Sewing machine

A sewing machine and housing technology, applied in sewing machine components, sewing equipment, program-controlled sewing machines, etc., can solve problems such as time-consuming, and achieve the effect of reducing setting time and avoiding adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

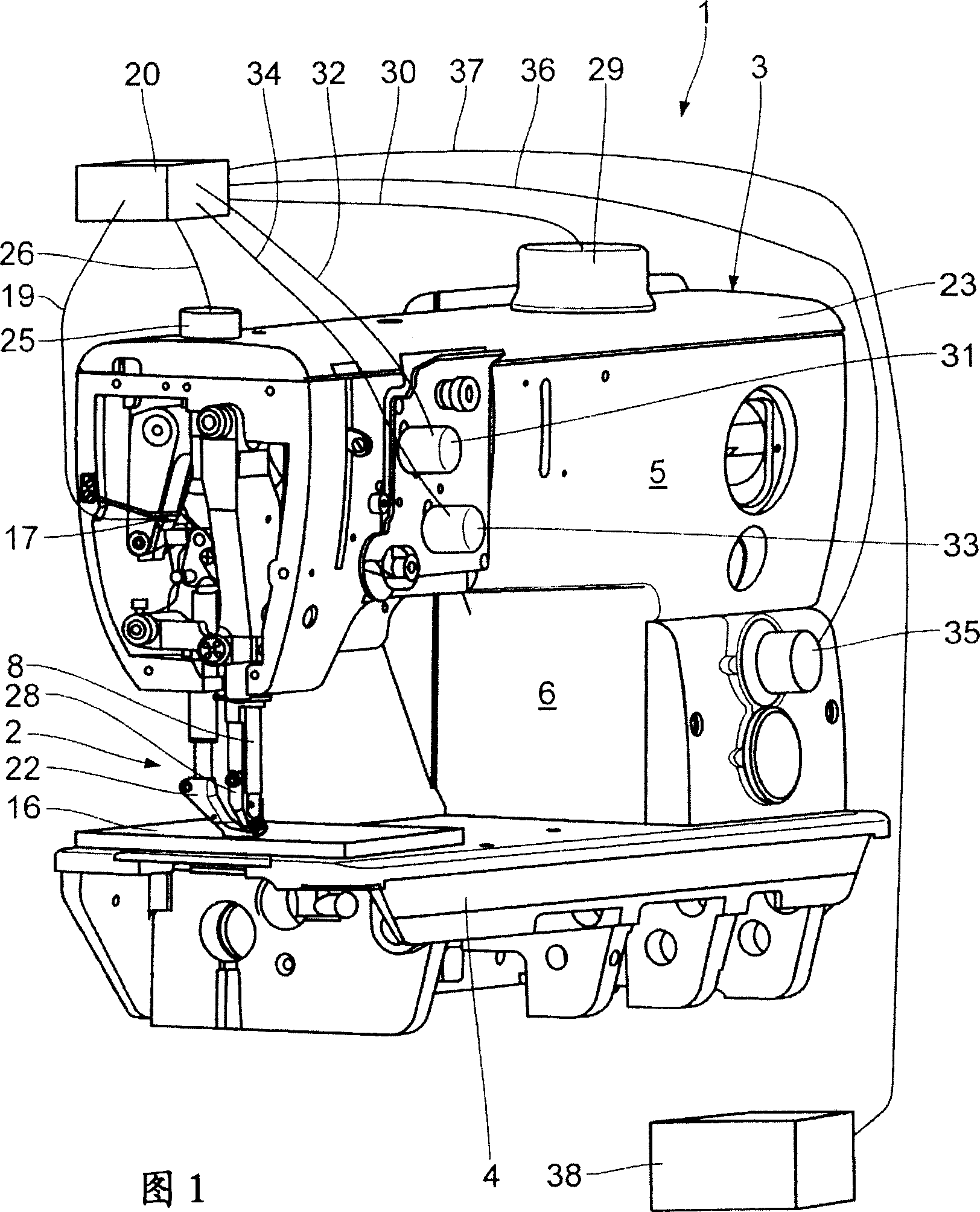

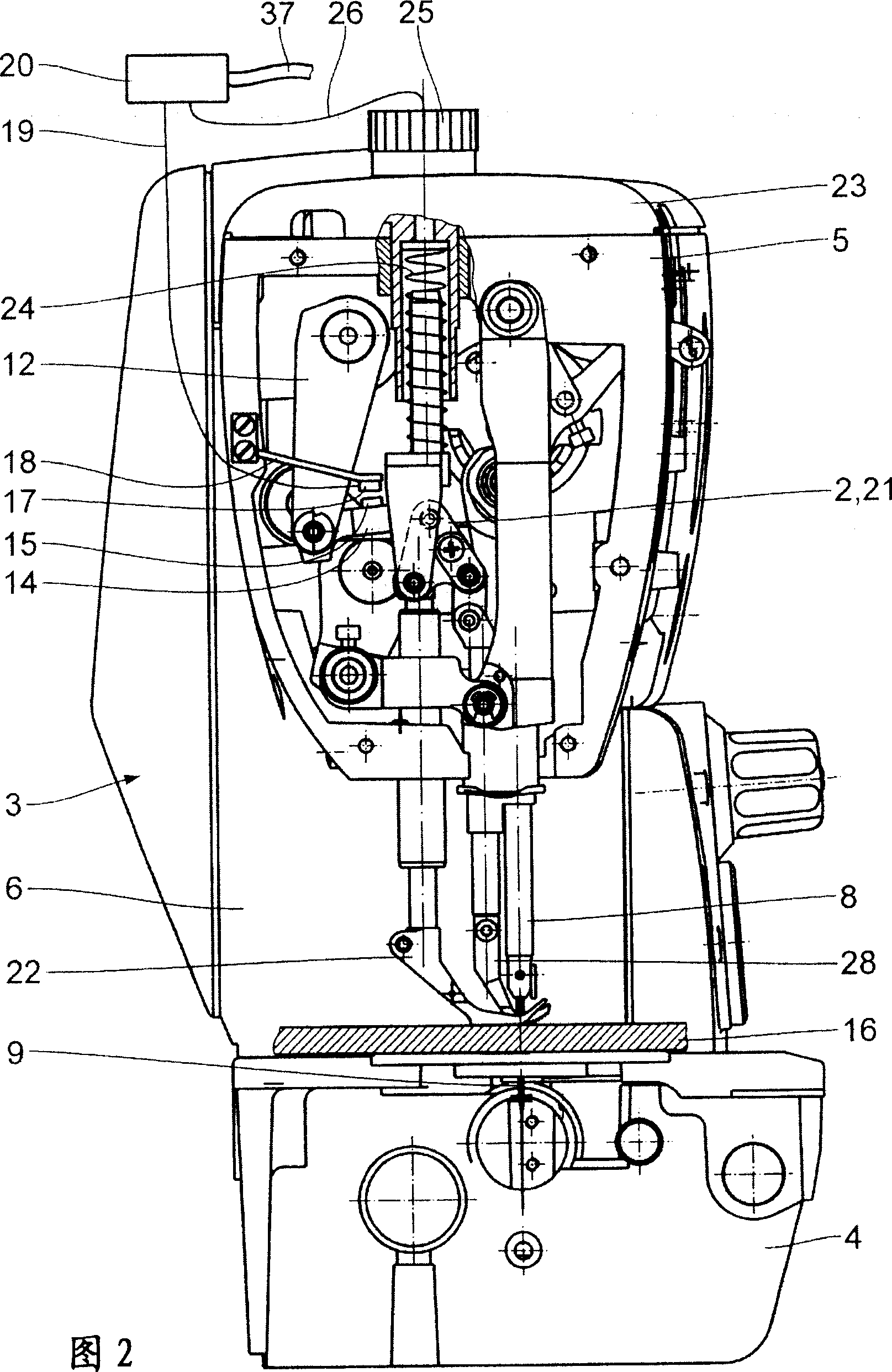

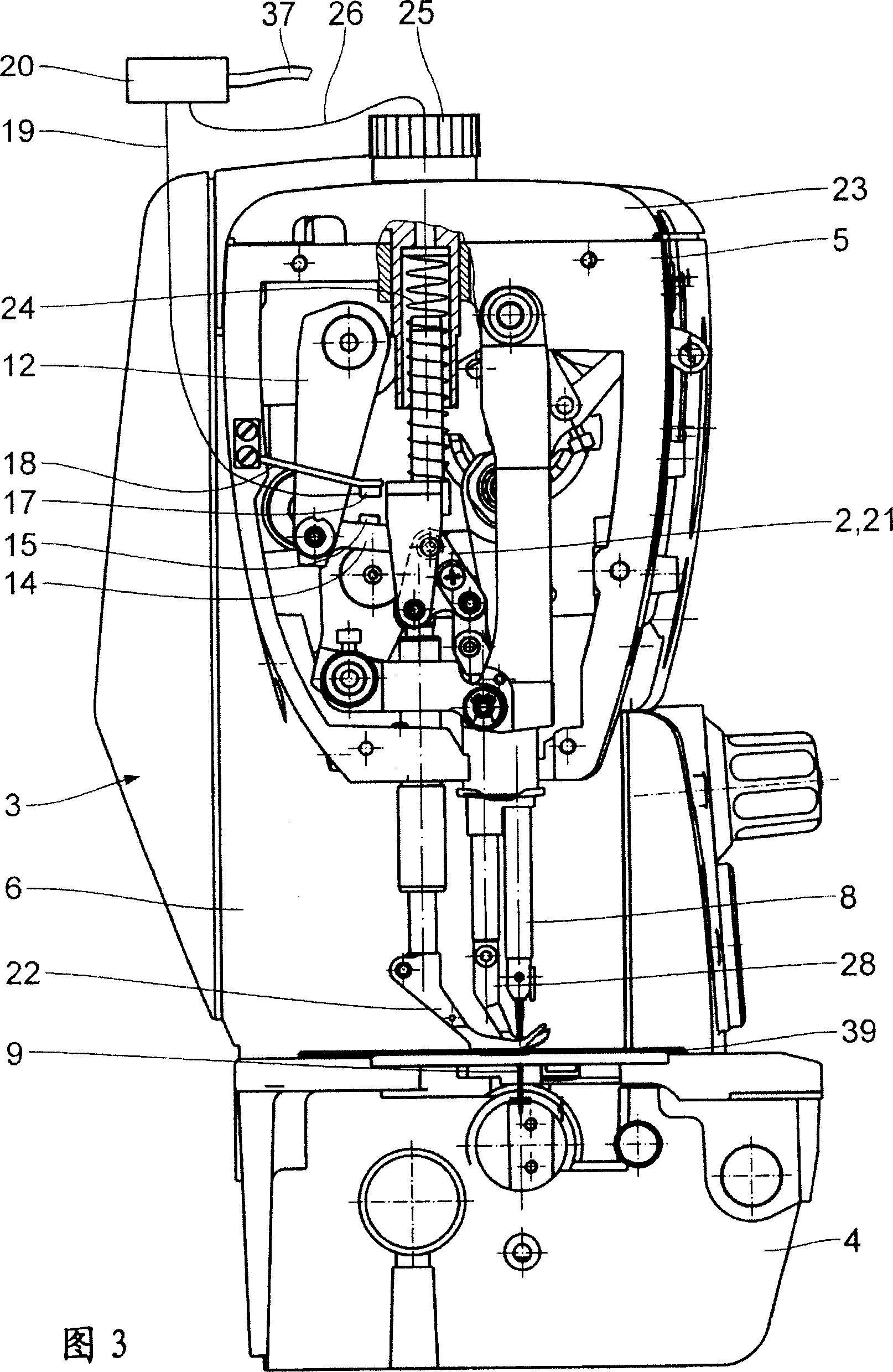

[0020] Figures 1-3 realistically show a partially disassembled sewing machine 1 except for the control components. Figure 4 and 5 A schematic diagram of the sewing machine 1 is shown showing the coupling of the mechanical parts of the top feed device generally referenced 2 . The basic design of the sewing machine 1 is quite common, so only the components which are important for the invention will be described below.

[0021] The sewing machine 1 has a C-shaped housing 3 . The housing 3 includes a base plate 4 and a top arm 5 . To form the C-shape, the uprights 6 join the base plate 4 and the arms 5 . The arm 5 houses an arm shaft 7 driven by a motor (not shown) (see Figure 4 ). The needle bar 8 with the sewing needle 9 is moved up and down and the top feeder 2 is moved by a rotational mechanical coupling with the arm shaft 7 . Regarding the actuation of the top feeder 2, see in Figure 4 and 5 The kinematic design of the device 2 is clearly shown, the arm shaft 7 being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com