Sewing processing equipment

A processing equipment and sewing machine technology, applied in sewing equipment, textiles and papermaking, etc., can solve the problems of high production cost, complicated installation and debugging, difficult maintenance of sewing machines, etc., and achieve the effect of avoiding needle breakage and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

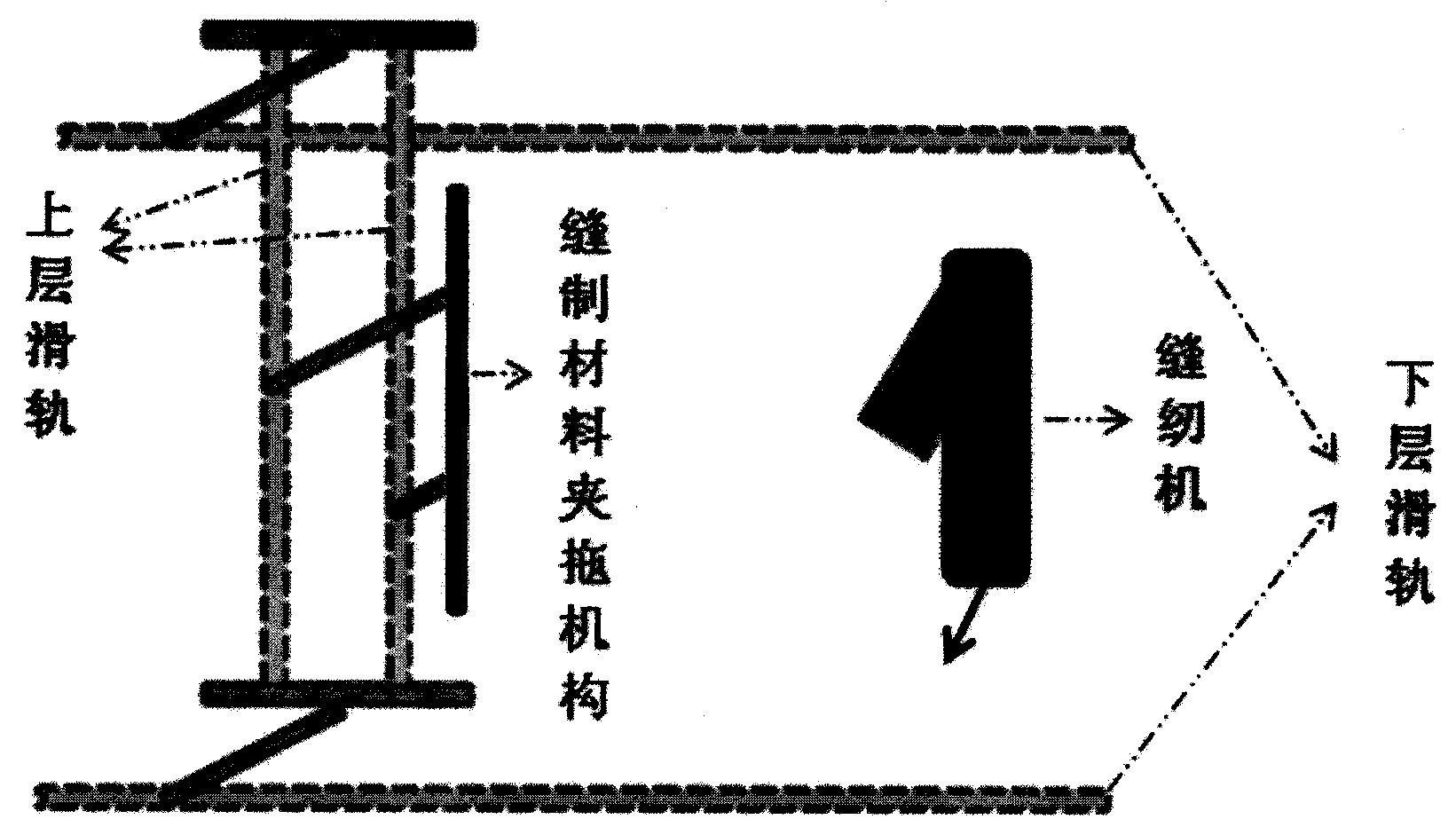

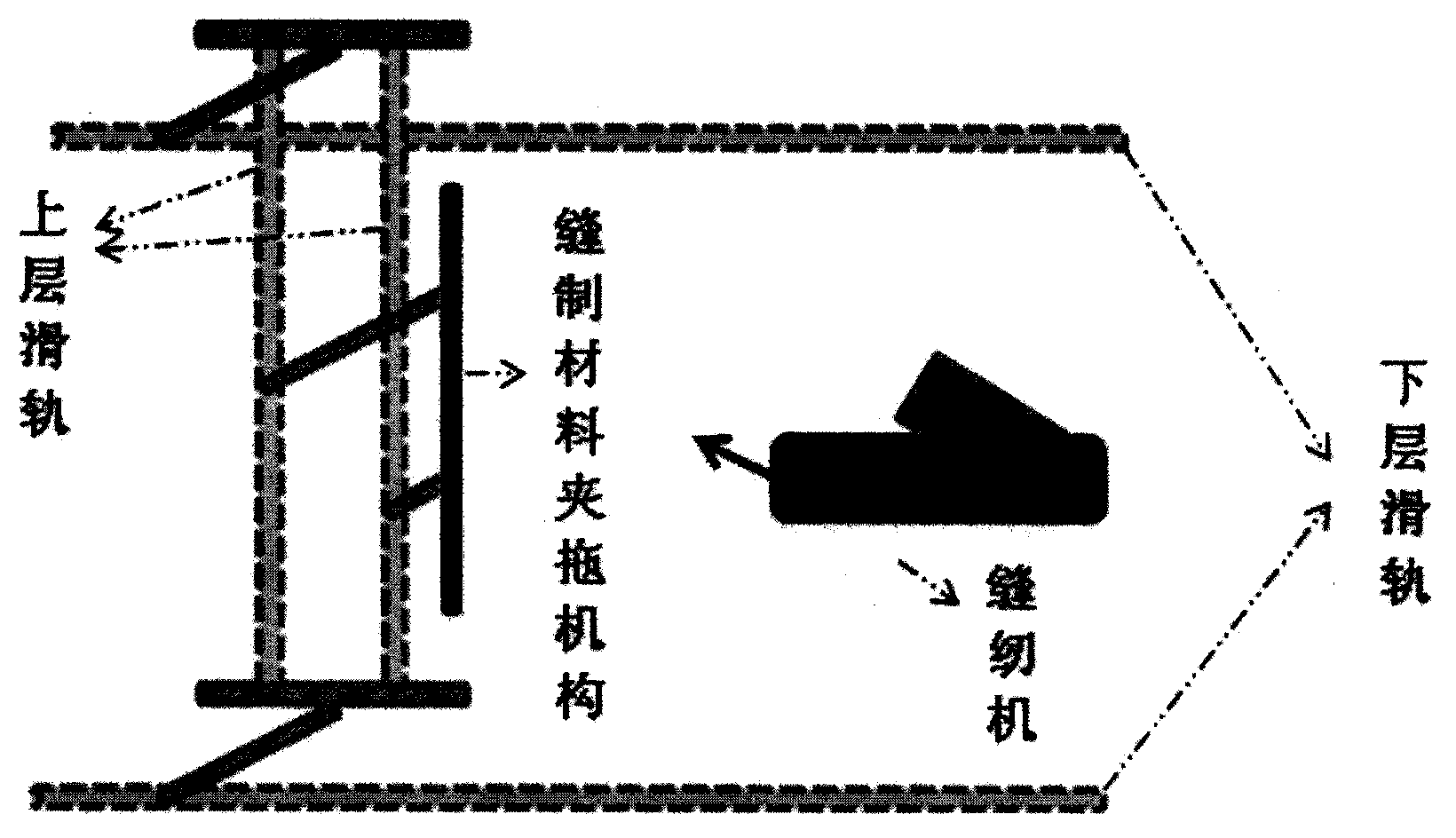

[0010] Such as Figure 1-2 As shown, a sewing processing equipment includes a sewing machine, a sewing material clamping and dragging mechanism, two parallel slide rails on the upper layer, and two parallel slide rails on the lower layer. The two parallel slide rails on the upper floor and the two parallel slide rails on the lower floor are perpendicular to each other. The two parallel slide rails on the upper floor are connected with the two parallel slide rails on the lower floor through movable brackets. The two parallel slide rails on the upper layer are connected with a sewing material clamping and dragging mechanism to realize plane movement. The two parallel slide rails of the upper layer and the two parallel slide rails of the lower layer are all independently placed on the periphery of the sewing machine. The sewing machine is relatively independent from the sewing material clamping and dragging mechanism, the two parallel slide rails on the upper layer, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com