Cloth feeding mechanism of sewing machine

A technology of cloth feeding device and sewing machine, which is applied in the direction of sewing machine components, program-controlled sewing machines, cloth feeding mechanism, etc., and can solve the problem of not being able to fine-tune the amount of cloth feeding with proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

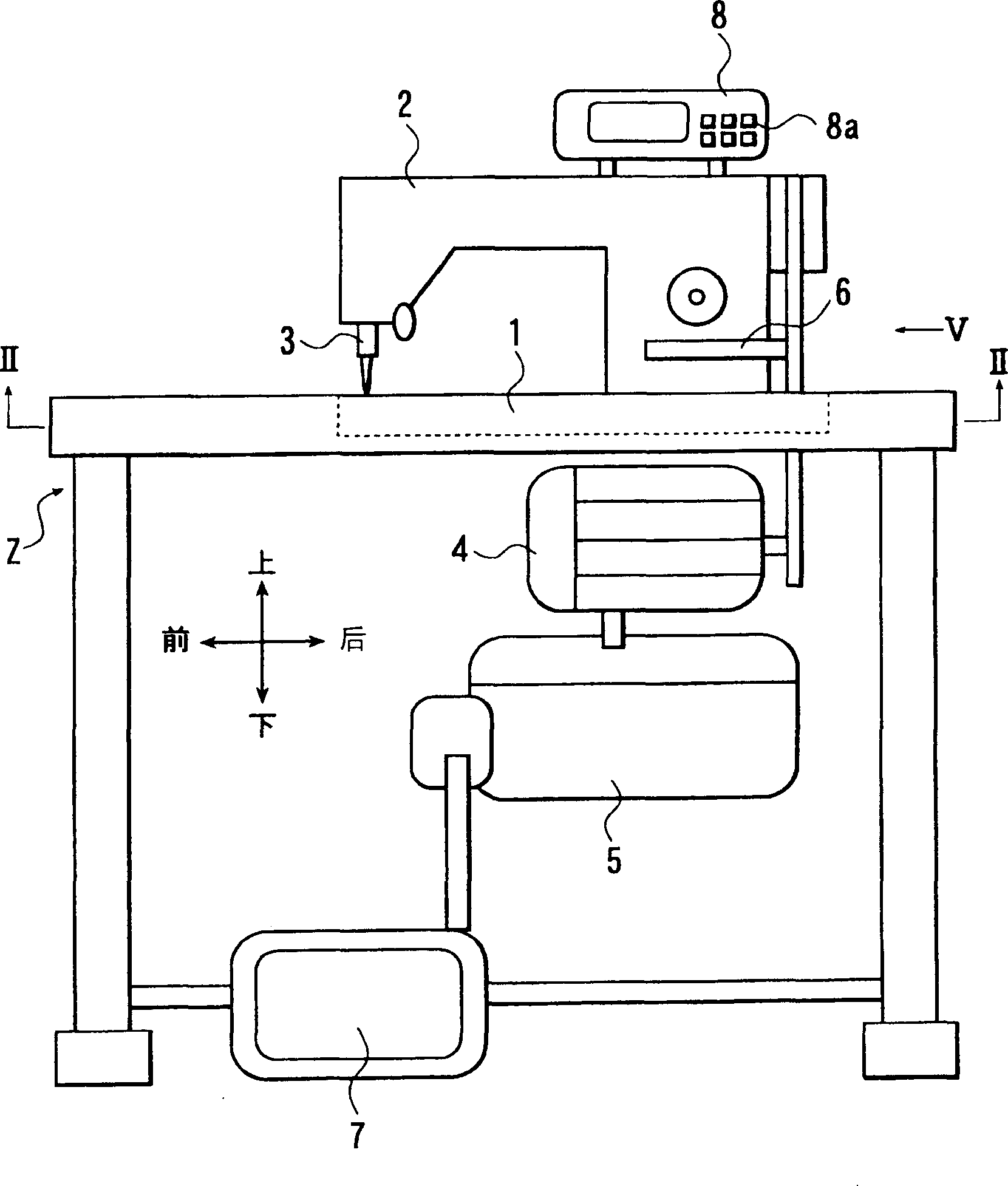

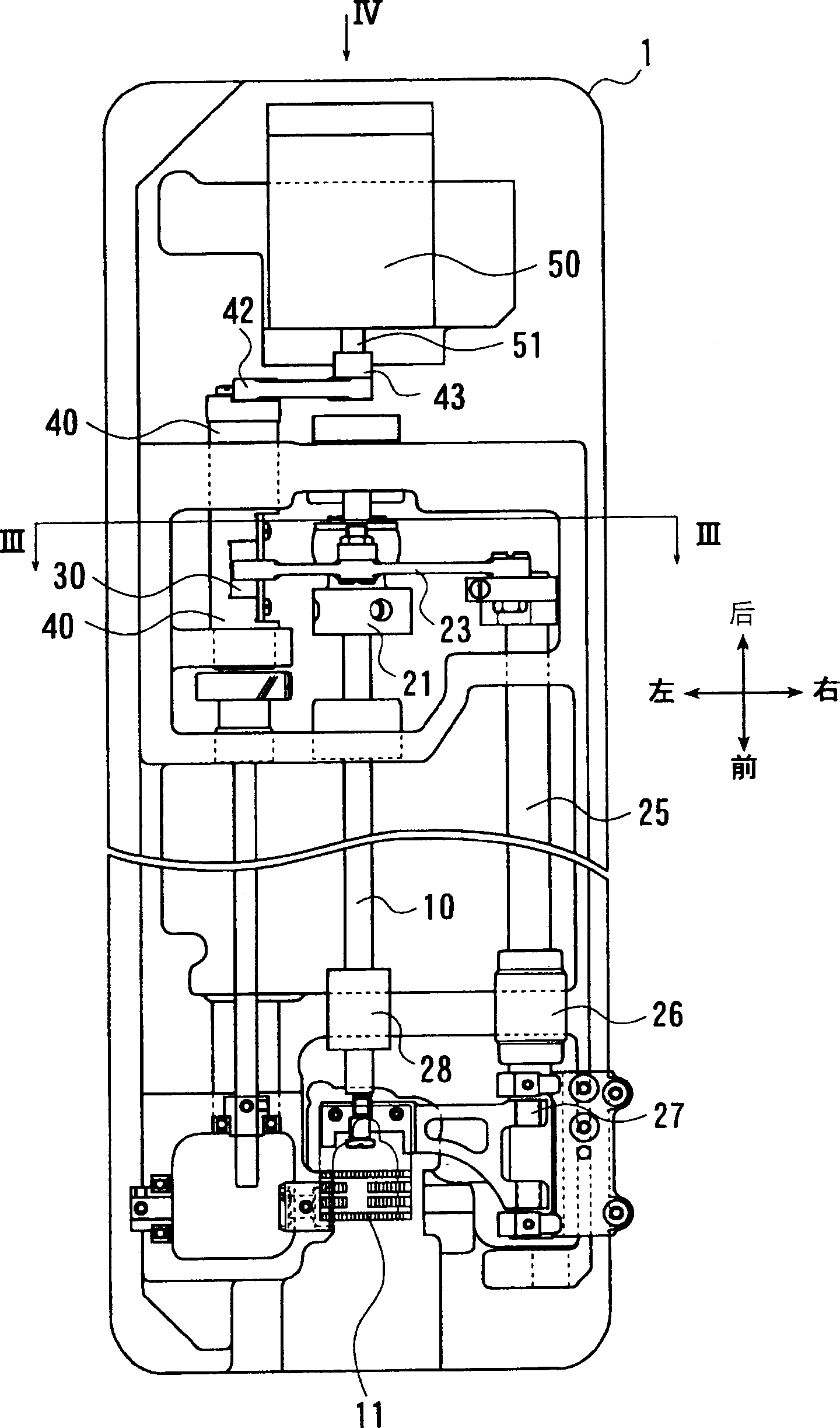

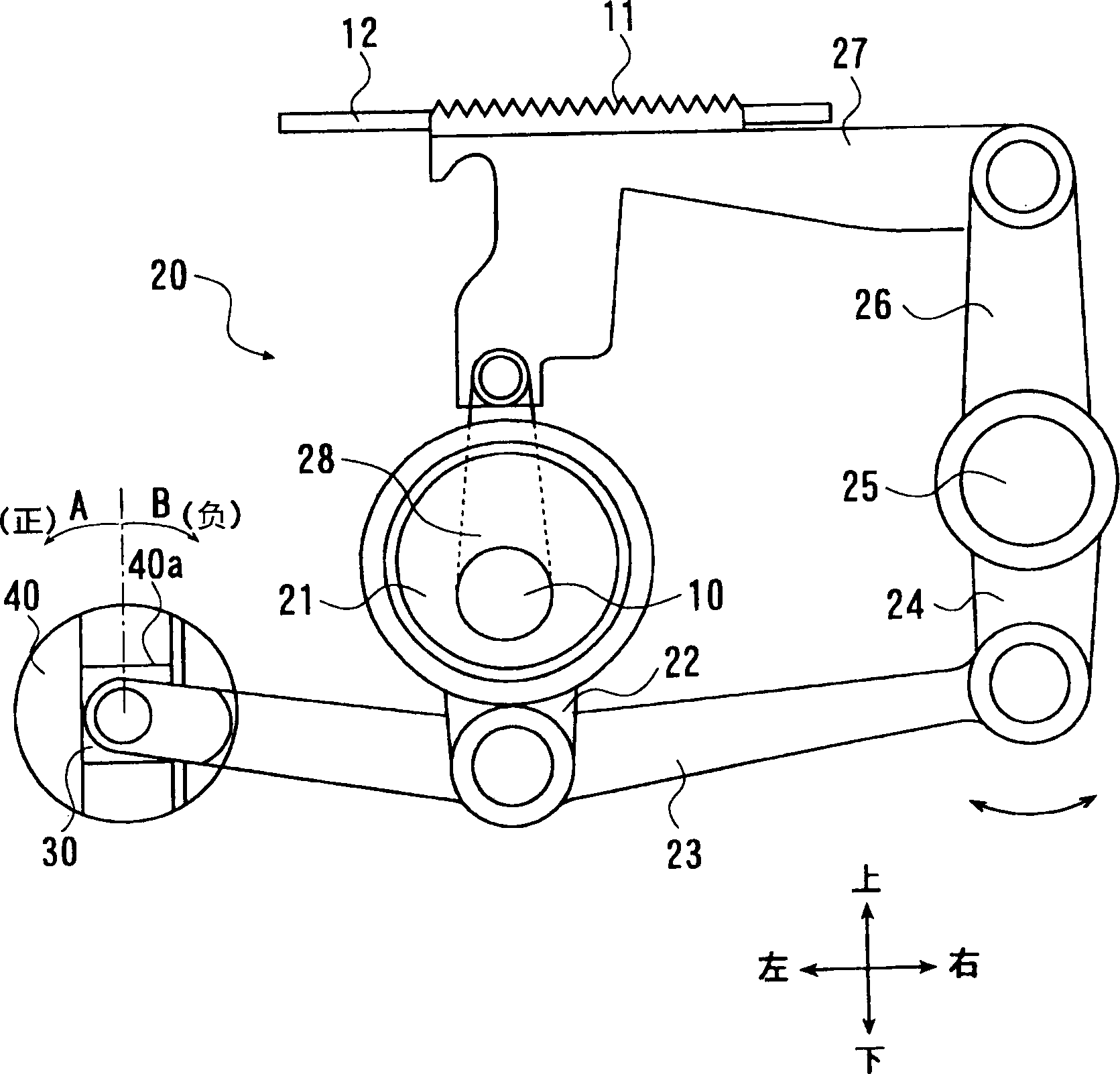

[0047] The sewing machine involved in this embodiment, such as figure 1 As shown, it includes: a bottom plate part 1 (dashed line) which is placed on the sewing machine workbench Z and provided with a needle plate thereon, and a machine head 2 extending slightly parallel to the bottom plate part 1 above the bottom plate part 1, and The needle bar 3 that extends downward from the front end of the machine head 2 and freely moves up and down, the spindle motor 4 that moves the needle bar 3 up and down through an unshown upper shaft (main shaft) and crank mechanism, and the handle The cloth feeding device for conveying the cloth placed on the bottom plate part 1, and the control device 5 for comprehensively controlling the overall operation of the sewing machine, and the cloth feeding device that can be used to operate the cloth feeding device for reverse sewing (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com