Embroidery bead feeding apparatus and method

A technology of feeding device and embroidery beads, applied in the field of machine embroidery devices, can solve the problems of inability to guarantee the orientation, uncontrollable rolling of embroidery beads, and no application of the center guiding mechanism, etc., and achieves high practical value, ingenious structure and low processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

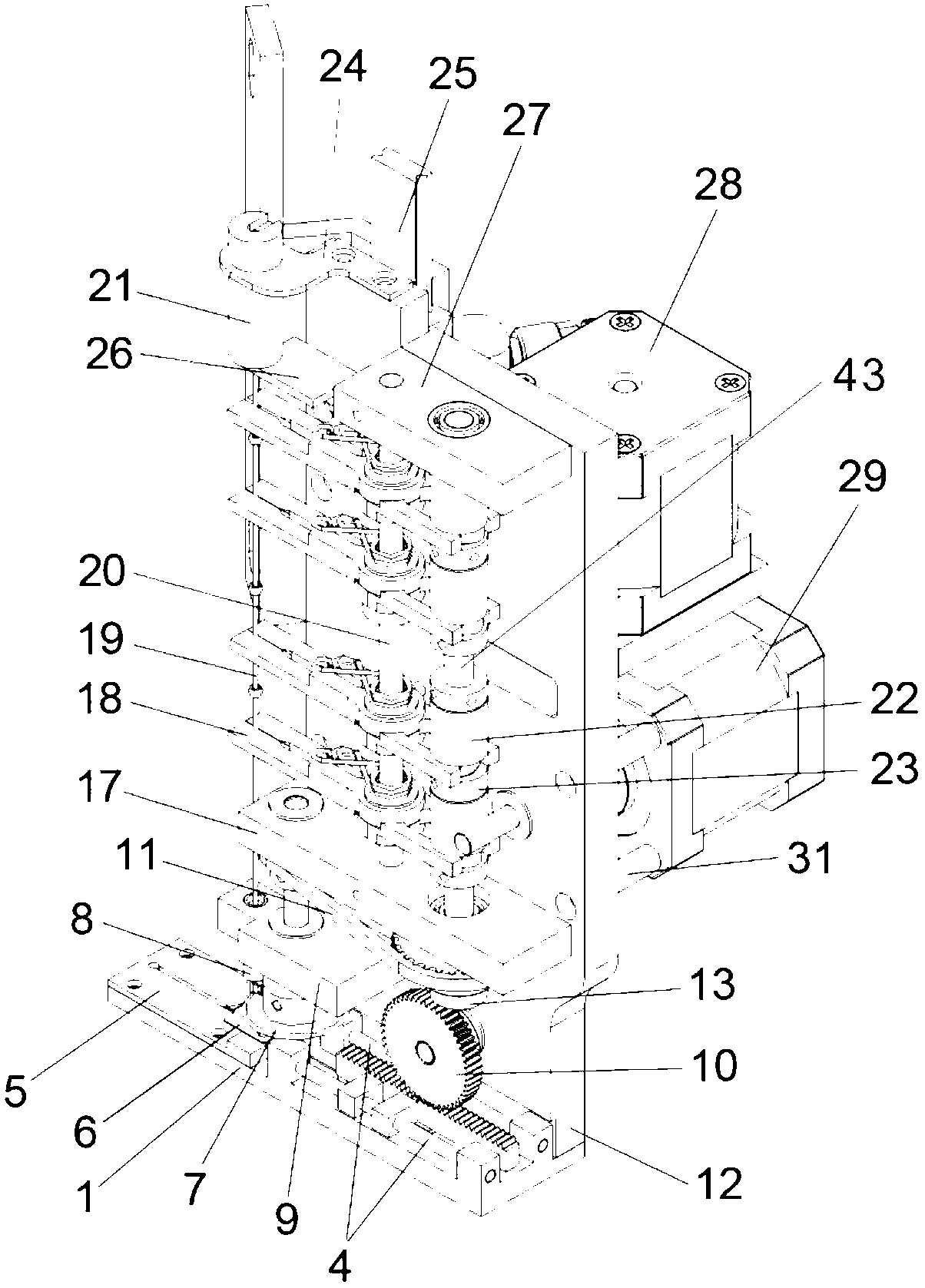

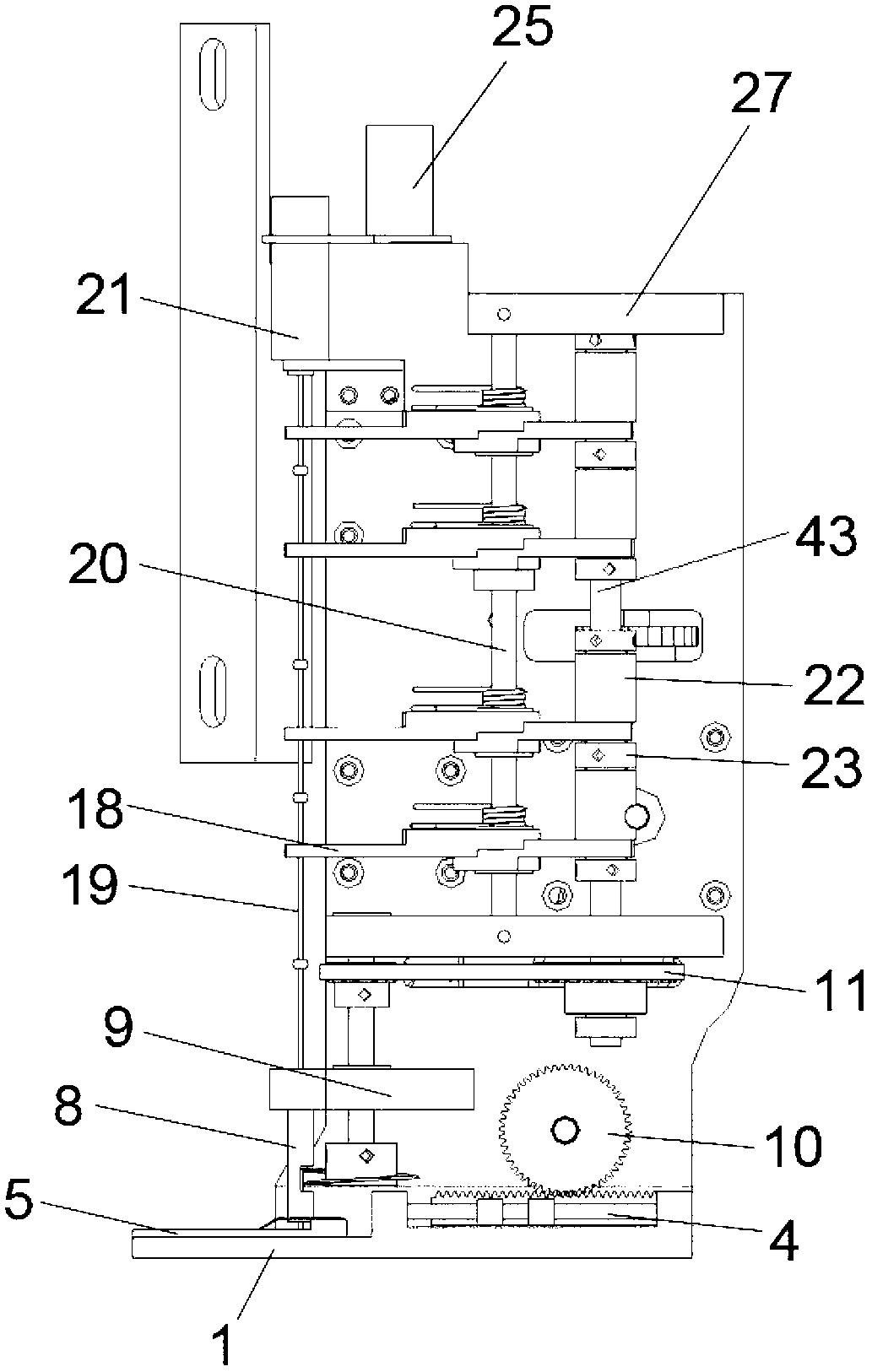

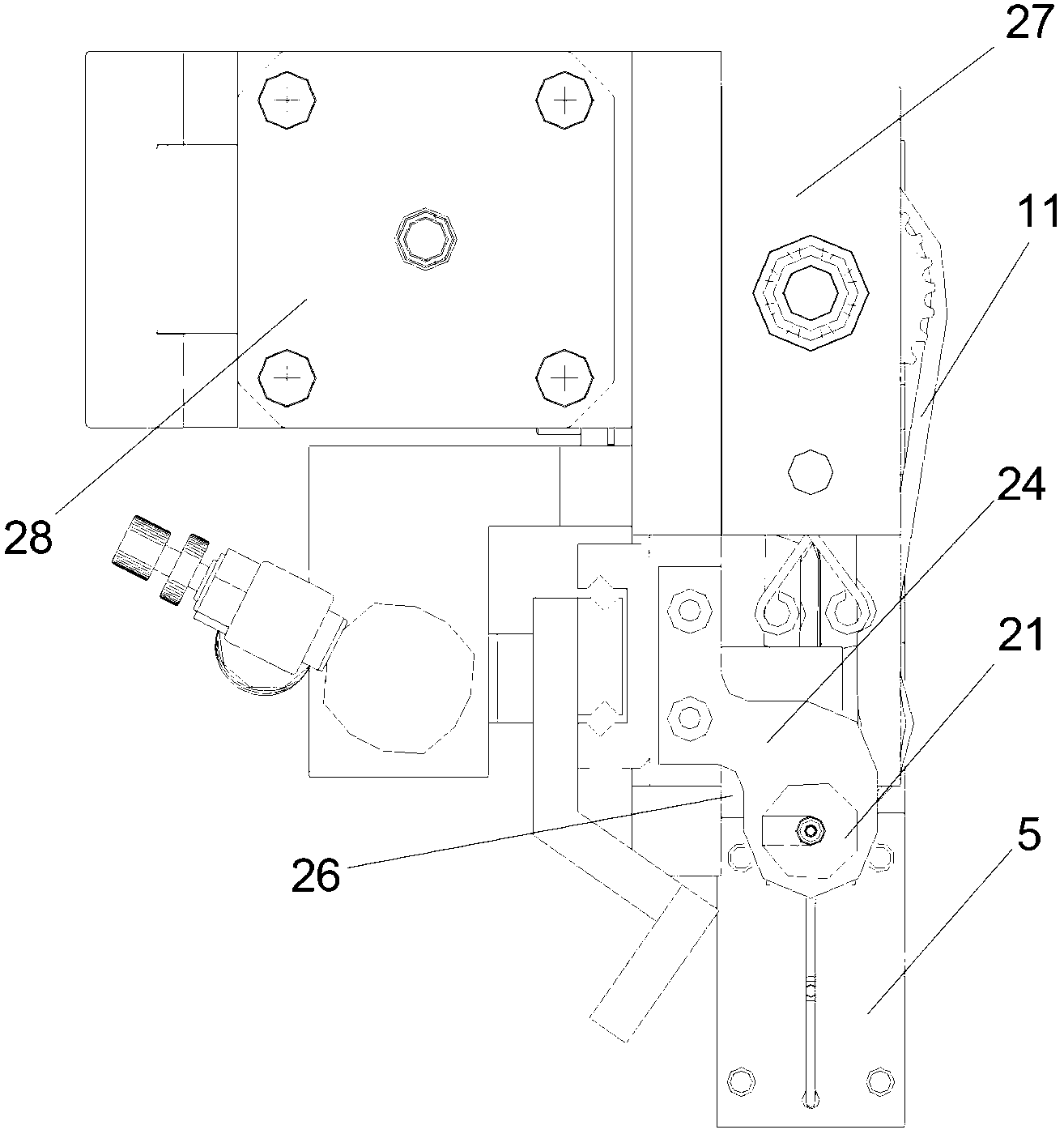

[0054] refer to figure 1 , figure 2 , image 3 with Figure 4 , a kind of embroidered bead feeding device as shown in the figure includes a bead guide tube 19 for guiding the bead embroidery to fall, and also includes a time-sharing clamping mechanism. The time-sharing clamping mechanism includes several clampers 18, which drive The shaft 43 and the one-way sleeve 22 sleeved on the drive shaft 43, under the drive of the clamping motor 28, the one-way sleeve 22 drives the grippers 18 that are spaced apart from each other in time-sharing, so that the bead tube 19 is always in the position of fixed position, the time-sharing clamping mechanism is connected on the motor plate 12 through the lower fixed support 17 and the upper fixed support 27; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com