Multifunctional digital control sewing machine for feeding by clamping cloth sheets through template

A sewing machine and multifunctional technology, which is applied in the field of multifunctional CNC sewing machines for clamping and feeding cloth with templates, can solve problems such as low production efficiency, low yield rate, and uneven stitch pitch, and achieve production efficiency and product quality. Improvement, simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

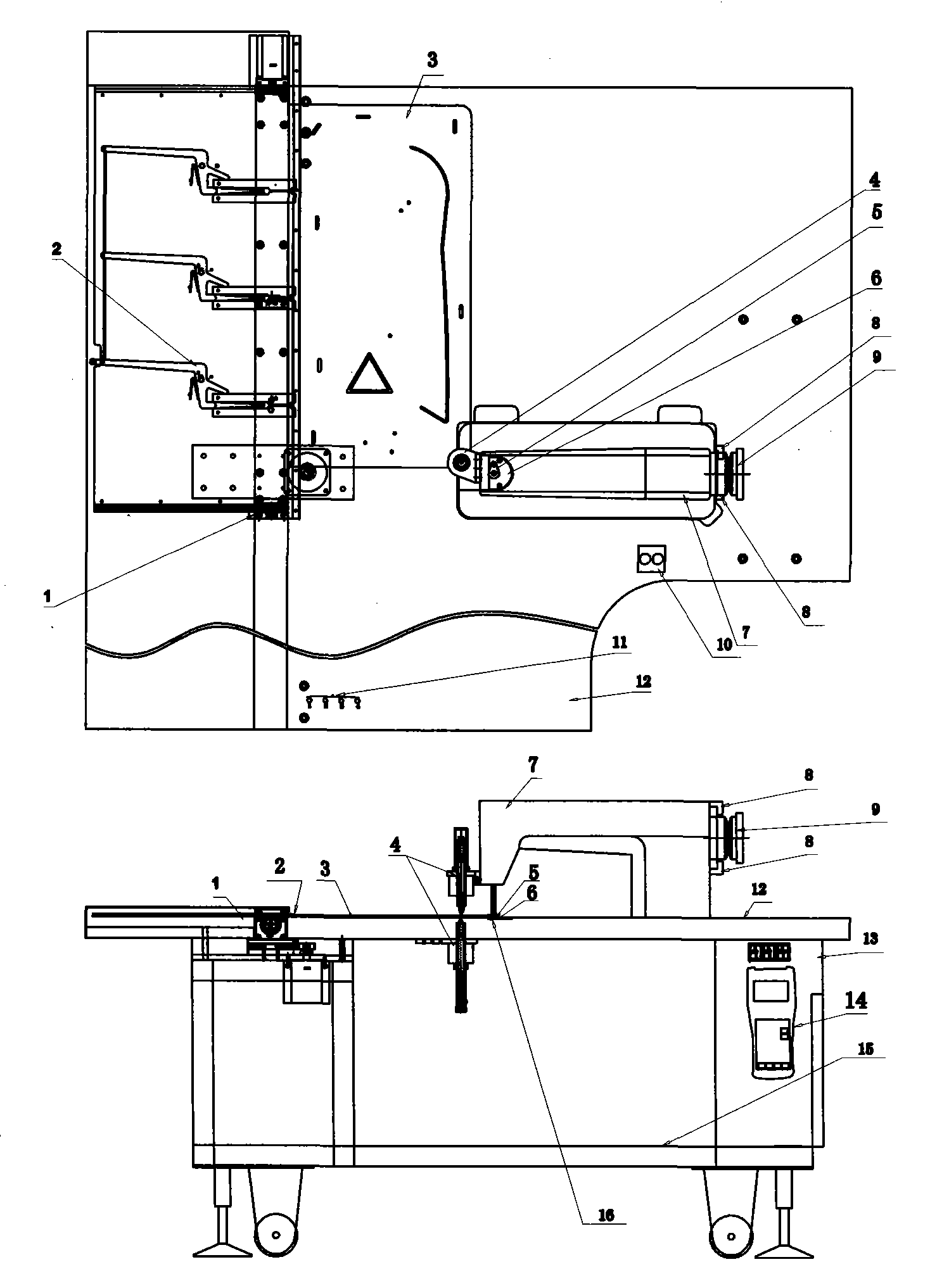

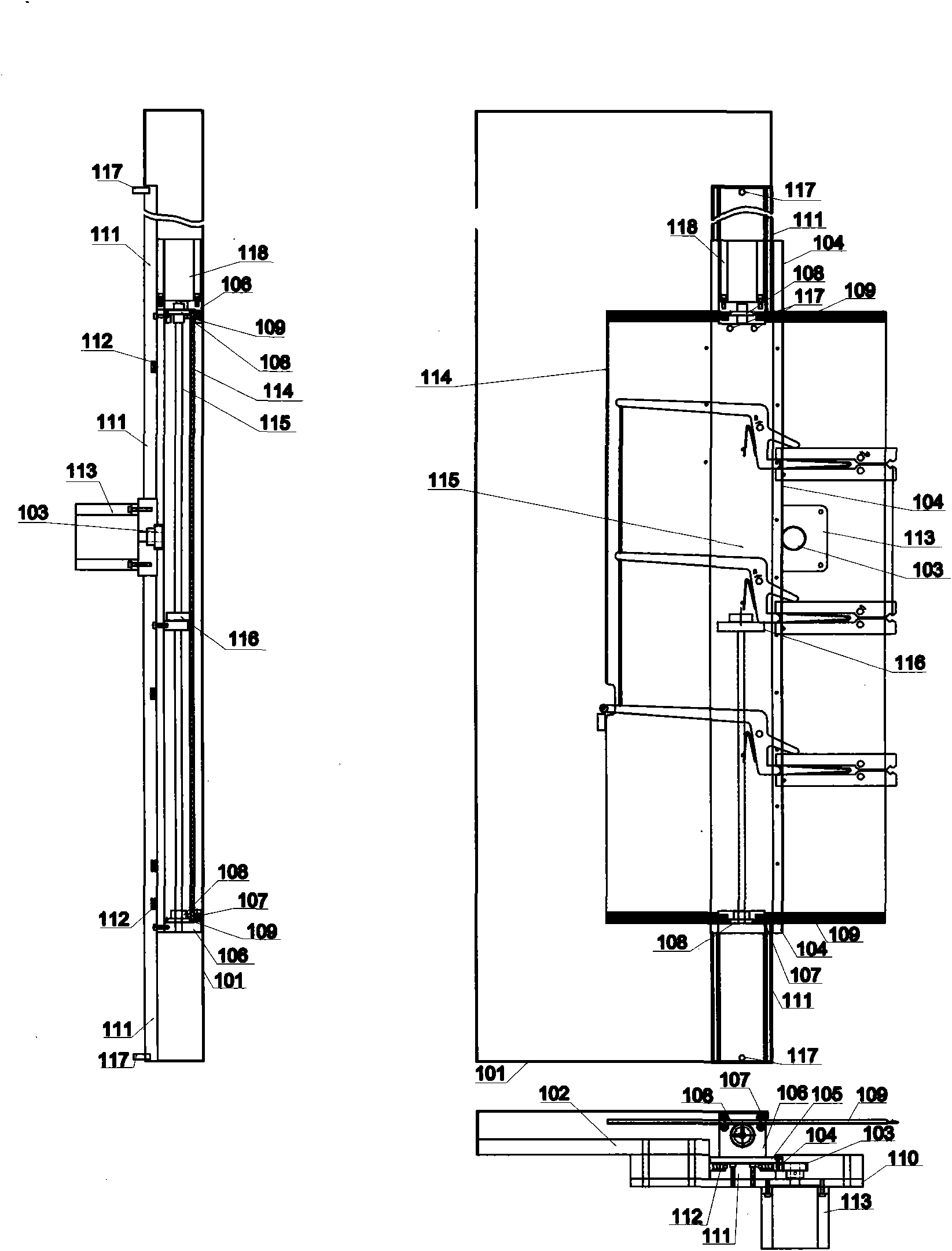

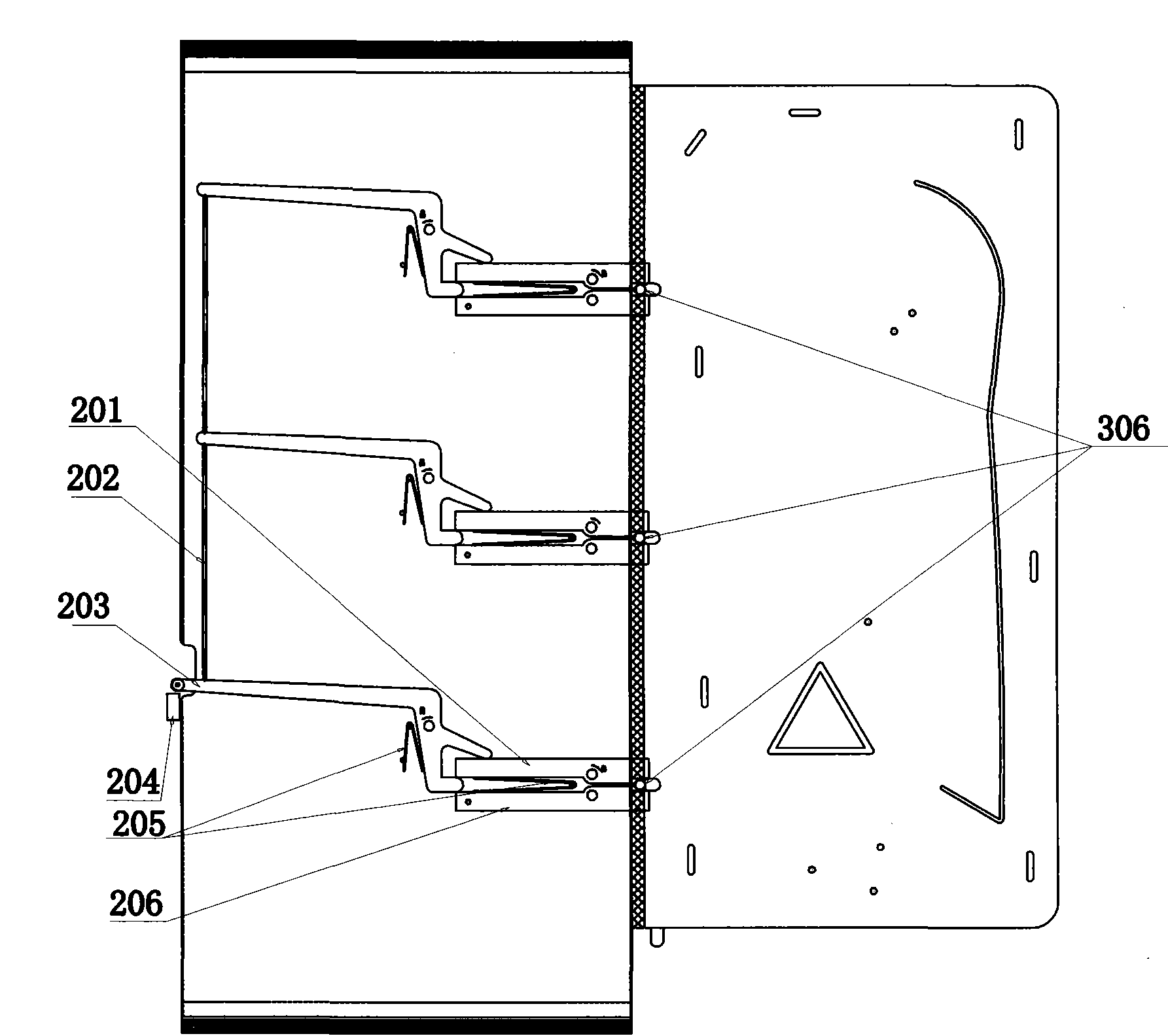

[0020] The template clamps the cloth piece and feeds the multifunctional numerical control sewing machine, see figure 1 , consisting of X, Y movement devices ( figure 2 ); pattern plate automatic clamping mechanism device ( image 3 ); sewing template ( Figure 4 ); stippling device ( Figure 5 ); rotating core trocar plate device ( Figure 6 ); Wooden worktops for sewing ( Figure 7 ); Z-axis rotary speed control device ( Figure 8 ); electric control box ( Figure 9 ), electric control system and sewing CNC programming system ( Figure 10 ), the simplified and refitted ordinary computer flat sewing machine head ( figure 1 ) 7 and its control system 812 (the present invention does not include the unmodified ordinary computer plane sewing machine and its control system) and frame ( figure 1 )15.

[0021] Described X, Y movement device is by X direction motor (118), Y direction motor (113), X, Y axis movement position sensor (117), X direction linear guide rail rack (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com