Thread trimming mechanism of sewing machine

A thread-cutting mechanism and sewing machine technology, which are applied to the thread-cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, can solve the problems of instability, residual thread length, increase the manual thread trimming process, etc., and achieve the effect of position stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

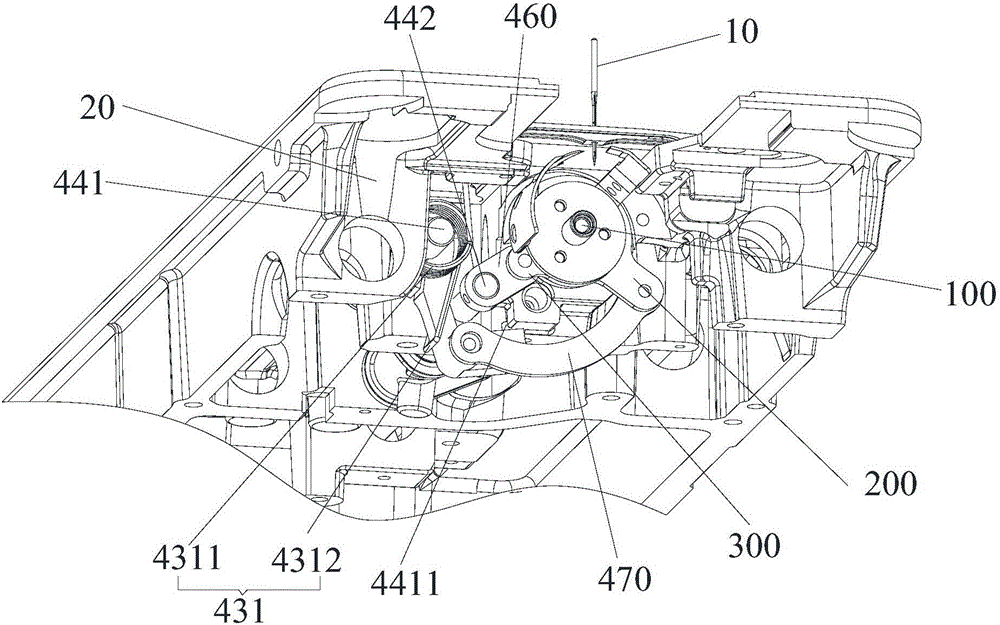

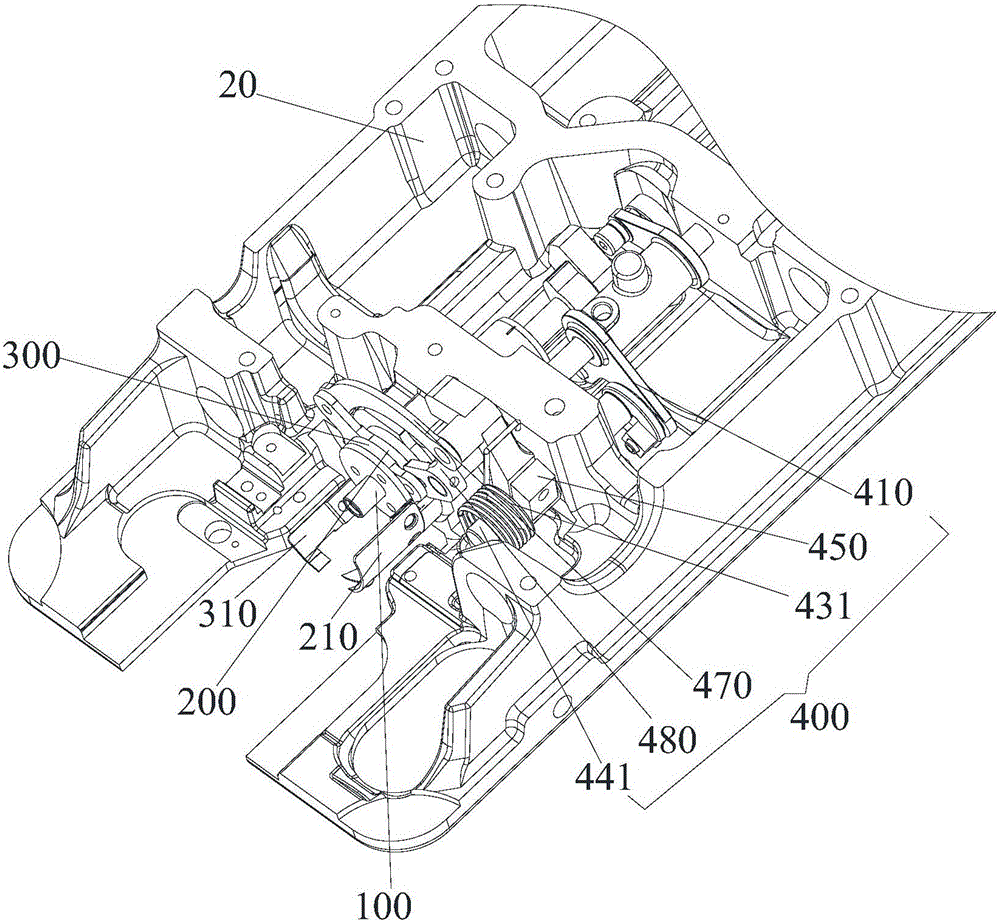

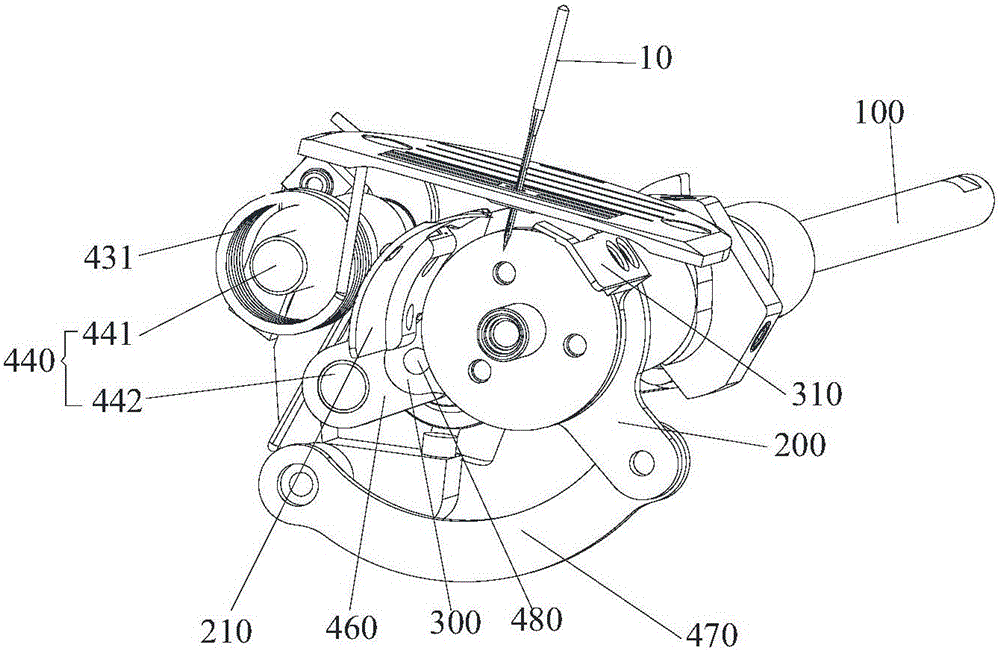

[0066] Such as Figure 1 to Figure 5 and Figure 7 As shown, the thread trimming mechanism of the sewing machine of the present embodiment is provided with a rotating shaft 100 in the casing of the sewing machine, and the thread trimming mechanism includes:

[0067] The main tool holder 200, the auxiliary tool holder 300 and the driving mechanism 400 arranged in the casing;

[0068] The main movable knife 210 is installed on the main knife rest 200; the auxiliary movable knife 310 is installed on the auxiliary knife rest 300;

[0069] The output end of the driving mechanism 400 is connected with the main crank 450 and the auxiliary crank 460, the main crank 450 is connected with the main tool rest 200, and the auxiliary crank 460 is connected with the auxiliary tool rest 300;

[0070] The output end of the drive mechanism 400 rotates reciprocatingly; the drive mechanism 400 drives the main tool rest 200 to reciprocate around the rotation axis 100 through the main crank 450, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com