Sewing machine

A sewing machine and thread technology, applied in sewing machine components, sewing equipment, program-controlled sewing machines, etc., can solve problems such as cloth movement and deviation, and achieve the effect of improving work efficiency and reliable sewing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

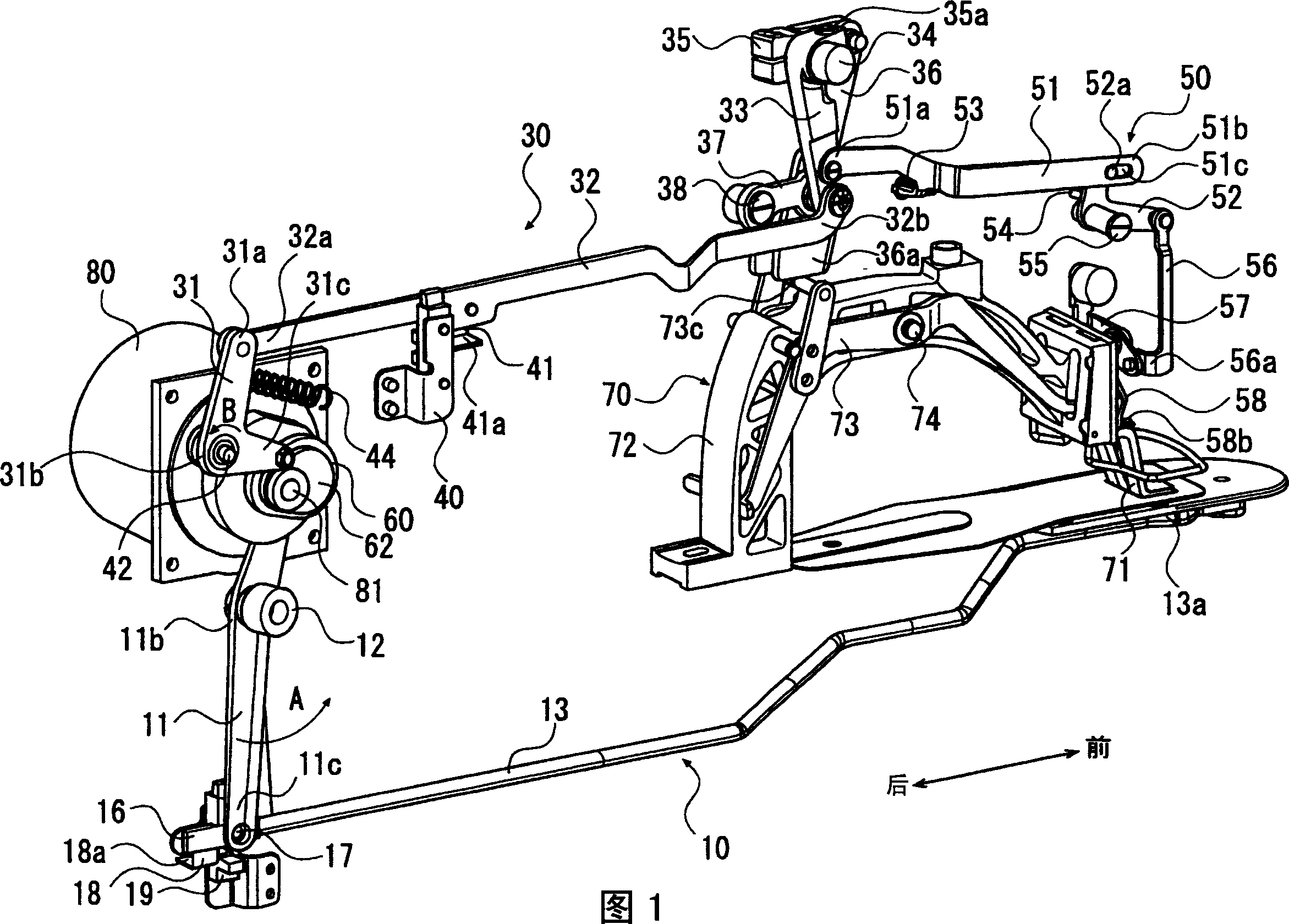

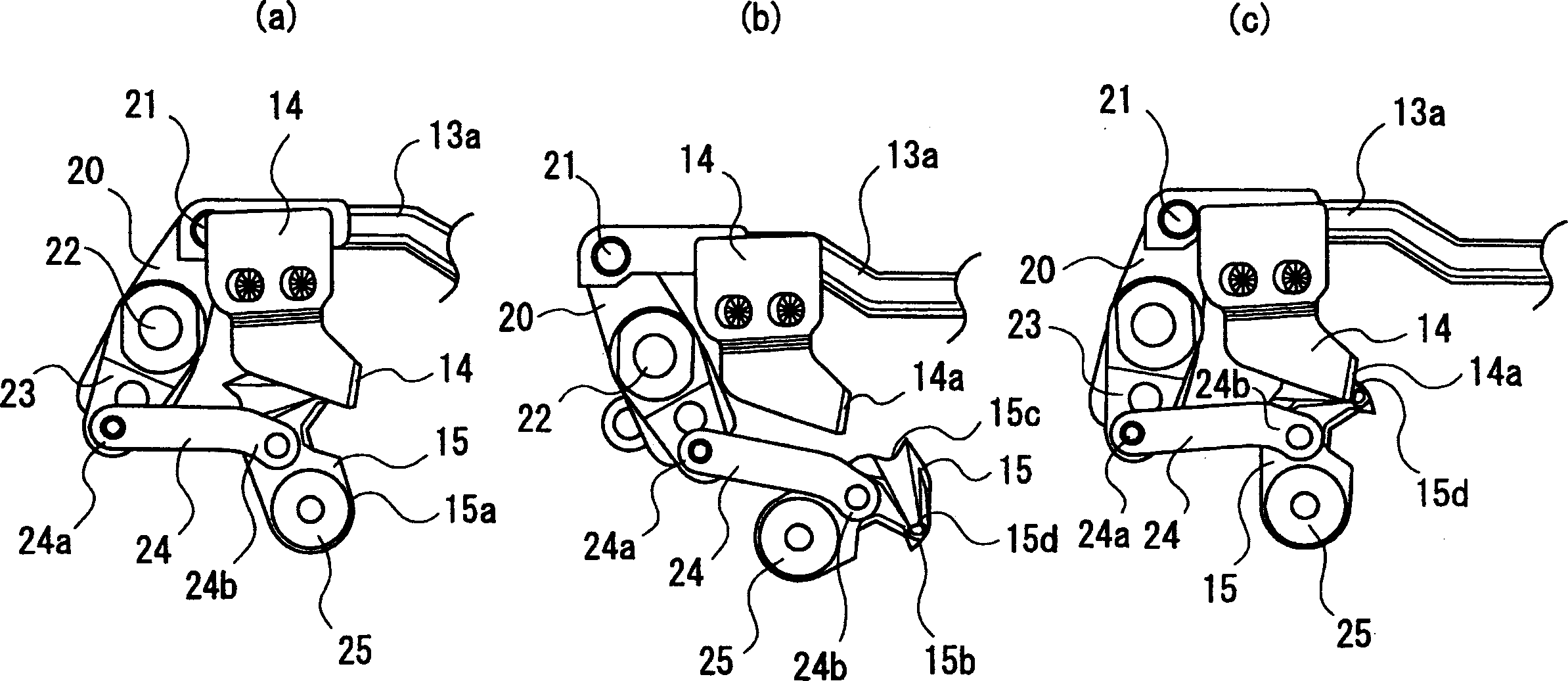

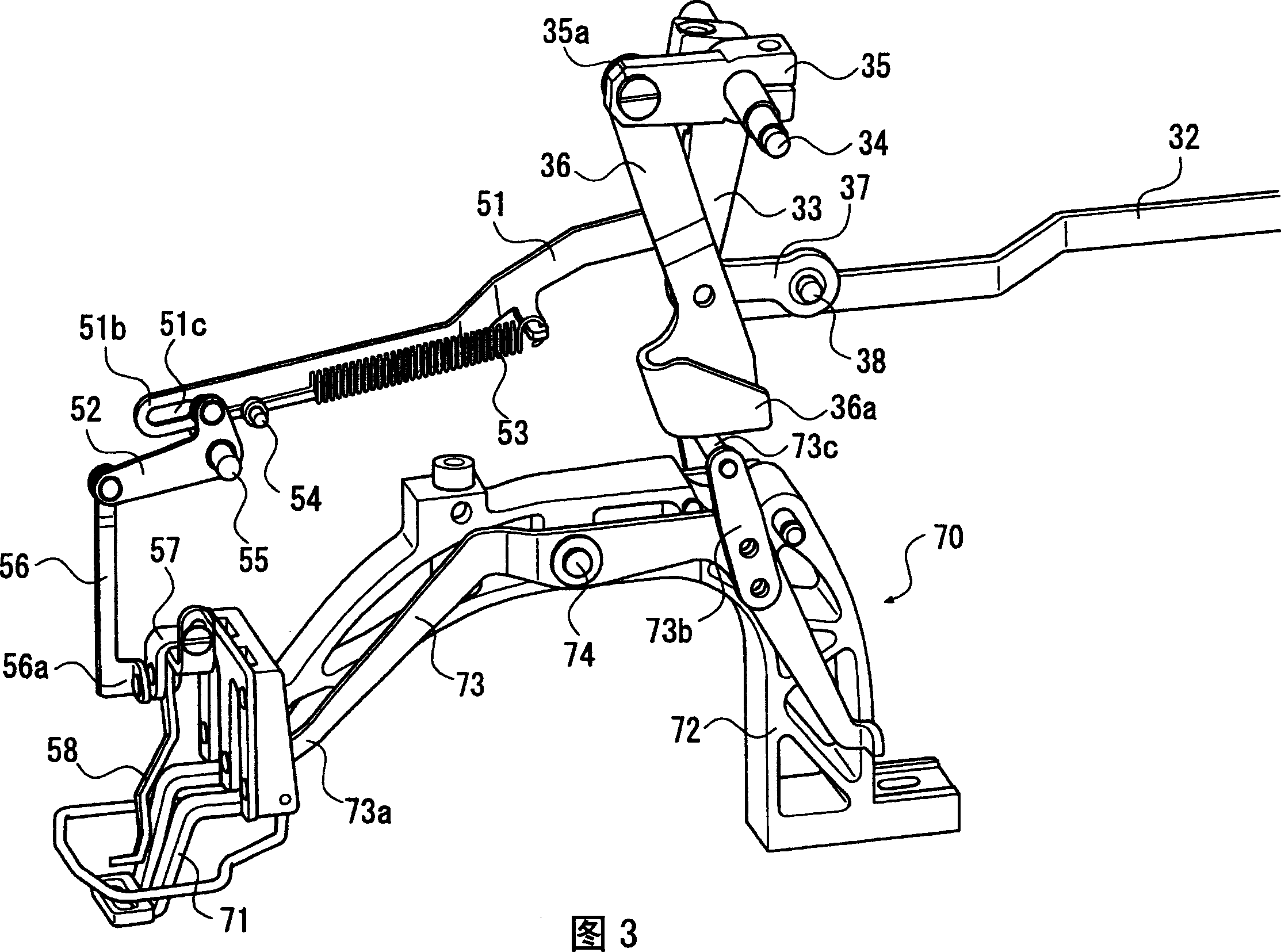

[0051] In this embodiment, taking the sewing machine of the present invention as an example, a backtack sewing machine for forming zigzag stitches with flat seams will be described. The backtacking sewing machine of this embodiment sews according to the prescribed sewing pattern stored in the unillustrated memory by the cooperative action of the needle and the shuttle, and after sewing, according to the tangent included in the sewing pattern Command or presser foot lift command starts thread trimming and presser foot lift operation at the specified timing.

[0052] The backtack sewing machine of this embodiment includes: a thread trimming mechanism 10 for cutting the upper thread and the lower thread immediately after the sewing operation is finished, and a presser foot lifting mechanism 30 for raising the presser foot 71 of the presser foot device 70 before a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com