Translucent applique cutwork machine embroidery and method

a technology of applique cutwork and embroidery machine, applied in the field of embroidering, can solve the problems of limiting the scope of applique cutwork embroidery on the foundation fabric, limiting the scope of applique cutwork embroidery on the overall foundation fabric, and reducing the amount of material required. , the effect of reducing complexity and skill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] For purposes of describing the preferred embodiment, the terminology used in the reference to the numbered components in the drawing is as follows: [0046]11. foundation fabric [0047]12. removable stabilizer [0048]13. concentric underlay stitches [0049]14. cutwork section [0050]15. cut fabric edge [0051]16. applique fabric [0052]17. zigzag stitches [0053]18. applique cutwork seam [0054]19. machine embroidery design [0055]20. satin stitches, or similar concealing stitches

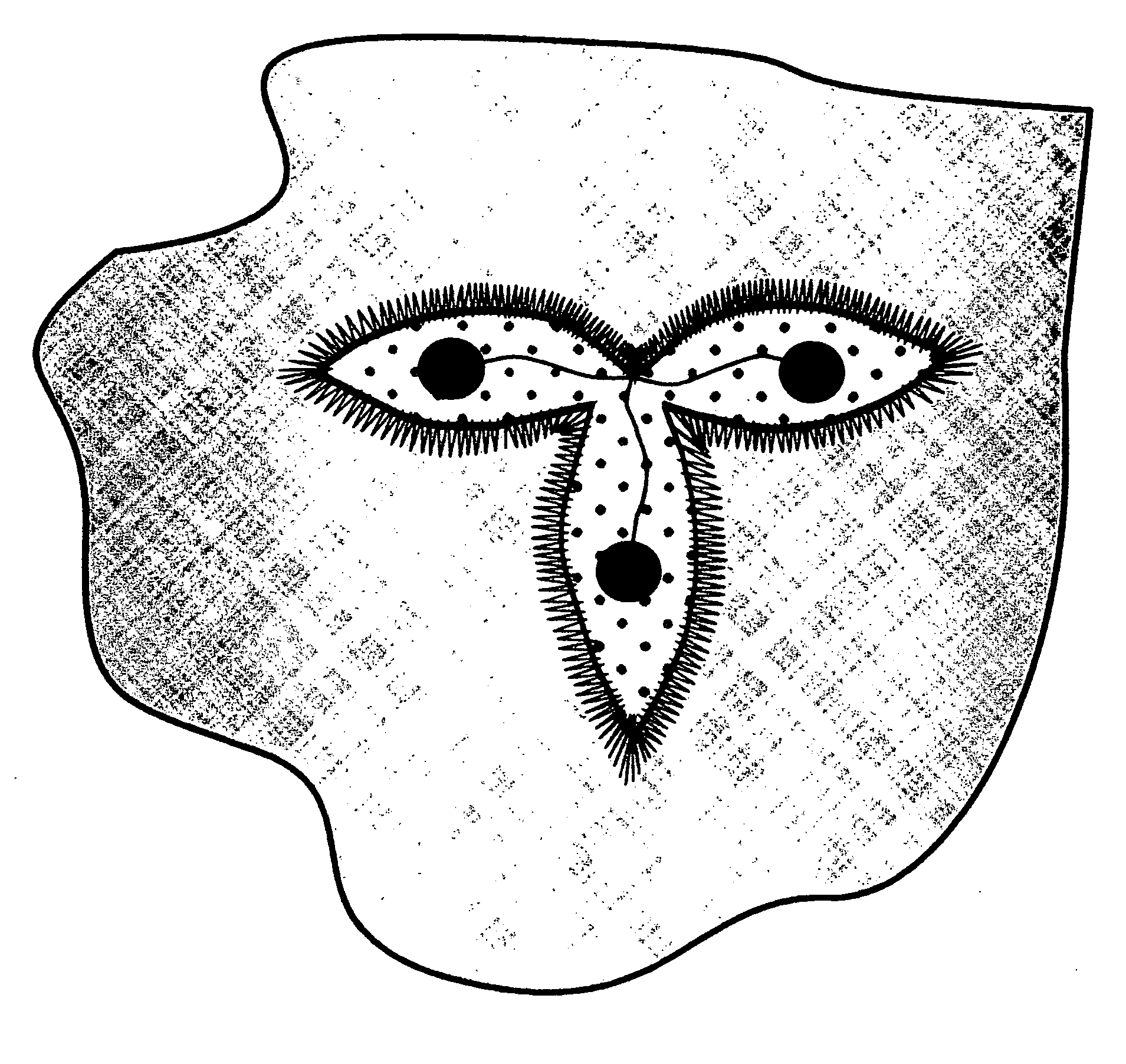

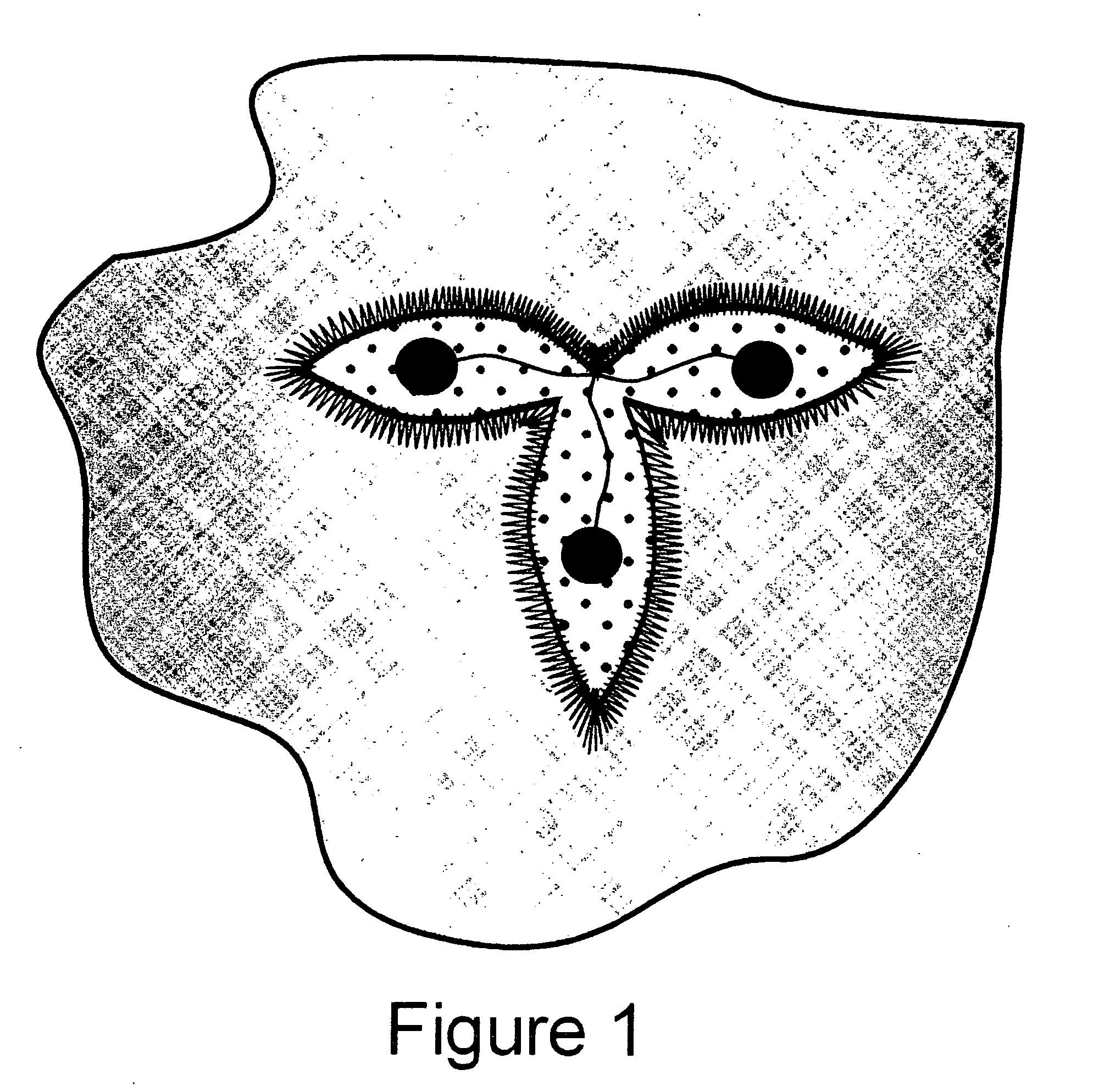

[0056] Referring now to the drawings, FIG. 1 shows applique cutwork embroidery design performed by prior art.

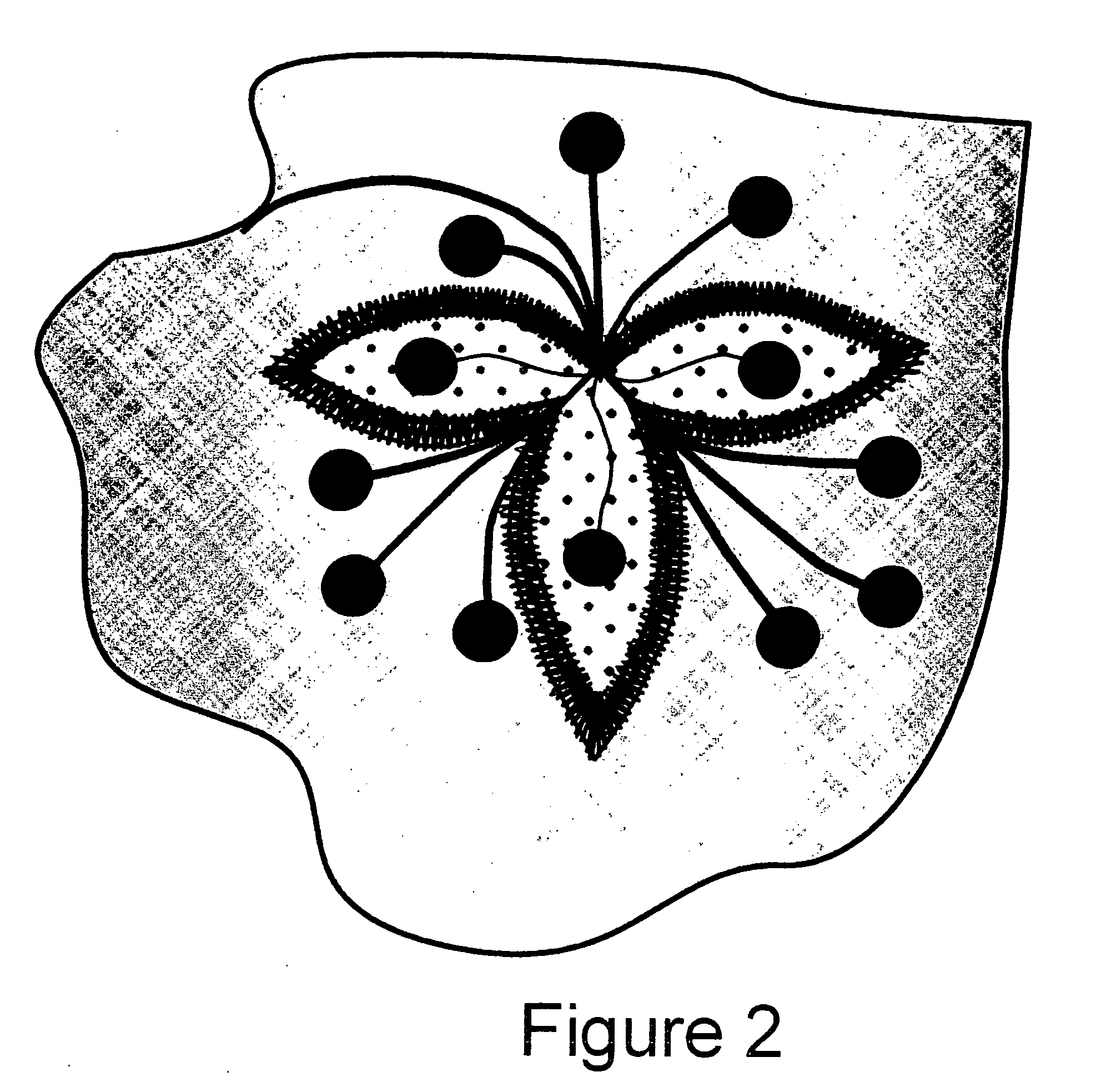

[0057] As shown and describe in relation to FIGS. 2-10, the present invention uses at least three layers of material, a layer of foundation fabric 11 a removable stabilizer 12 and an applique fabric 16.

[0058]FIG. 3 illustrates the application of concentric underlay stitches 13 about a cutwork section 14 of an applique cutwork embroidery design, binding together foundation fabric 11 and removable stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com