Motor control sewing machine feeding mechanism

A feeding mechanism and sewing machine technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems of complex transmission device and inability to overcome the difference between feeding displacement and set displacement, etc., and achieve simple and clear feeding mechanism, simple structure, control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

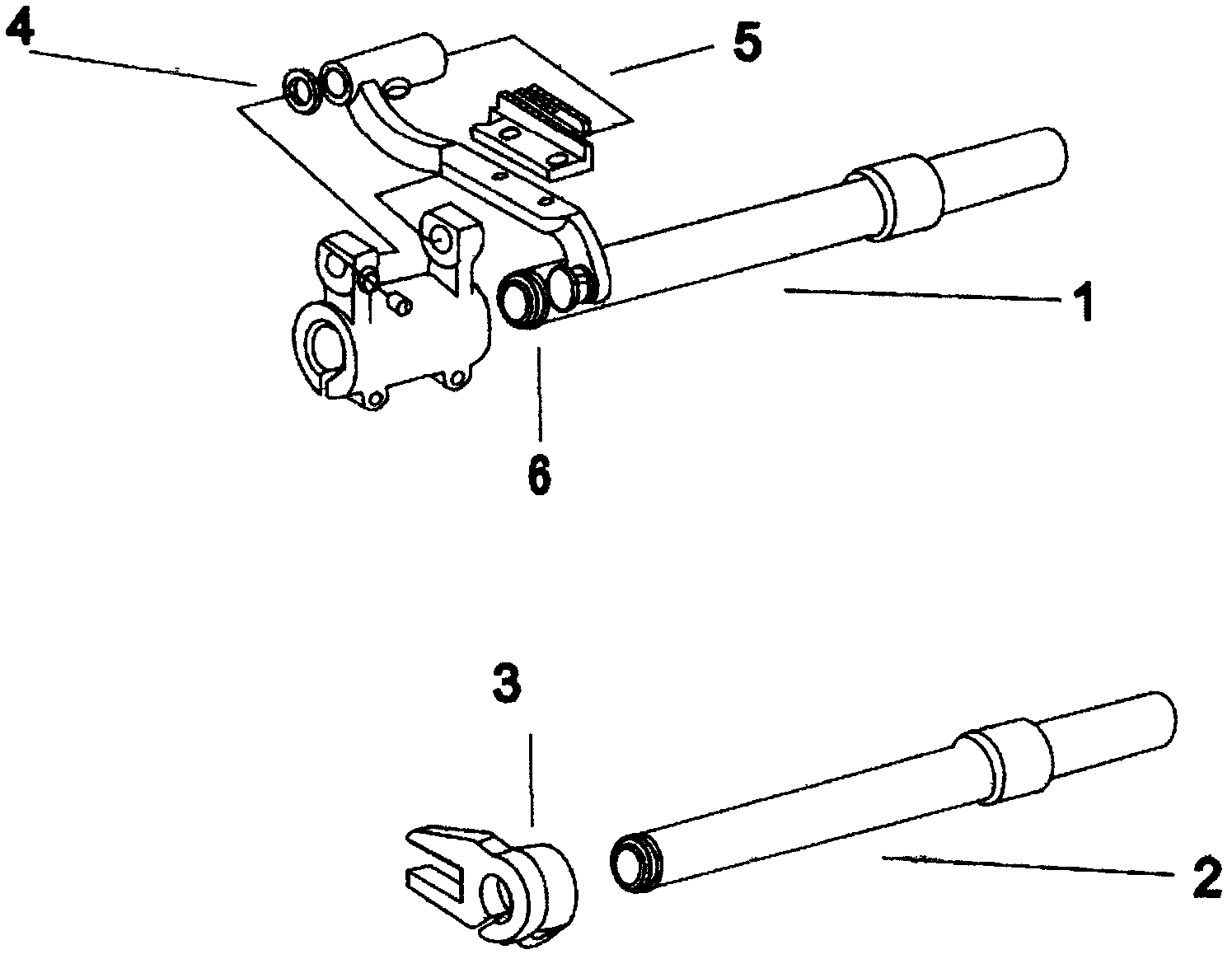

[0019] like figure 1 As shown, the direct-drive feeding mechanism of the sewing machine includes a horizontal feeding shaft 1, the tooth bracket group room 4 and the cloth feeding dog 5 are installed on the horizontal feeding shaft, the vertical feeding shaft 2, and the tooth picking fork 3 is coaxial with the vertical feeding shaft 2 Placement, and the teeth 6 are tightly bitten by the tooth picking fork.

[0020] Among them, the horizontal feeding shaft and the main shaft are directly driven by the motor to rotate. The horizontal feeding shaft rotates back and forth within a certain range to achieve the purpose of forward and backward feeding. The rotation of the vertical feeding shaft is driven by the rotation of the main shaft, which drives the tooth picking fork to swing up and down, and the teeth move up and down accordingly. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com