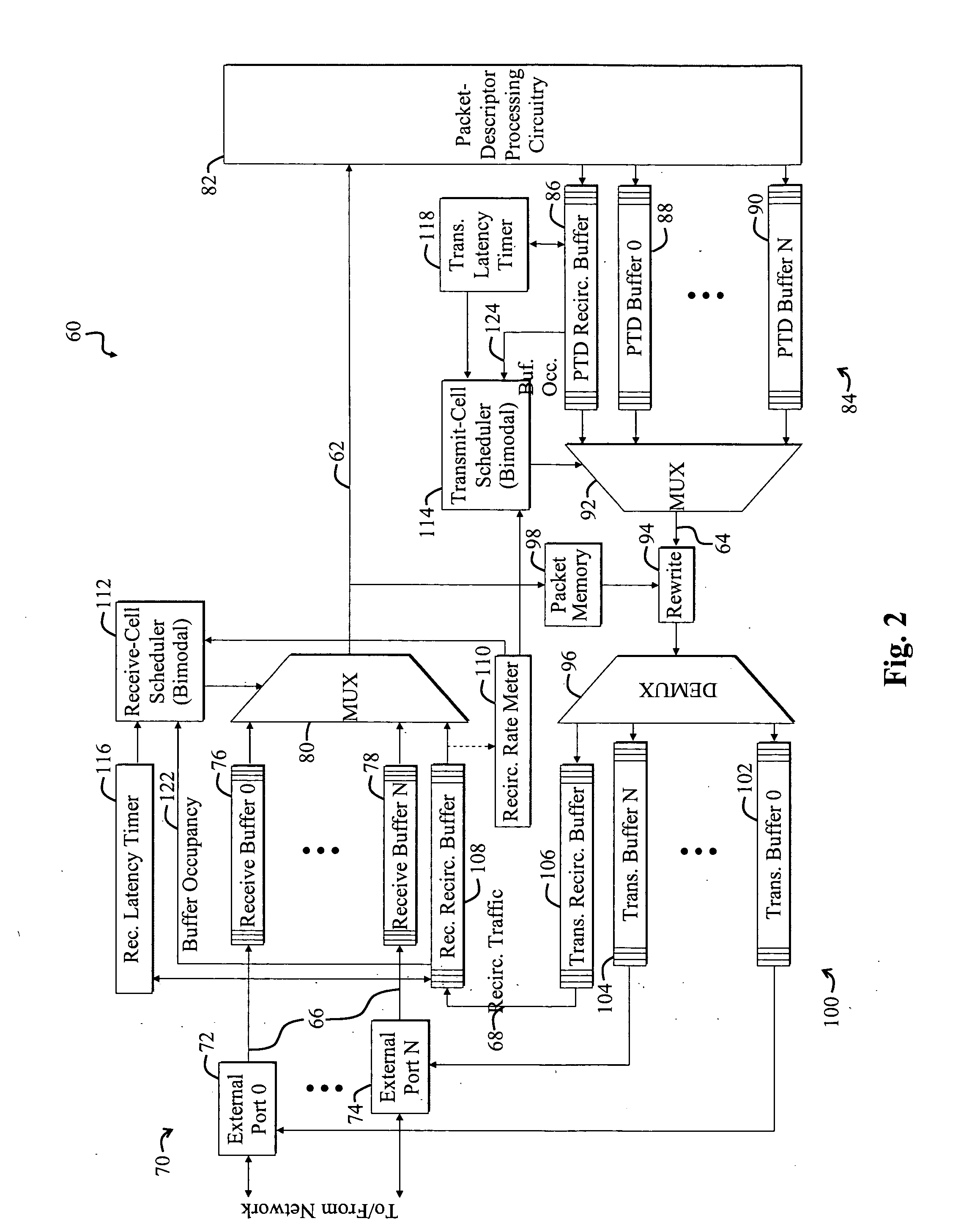

System and method for managing bandwidth

A system for managing bandwidth use in a device. In a specific embodiment, the device is a network device that includes a first data scheduler that is adapted to initially share available device bandwidth among a first type of traffic and a second type of traffic on an as-needed basis. A traffic monitor communicates with the first scheduler and causes the first data scheduler to guarantee predetermined transmission characteristics for the second type of traffic. The first data scheduler includes one or more routines for prioritizing first type of traffic above the second type of traffic when the network device is in a first operational mode, and prioritizing the second type of traffic above the first type of traffic when the network device is in a second operation al mode. The minimum transmission characteristics include a minimum service rate and a minimum latency for the second type of traffic.

Owner:CISCO TECH INC

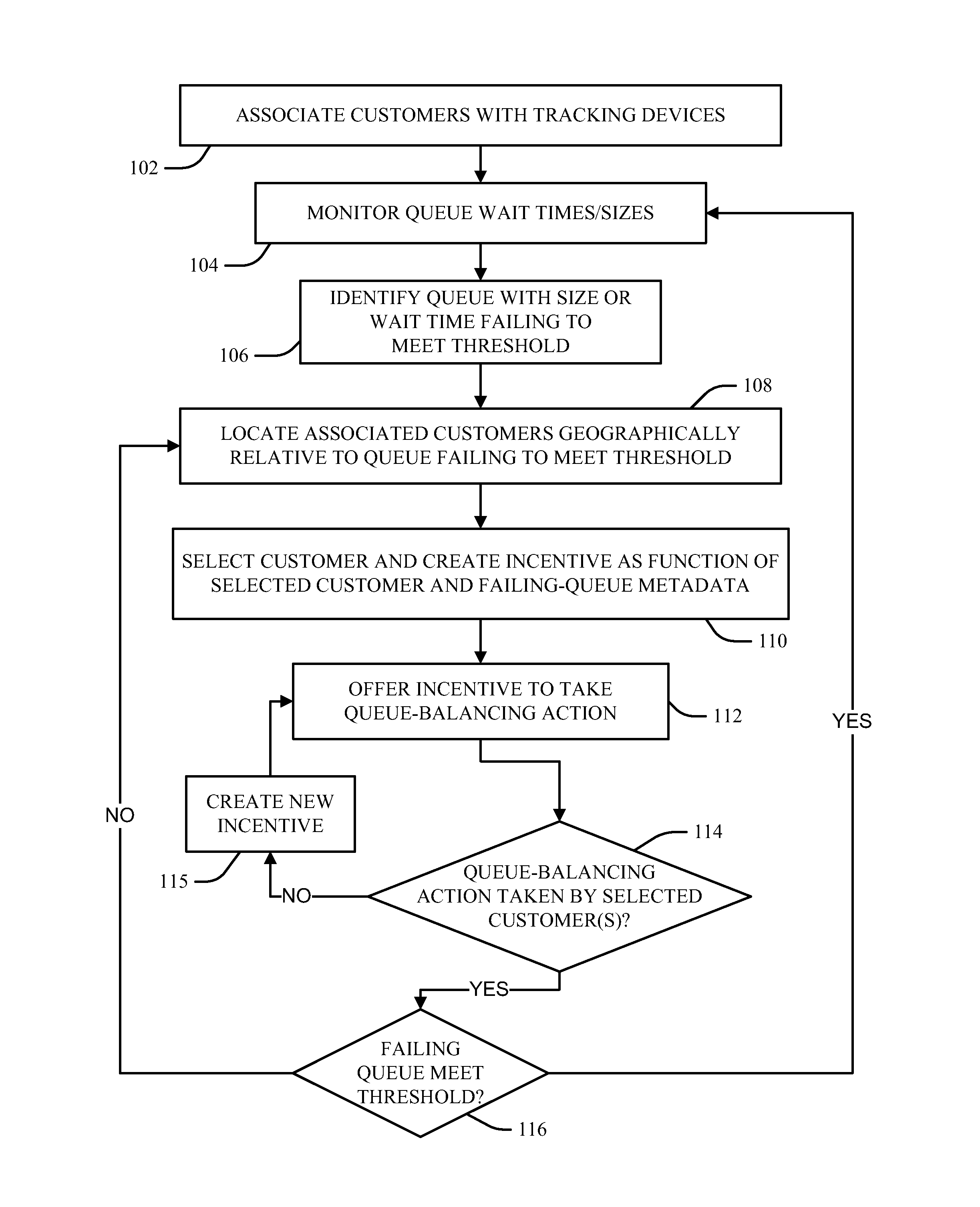

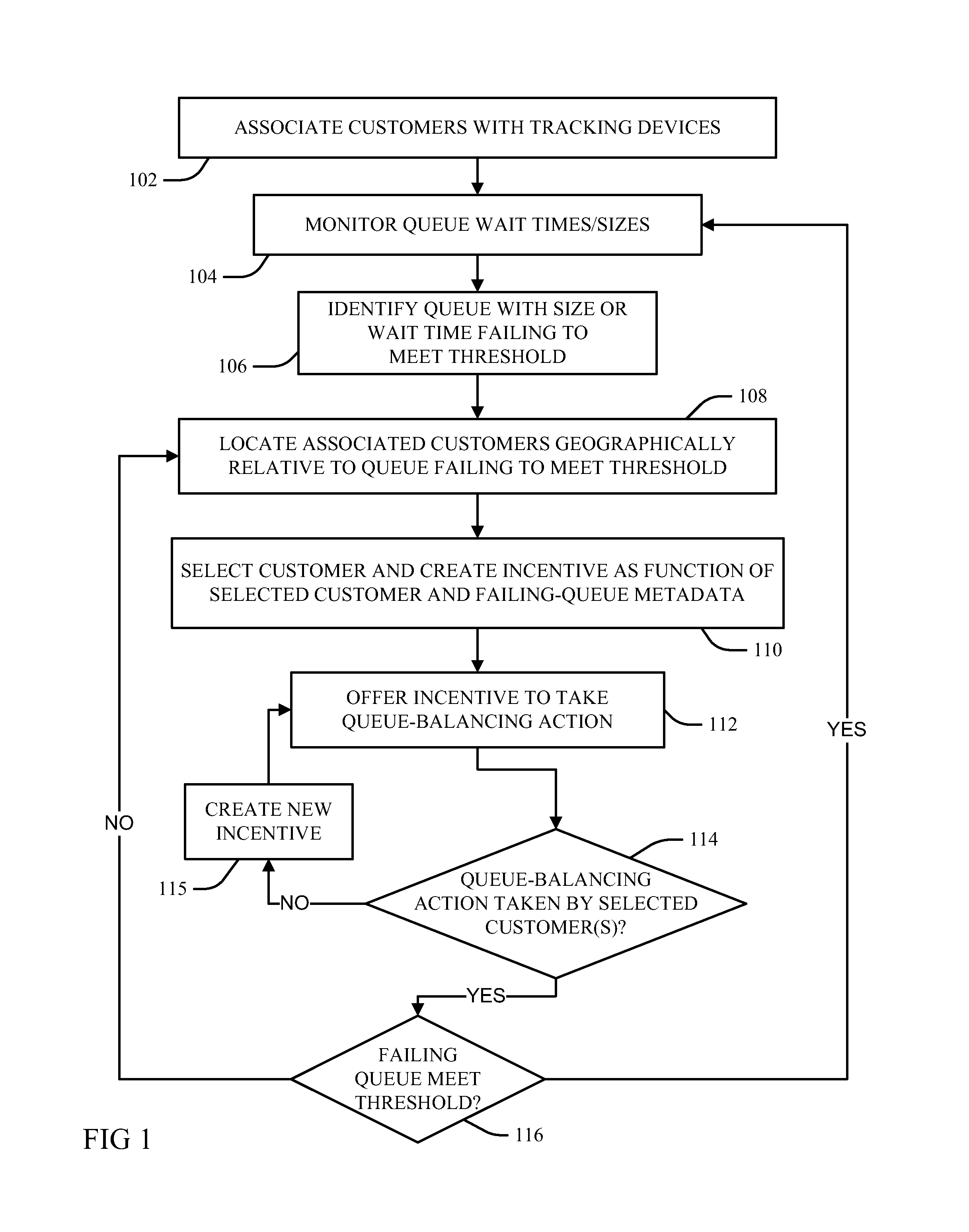

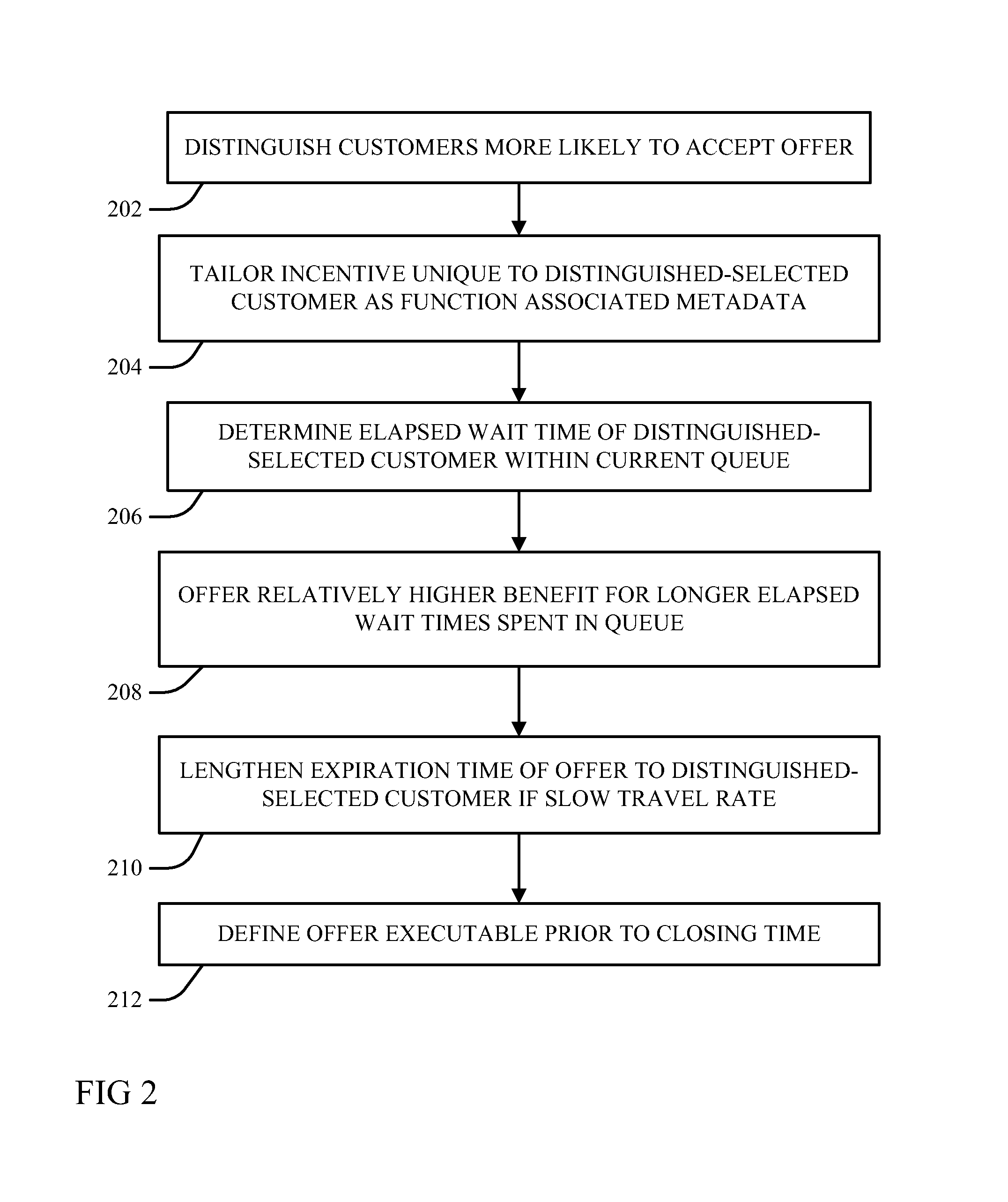

Optimal scheduling of venue attendance based on queue size and location

Embodiments of the invention provide for managing attraction attendance levels through tracking current attendance levels and notifying patrons of incentives to alter their attraction selections in real-time. Examples identify an attraction queue that has a customer wait time failing to meet a threshold and determine a geographic relationship of a tracking device associated with a registered customer to the queue. Accordingly, an incentive is created from metadata associated with the queue and offered to the registered customer to urge the registered customer to take a queue balancing action. The queue balancing action may be leaving the queue if the customer wait time exceeds a threshold maximum wait time and the tracking device is within the queue, or choosing to enter the queue if the customer wait time is less than a threshold minimum wait time and the tracking device is outside of the queue.

Owner:INT BUSINESS MASCH CORP

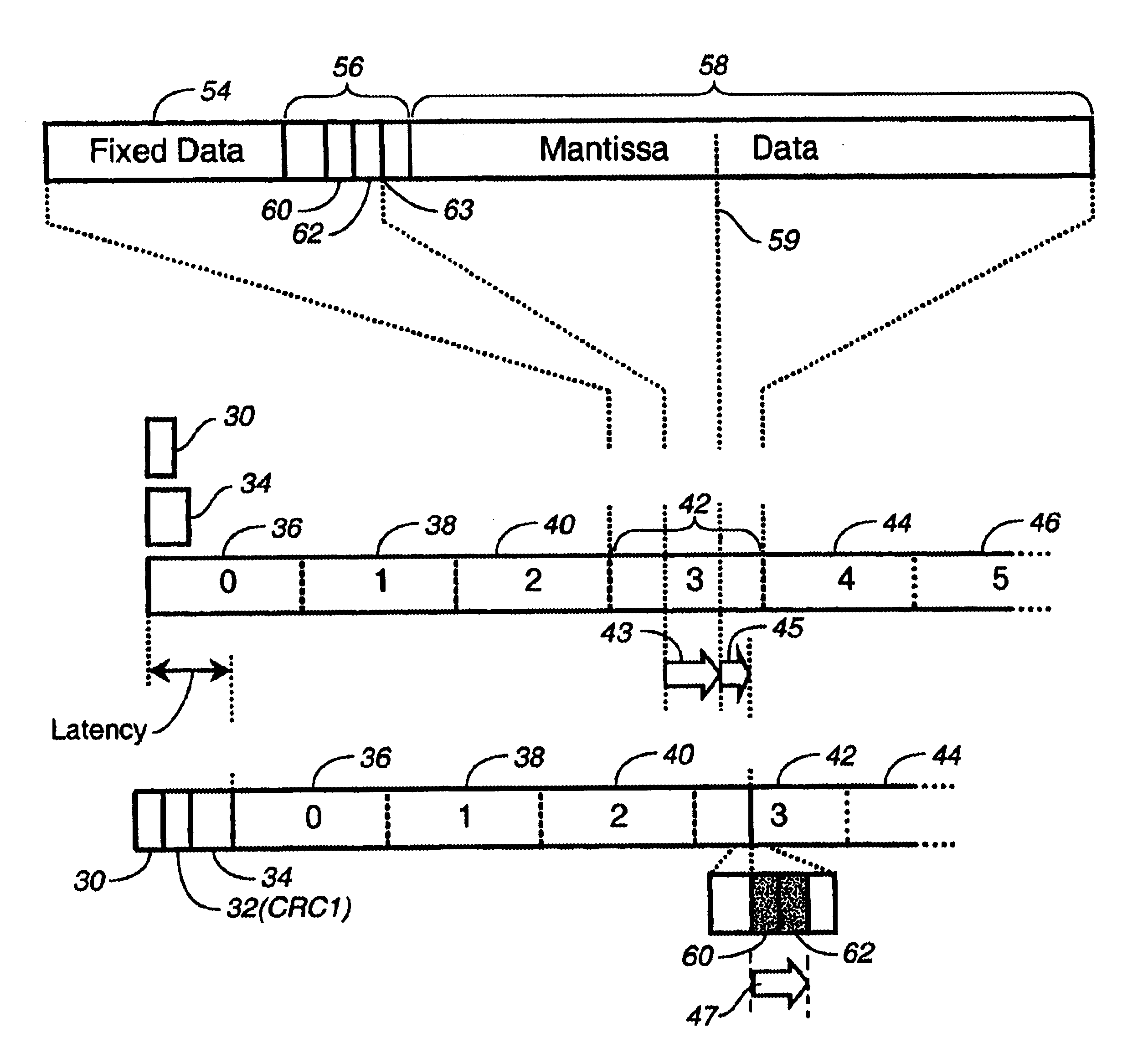

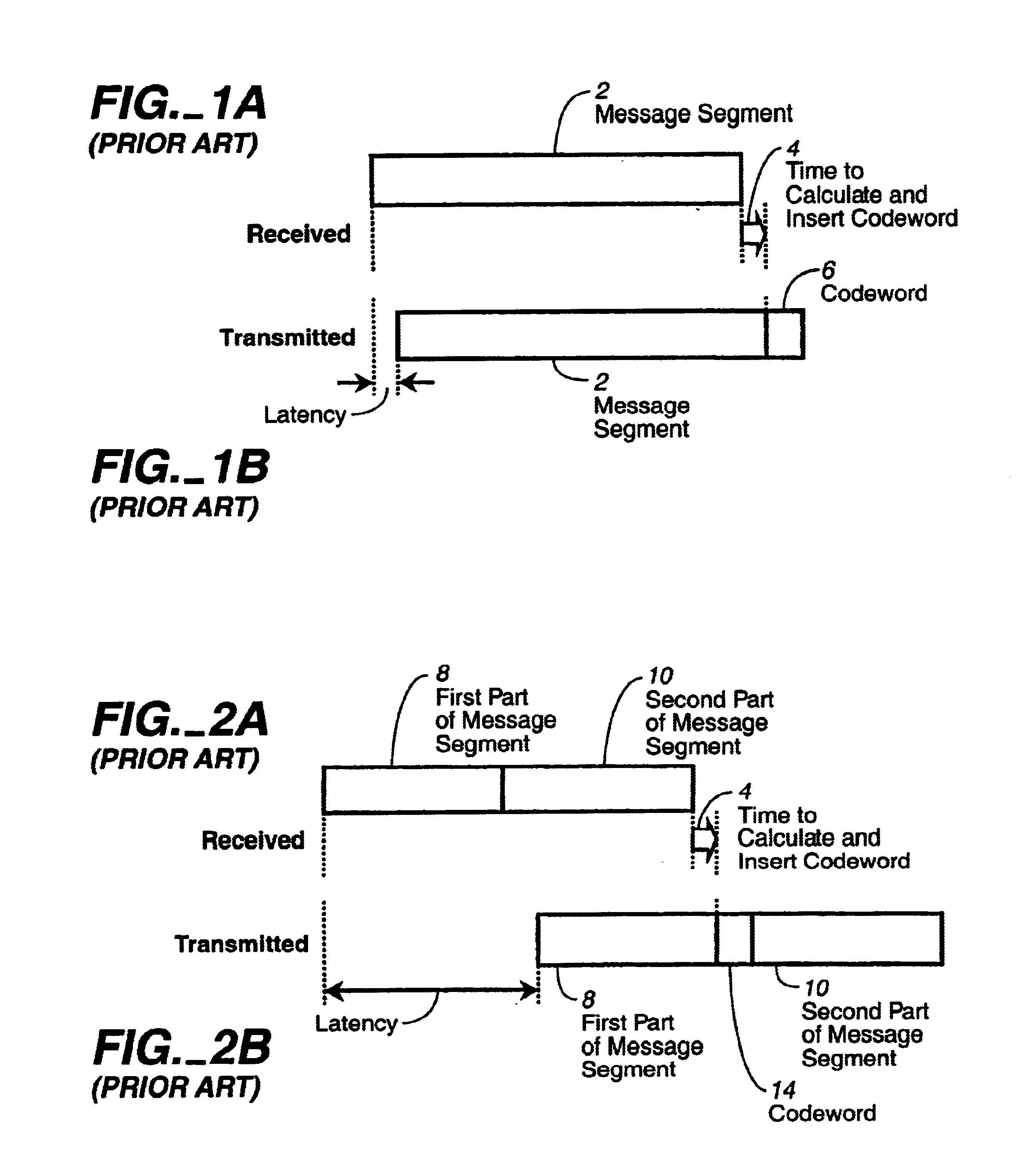

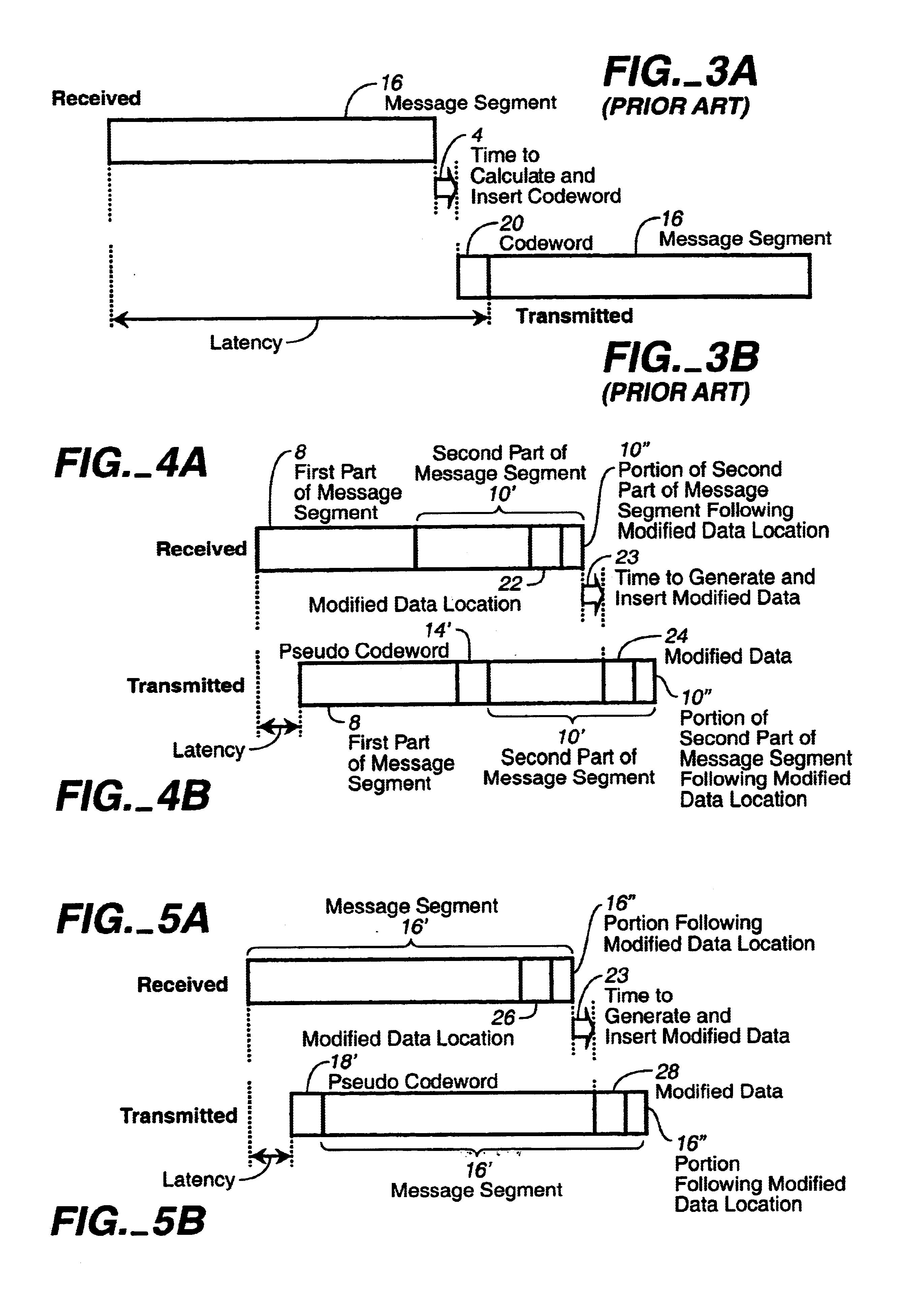

Low latency data encoder

InactiveUS6725412B1Reduce codeword-position-caused latencyPromote lowerSpeech analysisCode conversionAlgorithmLow delay

Codeword-position-caused encoder latency is reduced by avoiding the requirement for knowledge of the message prior to generating an error detecting or concealing codeword associated with the message. A pseudo error detecting or concealing codeword is inserted in place of the normal error detecting or concealing codeword appropriate for the segment of information to which the error detecting or concealing codeword relates. In order to satisfy the requirement of conventional decoders, the pseudo error detecting or concealing information must match or be appropriate for the segment so that the decoder sees the codeword and message segment as valid or error free. This is accomplished by modifying or perturbing at least a portion of the segment to which the pseudo codeword relates. The invention is particularly useful for maintaining the backward compatibility of audio data encoding formats in which the minimum latency is too long (e.g., computer games, where the player performs some operation leading to a sound, and that sound must not be perceptibly delayed with respect to the operation).

Owner:DOLBY LAB LICENSING CORP

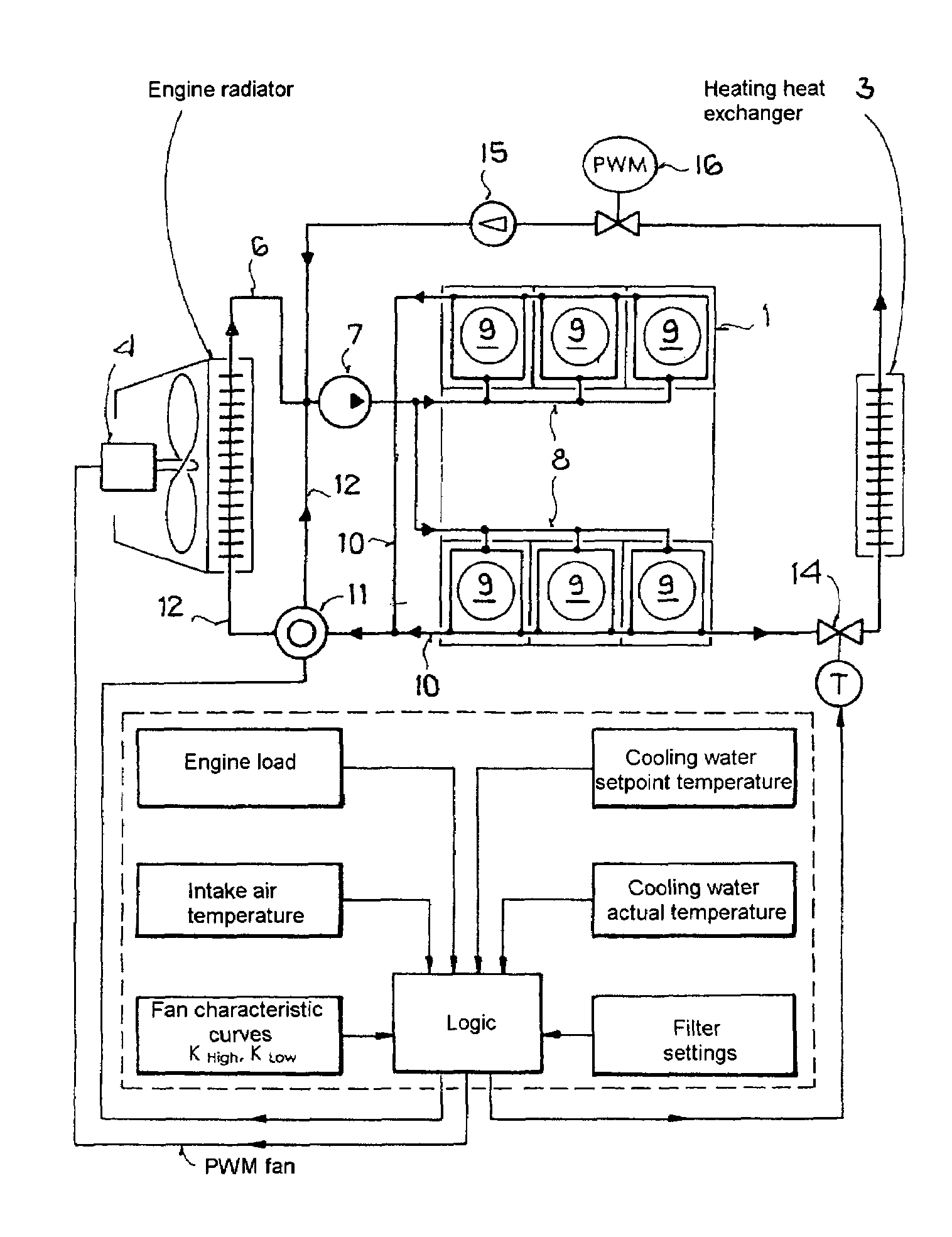

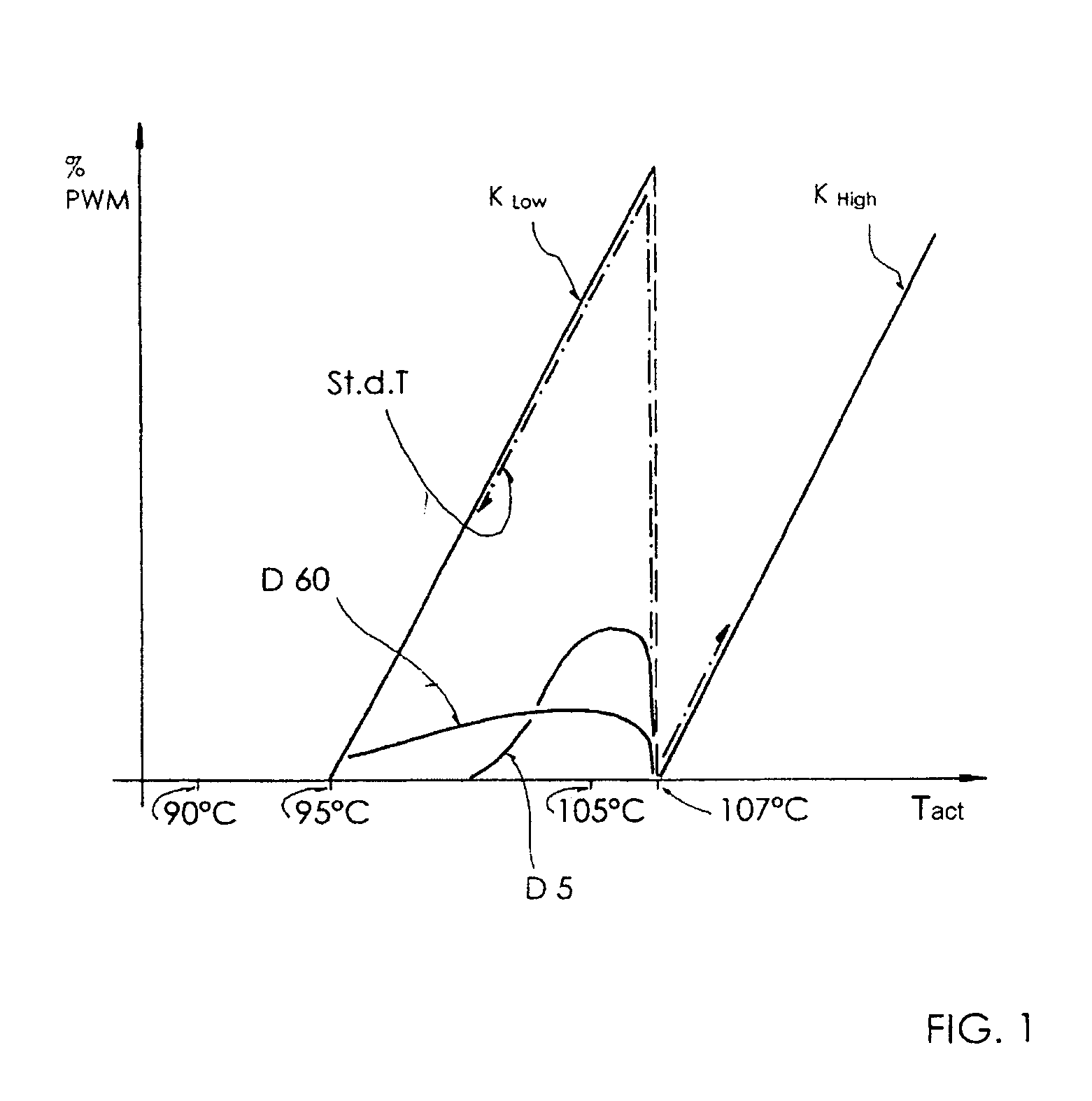

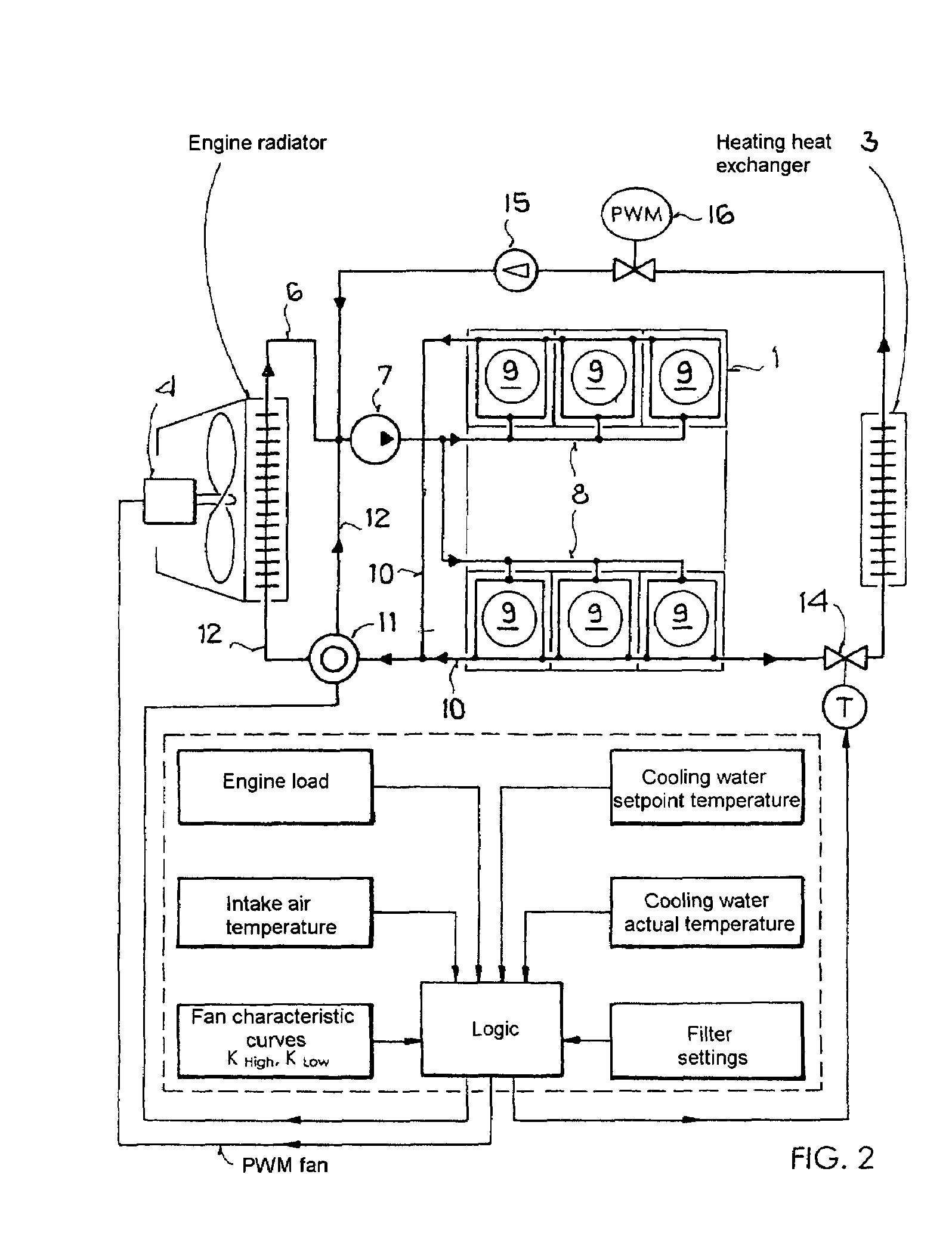

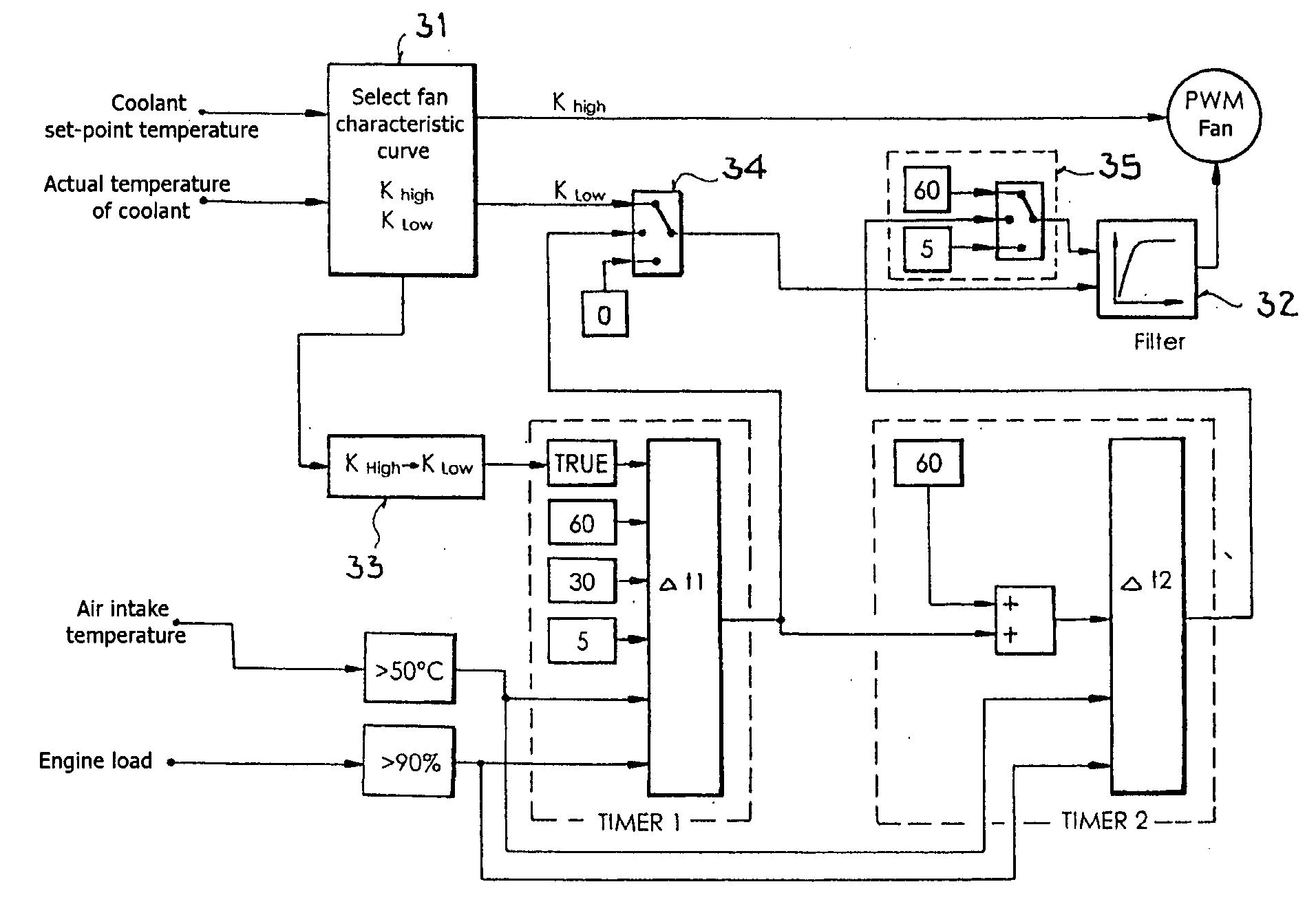

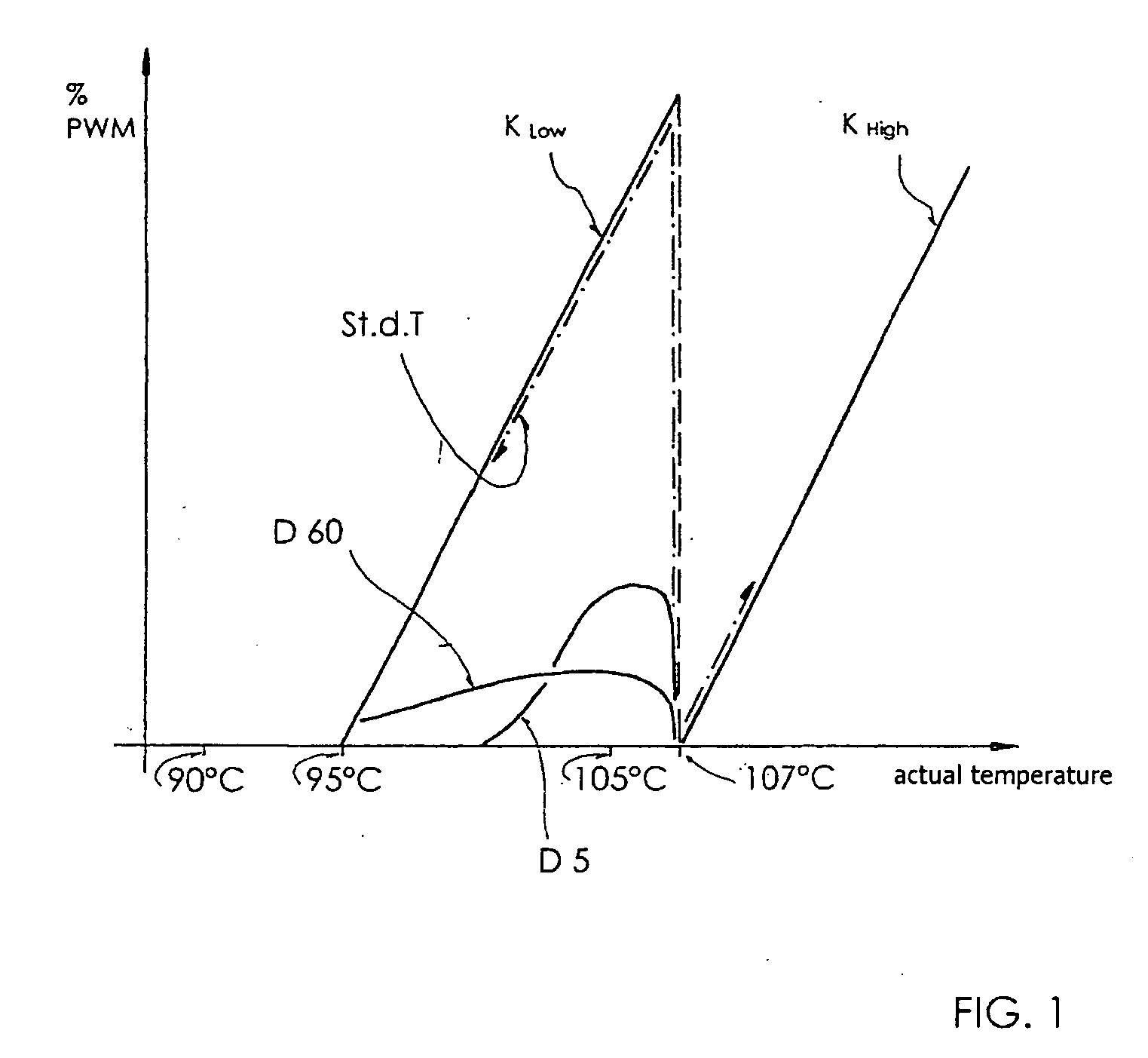

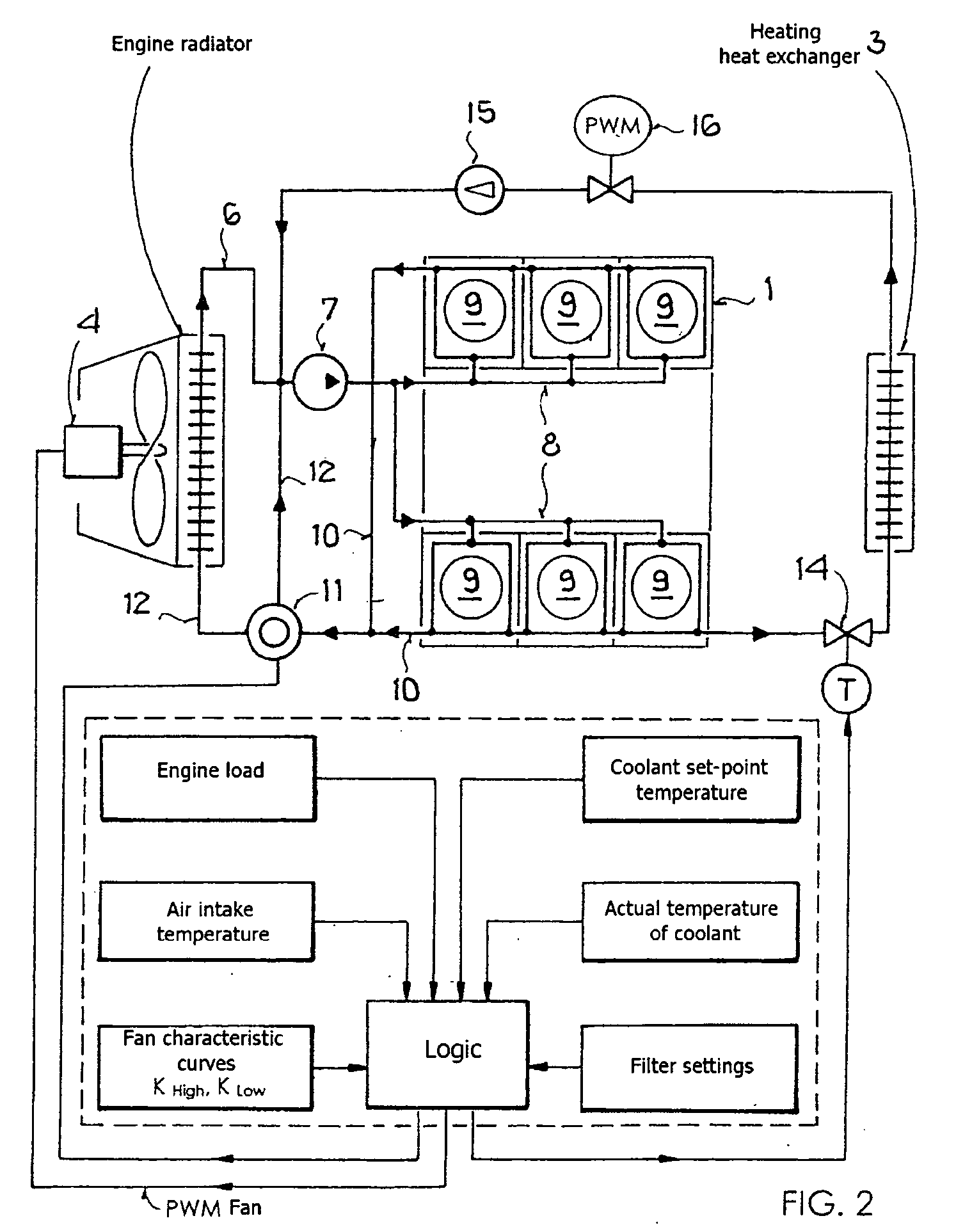

Method for actuating a fan using a plurality of characteristic curves and a control program for controlling the power of the fan

ActiveUS7310959B2Avoid problemsReduce waiting timePropellersWind motor controlElectric machineEngineering

The present invention relates to control of a fan during which the power of the fan is determined from the characteristic curves of the fan motor, the operating parameters of the cooling system and the reference variables which are predefined in the form of temperature levels. The various temperature levels which are to be set have different associated characteristic curves for actuating the fan motor. If the reference variable for the control changes, this also means a change in the characteristic curves for actuating the fan motor. In order to prevent the fan motor from whining, the operation of the fan motor is kept constant for a settable minimum waiting time when the reference variable for the control of the fan changes. During this minimum waiting time, the operating parameters of the cooling system can, if appropriate, be adapted by means of other control mechanisms which are independent of the fan to the new reference variable to such an extent that it is no longer necessary to take measures with respect to the whining of the fan motor.

Owner:VOLKSWAGEN AG

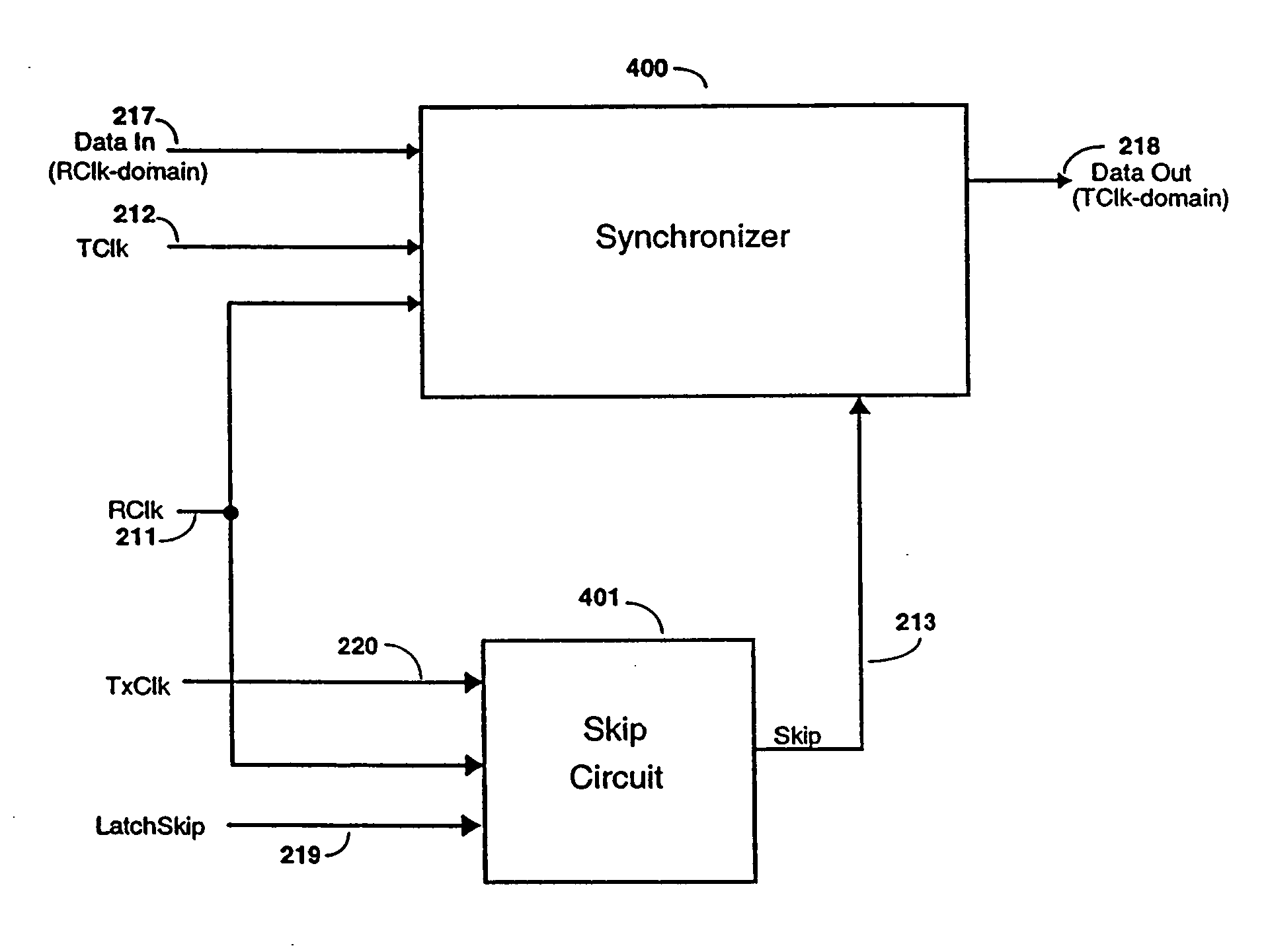

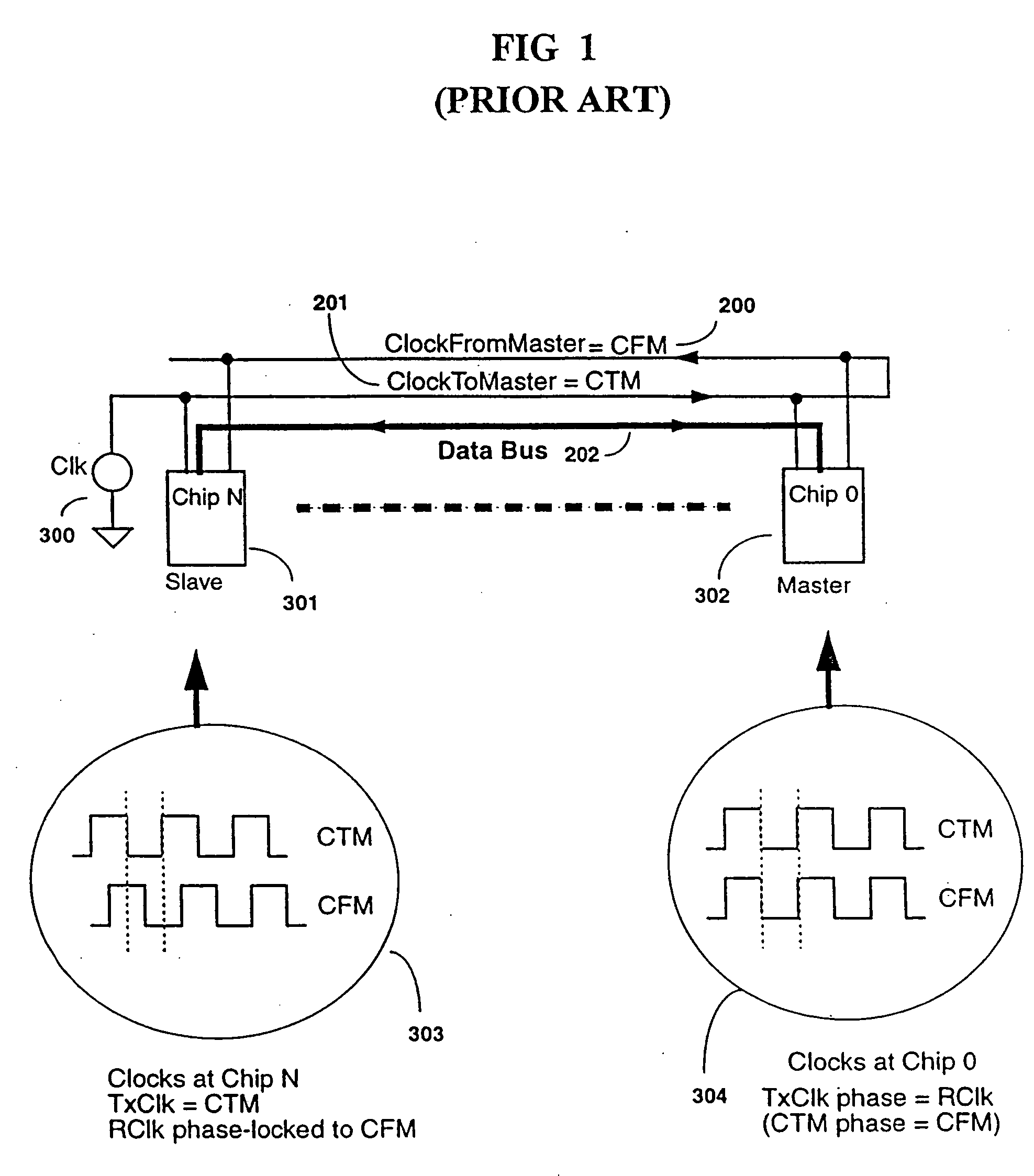

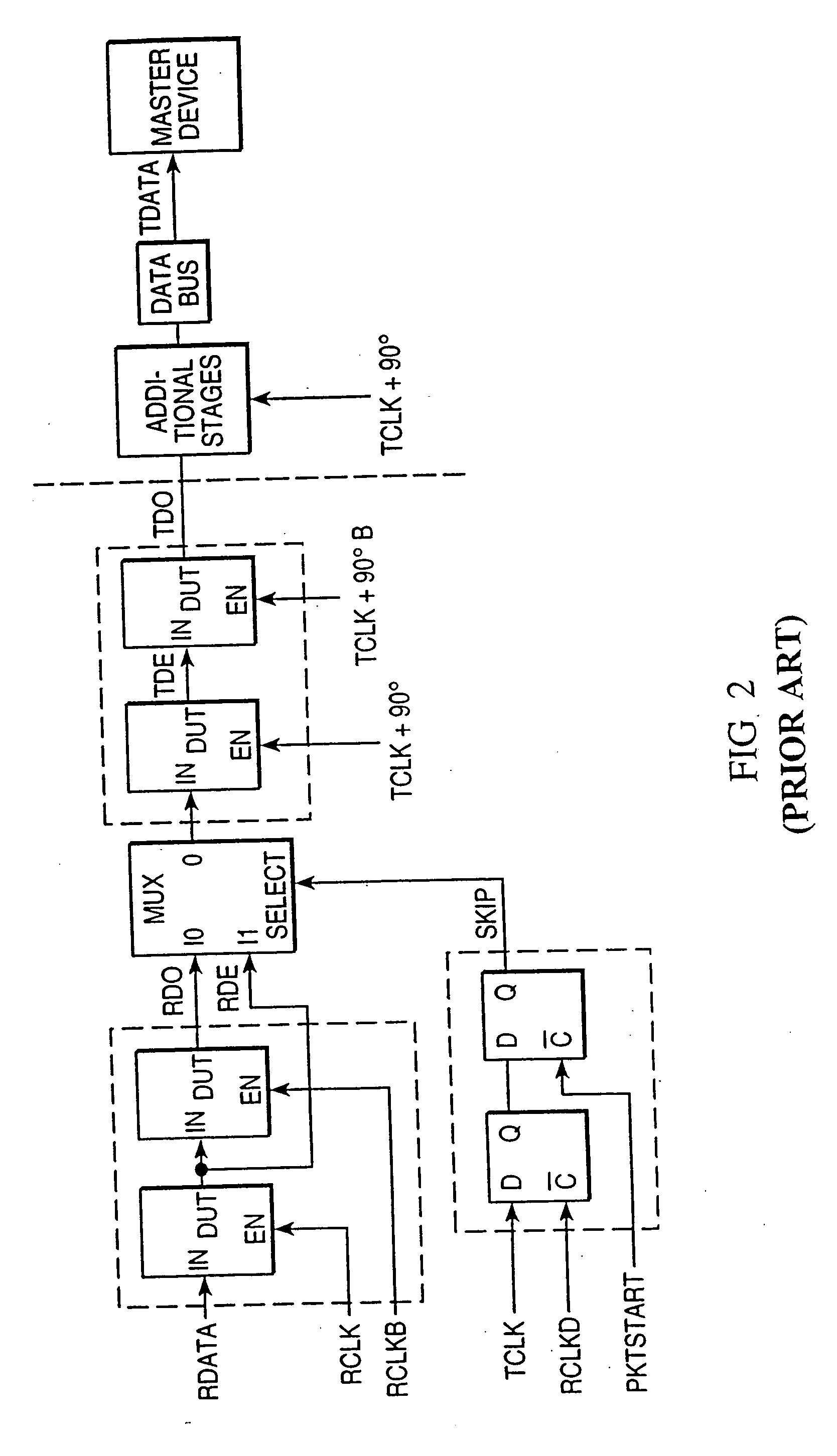

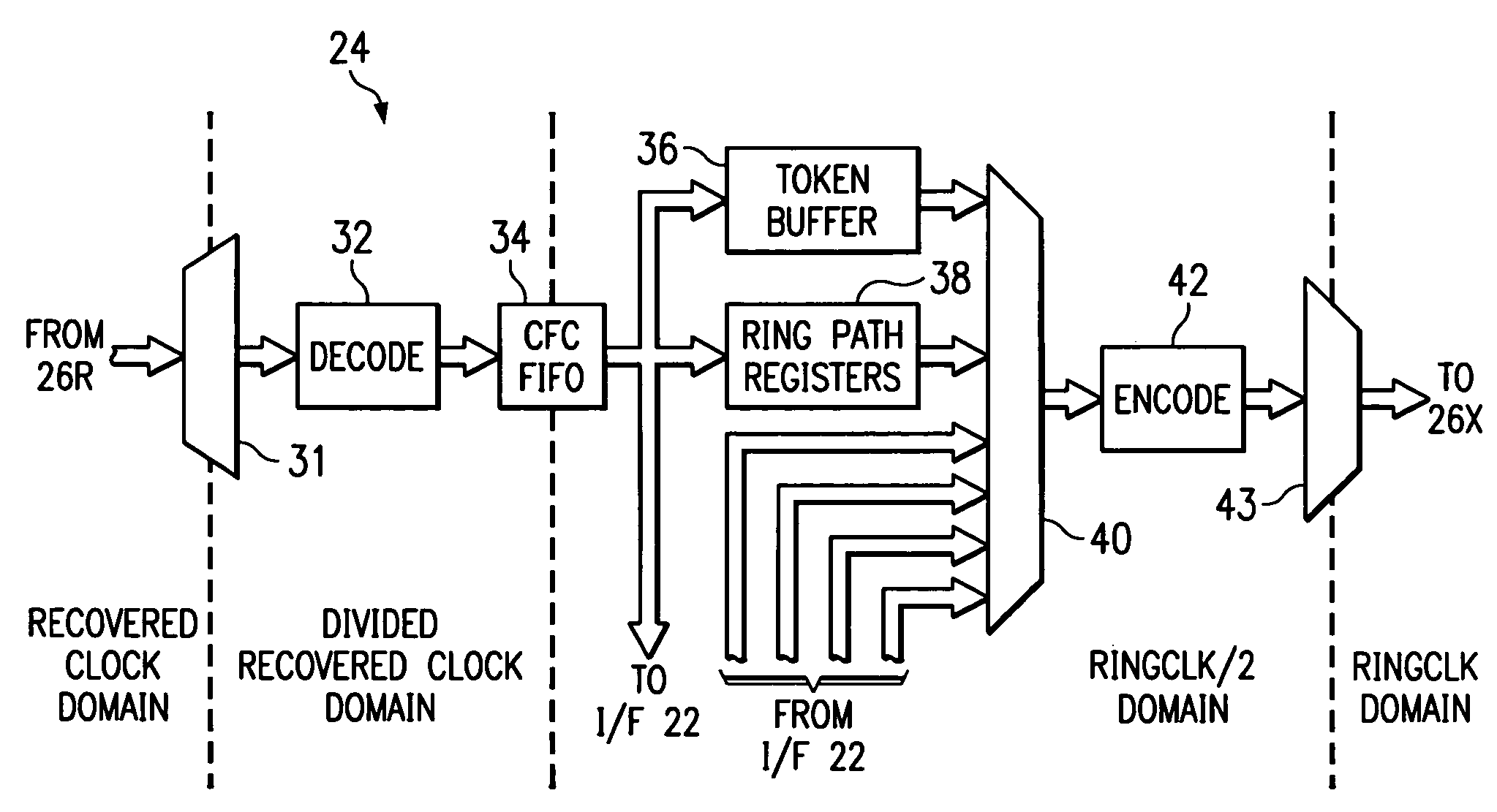

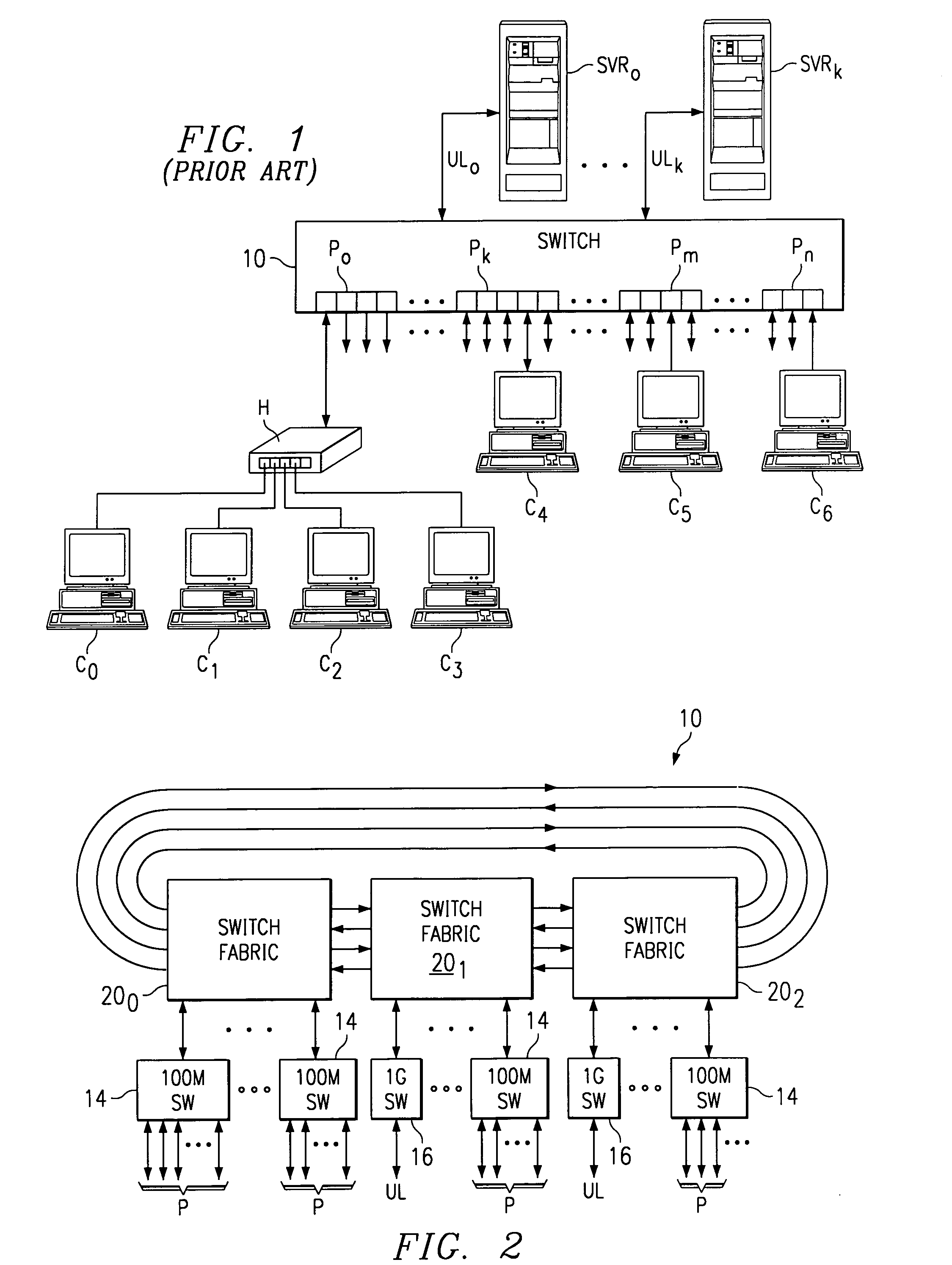

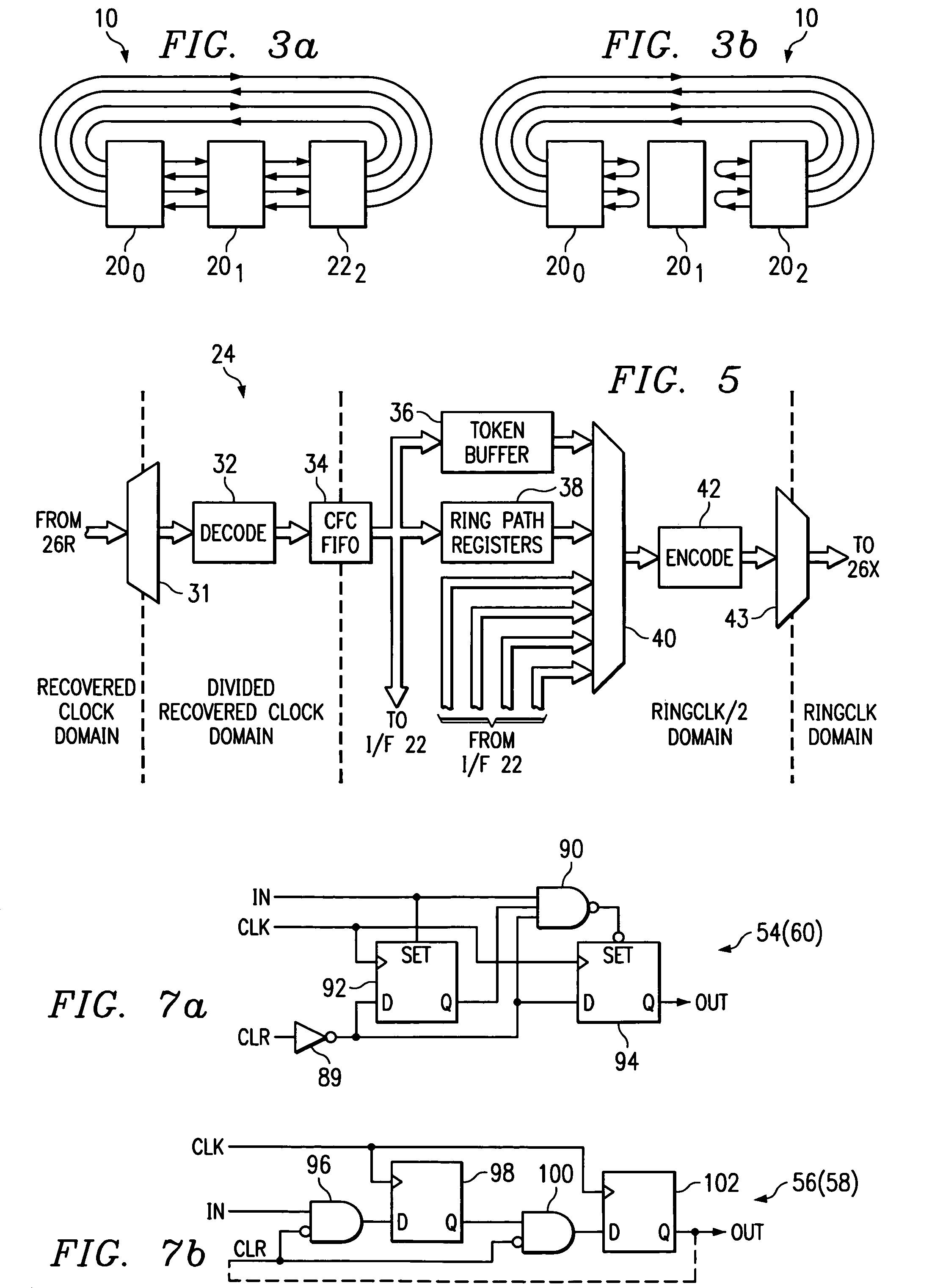

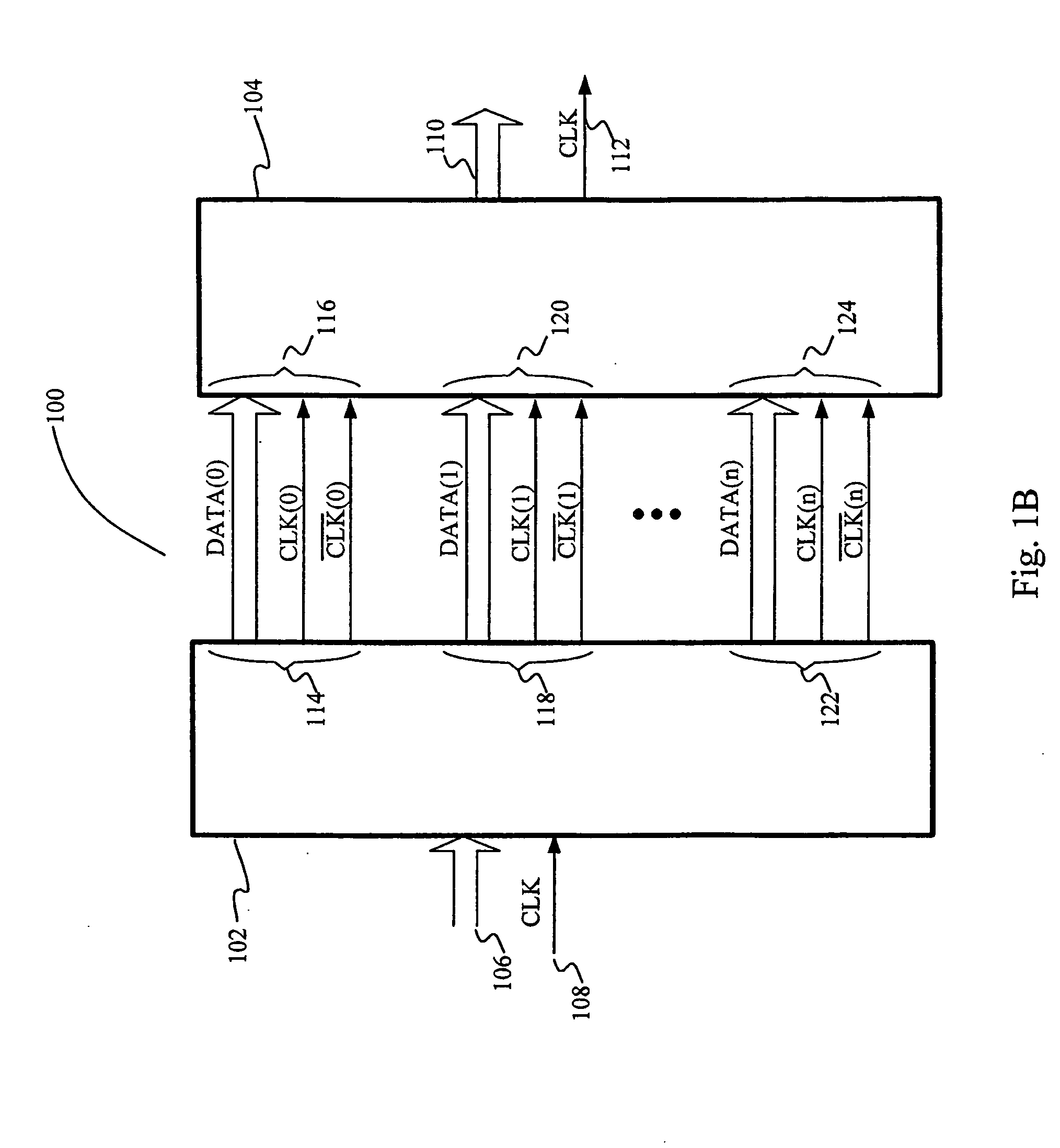

Communications interface between clock domains with minimal latency

InactiveUS7027447B2Minimizes network latencyDelay minimizationSynchronisation information channelsTime-division multiplexCommunication interfaceClock rate

A network switch system (10) is disclosed, in which a plurality of switch fabric devices (20) are interconnected according to a ring arrangement, each of the switch fabric devices (20) including therein switch interfaces (22) coupled to corresponding network switches (14, 16). Each switch fabric device includes a plurality of ring paths (24), each of which is associated with a receive ring interface (26R) and a transmit ring interface (26X). Each ring path (24) includes a circular buffer (44) having a plurality of entries, each of which is associated with valid logic (50). The valid logic (50) for each entry presents valid signals on valid lines (WV, RV) to the receive and transmit domains of the ring path (24), and receives signals on write and read word request lines (WRW, RDW) therefrom. Control of the access to the circular buffer (44) is made according to the write and read word request lines (WRW, RDW) for the corresponding entries of the circular buffer (44) to which write pointers and read pointers point. The write word request line (WRW) sets the valid lines (WV, RV) for the corresponding entry in each of the two clock domains, while the read word request line (RDW) resets these valid lines (WV, RV) for that entry. Differences in clock frequency between the receive and transmit clock domains are thus compensated, with a minimum latency.

Owner:TEXAS INSTR INC

Cooling system for an internal combustion engine of a motor vehicle

InactiveUS20050081801A1Effective duration is reducingMinimal wait timeCoolant flow controlLighting and heating apparatusMinimum latencyInternal combustion engine

The invention relates to a cooling system in which the fan output is determined by an output control from the characteristic curves of the fan motor, the operating parameters of the cooling system and the reference input variables predetermined in the form of temperature levels. Different characteristic curves for the activation of the fan motor are here assigned to the different set temperature levels. If the reference input variable for the control changes, this also results in a change of the characteristic curves for activation of the fan motor. In order to prevent the fan motor starting to howl, in the event of a change in the reference input variable for the fan control the operation of the fan motor is kept constant for an adjustable minimum waiting time. During this minimum waiting time, switching over of the cooling circuit may have caused the operating parameters of the cooling system to adjust to the new reference input variable to such a degree that howling of the fan motor is no longer of concern.

Owner:DAIMLER AG

Apparatus And Method For Increasing The Utilization By The Processors On The Shared Resources

ActiveUS20080104604A1Increase profitOvercomes drawbackMultiprogramming arrangementsMultiple digital computer combinationsMulti processorShared resource

The present invention provides an apparatus and method that increases the utilization by the processors on the shared resources. It provides the minimum latency in a multiprocessor system during exchanging the usage right between multi-processors on a shared resource. The apparatus provides a timer mailbox including a timer. The timer mailbox is at least associated with a first processor and a second processor. The second processor starts to utilize a shared resource to perform a task. According to a predetermined clock cycle number, the timer mailbox issues a signal in advance to notify the first processor of the availability of the shared resource to be utilized by the first processor. It shows the advantages of preventing creating task latency and wasting system resources. The present invention increases the utilization by the processors on the shared resources without extra hardware cost.

Owner:IND TECH RES INST

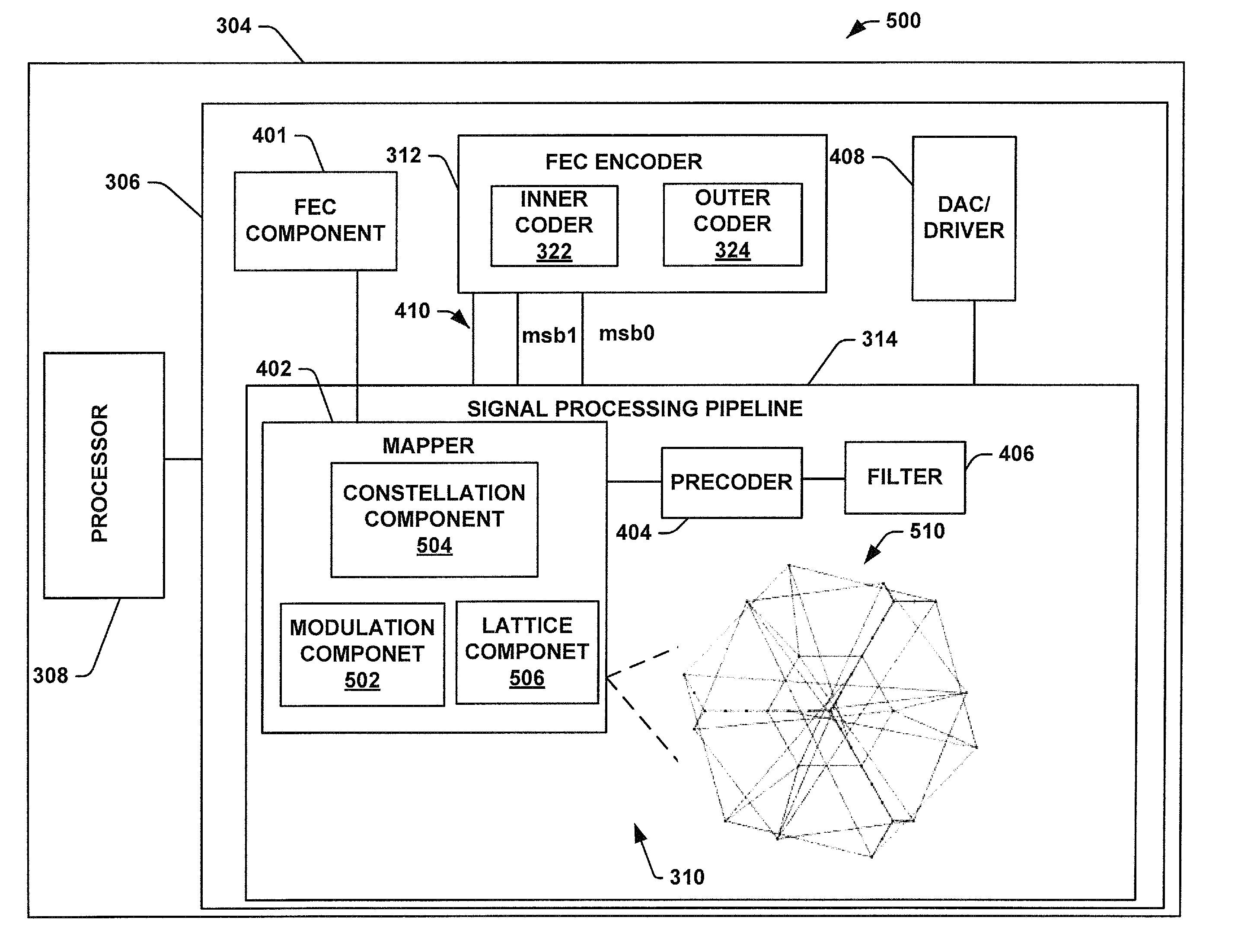

High speed transceiver based on concatenates of a leech lattice with binary and nonbinary codes

ActiveUS8989283B1Easy to implementError prevention/detection by using return channelJoint error correctionFrequency spectrumConcatenation

A transceiver architecture can contain an encoder and a decoder for communicating high speed transmissions. The encoder can modulate signal data for being mapped in a constellation that is generated based on concatenations of a leech lattice having binary and non-binary codes. The data can be transmitted at a high speed according to the constellation with an embedded leech lattice configuration in order to generate a coding gain. A decoder operates to decode the received input signal data with a decreased latency or a minimal latency with a high spectral efficiency.

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

Alignment mode selection mechanism for elastic interface

Methods and apparatus are disclosed for aligning received data bits in elastic interface systems. Depending upon which one of several alignment modes is selected, data bits can be loaded into FIFO latches on rising clock edges if the data was sent on rising clock edges, on falling clock edges if the data was sent on falling clock edges, or on the nearest clock edge if minimum latency is desired. Alternatively, data bits can be delayed by one or more bit times before loading into FIFO latches to reduce the elastic interface system's sensitivity to drift. The present invention permits a user to trade off factors related to for latency, drift, and skew by choosing among different alignment modes in an elastic interface system.

Owner:IBM CORP

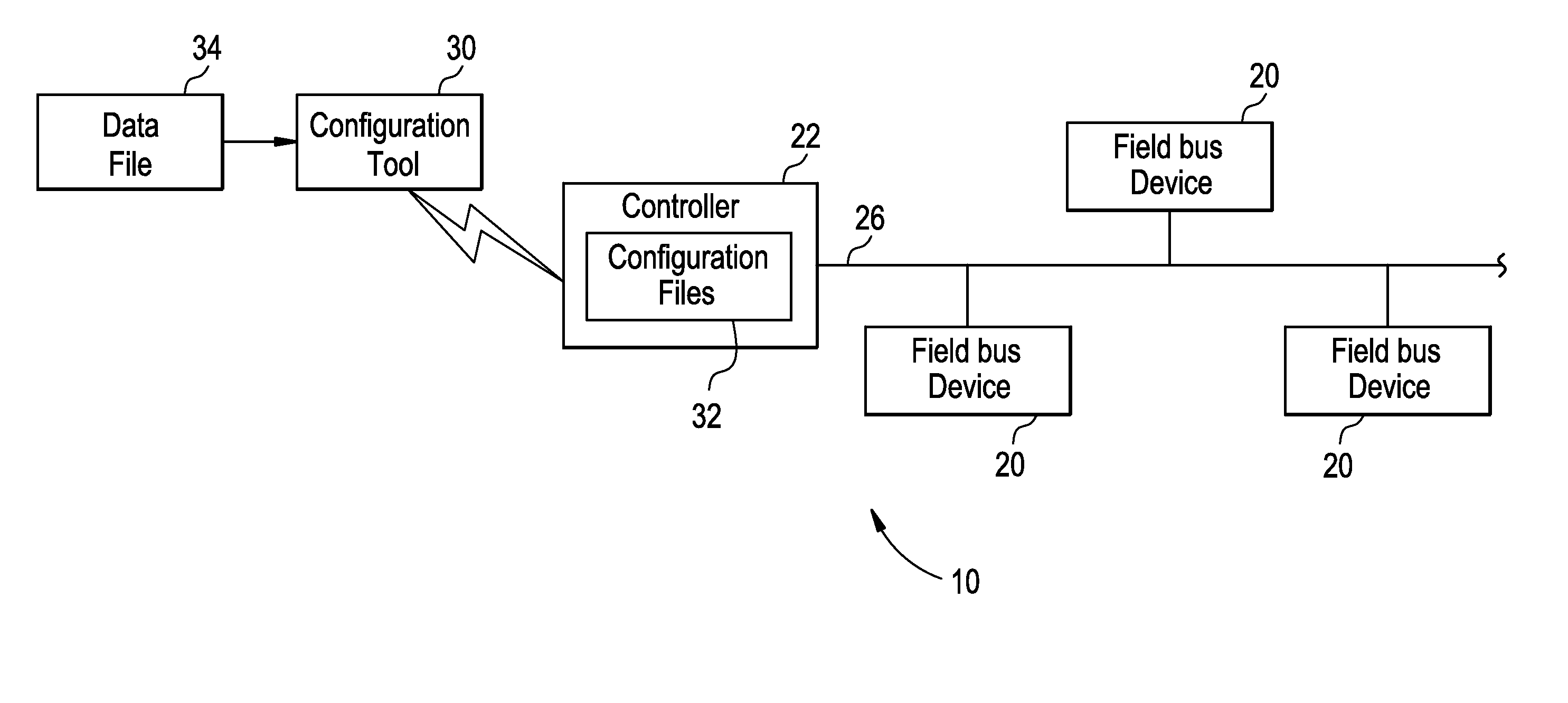

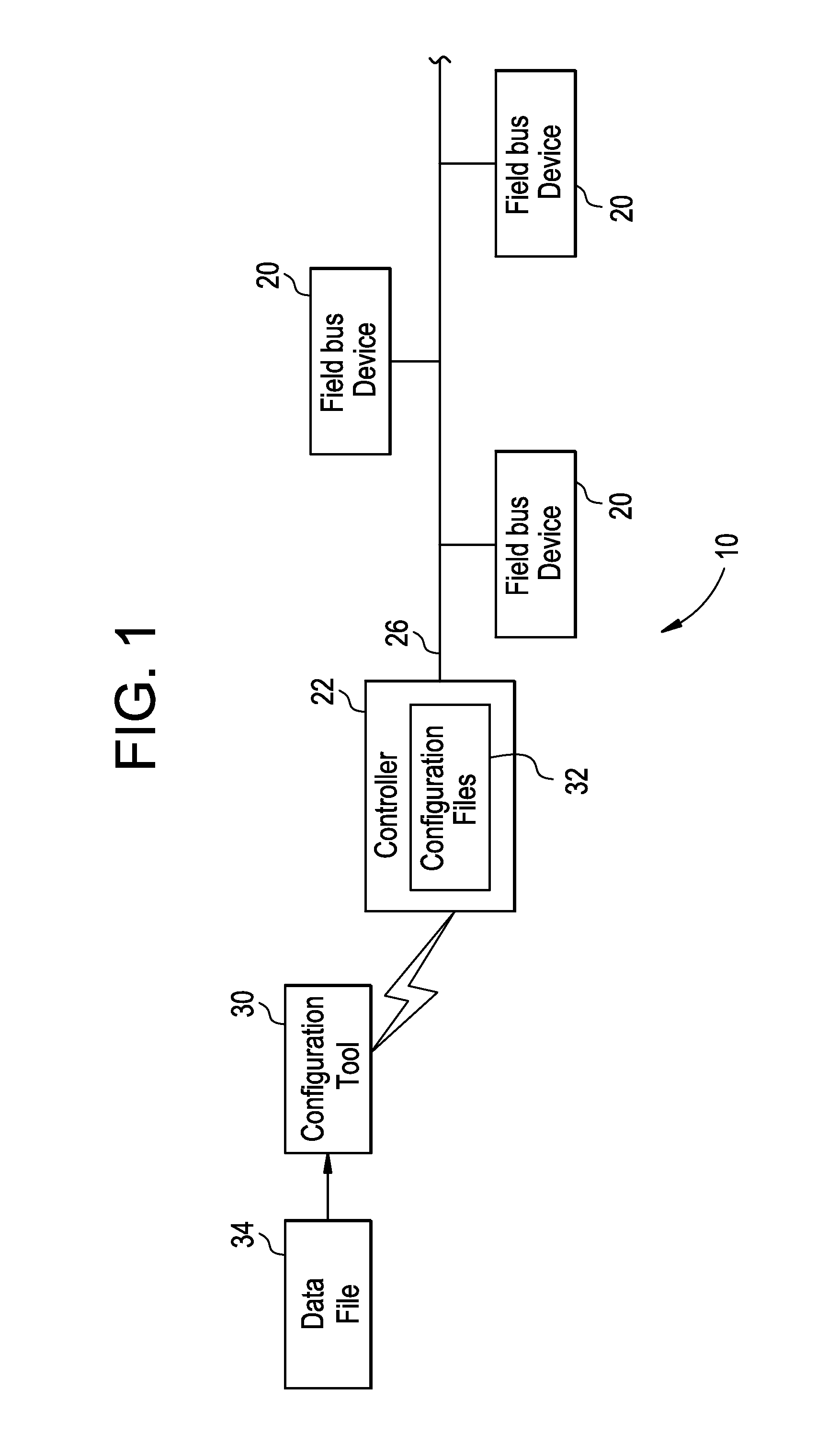

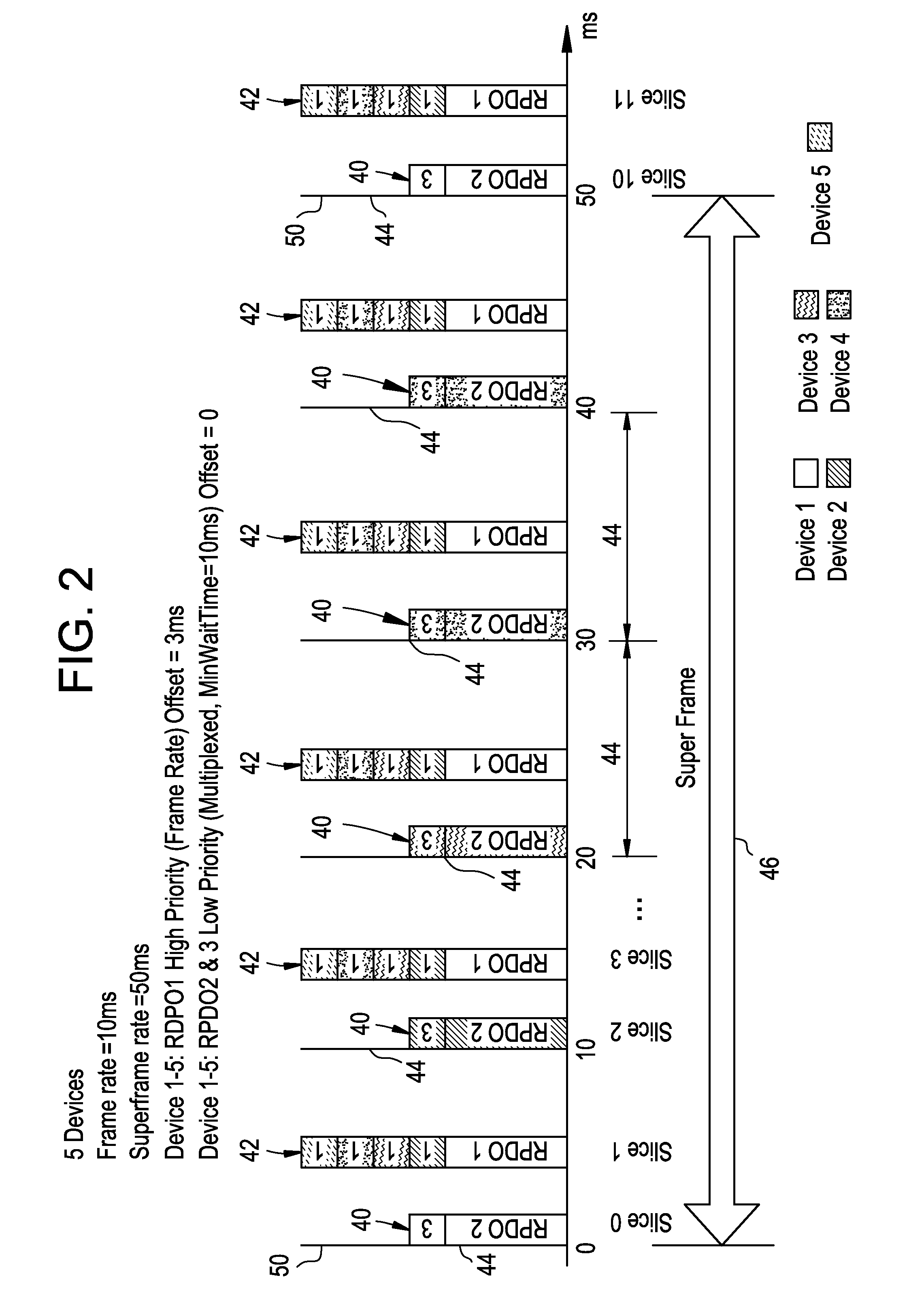

Fieldbus device control system

InactiveUS20130066443A1Preventing executionProgramme controlElectric controllersComputer scienceControl logic

A fieldbus system is provided, having a plurality of fieldbus devices and a controller. The controller is in communication with the plurality of fieldbus devices though a fieldbus. The controller transmits a plurality of high priority Receive Process Data Objects (RPDOs) and a plurality of low priority RPDOs to the plurality of fieldbus devices through the fieldbus. The controller includes a control logic for sending each of the plurality of fieldbus devices one of the plurality of high priority RPDOs during a frame. The frame is the fastest rate at which the high priority RPDOs are transmitted. The controller includes a control logic for sending at least one of the plurality of fieldbus devices at least one of the plurality of low priority RPDOs. The low priority RPDOs are grouped by a minimum wait time.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com